Thanks for all of the great information you guys! I have my next project. Good thing we made the back removable. I have easy access to pull the rear chamber off while leaving everything pretty from the front.

Attachments

Last edited:

Thanks for all of the great information you guys! I have my next project. Good thing we made the back removable. I have easy access to pull the rear chamber off while leaving everything pretty from the front.

Wow!, nice studio speakers.

Wow!, nice studio speakers.

Thank you. I added another for ya! I made a thread for these when we first created them a few years ago, but myself and the engineer at the studio have always felt that there was something going on around 1.5-2KHz that stood out compared to the rest of the range. We even did a little dip in the response there like an old school BBC thing but it still bothered me. We are crossing at 1.85KHz and steep 48dB/oct. I never understood how anyone could use them down to 1KHz like so many people mention. Do they not hear the straining sound? The slight harshness to vocals?

Greg

On my loudspeakers I crossed them 2,2kHz (tweeter high pass) (passive 2º order). I'm using this speakers for mastering and mixing. I'm very happy with them.

Ok, so you crossing higher. What size woofer is that?

Greg

Ok, so you crossing higher. What size woofer is that?

Greg

Is a 12" from JBL (One of the woofers with less distortion of the market)

Last edited:

Very nice. Thank you.

You might want to consider some better internal material than the "acoustical" foam. You made a nice heavy box AND used the rubber damping for vibration, but what about the soundwaves inside the cabinet? Either 2" rigid fiberglass or even better, some type of product like Bonded Logic. We use this in all speakers and all around the studio for absorption. Works great and no itchy stuff like the rigid fiberglass.

Bonded Logic - Construction Products - UltraTouch Denim Insulation

It absorbs far more of the back wave of the woofer than the foam, generally resulting in a more clear midrange. Especially since you are taking it all the way up to 2.2KHz passive at 12dB. That means there is still significant output up to and above 5KHz coming from the JBL.

Not too scientific, but if you talk into your cabinet through the woofer hole the way it is and then swap the other cabinet for the better material, I think you will notice the new version is much more dead inside.

You might want to consider some better internal material than the "acoustical" foam. You made a nice heavy box AND used the rubber damping for vibration, but what about the soundwaves inside the cabinet? Either 2" rigid fiberglass or even better, some type of product like Bonded Logic. We use this in all speakers and all around the studio for absorption. Works great and no itchy stuff like the rigid fiberglass.

Bonded Logic - Construction Products - UltraTouch Denim Insulation

It absorbs far more of the back wave of the woofer than the foam, generally resulting in a more clear midrange. Especially since you are taking it all the way up to 2.2KHz passive at 12dB. That means there is still significant output up to and above 5KHz coming from the JBL.

Not too scientific, but if you talk into your cabinet through the woofer hole the way it is and then swap the other cabinet for the better material, I think you will notice the new version is much more dead inside.

Thank you.

I tried a material similar to Bonded Logic, but thanks for the link.

The box have two types of fill, one on the wall is polyurethane foam and the other is wool filling the box.

With the first I added some absorption and increased the apparent volume of the box (The internal resonances going down in frequency), the wool is for decrease the Q of the resonances (by sharing the energy of the resonance in a greater number of frequencies), as well, the box have some braces for avoid some resonant modes of the walls (I did several waterfalls with a contact pickups). My first idea was do a losing cabinet (Like Rogers or Spendor) for expend part of the back energy on the walls. The box is made from 21mm baltic birch with the special rubber on the walls (very high density and weigth).

Not so much output at 5 kHz from the woofer, the piece in front of them partially prevents the output over 2kHz (Isn't designed for this function is just for high frecuency dispersion) (the woofer's low pass is much lower than the tweeter high pass)

I tried a material similar to Bonded Logic, but thanks for the link.

The box have two types of fill, one on the wall is polyurethane foam and the other is wool filling the box.

With the first I added some absorption and increased the apparent volume of the box (The internal resonances going down in frequency), the wool is for decrease the Q of the resonances (by sharing the energy of the resonance in a greater number of frequencies), as well, the box have some braces for avoid some resonant modes of the walls (I did several waterfalls with a contact pickups). My first idea was do a losing cabinet (Like Rogers or Spendor) for expend part of the back energy on the walls. The box is made from 21mm baltic birch with the special rubber on the walls (very high density and weigth).

Not so much output at 5 kHz from the woofer, the piece in front of them partially prevents the output over 2kHz (Isn't designed for this function is just for high frecuency dispersion) (the woofer's low pass is much lower than the tweeter high pass)

Last edited:

Lgrau, any more picts of the whole system? Thanks.

Greg

Hi,

The TPL is not yet integrated in a system, still experimenting.

Some pictures of my current(also unfinished) system can be found in my danish thread here:

HIFI4ALL Forum: Lyd laboratoriet

Could not connect to User databaseUnknown database 'dev_diyaudio_forum'

I want to see too

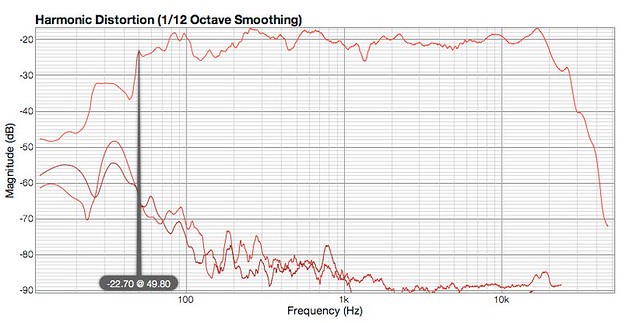

Without the felt damping pad, the 2º order distortion drops 20dB[/QUOT

a question about the felt damping pad. what type of felt and what was the orientation of the felt? SAE rated F-11 is very broad band absorber and if you orient so the back wave strikes the edge surface of the felt rather than the flat it can make a big difference (same with fiberglass). Best regards Moray James.

Without the felt damping pad, the 2º order distortion drops 20dB[/QUOT

a question about the felt damping pad. what type of felt and what was the orientation of the felt? SAE rated F-11 is very broad band absorber and if you orient so the back wave strikes the edge surface of the felt rather than the flat it can make a big difference (same with fiberglass). Best regards Moray James.

Hi,

The felt is the original and must be leave off (is glued to the metal body), this felt is very dense and this is the problem (probably with the age will lose his strength and then improve its measures).

But thanks for the tip

Cheers

Hi,

Its hard to dampen, Ive tried some experiments using bitumen directly on the diagphram. It daemped the resonanse but it was also spreaded out.

If you want to below its better to buy the Aurum Cantus diagphram IMO with a fs around 1KHz.

I also wants to try this because I wanted to crossover around 1KHz

Its hard to dampen, Ive tried some experiments using bitumen directly on the diagphram. It daemped the resonanse but it was also spreaded out.

If you want to below its better to buy the Aurum Cantus diagphram IMO with a fs around 1KHz.

I also wants to try this because I wanted to crossover around 1KHz

That's a bummer. It looks like the Aurum Cantus has much poorer distortion figures. There is always a 'gotcha!' in audio it seems.

Where did you apply the bitumen? The sides or the tops or both?

It might be best for us to learn the best way of making these. It would seem that it requires manual labor which explains the costs. The traces are simply enough. Bandsei has made some pretty decent progress so far. Etching should not be too difficult with a mask or stencil, given the right foil.

Where did you apply the bitumen? The sides or the tops or both?

It might be best for us to learn the best way of making these. It would seem that it requires manual labor which explains the costs. The traces are simply enough. Bandsei has made some pretty decent progress so far. Etching should not be too difficult with a mask or stencil, given the right foil.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- TPL150 DIY