Hi, what is the widt of the ribbon, and the size of your magnets?

Interesting build!

Regards

bent

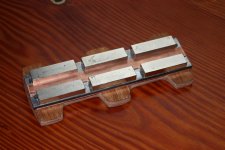

The ribbon in my first post is 27mm wide and 1050mm long. Magnets are N35 10*10*150mm.

I use capacitor paper from a now closed capacitor factory.

No problem too corrugate when sandwiched with paper.

It is very strong ribbon. the planar ribbon in the youtube clip

is crossovered at 200hz. Ok very step digital filter.The 1meter

true ribbon is crossed at 1000hz 12db

Thanks ABJensen,

I'm trying to find source of that fine Washi paper, should'nt be far off the thickness of the capacitor paper, I think. Otherwise I've got few meters left of DuPont Mylar 3um, but that will not corrugate well.

This ribbon is made of 0.6my aluminium and 12my paper back.

The ribbon is 27 mm wide and 1050 mm long. This gives 2,2 0hm,

so no need for transformer or resistor.

Would a 6 microns aluminium ribbon with a 2 ohms resistor in series be equivalent? The 12 microns thick paper is probably lighter (factor 1.35 estimated) than 6 microns aluminium ribbon.

The ribbon in my first post is 27mm wide and 1050mm long. Magnets are N35 10*10*150mm.

With such a wide gap (27 mm) and small magnets with a square section (10x10 mm), the magnetic field is very uneven in the ribbon gap - weak in the middle compared to the magnet surface. But then, if it sounds good ...

With such a wide gap (27 mm) and small magnets with a square section (10x10 mm), the magnetic field is very uneven in the ribbon gap - weak in the middle compared to the magnet surface. But then, if it sounds good ...

Brunob , could you explain your position on this a bit more , the middle will always be weaker than the ends, are you suggesting a different magnet size (instead of 10x10 ) to give more field strength in the middle ..

regards,

With such a wide gap (27 mm) and small magnets with a square section (10x10 mm), the magnetic field is very uneven in the ribbon gap - weak in the middle compared to the magnet surface. But then, if it sounds good ...

What about adding helper magnets in the middle, instead of steel pieces to close the magnetic circuit. You could space them out to

compensate for weaker field in the middle and no problems with saturation point of steel. Also use stacked disc or rod magnets to

minimise reflections from the back.

Peter.

Last edited:

What software are you using to measure?

This build is very similar to my ribbon prototype that I built a few weeks ago.

I will redo the ribbon with supports spaced along the ribbon as it tends to move out of the magnetic field. Also I will build a more "domestic" construction in a wife-acceptable design and colour when the time comes.

regards,

Bent

This build is very similar to my ribbon prototype that I built a few weeks ago.

I will redo the ribbon with supports spaced along the ribbon as it tends to move out of the magnetic field. Also I will build a more "domestic" construction in a wife-acceptable design and colour when the time comes.

regards,

Bent

I havent measuret them yet. But will use the software for my DSN28 pre Ground Sound . And Holm freeware.

And yes mine is very smilar, they will probably almost measure identical.

I will probably have too put some spacers one mine too. This super thin aluminium gives very little spring effect.

And yes mine is very smilar, they will probably almost measure identical.

I will probably have too put some spacers one mine too. This super thin aluminium gives very little spring effect.

Last edited:

Brunob , could you explain your position on this a bit more , the middle will always be weaker than the ends, are you suggesting a different magnet size (instead of 10x10 ) to give more field strength in the middle ..

regards,

I performed several FEMM simulations and measurements. Narrower magnets and deeper cavities give a more homogenous magnetic field in the gap.

See "The tall neodymium ribbon". Part 1. See also http://www.diyaudio.com/forums/plan...d-constructing-ribbon-unit-2.html#post2466928

Just got some alu leaf tape this morning. Wow, 25 cm length of 45mm wide tape measured 1.2R. I'll be replacing the ribbon over the weekend on my 1.3 m ribbons  . Quick test of corrugating the ribbon bonded to 3um Mylar worked a treat, thanks ABJensen, great idea. Btw was your aluminium leaf tape made up of small sections or was it continuous length? That might be the reason for higher resistance (apart from thickness) since there will be contact resistance between the small pieces that make up the tape.

. Quick test of corrugating the ribbon bonded to 3um Mylar worked a treat, thanks ABJensen, great idea. Btw was your aluminium leaf tape made up of small sections or was it continuous length? That might be the reason for higher resistance (apart from thickness) since there will be contact resistance between the small pieces that make up the tape.

Peter

Peter

Last edited:

Just got some alu leaf tape this morning. Wow, 25 cm length of 45mm wide tape measured 1.2R. I'll be replacing the ribbon over the weekend on my 1.3 m ribbons. Quick test of corrugating the ribbon bonded to 3um Mylar worked a treat, thanks ABJensen, great idea. Btw was your aluminium leaf tape made up of small sections or was it continuous length? That might be the reason for higher resistance (apart from thickness) since there will be contact resistance between the small pieces that make up the tape.

Peter

Now does the increased resistance comes at a cost in sonics ...?

Brunob :

To make sure i'm following you correctly . Are you saying it is better to have

a a 10mm (H) x30 mm ( d) magnet vs 10 mm x10 mm .?

wider magnets are much stronger

but only makes sense if you place them like this

ribbon is placed in level with front of magnet

felt between the magnets

very easy to build it like this

no need to use glue on magnets either

Attachments

wider magnets are much stronger

but only makes sense if you place them like this

ribbon is placed in level with front of magnet

felt between the magnets

very easy to build it like this

no need to use glue on magnets either

I have made a short ribbon 60cm*2.2cm like that with doppel layer of magnets.

It works quite well.

What do you use to bond the ribbon to the mylar? jer

Hi Jer,

Used spray adhesive but it's way to thick, I'll have to get some 3M stuff.

Peter

Mine is made of 15cm leaf that overlap. Is yours continuous ? UKPD.Looking forward too your opinion of the sound.Well I am happy too bring some too diy comunity. Just call it the Jensen ribbon

Mine are with 10 cm leaf which is very loose on joints, when rechecked previous measurement pressing at the joint lines the resistance was dropping.

I will try to press the ribbon while gluing & see if that helps. Maybe put some thinned down silver conducting adhesive on the joint.

Jensen ribbon... like it

Cheers

Peter

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- 0.6my aluminium ribbon