That low sensitivity of these would improve if the motor was at the top pushing down rather than trying to pulse upward? Would it not?

I listened to these at our recent Newport highend show here in California and they are quite impressive.

Regards

David

Should not make any difference - you can build a single section and merely flip it upside down, thought experiment, any difference?

I think they play the same in Australia too!

_-_-bear

Thank you. Jurgen Reis keywords helped..LOTS of sites AND brochures as well from review sites they took along time to get. I could however point you in a general direction. Try searching for jurgen reis mbl (IMAGE), and a good one is mbl 101 PDF.Ill provide some links anyway it would be a pain in the **** to go find every pic again through the web so here are some links. https://www.google.com/search?q=mbl....,cf.osb&fp=5f551c48dd37d1b2&biw=1280&bih=601

New info/Images

I searched a little more and was able to find this site could anyone translate?

Welcome to Adobe GoLive 4

Progress is well progressing but i went into this project not even knowing what a former ( bobbin) was. I have learned a lot and am well on my way to designing the motor structure.

Images found on the site listed above

I searched a little more and was able to find this site could anyone translate?

Welcome to Adobe GoLive 4

Progress is well progressing but i went into this project not even knowing what a former ( bobbin) was. I have learned a lot and am well on my way to designing the motor structure.

Images found on the site listed above

Attachments

Btw, if I was doing the project, I would start by taking an existing speaker and excising the cone and the dustcap, leaving the spider, VC and magnet structure, brewing up some sort of mounting arrangement for the petals, and trying a quick and dirty version before committing to a complicated and expensive build... make sure you can get it to sort of work.

_-_-bear

_-_-bear

Btw, if I was doing the project, I would start by taking an existing speaker and excising the cone and the dustcap, leaving the spider, VC and magnet structure, brewing up some sort of mounting arrangement for the petals, and trying a quick and dirty version before committing to a complicated and expensive build... make sure you can get it to sort of work.

_-_-bear

But first, a die cutter needs to be fabricated to cut the aluminum petals to the perfect shape. Then a corrugating rolling press needs to fabricated to roll them into the perfect curve with perfectly formed corrugations. The petals are easy to make. It's the die and press used to make them that are difficult to fabricate (extremely).Only then he can can attempt the next (dirty) step. If he can do this, I am confident that he has the will and the means to do the rest, regardless of how it sounds at the end of the process..

Last edited:

Dunno the google translation was plenty good enough for me... otoh I can sort of read the French, not quite well enough to get all the subtle details but to get the idea... whatever.

There are other online translations available too, so maybe a composite mental assembly after reading them all will fill the gaps?

_-_-bear

There are other online translations available too, so maybe a composite mental assembly after reading them all will fill the gaps?

_-_-bear

Thanks for the translation btw first time i found out about the whole web translation.Dunno the google translation was plenty good enough for me... otoh I can sort of read the French, not quite well enough to get all the subtle details but to get the idea... whatever.

There are other online translations available too, so maybe a composite mental assembly after reading them all will fill the gaps?

_-_-bear

I know enough about how the whole speakers work. I just need to get the specifics down. I kinda doubt theres any more information out there that i havent already comsumed either through text or detailed pictures. I think now its just about engineering my own drivers

Just letting you know this clone is not mine. It is Areczek'sMan, that is work of art

On the speaker to the left ... what is the middle round thingy ....

More pictures please

Kind regards Baldin

http://www.diyaudio.com/forums/planars-exotics/153337-my-mbl-101e-replicas.html

The round thing is just being used to hold up the unfinished speaker.It is missing the big aluminum lower-mid-range driver other than that they are both completed. I will agree they look exactly like the real thing and I have heard they play like it too.

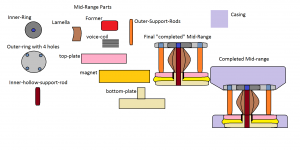

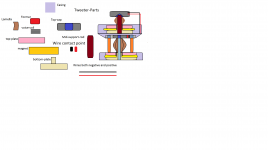

Tweeter and Mid-Range Model

Tweeter and Mid-Range Model showing the bare construction. Lamella dimensions and cooking process have been realized. Next step is to make a model using a pre-existing driver with a native 50mm diameter voice-coil and modifying it to make a mbl Mid.

Tweeter and Mid-Range Model showing the bare construction. Lamella dimensions and cooking process have been realized. Next step is to make a model using a pre-existing driver with a native 50mm diameter voice-coil and modifying it to make a mbl Mid.

Attachments

Last edited:

Driver has been chosen as the Dayton Audio RS52AN. This is a Dome mid-range witch have inherently large voice-coils for their size. In this case it fits one of the many requirements e.g. a 50mm voice-coil.

Attachments

I think all that would be easier if you slaughtered DC Gold drivers (spiderless design fullrange drivers).

http://dcgold.com/

An interesting material for the lamellas (unfortunately only available in the US):

http://www.taskboard.com/

http://dcgold.com/

An interesting material for the lamellas (unfortunately only available in the US):

http://www.taskboard.com/

Last edited:

I think all that would be easier if you slaughtered DC Gold drivers (spiderless design fullrange drivers).

DC Gold Audio :: Home

An interesting material for the lamellas (unfortunately only available in the US):

Task Board, Model Making Cardboard

I don't know they look pretty expensive the Dayton is also spider less, has a 50mm voice-coil, is relatively affordable, and can be dismantled without damage. This driver isn't for the final production run. It is merely experimental to test different variables in carbon fiber etc. I wouldnt say thats at all an interesting material for the lamellas. Maybe if you were making a visual only copy.

No mbl does not use a push push configuration. I would guess it would increase sensitivity. I don't think they would cancel since they are not out of phase.I have always wanted to ask.. Are the lamellas driven from both ends? (eg Push/Push)

What would be the advantages/disadvantages of doing this? (eg raised sensitivity vs cancellation?

Dean

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Summer Project - Replication of MBL loudspeaker 101mkII