I have been PMed this very same question "what grade of magnets are used?".

Sorry,I do not know what grade of magnets were used.

I don't know what types were available in the late 80's when they were built.

They appear to be of the same grade that used to be commonly sold at radio shack in similar sizes for $.99 ti $1.19 only thicker.

Overall they are the exact same size only thicker.

I have experimented with such magnets and they appear to be about the same strength for an equal thickness.

I had stated this info somewhere in one of the threads, But since threads very easily get buried I couldn't tell you which one it was, as it was a while ago.

I would assume they would be of grade 8.

Maybe some of the earlier models were a grade 5 or something as I have read that some of the later models may have had a higher efficiency.

But they could very well have used more of them instead for that matter.

My set was made in March of 1987.

I had made a magnetometer a while back where I could measure the filed strength but I don't have a known type that I could use to calibrate it with.

I can tell you that every time you double the thickness of a magnet of the same type you also double the lines of forces therefore doubling its strength.

Just like putting two 1.5V batteries in series you get 3V.

I can tell you that they are ceramic magnets and that is all I know about them for now until I can build a calibrated magnetometer.

FWIW

jer

Sorry,I do not know what grade of magnets were used.

I don't know what types were available in the late 80's when they were built.

They appear to be of the same grade that used to be commonly sold at radio shack in similar sizes for $.99 ti $1.19 only thicker.

Overall they are the exact same size only thicker.

I have experimented with such magnets and they appear to be about the same strength for an equal thickness.

I had stated this info somewhere in one of the threads, But since threads very easily get buried I couldn't tell you which one it was, as it was a while ago.

I would assume they would be of grade 8.

Maybe some of the earlier models were a grade 5 or something as I have read that some of the later models may have had a higher efficiency.

But they could very well have used more of them instead for that matter.

My set was made in March of 1987.

I had made a magnetometer a while back where I could measure the filed strength but I don't have a known type that I could use to calibrate it with.

I can tell you that every time you double the thickness of a magnet of the same type you also double the lines of forces therefore doubling its strength.

Just like putting two 1.5V batteries in series you get 3V.

I can tell you that they are ceramic magnets and that is all I know about them for now until I can build a calibrated magnetometer.

FWIW

jer

As it happens I recently acquired my first pair of Apogee speakers, the Stage. These suffer from a sort of "flapping" sound from the woofer panel, and a slight buzz, much more evident on one speaker than the other.

I started checking them out and found that on the rear, foam is almost gone or sort of sticky-goo consistence using a flash light to inspect them. Searching through the old Apogee forum I found that Graz recommended loosening the woofer panel clamp screws 1/4 of a turn. It helped quite a bit, but still some buzz could be heard. As I read on the old Apogee forum and on this forum, member taotao's clever silicone method could be easily used, especially as on the Stage the perforated steel can be removed from the rear side without destroying the woofer membrane. This way I could also easily inspect the rear foam much better. So I ordered some Zhermack HT33+silicone oil through amazon.de from Polymer-schmiede.

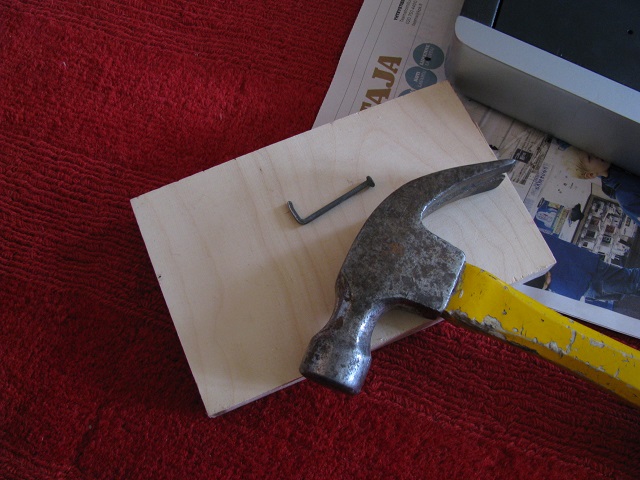

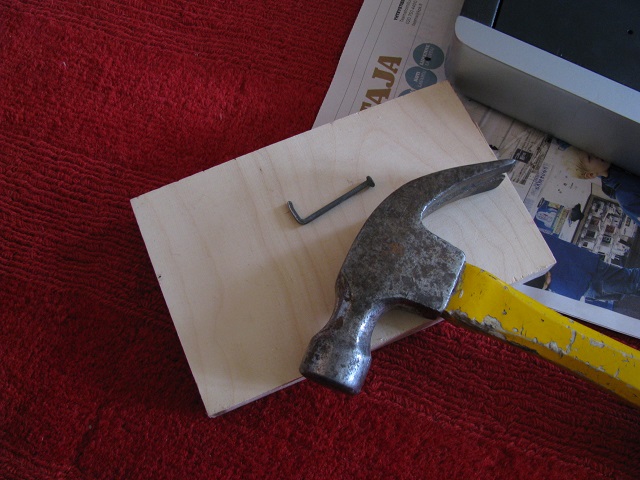

I started by dismantling the perforated steel with magnets. The magnet plate is attached with screws and some sort of silicone, so I had to make tools to safely remove it. First I tried with some zip ties starting from one corner, without success. I decided to use a bit more force, bent a nail and wrapped some tape around it. Then set the nail through the perforated steel and started pulling with the hammer from one corner using a piece of plywood as a sheet between. It helped, and after a few gentle pulls I could move on to the zip ties. On the second speaker the steel could be pulled with just the zip ties. Just need to be very carefully not to damage anything. Finally I very gently vacuumed the woofer suspension area from debris.

When inspecting the rear side I could see on one speaker some silicone that appeared to have been there from factory. From the looks of it, it appears to have bursted from the clamps when installing the woofer panel. Probably too much silicone. It had bursted throught almost the whole clamp. Factory-made buzz removal? This was on the speaker with almost no issues.

For injecting the silicone I used a syringe with a soft tube on the end. For now I've only "fixed" one vertical clamp on both speakers.

I used a mixture of 20ml base, 20ml catalyst and 14 ml silicone oil based on some experiments. About 2/3 of this amount was needed the fix one rear clamp on both speakers. It took some time as the silicone slowly creeped through the old foam, and more silicone had to be added.

Keep fingers crossed that this will work! I will let you know later on as I proceed.

I started checking them out and found that on the rear, foam is almost gone or sort of sticky-goo consistence using a flash light to inspect them. Searching through the old Apogee forum I found that Graz recommended loosening the woofer panel clamp screws 1/4 of a turn. It helped quite a bit, but still some buzz could be heard. As I read on the old Apogee forum and on this forum, member taotao's clever silicone method could be easily used, especially as on the Stage the perforated steel can be removed from the rear side without destroying the woofer membrane. This way I could also easily inspect the rear foam much better. So I ordered some Zhermack HT33+silicone oil through amazon.de from Polymer-schmiede.

I started by dismantling the perforated steel with magnets. The magnet plate is attached with screws and some sort of silicone, so I had to make tools to safely remove it. First I tried with some zip ties starting from one corner, without success. I decided to use a bit more force, bent a nail and wrapped some tape around it. Then set the nail through the perforated steel and started pulling with the hammer from one corner using a piece of plywood as a sheet between. It helped, and after a few gentle pulls I could move on to the zip ties. On the second speaker the steel could be pulled with just the zip ties. Just need to be very carefully not to damage anything. Finally I very gently vacuumed the woofer suspension area from debris.

When inspecting the rear side I could see on one speaker some silicone that appeared to have been there from factory. From the looks of it, it appears to have bursted from the clamps when installing the woofer panel. Probably too much silicone. It had bursted throught almost the whole clamp. Factory-made buzz removal? This was on the speaker with almost no issues.

For injecting the silicone I used a syringe with a soft tube on the end. For now I've only "fixed" one vertical clamp on both speakers.

I used a mixture of 20ml base, 20ml catalyst and 14 ml silicone oil based on some experiments. About 2/3 of this amount was needed the fix one rear clamp on both speakers. It took some time as the silicone slowly creeped through the old foam, and more silicone had to be added.

Keep fingers crossed that this will work! I will let you know later on as I proceed.

Last edited:

Some thoughts:

1. We, meaning Apogee DIY members, have always been "officially" discouraged by the "true" Apogee members of the Apogee forum about attempting to repair the buzzing issue. I cannot recall one post where it was noted by those who knew, and there must have been at least a few who did, that ANY Apogee's back panel could be unscrewed to access the rear bass foam. Never mentioned! Now I see why: because there is a cheap repair available which goes against certain interests, at least for this Apogee model.

2. How are the magnets attached to the screen? I always thought that there was a real risk of them falling out. That's why you never transfport Apogees upside down, always the front is up. I think you were very fortunate that one didn't fall on the ribbon.

3. Rather than pour new silicone into the old foam, why not take out the old foam, pour some silicone in the slot and press in new foam. The silicone then acts as a glue to hold in the new foam. Since it is new foam, it will not deteriorate - without the need for silicone poured into it.

I look forward to your update.

1. We, meaning Apogee DIY members, have always been "officially" discouraged by the "true" Apogee members of the Apogee forum about attempting to repair the buzzing issue. I cannot recall one post where it was noted by those who knew, and there must have been at least a few who did, that ANY Apogee's back panel could be unscrewed to access the rear bass foam. Never mentioned! Now I see why: because there is a cheap repair available which goes against certain interests, at least for this Apogee model.

2. How are the magnets attached to the screen? I always thought that there was a real risk of them falling out. That's why you never transfport Apogees upside down, always the front is up. I think you were very fortunate that one didn't fall on the ribbon.

3. Rather than pour new silicone into the old foam, why not take out the old foam, pour some silicone in the slot and press in new foam. The silicone then acts as a glue to hold in the new foam. Since it is new foam, it will not deteriorate - without the need for silicone poured into it.

I look forward to your update.

Thanks for the info an pic......

My got frist pr of Stages.....93....have had 5pr....i have had no buzz in any Stages.... not even the pr i am playing now .......Duittas sig...had 2 pr BuzZ........ all Apogee Full ribbons i ever saw... other than the Stages Buzzzz at one note are more...........

Cant move them after there New out of the Box frist time..you were good to go but oneces there move 50'....it started...

I think its the 100lb are more in magnets....An the foam root rott ..

But the stages............at 60lb ea can be move an still live an not buzz...an can be driven with tubes..........lot of fun......$3-400. a pr off CL...

most feel thay well die any min....like a give away...nuts

One thing for sure....dont put to much daping on the back magnet plate ...damping it good.. sound like the thing to do.............but..

i have felt if i ever pulled my magnet plate off i would not add any new damping ..

I have found that if you add just one are two peaces of damping like blu tack on the magnet plate.... it makes a Big diff in the bass an the over all sound...1or 2 ok..3-4 not so much.... An as for the silicone Fix..an not foam...it

Well chang the sound!....i would add only at the buzz spot..if i could....less is more...

So if to much damping is added it wlll take some life out of the sound....it changes the topend an mid blind.........just saying... Good luck....great sound

My got frist pr of Stages.....93....have had 5pr....i have had no buzz in any Stages.... not even the pr i am playing now .......Duittas sig...had 2 pr BuzZ........ all Apogee Full ribbons i ever saw... other than the Stages Buzzzz at one note are more...........

Cant move them after there New out of the Box frist time..you were good to go but oneces there move 50'....it started...

I think its the 100lb are more in magnets....An the foam root rott ..

But the stages............at 60lb ea can be move an still live an not buzz...an can be driven with tubes..........lot of fun......$3-400. a pr off CL...

most feel thay well die any min....like a give away...nuts

One thing for sure....dont put to much daping on the back magnet plate ...damping it good.. sound like the thing to do.............but..

i have felt if i ever pulled my magnet plate off i would not add any new damping ..

I have found that if you add just one are two peaces of damping like blu tack on the magnet plate.... it makes a Big diff in the bass an the over all sound...1or 2 ok..3-4 not so much.... An as for the silicone Fix..an not foam...it

Well chang the sound!....i would add only at the buzz spot..if i could....less is more...

So if to much damping is added it wlll take some life out of the sound....it changes the topend an mid blind.........just saying... Good luck....great sound

Last edited:

Good Deal !!!!

You got lucky Samppo!!!!

The Duette's have their magnet plate mounted from the inside to the back panel.

I had considered this, But I would have to cut the back panel around the perimeter of the magnet plate while devising some sort of jig to keep the whole assembly from falling in and crushing the diaphragm!!

jer

You got lucky Samppo!!!!

The Duette's have their magnet plate mounted from the inside to the back panel.

I had considered this, But I would have to cut the back panel around the perimeter of the magnet plate while devising some sort of jig to keep the whole assembly from falling in and crushing the diaphragm!!

jer

Some thoughts:

2. How are the magnets attached to the screen? I always thought that there was a real risk of them falling out. That's why you never transfport Apogees upside down, always the front is up. I think you were very fortunate that one didn't fall on the ribbon.

3. Rather than pour new silicone into the old foam, why not take out the old foam, pour some silicone in the slot and press in new foam. The silicone then acts as a glue to hold in the new foam. Since it is new foam, it will not deteriorate - without the need for silicone poured into it.

I look forward to your update.

2. Magnets appear to be glued with some sort of epoxy, in good amounts. I have a hard time seeing they would come loose. What I don't like is the accuracy of the magnet alignment. Some magnets are quite poorly fixed and not in line. I wonder if I should make a new magnet plate with more accurate alignment. The magnets used are about 65mm x 21mm x 12mm. I know a supplier that has C5 XXmm x 20mm x 12mm.

3. The foam on Stages is very thin, I think it would be very difficult to get out all the old foam and stick in some new foam without damaging the ribbon. Using a good mixture of silicone will give soft a suspension, which I think is at least as good as the original, and it distributes very evenly. The spring rate will for sure alter a bit, but I don't think it's critical. Anyhow I poured silicone also on the front, which seems to have intact foam, but it looks a bit tired at some places. I want the ribbon suspension to be as linear as possible. Later on I will measure and see if the tuning is still correct after many years.

The front foam took only about half as much silicone as the back.

I certainly encourage people to buy new ribbons from Graz, but with the Stage it's a bit difficult, as he does not supply any woofer ribbons. I will most probably get new ribbon tweeters from him at some point. Mine are a bit curved on the lower parts. Maybe not much difference in sound, but still.

Personally I think the Stage has a very elegant woofer ribbon design that maximizes the use of the magnet field with only one conductor in each magnetic field. If only the magnets were a bit better aligned..

Good go...

Hey Samppo,

you`ll be lucky with you new born Apogees once you are finished.

The stage has a wonderfull midrange and the top and low frequencies are also well balanced.

Better bass you`ll get, if you tame the big resonance arround 46 Hz or 50 Hz, with a peak of nearly 9 dB.

You coud to it in the digital, or cheaper, analog domain. A simple notch with opamps is sufficient.

My Duetta Signatures still play without disturbing buzz or noise.

It`s long ago, since I put silicone into the gaps, still perfect damping.

If your silicone is soft enough (reason for using silicone oil) you don`t need to put in new foarm. But I guess it`s also possible.

Good luck and tell us how it went.

Hey Samppo,

you`ll be lucky with you new born Apogees once you are finished.

The stage has a wonderfull midrange and the top and low frequencies are also well balanced.

Better bass you`ll get, if you tame the big resonance arround 46 Hz or 50 Hz, with a peak of nearly 9 dB.

You coud to it in the digital, or cheaper, analog domain. A simple notch with opamps is sufficient.

My Duetta Signatures still play without disturbing buzz or noise.

It`s long ago, since I put silicone into the gaps, still perfect damping.

If your silicone is soft enough (reason for using silicone oil) you don`t need to put in new foarm. But I guess it`s also possible.

Good luck and tell us how it went.

Good Deal !!!!

You got lucky Samppo!!!!

The Duette's have their magnet plate mounted from the inside to the back panel.

I had considered this, But I would have to cut the back panel around the perimeter of the magnet plate while devising some sort of jig to keep the whole assembly from falling in and crushing the diaphragm!!

jer

Thanks jer!!

I was thinking that maybe you could use a long medical infusion hose on the end of the syringe and trickle the hose all the way from top to bottom, with the speaker laying horizontally and pour in the silicone while gradually pulling out the syringe&infusion hose.

I think taotao also suggested pouring in the silicone from the top letting the silicone flow to the lower parts.

Worth a shot? I don't think you have anything to lose.

Thanks agin.... great pic... an insite for a Stage guy like myself....your the only guy that i seen pull them apart.....

.Looking at the pic...i see your pr were made early.. the date is at the top bass bare inside on most..

What i see is the bake away madal foot brace....the frist ones had the cut out foot like yours...That was bent out of the back foot...only one peace...an work better than the later two peace foot i think.... with the front point on one peace back brace with bolt for seting the kant ......

I like the one you had better than the newer two peace foot.....because when one like yours was bent out to make the front point... the point was under the speaker.....this changed the center of gravity of the speaker.......the new ones on the back only....not under frame at all ...

But it looks like your front foot is broke off....not there ....So .....just the front covers of the frame are on the floor??

I have seen this done before on a pr i was going to get....an it had cracket the front wood at the top.......just a heads up....these Old Stages can behad for vary littel cash.....but thay sound way diff on there feet....have fun.....

.Looking at the pic...i see your pr were made early.. the date is at the top bass bare inside on most..

What i see is the bake away madal foot brace....the frist ones had the cut out foot like yours...That was bent out of the back foot...only one peace...an work better than the later two peace foot i think.... with the front point on one peace back brace with bolt for seting the kant ......

I like the one you had better than the newer two peace foot.....because when one like yours was bent out to make the front point... the point was under the speaker.....this changed the center of gravity of the speaker.......the new ones on the back only....not under frame at all ...

But it looks like your front foot is broke off....not there ....So .....just the front covers of the frame are on the floor??

I have seen this done before on a pr i was going to get....an it had cracket the front wood at the top.......just a heads up....these Old Stages can behad for vary littel cash.....but thay sound way diff on there feet....have fun.....

Attachments

tyu, these were made in August 1990 and came with the stands. I think some pieces are missing as now the speakers are resting on the front frames while on their stands. I've got the feet shown earlier and this is what the stands look like with all the bolts&nuts I've got. Could someone tell me what's missing, and is there something that shouldn't be there? I want these as original as possible.

You well see in the Manul what the newer two peace foot look like....I have had the stans

I dont care for the sound of the stock stands ........

i like real wood.it gives much better sound... to me anyway....

.but the front point on the footer need to be there.. not the small peaces i see in the pic... when front foot point is there.... front of the Stages are up above... top of the stands front..just a littel..

It makes the Stages an stans look like one speakers....

Thay still set on there feet on the stand!.... Seen in pic... feethttp://www.apogeespeakers.com/manuals/stage_manual.pdf

http://www.apogeespeakers.com/manuals/stage_stand_assembly.pdf

I dont care for the sound of the stock stands ........

i like real wood.it gives much better sound... to me anyway....

.but the front point on the footer need to be there.. not the small peaces i see in the pic... when front foot point is there.... front of the Stages are up above... top of the stands front..just a littel..

It makes the Stages an stans look like one speakers....

Thay still set on there feet on the stand!.... Seen in pic... feethttp://www.apogeespeakers.com/manuals/stage_manual.pdf

http://www.apogeespeakers.com/manuals/stage_stand_assembly.pdf

Attachments

Last edited:

Thanks tyu, the speaker feet I have are clearly missing something:

http://www.multi.fi/~samppo/Apogee/buzz2.jpg

I found a picture, but it's a one piece foot, not like mine with a hole on the lower part:

http://www.springair.de/media/image/thumbnail/h52011-2-52011b_1000x1000.jpg

I finished doing the silicone, now just waiting for it to dry and start assembling tomorrow.

Did notice while working on the speakers that the left woofer ribbon is somewhat looser about 2/3 rd up from bottom. Need to fix that at some point.

http://www.multi.fi/~samppo/Apogee/buzz2.jpg

I found a picture, but it's a one piece foot, not like mine with a hole on the lower part:

http://www.springair.de/media/image/thumbnail/h52011-2-52011b_1000x1000.jpg

I finished doing the silicone, now just waiting for it to dry and start assembling tomorrow.

Did notice while working on the speakers that the left woofer ribbon is somewhat looser about 2/3 rd up from bottom. Need to fix that at some point.

North Creek Music......George Short...he work on the Stages With Jason Bloom

Makes a New crossover for the Stages.....

I have added some of his upgreads to my Stage Crossover he uses....

An i too think that the Apogee Stages Canbe..... the Best twoway fullrang Ribbon Left standing....

Like he sayes.......

....I kept of a pair of upgraded Stage's and a pair of Duetta Signatures in my listening room as reference. I can say with no reservations, the Duetta Signatures are great speakers, but the upgraded Stage's blow them away....

To bad all the other Apogees all are over 100lbs....an well not last like the stages can......But if you like Big....like us all..an can live with one amp....Like i cant......The other Apogees Well rock the house.....Tell you move them an you Get BIG heart burn............From the BUZzzzzzzzzz.....

.....My Stages are Playing Now.....

An i also have a pr of the Centaur Minor ......Same 26" mid-tweeter.....on the stock stans...Killer sound just a littel richer in the mid bass than the Stages... lot of fun...Tubes driver ezaly

Makes a New crossover for the Stages.....

I have added some of his upgreads to my Stage Crossover he uses....

An i too think that the Apogee Stages Canbe..... the Best twoway fullrang Ribbon Left standing....

Like he sayes.......

....I kept of a pair of upgraded Stage's and a pair of Duetta Signatures in my listening room as reference. I can say with no reservations, the Duetta Signatures are great speakers, but the upgraded Stage's blow them away....

To bad all the other Apogees all are over 100lbs....an well not last like the stages can......But if you like Big....like us all..an can live with one amp....Like i cant......The other Apogees Well rock the house.....Tell you move them an you Get BIG heart burn............From the BUZzzzzzzzzz.....

.....My Stages are Playing Now.....

An i also have a pr of the Centaur Minor ......Same 26" mid-tweeter.....on the stock stans...Killer sound just a littel richer in the mid bass than the Stages... lot of fun...Tubes driver ezaly

Attachments

I certainly encourage people to buy new ribbons from Graz, but with the Stage it's a bit difficult, as he does not supply any woofer ribbons.

This explains why he does not sell the Stage Woofers ribbon replacements. To easy to fix..yes? He is no dummy....If he can fab replacement Scintilla and all other model replacement woofer ribbons, why not Stages? No magic in Stage woofer Ribbons..

Damn, this is going to make the Stages go up in value now... gotta keep an eye out for my next pair...

maybe you could use a long medical infusion hose on the end of the syringe and trickle the hose all the way from top to bottom, with the speaker laying horizontally

Had a horrible accident while doing just that on my Scinnies....had the first speaker on side tilted with hose laying silicone - working perfectly. While I watched the silicon flow, imagining how awesome they will sound after dried, my Multimeter fell from my desktop onto the bare ribbon and destroyed the panel. I screamed at the top of my lungs...horrible expletives. I was depressed for weeks, as I paid quite a bit for them.

I eventually awoke out of my stupor and bought a pair of new replacement woofer ribbon panels (1 ohm version - and NOT CHEAP) from the German outfit (as you all know Graz does not sell to us DIY'ers) and they have been sitting boxed in my back room awaiting the replacement project for 9 months. It will take some time once I start, and I am trying to clear my bench of all other projects (amps and speakers) before I start on the Scinnies...I am quite sure I can do it without any issues. I will then use good permanent foam and have these "One of the Best Speakers Ever" speakers for life.

At least that is what I keep telling myself.

Currently enjoying my 2+2 while I clear my project bench. Juggling wife / kids / work while working away the bench load.

Last edited:

- Home

- Loudspeakers

- Planars & Exotics

- Apogee Speakers Construction

![buzz1[1].jpg](/community/data/attachments/394/394135-d38edd99cc0a9f75a45ef203010c0a52.jpg)

![image[1] (4).jpg](/community/data/attachments/394/394327-5b7c27e8a8df1826a3f2f05e49fee693.jpg)

![NCMXOandStock[1].jpg](/community/data/attachments/394/394351-b84b37a963b7a9f8f047a0f188f33981.jpg)

![stage_crossover[1].jpg](/community/data/attachments/394/394353-a0d727374c499bb17e41d0daa532bded.jpg)