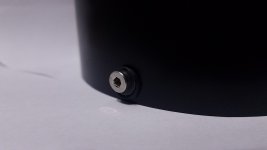

Thought so, just wanted to verify. Too smooth for powder coat, and I can see 'skid marks' in the visible countersunk hole. Normal for alum...

That's what happens when one has had his nose rubbed into materials a lot....you notice the 'fiddly bits' of minimal consequence. *L*

Unless the bit is 'newish' and is precisely the right speed, the alum 'smears' like butter right from the fridge. I've dealt with people that have noticed such. Wanted to slap them. Thousandths of an inch, doesn't effect fit, and they see That. You pick up on the anality of it, and people stop inviting you to parties. Industrial disease....

That's what happens when one has had his nose rubbed into materials a lot....you notice the 'fiddly bits' of minimal consequence. *L*

Unless the bit is 'newish' and is precisely the right speed, the alum 'smears' like butter right from the fridge. I've dealt with people that have noticed such. Wanted to slap them. Thousandths of an inch, doesn't effect fit, and they see That. You pick up on the anality of it, and people stop inviting you to parties. Industrial disease....

Beautiful....*L*...but it starts to look like a sonic revolver, 'bout 22 caliber...

"Stand back...these speakers are killa. See those holes in the floor?"

I remember back when a poster asked if you could make a kit of parts for assembly. You could, based on what you're posting but I suspect only a few would have the skill and patience to put them together. Not to mention any jigs that would be absolutely necessary to do elements of the routine Correctly....

You're amazing, Sir. *S* Your efforts are beginning to start looking legendary. It's inspiring to 'look over your shoulder' as it transpires. Makes looking like fab'ing an ESL or a ribbon driver child's play in contrast. Absolutely awesome....^5's...

"Stand back...these speakers are killa. See those holes in the floor?"

I remember back when a poster asked if you could make a kit of parts for assembly. You could, based on what you're posting but I suspect only a few would have the skill and patience to put them together. Not to mention any jigs that would be absolutely necessary to do elements of the routine Correctly....

You're amazing, Sir. *S* Your efforts are beginning to start looking legendary. It's inspiring to 'look over your shoulder' as it transpires. Makes looking like fab'ing an ESL or a ribbon driver child's play in contrast. Absolutely awesome....^5's...

Complete Metal Fab

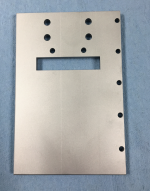

Here I have the completed metal structure for the mid-range. here you can see there is a lot of metal and the bottom fits flush accurate so far.

Here I have the completed metal structure for the mid-range. here you can see there is a lot of metal and the bottom fits flush accurate so far.

Attachments

I wonder if 3D printing can help make these parts more reproducible. You can print anything from steel to gold these days. Plus there are exotic materials like TPU and carbon fiber and the like.

I was looking at the picture on post #220 and thinking that could be done accurately with a printing service.

I don't pretend to know much about the requirements of assembly on this thing but maybe you could optimize the design for ease of assembly with printed parts minimizing the effort and know-how allowing for group buys and diy assembly.

Lord knows I would buy one. This is the kind of stuff that gets me going, unfortunately I don't have the funds, knowledge, or proximity to help you much in your project or I would.

Keep at it.

I was looking at the picture on post #220 and thinking that could be done accurately with a printing service.

I don't pretend to know much about the requirements of assembly on this thing but maybe you could optimize the design for ease of assembly with printed parts minimizing the effort and know-how allowing for group buys and diy assembly.

Lord knows I would buy one. This is the kind of stuff that gets me going, unfortunately I don't have the funds, knowledge, or proximity to help you much in your project or I would.

Keep at it.

very small update

All i did was bore out the existing threads in the motor so that the threads to the chassis didnt cause the motor to rise and not make flush contact. Also the bottom piece where the metal casing bolts are attached to where not properly done which did not allow me to use my existing screws I found some that worked just as well and now we know what it looks like assembled at last the biggest thing left is making a high quality lamella process and molds

All i did was bore out the existing threads in the motor so that the threads to the chassis didnt cause the motor to rise and not make flush contact. Also the bottom piece where the metal casing bolts are attached to where not properly done which did not allow me to use my existing screws I found some that worked just as well and now we know what it looks like assembled at last the biggest thing left is making a high quality lamella process and molds

Attachments

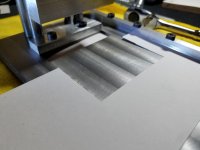

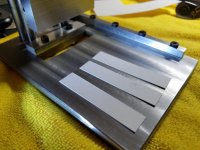

I've had the bases for my project CNC'd to make the end result a tad less 'garage DIY'. I've spent a lot of time considering a better approach to forming cones, as 'hand forming' yields variations that I'm trying to avoid. A small slip roller would be ideal, but they're not made small enough 'off the shelf'. So I'm working towards making one that's 'purpose built' for the goal...

That seems to be a common issue for the both of us, that 'driven element' that drives you nutz. But I will admit yours is more of a challenge and a feat to do properly. But you're doing great at it...keep on keepin' on.

That seems to be a common issue for the both of us, that 'driven element' that drives you nutz. But I will admit yours is more of a challenge and a feat to do properly. But you're doing great at it...keep on keepin' on.

I've had the bases for my project CNC'd to make the end result a tad less 'garage DIY'. I've spent a lot of time considering a better approach to forming cones, as 'hand forming' yields variations that I'm trying to avoid. A small slip roller would be ideal, but they're not made small enough 'off the shelf'. So I'm working towards making one that's 'purpose built' for the goal...

That seems to be a common issue for the both of us, that 'driven element' that drives you nutz. But I will admit yours is more of a challenge and a feat to do properly. But you're doing great at it...keep on keepin' on.

Thanks Jerry CNC and 3d printing are my lord and savior

Amen to that! *G* I've yet to foray into 3D printing anything for my 'exploits', but printing metal does seem attractive...but not quite yet.

I've been struggling with that simple yet effective means of rolling materials for cones in a predictable fashion. I finally arrived at an approach that has those answers; more on that as I cobble together 'the widget'.

Meanwhile, our 'regular business' is on the cusp of a large project using the CNC source I used for the bases. We having him route 206 pieces in treated wood for the ribs of a 45' long fish play structure we're going to build for a town near Burlington, NC. Since it's size precludes us assembling in shop, it's going to be done outdoors literally on our doorstep. I suspect that might cause a bit of a stir amongst the locals here...not to mention when it 'hits the road' to the final destination...*L* Not often when one sees a 'fish out of water' on the interstate.

BTW, hope your going to join in the Great Migration to watch the eclipse. A cousin of mine remarked that it might feel like a national version of Woodstock. Well, a 3 minute version of it, Yes...it'll certainly be a national 'jam' both before and after fer chure. *L* Pity no chance for an encore if the weather doesn't 'shine' on the festival.

I've been struggling with that simple yet effective means of rolling materials for cones in a predictable fashion. I finally arrived at an approach that has those answers; more on that as I cobble together 'the widget'.

Meanwhile, our 'regular business' is on the cusp of a large project using the CNC source I used for the bases. We having him route 206 pieces in treated wood for the ribs of a 45' long fish play structure we're going to build for a town near Burlington, NC. Since it's size precludes us assembling in shop, it's going to be done outdoors literally on our doorstep. I suspect that might cause a bit of a stir amongst the locals here...not to mention when it 'hits the road' to the final destination...*L* Not often when one sees a 'fish out of water' on the interstate.

BTW, hope your going to join in the Great Migration to watch the eclipse. A cousin of mine remarked that it might feel like a national version of Woodstock. Well, a 3 minute version of it, Yes...it'll certainly be a national 'jam' both before and after fer chure. *L* Pity no chance for an encore if the weather doesn't 'shine' on the festival.

*L* It is crazy, but we're crazy enough to tilt windmills like that...

Nice piece of metal...no clue as to what it's for or will do, but...*G*shrug*

Yeah, there seems to be an uptick in interest 'bout them. The 'original' full-range versions like the F and A will still prove to be a challenge (ask HHR/Dale about that). There's omnis showing up in the 'digital assistants', but what I've 'seen' or aware of are still not a 'true' Walsh radiator...at least in the sense of the profile of the cone and the way it's implemented. But we'll see....esp. in pricing, which tends to be get insanely high for what basically isn't that difficult IMHO...

I'd like to take some credit for that 'uptick', but I'd be patting my own back in a self-delusional fashion.... *L* But it's an overdue resurgence in interest, IMHO. They're too revolutionary, underappreciated, and would make 'home theater' really ACT like it should. The MBL's (and yours *S*) are just the pinnacle of how far the omni concept can be taken, and how successful it can be.

I'll keep plunking away with my 'trash'....likely I won't be able to afford whatever and however the 'new Walsh' may be. And it keeps me off the streets and out of other people's hair. *L*

Nice piece of metal...no clue as to what it's for or will do, but...*G*shrug*

Yeah, there seems to be an uptick in interest 'bout them. The 'original' full-range versions like the F and A will still prove to be a challenge (ask HHR/Dale about that). There's omnis showing up in the 'digital assistants', but what I've 'seen' or aware of are still not a 'true' Walsh radiator...at least in the sense of the profile of the cone and the way it's implemented. But we'll see....esp. in pricing, which tends to be get insanely high for what basically isn't that difficult IMHO...

I'd like to take some credit for that 'uptick', but I'd be patting my own back in a self-delusional fashion.... *L* But it's an overdue resurgence in interest, IMHO. They're too revolutionary, underappreciated, and would make 'home theater' really ACT like it should. The MBL's (and yours *S*) are just the pinnacle of how far the omni concept can be taken, and how successful it can be.

I'll keep plunking away with my 'trash'....likely I won't be able to afford whatever and however the 'new Walsh' may be. And it keeps me off the streets and out of other people's hair. *L*

- Home

- Loudspeakers

- Planars & Exotics

- Summer Project - Replication of MBL loudspeaker 101mkII