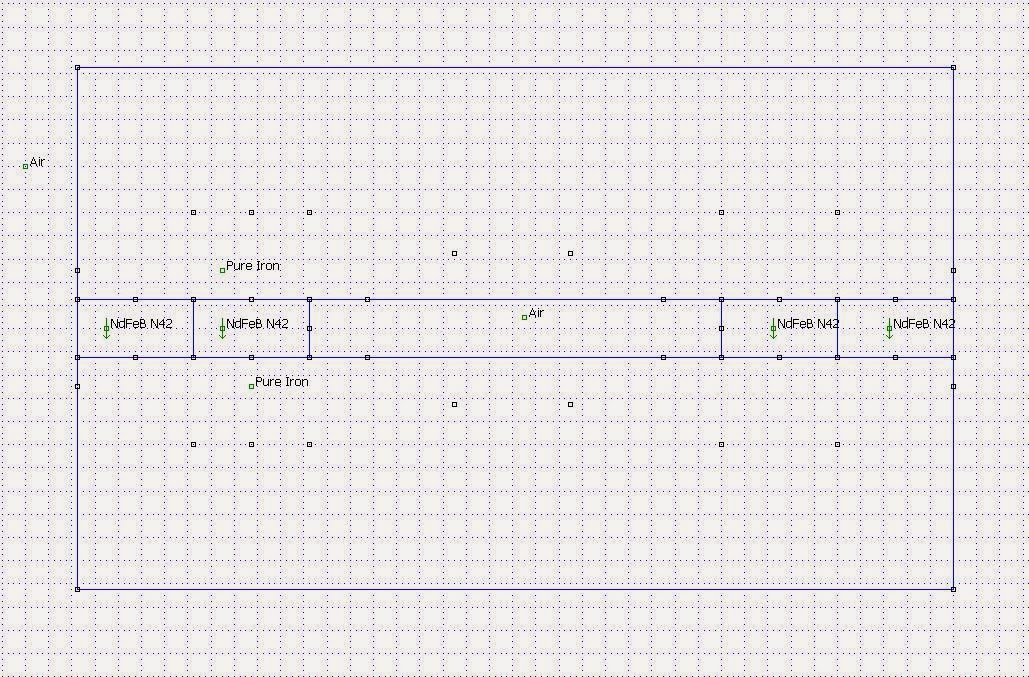

The latter is the same that I got with my simulation above.Here a 70mm gap.

[/url][/IMG]

Field is 0.3T. and iron max is 1,95T.

2x30mm

field is 0,5T. and iron max is 1,5T.

Bernt

My theory is that the depth and width of the pleat determines the HF response due to that it constitutes HH resonators.I have nice results with my new membranes only 40mmX80mm 8,5mm Deep.

I don't think length and width the most important to get low freq.

Pleat depth(weight) and compliance matters more.

I use 10my alu now .

Bernt

The LF response is limited by the width of the pleat and how rigid it is.

Too narrow limits the excursion and not stiff enough means that it is breaking up with distortion7farthing as a result.

I will try to have more aluminium in the pleat in order to make it stiffer (and to lower the resistance).

When it comes to the compliance, that is the actual fold, I was thinking of actually making it higher by applying a layer of 9460 tape.

It is really thin, but my thought was that it would reduce the distortion provided that it also emanates from noise from the 74 tape when it folds.

This would also open up an opportunity to test to have aluminium on both sides of the 74 film thus doubling the force.

Did you have an answer to:

What's the benefit of having two membranes side by side?

works nicely, but you neet to let it cut ? i mean the steel ?

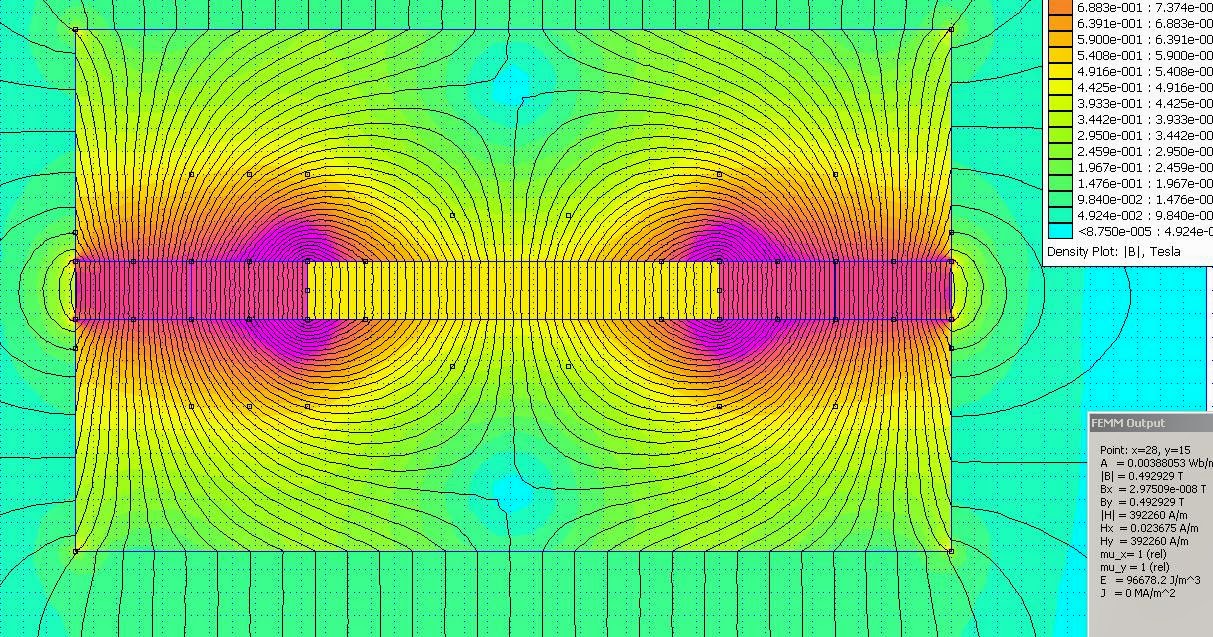

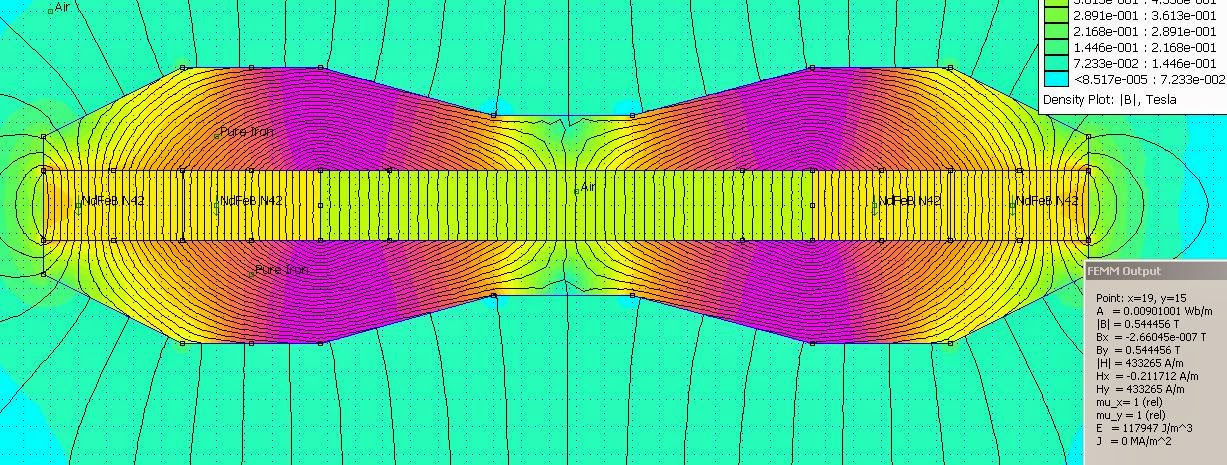

If a whooping 40 mm steel bar is used without any trimming:

You get 0,49 T in the gap (and probably some strange frequency response as the "lens" is 40 mm in depth and 5 mm wide):

But I prefer the "lens" to be as small as possible so it perhaps isn't a lens anymore, so I make some cuts thus creating a profile:

Now I get 0,55 T in the gap and a 10 mm deep lens:

In fact, it can be seen as a double sided Kithara layout.

A slicker profile can for sure be simulated but probably at a cost of lower flux density.

Subjectively speaking? No, I don't think so. But then I don't listen to classic rock that much.Hi Solhaga,

Thanks for responding! With regards to music, I mostly listen to rock music and at some point I had AER MD3 drivers in Oris 150 front horns. This combo sounded incredible on acoustic recordings and female voices, but when listening to classic rock music (e.g., Pink Floyd, Jethro Tull, Porcupine Tree, or Red Hot Chilli Peppers) they tended to sound somewhat 'thin'.

Do you think the increased resolution/clarity when lowering the crossovers point comes at a cost with regards to 'punch' and 'weight'? I'm sorry about all the subjective terms, but this is probably the best way I can present the question...

Best regards

Peter

Are you sure that you listened to the same recording, with the loudness war still going a thin sound could very well be an un-mastered one and fat with punch and weight a compressed and re-mastered one.

Hi Solhaga,

Thanks for responding. Although my impressions were clearly subjective, there is no doubt in my mind that the AER/Oris setup could be 'thin' sounding on complex material - something I have also experienced with at least some electrostatic speakers (e.g. Martin Logan CLS). I am just pleased to hear that you don't have the same experience with using your large AMT's in the mid range .

.

Best regards

Peter

Thanks for responding. Although my impressions were clearly subjective, there is no doubt in my mind that the AER/Oris setup could be 'thin' sounding on complex material - something I have also experienced with at least some electrostatic speakers (e.g. Martin Logan CLS). I am just pleased to hear that you don't have the same experience with using your large AMT's in the mid range

Best regards

Peter

Subjectively speaking? No, I don't think so. But then I don't listen to classic rock that much.

Are you sure that you listened to the same recording, with the loudness war still going a thin sound could very well be an un-mastered one and fat with punch and weight a compressed and re-mastered one.

Here's a table showing steel grades from different contry.

[/url][/IMG]

[/url][/IMG]

S235 JR is the same as SAE 1015.

If you simulate with 1015 you will get a different result.

My simm.shows effectiv stellareal 5mm. for 5x10mm steelbars 50% air.

Side by side to avoid a higher AMT.

Bernt

Difficult to read table,see my gallery.

S235 JR is the same as SAE 1015.

If you simulate with 1015 you will get a different result.

My simm.shows effectiv stellareal 5mm. for 5x10mm steelbars 50% air.

Side by side to avoid a higher AMT.

Bernt

Difficult to read table,see my gallery.

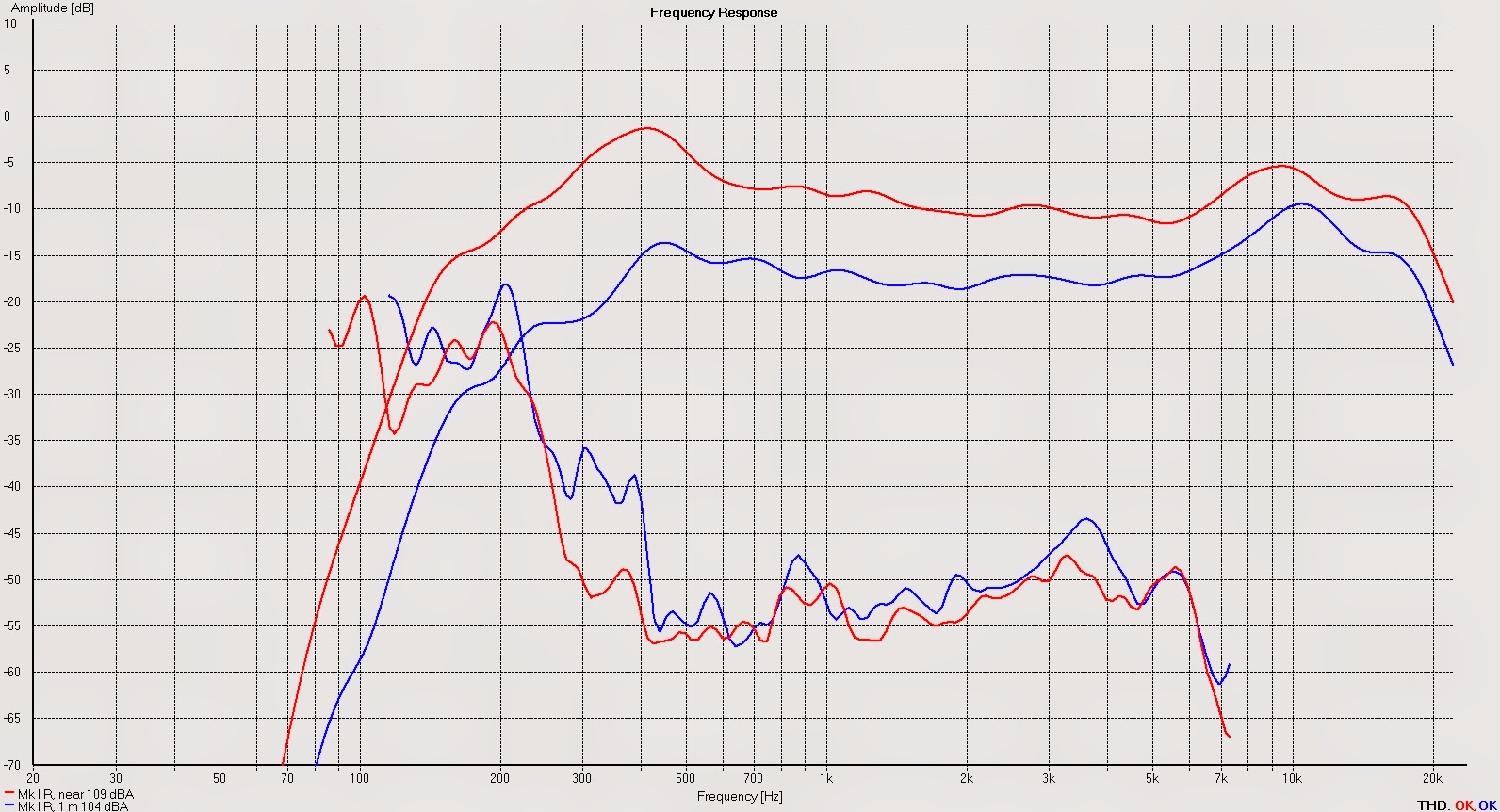

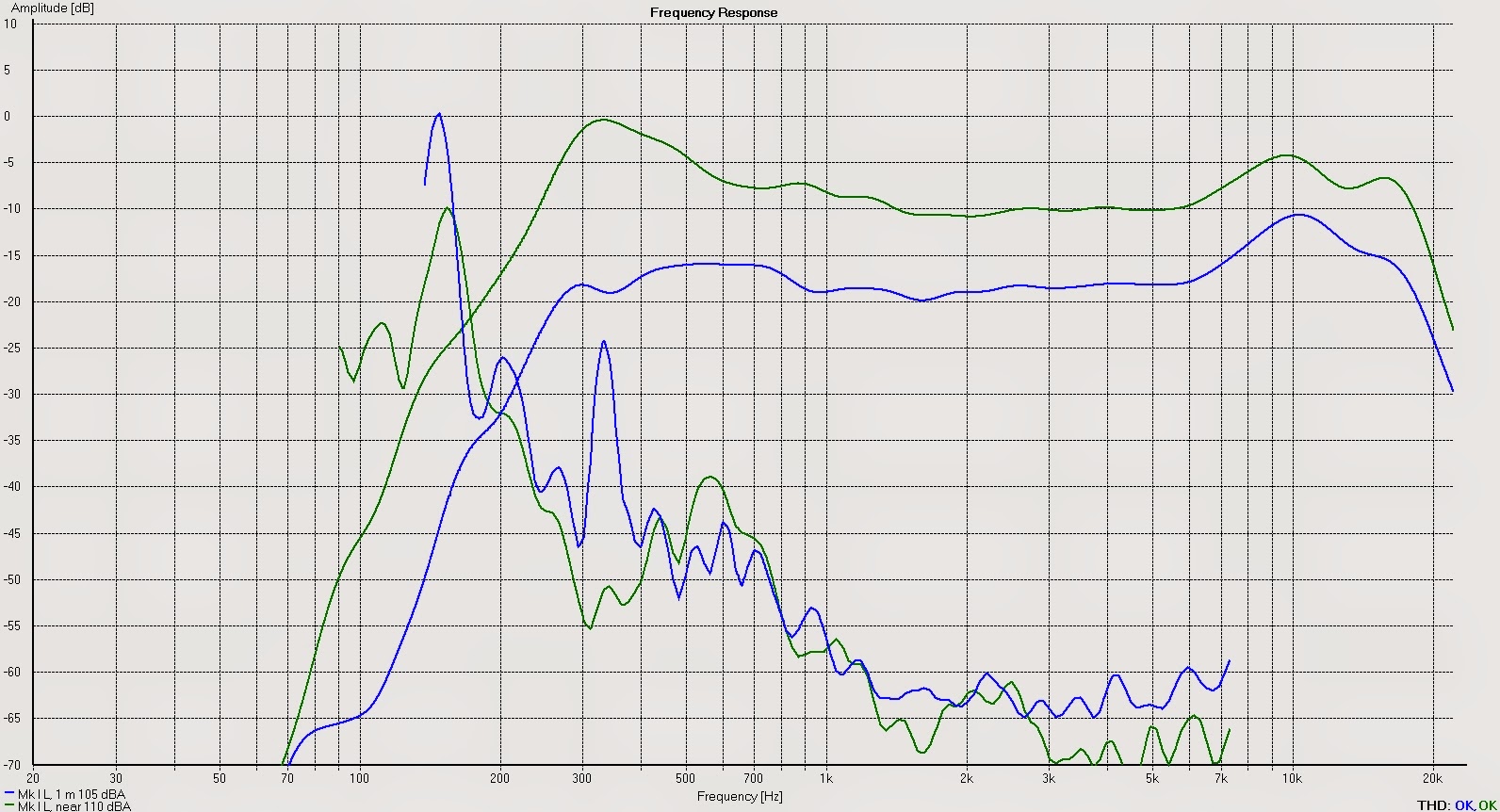

Mk I measurements

Thanks Baldin.

Here's some very recent measurements, it could be good to have the measurements on Mk I for reference.

Sweep started at 125 Hz.

Right AMT

Resistance 11,3 ohms, measured at 3,4 Vrms:

Level at waveguide: 109 dBA

Level 1 m from waveguide: 104 dBA

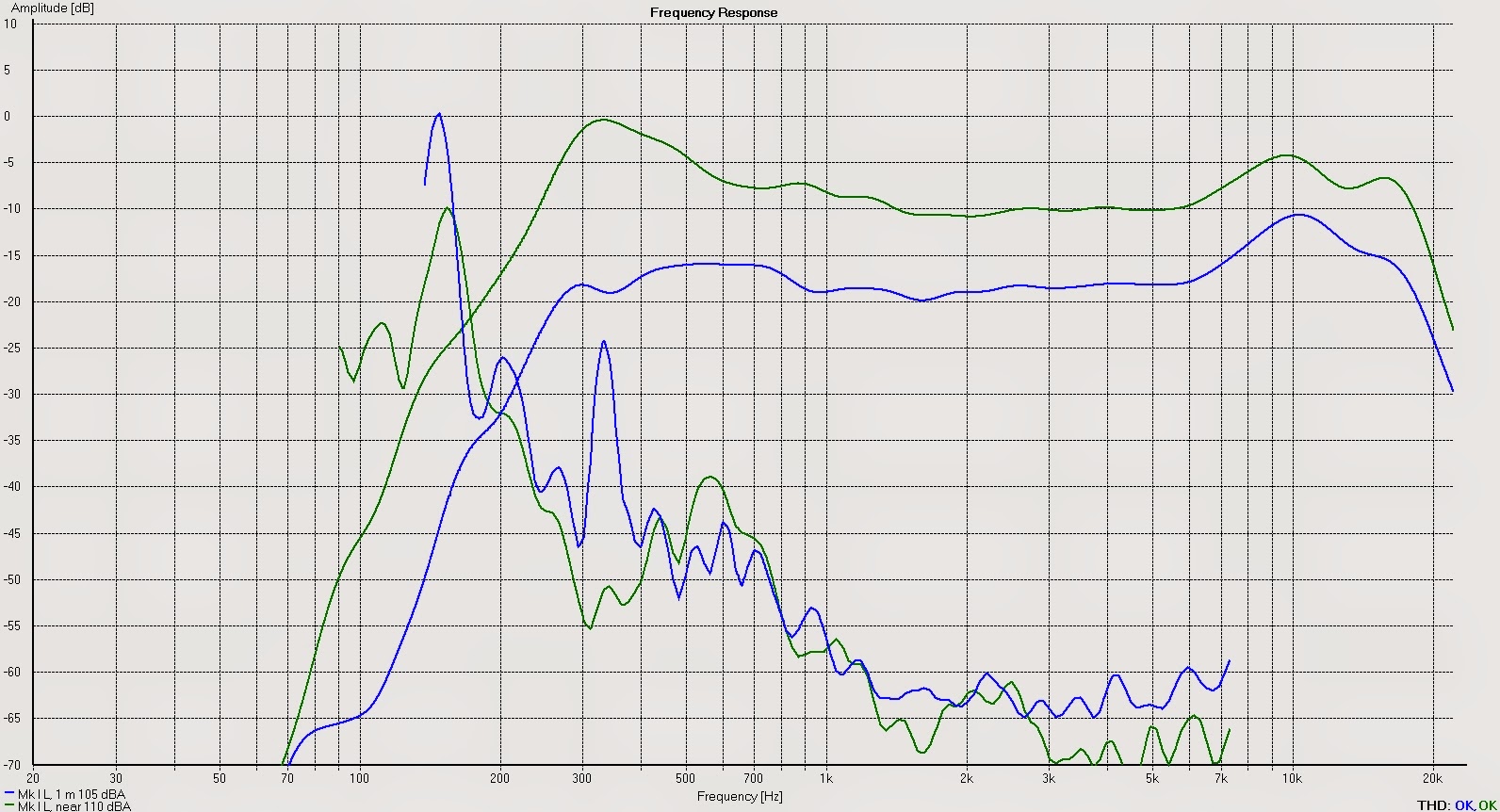

Left AMT

Resistance 9,7 ohms, measured at 3,4 Vrms:

Measured at 3,4 Vrms:

Level at waveguide: 110 dBA

Level 1 m from waveguide:105 dBA

The SPL meter seemed to have saved the upper peak as maximum level.

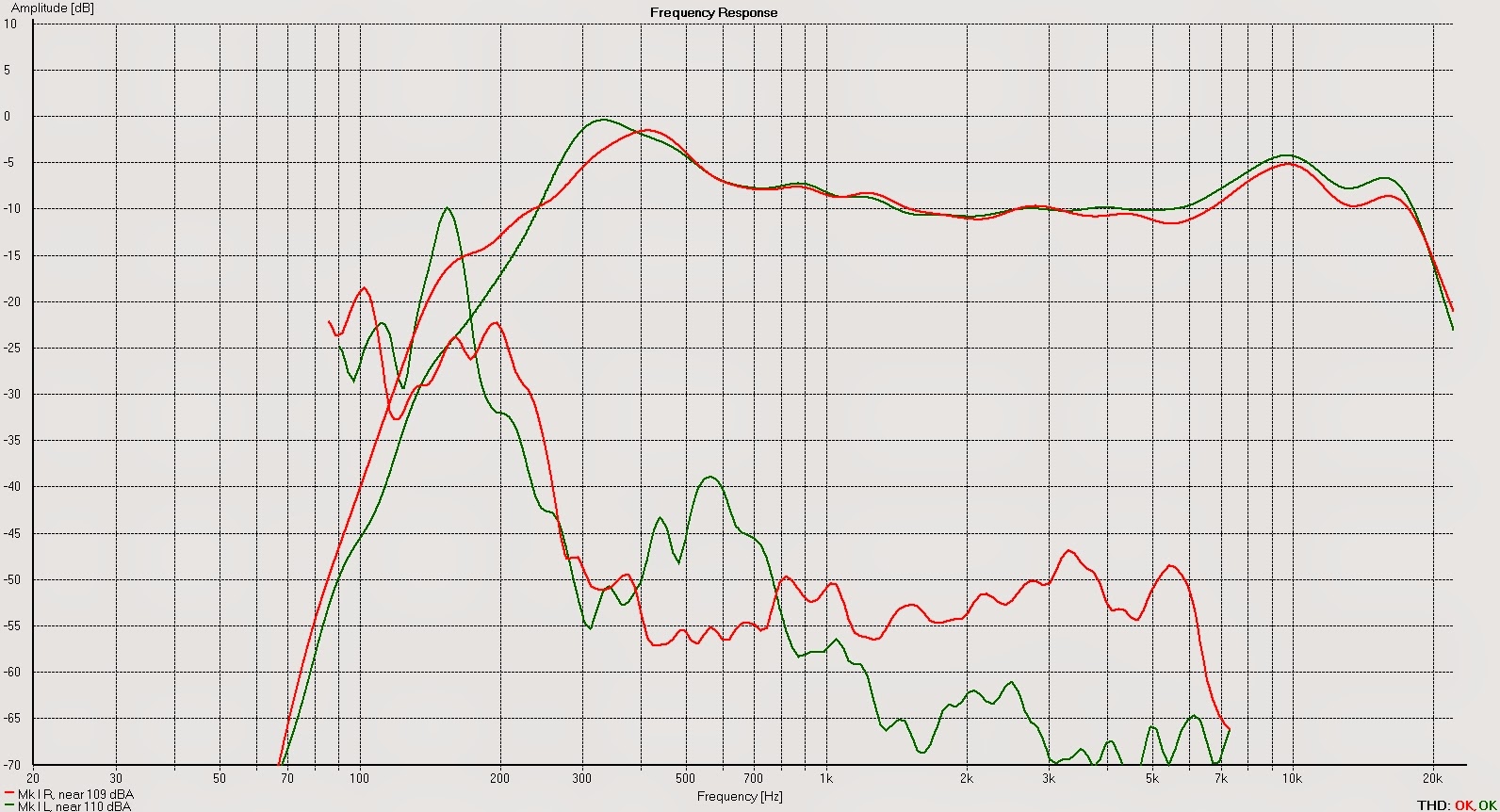

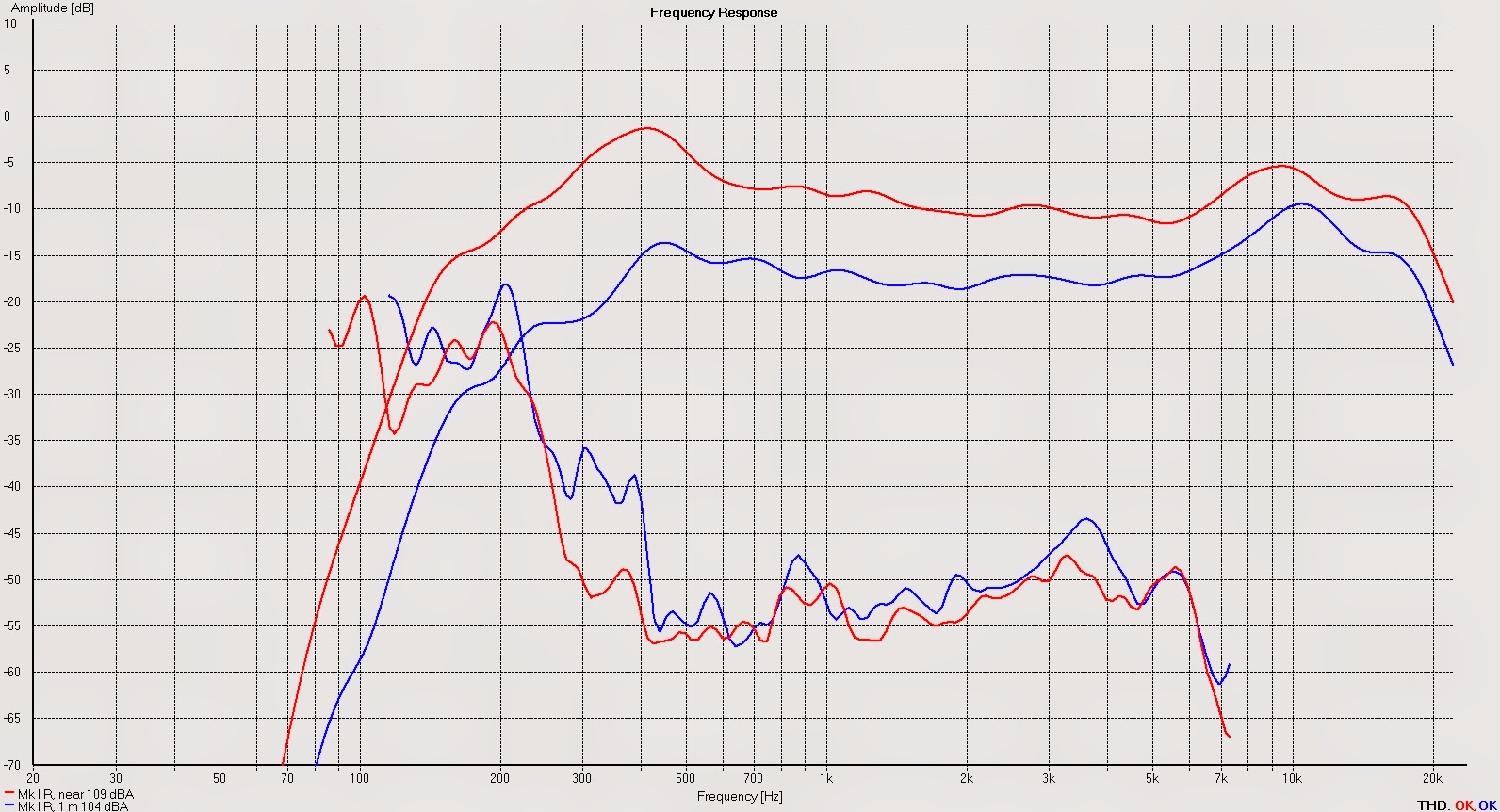

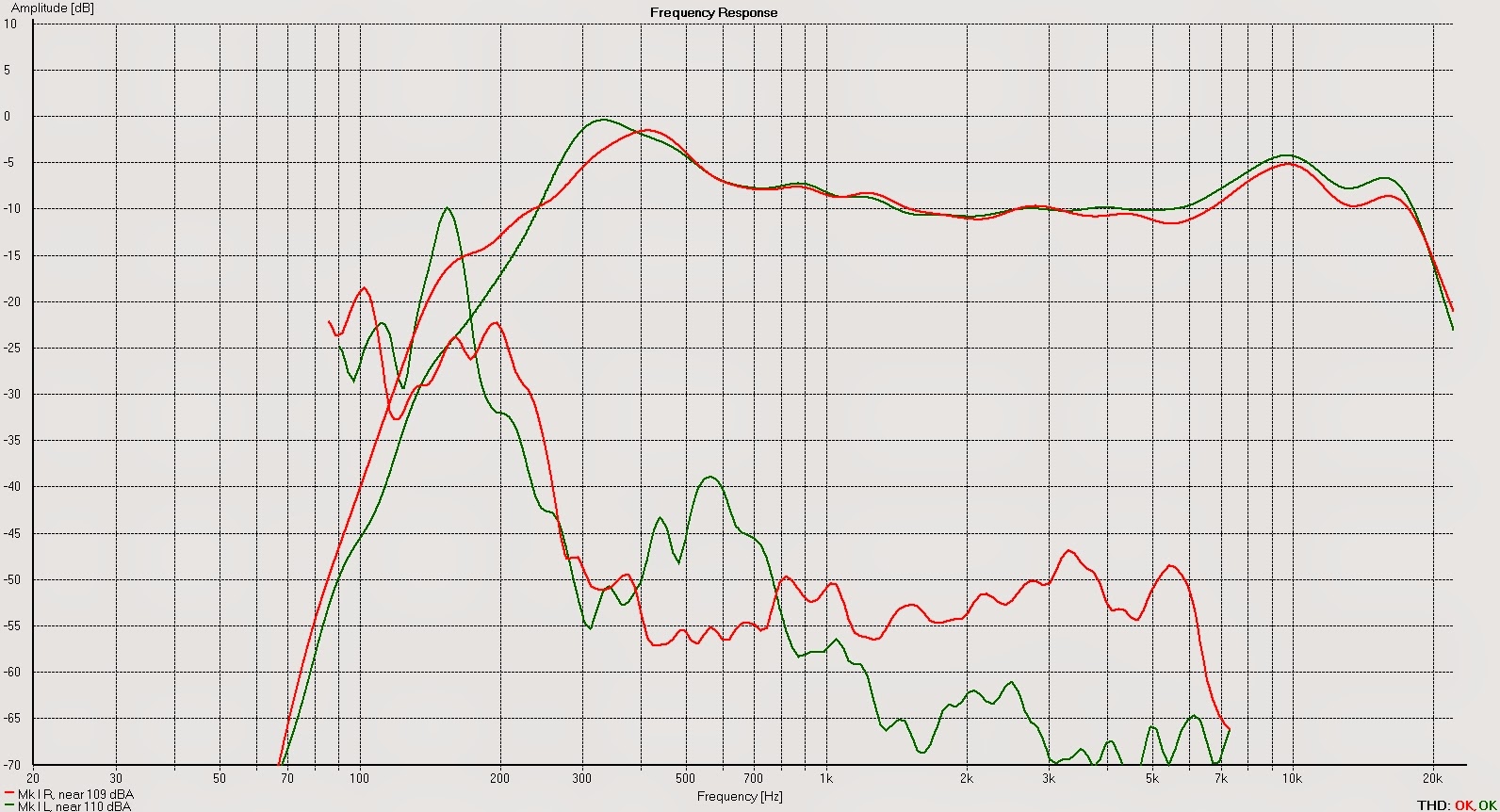

Comparision between L & R Near:

Comparision between L & R 1 m:

AFAIK, the Kapton tape isn't thermo setting. That is, it is difficult to get the folds for a DIY:er.

Or do you have any suggestion an how to do it?

Thanks Baldin.

Here's some very recent measurements, it could be good to have the measurements on Mk I for reference.

Sweep started at 125 Hz.

Right AMT

Resistance 11,3 ohms, measured at 3,4 Vrms:

Level at waveguide: 109 dBA

Level 1 m from waveguide: 104 dBA

Left AMT

Resistance 9,7 ohms, measured at 3,4 Vrms:

Measured at 3,4 Vrms:

Level at waveguide: 110 dBA

Level 1 m from waveguide:105 dBA

The SPL meter seemed to have saved the upper peak as maximum level.

Comparision between L & R Near:

Comparision between L & R 1 m:

AFAIK, the Kapton tape isn't thermo setting. That is, it is difficult to get the folds for a DIY:er.

Or do you have any suggestion an how to do it?

Last edited:

Here's a table showing steel grades from different contry.

[/url][/IMG]

S235 JR is the same as SAE 1015.

If you simulate with 1015 you will get a different result.

My simm.shows effectiv stellareal 5mm. for 5x10mm steelbars 50% air.

Side by side to avoid a higher AMT.

Bernt

Difficult to read table,see my gallery.

As long as I'm far from saturation (1,5 T in the recent simulation) I'll go for using pure iron. The simulations are for comparison anyway.

Yes, I found more or less the same table.

1015 gives a couple of percent lower field. It "better" than 1018 anyway.

I am a little doubtful of having two sound sources beside each other, especially with a space between. I'd rather go for the longer, or higher, AMT.

Last edited:

My ovn simm. is made with 1018 as i didn,t search for this table before.

It was a gues i made .

I use same steel quality as you. Didn,t know it was 1015.

Bernt

Kapton might be thermosetting at higher temperatures,but I like the selfadhesive tape we use.

Haven't found any 12my thin.

It was a gues i made .

I use same steel quality as you. Didn,t know it was 1015.

Bernt

Kapton might be thermosetting at higher temperatures,but I like the selfadhesive tape we use.

Haven't found any 12my thin.

Last edited:

Thinnest Kpton is 50HN which is 12,7 um. I found a place wher you can get it in short lengths. I t seems to be without adhesive.

Kapton polyimide film, short roll service

I was just thinking that as Solhage was asking for more stiffness, it might be a good choice. But yes if it is stiffer it is also not so easy to work with and get the folds right. Seems you are both getting some really good results now

Must find myself some time to try it out.

Baldin

Kapton polyimide film, short roll service

I was just thinking that as Solhage was asking for more stiffness, it might be a good choice. But yes if it is stiffer it is also not so easy to work with and get the folds right. Seems you are both getting some really good results now

Must find myself some time to try it out.

Baldin

Thinnest Kpton is 50HN which is 12,7 um. I found a place wher you can get it in short lengths. I t seems to be without adhesive.

Kapton polyimide film, short roll service

I was just thinking that as Solhage was asking for more stiffness, it might be a good choice. But yes if it is stiffer it is also not so easy to work with and get the folds right. Seems you are both getting some really good results now

Must find myself some time to try it out.

Baldin

Even if the Kapton is thin, it must still be thermosetting, that is that it keeps its shape after the baking in the folding tool.

The Kapton tape I have tested doesn't have that property.

My idea to make the sides stiffer is to have an additional layer of aluminium on the backside. I'll the VHB tape for that.

I will also try to increase the amount of aluminium versus bare mylar. That would require a better, more precise, folding method.

Just some thoughts

Just take it for what it is .... I'm just thinking ... and I know you guys have tried it all, and have gained lots of first hand experience here ...

Could it be that the pleats, when folded between more rectangular plates/rods will get a more rectangular bend. If this was the surroud of a conventional come driver, this would of couse not be ideal, and for an AMT it must be the same. Could this cause some resonance in the film? ... and therefore distortion?

Are you sure that e.g. Mundorf heat cures the diaphragm to get it to stay in place?

Also look at the picture from the Mundorf tour, that on the top of each bend i placed a very thin trace (not connected) ... could this provide damping the the film?

To dampen the fold, you could maybe apply some thin paint.

Also seem you have omitted the extra strps of alu at the top an buttom of the diaphragm that is normally seen and is there to help the folding process.

Keep up the super good work .... really looks good

BR Baldin

Just take it for what it is .... I'm just thinking ... and I know you guys have tried it all, and have gained lots of first hand experience here ...

Could it be that the pleats, when folded between more rectangular plates/rods will get a more rectangular bend. If this was the surroud of a conventional come driver, this would of couse not be ideal, and for an AMT it must be the same. Could this cause some resonance in the film? ... and therefore distortion?

Are you sure that e.g. Mundorf heat cures the diaphragm to get it to stay in place?

Also look at the picture from the Mundorf tour, that on the top of each bend i placed a very thin trace (not connected) ... could this provide damping the the film?

To dampen the fold, you could maybe apply some thin paint.

Also seem you have omitted the extra strps of alu at the top an buttom of the diaphragm that is normally seen and is there to help the folding process.

Keep up the super good work .... really looks good

BR Baldin

Attachments

Just keep the ideas coming!Just take it for what it is .... I'm just thinking ... and I know you guys have tried it all, and have gained lots of first hand experience here ...

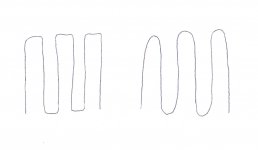

They get fairly rounded even if the folding tool has sharp edges. So the end result is as your right example.Could it be that the pleats, when folded between more rectangular plates/rods will get a more rectangular bend. If this was the surroud of a conventional come driver, this would of couse not be ideal, and for an AMT it must be the same. Could this cause some resonance in the film? ... and therefore distortion?

Some manufactures do, that I know. Don't know about Mundorf though. The curing is a easy way of doing it for a DIY:er.Are you sure that e.g. Mundorf heat cures the diaphragm to get it to stay in place?

Good idea. This is definitely worth a try. It is very easy to do with the Silhouette cutter.Also look at the picture from the Mundorf tour, that on the top of each bend i placed a very thin trace (not connected) ... could this provide damping the the film?

I haven't heard the Mundorf AMTs or made any measurements; but if they aren't any better, why mimic them?

Good idea. This is definitely worth a try. It is very easy to make a template with the Silhouette cutter and then spray some color or apply some rubber in the folds.To dampen the fold, you could maybe apply some thin paint.

The paint or rubber must endure the 170 degrees curing though. And then easily come off the folding tool.

I think it would be hard to apply it after the curing on the finished diagram.

The two above ideas makes the hinge in the folds more unmovable. The second one would for sure dampen any cracking noise from the fold.

I have silicone at the ends, so an extra aluminium strip doesn't matter.Also seem you have omitted the extra strps of alu at the top an buttom of the diaphragm that is normally seen and is there to help the folding process.

If i don't have silicone, the membrane would oscillate upwards and downwards as the current is horizontal.

Thanks!Keep up the super good work .... really looks good

BR Baldin

Mundorf have the best distortion figures of all the AMTs I have seen tested.

I can maybe send you a copy of tests from Klang&Ton and HobbyHiFi on private e-mail if you would like to see difference btw e.g. Dayton AMT Pro-4, Mundorf AMT29CM1.1-R and Bayma TLP-200S

Biggest difference though is with regards to 3. and higher harmonics ... otherwise all these 3 have around 0,1% @ 95 db 1m from ca. 1k and up

With regards to paint, I was actually thinking of just using a very small brush after it has been mounted ..... could also be some kind of glue ... maybe thinned contact adhesives ... it is kind of rubber like

I can maybe send you a copy of tests from Klang&Ton and HobbyHiFi on private e-mail if you would like to see difference btw e.g. Dayton AMT Pro-4, Mundorf AMT29CM1.1-R and Bayma TLP-200S

Biggest difference though is with regards to 3. and higher harmonics ... otherwise all these 3 have around 0,1% @ 95 db 1m from ca. 1k and up

With regards to paint, I was actually thinking of just using a very small brush after it has been mounted ..... could also be some kind of glue ... maybe thinned contact adhesives ... it is kind of rubber like

Have you tried a conformal compound used in electronics? Many are paraffin/silicone based and have excellent dampening characteristics. Most also have a florescent dye added for visual inspection. I had a type in mind but 20 years later for the life of me cannot remember what. Go figure

Hydrophobic Moisture Blocking Conformal Coatings for Printed Circuit Boards and Electronic Devices Protection | AI Technology, Inc.

Hydrophobic Moisture Blocking Conformal Coatings for Printed Circuit Boards and Electronic Devices Protection | AI Technology, Inc.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Yet another DIY AMT