Alex, I sense your fustration with me and I very much appreciate your patients.

As you have helped me alot to understand how to go about what I am trying to do.

I knew it would a matter of a day or two that a light would gone on and now it is burning brighter than ever, thanks.

Thankfully it has been less than a day.

So, lets see if I can clarify a few things.

The name of this thread is " how to make a good transformer for a ribbon tweeter".

Hence " tweeter " the lowest frequency was never specified.

So, in my mind I'm thinking I have gotten good results from the cores that I have and it would be only a matter of adding a secondary winding to keep things simple. Right?

Then In the back of my mind I thought this would work for a small bass panel aswell and this is where all the confusion started.

Because now I am thinking full range and everyone else is thinking tweeter. Without me realizing it.

My bad and I'm very sorry for all the confusion I have caused everyone and I apologise for any sharpness that I may have displayed.

Then when you mentioned cable x-former and balun,I instantly started thinking rf stuff and powdered cores.

It was then I really started to confuse my self even more.

Because I was not familar with the term "cable x-former".

Then got to thinking that with a transformation ratio of 20:1 I could use 20 turns for the primary and still get down to 200hz at 100 watts with this core without saturation and one heavy turn for the secondary.

I am familar with this technique from my days of messing around with solid state rf power amplifiers.

It was then that the light went on and I had realized what you and Bear were coming from and trying to tell me.

So therefore, I am very sorry to both of you for my ignorance and sharpness as it was uncalled for on my part.

I really feel like idiot.

Anyway, I have taken a closer look at the core that you had suggested and it is very nice indeed.

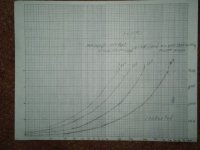

The B-H curve of the core that I have is the best I have seen and compared, too, anything else that I have on hand.

But nowhere as good as the one you have suggest indeed.

But the price would be about $70 to $100 (maybe more) each after tax and shipping.

Not to mention a minimum order of 20 pcs.

I did discover those last year aswell.

Thats when had discovered the company called ALPHA CORE.

They have some in a more comparable price range that suited my needs at that time.

Unfortunatly for me at the moment I don't have funds, and ,will consider this more as soon as my situation has been resolved.

I have included the B-H curves of my core and the data of the core you suggested for all to compare.

And hopes to persude anyone whom has the funds too invest in a quality core.

Although one should not despair ,because good results can be had with what is available.

I still stand firm on this.

My goal here was to show how to do it.

Again I am very sorry for the confusion.

I glad I had realized my mistake before I had wasted 36 yards of copper tape only to find out that it would have been less than optimum performance.

Meanwhile, I am currently working on the magnet structure and frame with an adjustable gap for the 4" ribbon. jer

As you have helped me alot to understand how to go about what I am trying to do.

I knew it would a matter of a day or two that a light would gone on and now it is burning brighter than ever, thanks.

Thankfully it has been less than a day.

So, lets see if I can clarify a few things.

The name of this thread is " how to make a good transformer for a ribbon tweeter".

Hence " tweeter " the lowest frequency was never specified.

So, in my mind I'm thinking I have gotten good results from the cores that I have and it would be only a matter of adding a secondary winding to keep things simple. Right?

Then In the back of my mind I thought this would work for a small bass panel aswell and this is where all the confusion started.

Because now I am thinking full range and everyone else is thinking tweeter. Without me realizing it.

My bad and I'm very sorry for all the confusion I have caused everyone and I apologise for any sharpness that I may have displayed.

Then when you mentioned cable x-former and balun,I instantly started thinking rf stuff and powdered cores.

It was then I really started to confuse my self even more.

Because I was not familar with the term "cable x-former".

Then got to thinking that with a transformation ratio of 20:1 I could use 20 turns for the primary and still get down to 200hz at 100 watts with this core without saturation and one heavy turn for the secondary.

I am familar with this technique from my days of messing around with solid state rf power amplifiers.

It was then that the light went on and I had realized what you and Bear were coming from and trying to tell me.

So therefore, I am very sorry to both of you for my ignorance and sharpness as it was uncalled for on my part.

I really feel like idiot.

Anyway, I have taken a closer look at the core that you had suggested and it is very nice indeed.

The B-H curve of the core that I have is the best I have seen and compared, too, anything else that I have on hand.

But nowhere as good as the one you have suggest indeed.

But the price would be about $70 to $100 (maybe more) each after tax and shipping.

Not to mention a minimum order of 20 pcs.

I did discover those last year aswell.

Thats when had discovered the company called ALPHA CORE.

They have some in a more comparable price range that suited my needs at that time.

Unfortunatly for me at the moment I don't have funds, and ,will consider this more as soon as my situation has been resolved.

I have included the B-H curves of my core and the data of the core you suggested for all to compare.

And hopes to persude anyone whom has the funds too invest in a quality core.

Although one should not despair ,because good results can be had with what is available.

I still stand firm on this.

My goal here was to show how to do it.

Again I am very sorry for the confusion.

I glad I had realized my mistake before I had wasted 36 yards of copper tape only to find out that it would have been less than optimum performance.

Meanwhile, I am currently working on the magnet structure and frame with an adjustable gap for the 4" ribbon. jer

Attachments

-

B-H%20curve%20for%20p3.jpg1.5 KB · Views: 961

B-H%20curve%20for%20p3.jpg1.5 KB · Views: 961 -

B-H%20curve%20for%20p4.jpg1.6 KB · Views: 954

B-H%20curve%20for%20p4.jpg1.6 KB · Views: 954 -

B-H%20curve%20for%20p5.jpg1.5 KB · Views: 949

B-H%20curve%20for%20p5.jpg1.5 KB · Views: 949 -

B-H%20curve%20for%20p6.jpg1.5 KB · Views: 954

B-H%20curve%20for%20p6.jpg1.5 KB · Views: 954 -

scope%20graph.jpg57.6 KB · Views: 908

scope%20graph.jpg57.6 KB · Views: 908 -

vergleich nano-ferrit_1_e.pdf84.6 KB · Views: 121

-

vergleich nano-ferrit_2_e.pdf75.3 KB · Views: 78

-

vergleich nano-ferrit_3_e.pdf148.7 KB · Views: 74

Yep...

The last time I quoted FT-3L (the one you need) from Metglas, in container (much better then impregnated) it was around $200 per kilo. The suggested core would be 245 g <=> $70-100 Oh, well...

Another suggestion then.

Amorphous core is ten times cheaper and still beats ferrite and steel. 2605SA1 Talk to them and ask for the one with transverse anneal. You may even specify the permuability level. Very linear curve, some audio transformers has similar cores

The last time I quoted FT-3L (the one you need) from Metglas, in container (much better then impregnated) it was around $200 per kilo. The suggested core would be 245 g <=> $70-100 Oh, well...

Another suggestion then.

Amorphous core is ten times cheaper and still beats ferrite and steel. 2605SA1 Talk to them and ask for the one with transverse anneal. You may even specify the permuability level. Very linear curve, some audio transformers has similar cores

I needed a way to measure the magnetic field so I created this handy little tool.

A magnetometer.

It is not calibrated be any means.

But it does allow me to check the uniformaty of the magnetic field.

I found that even a gap of a 1/4" to an 1/8" between the ends of the magnets showed a reduction in the field strength by as much as 50%.

At a measuring distance of 3/8".

Since I could not gain any significant amount length to warrant the reduction in strength I set the magnets touching end to end.

The field strength is compleatly uniform across the entire length. jer

A magnetometer.

It is not calibrated be any means.

But it does allow me to check the uniformaty of the magnetic field.

I found that even a gap of a 1/4" to an 1/8" between the ends of the magnets showed a reduction in the field strength by as much as 50%.

At a measuring distance of 3/8".

Since I could not gain any significant amount length to warrant the reduction in strength I set the magnets touching end to end.

The field strength is compleatly uniform across the entire length. jer

Attachments

quote from Peca,

"What you think about idea to winding secondary coil maybe with litz (stranded) wire to avoid eddy current in transformer?"

Acording to the clemson calculator a wire dia. of .038" (18 gauge) is the point were the a.c. resistance (impedence) starts to rise and is significantly high with a 12 gauge wire.

I think that it would be safe to assume that litz wire would be a wize choice for a secondary (or primary) winding if more current capablity Is required than an 18 gauge wire can handle or if a suitable size flat conductor can not be determined.

As flat conducters can be hard to work with at times. jer

"What you think about idea to winding secondary coil maybe with litz (stranded) wire to avoid eddy current in transformer?"

Acording to the clemson calculator a wire dia. of .038" (18 gauge) is the point were the a.c. resistance (impedence) starts to rise and is significantly high with a 12 gauge wire.

I think that it would be safe to assume that litz wire would be a wize choice for a secondary (or primary) winding if more current capablity Is required than an 18 gauge wire can handle or if a suitable size flat conductor can not be determined.

As flat conducters can be hard to work with at times. jer

Last edited:

Ribbon tweeter Matching Transformer That really Works

I had some of those Pioneer Tweeters and the transformer was a joke! I tried regular iron cores, and they are more than 50 percent lossy, so tried Ferrite. The size of the core is 2 3/16 inches square and no gap. It is wound based on RF tech, so not an easy job. For ribbon resistance of .03 ohm, which is what the ones I made are, the ratio is 17 to 1. just for 36 watts, that is 36 amps on secondary! I used 5 mil copper sheet that is wound so it is a tube when done. layer of foil, wind 16 turns of 2 ea #21, then another foil. Side ends are pinched together and soldered making it a flatened tube. 4 of these in series to complete it. The connection ends of both of the foils has a piece doubled over and soldered. This is because of the high current. I tested it for the amount of voltage it would take with little loss. For 3 Kc lowest frequency, it would take 35 volts RMS, which at 8 ohms is over 150 watts! The ribbon won't even handle that! This has almost 100 percent coupling, and very little loss.

I had some of those Pioneer Tweeters and the transformer was a joke! I tried regular iron cores, and they are more than 50 percent lossy, so tried Ferrite. The size of the core is 2 3/16 inches square and no gap. It is wound based on RF tech, so not an easy job. For ribbon resistance of .03 ohm, which is what the ones I made are, the ratio is 17 to 1. just for 36 watts, that is 36 amps on secondary! I used 5 mil copper sheet that is wound so it is a tube when done. layer of foil, wind 16 turns of 2 ea #21, then another foil. Side ends are pinched together and soldered making it a flatened tube. 4 of these in series to complete it. The connection ends of both of the foils has a piece doubled over and soldered. This is because of the high current. I tested it for the amount of voltage it would take with little loss. For 3 Kc lowest frequency, it would take 35 volts RMS, which at 8 ohms is over 150 watts! The ribbon won't even handle that! This has almost 100 percent coupling, and very little loss.

Attachments

"Amorphous Core is ten times cheaper" ? You just quoted what looks like about $400/ KG for Metglas (Amorphous Metal core)Yep...

The last time I quoted FT-3L (the one you need) from Metglas, in container (much better then impregnated) it was around $200 per kilo. The suggested core would be 245 g <=> $70-100 Oh, well...

Another suggestion then.

Amorphous core is ten times cheaper and still beats ferrite and steel. 2605SA1 Talk to them and ask for the one with transverse anneal. You may even specify the permuability level. Very linear curve, some audio transformers has similar cores

At any rate, this is insanity for this product. Might reflect the monopoly Hitachi had on this market. AT&M (china) now cranks out 40,000 metric tonnes of Amorphous Metal ribbon per year. Ya!, and Hitachi makes twice that. This is "power grid" transformer stuff'in (high efficiency) The demand is high, but I read somewhere, $3/ Kg I'm pretty sure they where talking about the foil (ribbon). And their own marketing shows Metglas built grid transformers at only 25% more. Which means manufacturers of such ( there are many) can't be paying that much.

So if we could get our hands on the ribbon, could we make our own cores. Nice money when you can get it Hitachi; 3 bucks will get ya $300. A 10,000% mark up. This just begs DIY.

I finally got around to actually testing the tweeter using the transformer I wound shown above. It is almost twice as loud as the Heil AMTs I have and sound is a lot more natural. The impedance of the input was totally flat from 3 Kc to over 40 Kc, and probably well beyond that. Transformer loss was less than 0.5 Db. Was exactly 8 ohms! Air core made the same way will work, but would be very large with a lot of turns.

Attachments

Well... If I attempt to recap this string. You could say "geraldfry jr" is promoting just that, although his contribution to this string is substantially beyond that. In Post #16 "linesource" introduced Amorphous Metal cores to the frey. This core has several great attributes, most notably a stable flux across the passband that results in substantial reduction of this distortion. The need for this, probably depends on what school of audio you are from. And if you are building ribbon tweeters, this idea probably fits well with your esoteric point of view. My guess is, that if you are building ribbons, you have the skill set to build this core; given the availability of the foil.why can't we just use air core transformers for tweeter driving?

Hence my DIY suggestion to put the price of a amorphous metal core where everyone will like it.

"fooeywufle" just reiterated the point, made a few times in the string, about about having such large "donuts"on a tweeter.

Was kinda hoping to hear back from "geraldfryjr" on some of his results. He put a lot in to this string. He may have started another one.

Sorry, But I never finished the project due to lack of interest and no response from the OP.

And the OP's post in #87 and no more responses left me feeling that maybe I was being accused of thread hijacking or something.

So I gave up on the project.

I wouldn't mind trying to finish it but I don't even know where I had put the magnets right now!

Since then I have finished my variable HV supply and been focusing an my ESL's again.

I have seen some examples of some air core transformers for audio and they were quite very large and the copper losses alone will be the biggest factor to deal with.

And I think that the amorphous cores are a great choice as well however they are extremely costly.

It would be great to find a good affordable source for some of this material for sure.

As shipping charges will be the bulk of the bill.

Great job fooeywuffle on your design, I had been tossing around the idea to use some cores out of old flyback transformers.

I used to have a bunch of them and I can't find them now and the last time I tried to extract one I shattered it into several pieces

not realizing that I probably could have superglued it back together with very little losses.

I do have some more laying around though, but they do work and are hard to come by freely anymore should I need one for some kind of HV apparatus.

Old PC supplies have come to mind as a source as well.

But again I destroyed the last core, out of one, trying to get it apart nicely.

Next time I will just cut the windings out with a fiber cutoff wheel !!! He,he,he,he

Cheers !!

jer

And the OP's post in #87 and no more responses left me feeling that maybe I was being accused of thread hijacking or something.

So I gave up on the project.

I wouldn't mind trying to finish it but I don't even know where I had put the magnets right now!

Since then I have finished my variable HV supply and been focusing an my ESL's again.

I have seen some examples of some air core transformers for audio and they were quite very large and the copper losses alone will be the biggest factor to deal with.

And I think that the amorphous cores are a great choice as well however they are extremely costly.

It would be great to find a good affordable source for some of this material for sure.

As shipping charges will be the bulk of the bill.

Great job fooeywuffle on your design, I had been tossing around the idea to use some cores out of old flyback transformers.

I used to have a bunch of them and I can't find them now and the last time I tried to extract one I shattered it into several pieces

not realizing that I probably could have superglued it back together with very little losses.

I do have some more laying around though, but they do work and are hard to come by freely anymore should I need one for some kind of HV apparatus.

Old PC supplies have come to mind as a source as well.

But again I destroyed the last core, out of one, trying to get it apart nicely.

Next time I will just cut the windings out with a fiber cutoff wheel !!! He,he,he,he

Cheers !!

jer

Last edited:

As a "Johnny come lately" who read this thread a year after it was written, I think this is one of the best threads I've ever read.

A lot of information, in a pretty short space (thread). I sensed know one had much left to say. I think you guy's covered the bases well, or more people would have jumped in.

Kinda left me wondering what you came up with though, and how I could further the "amorphous metal core" cause.

Fooeywuffle has since put forth a great, more conventional approach.

I will continue to pursue the Amorphous metal ribbon. Since there are now several Asian transformer manufacturers making AMT's; with their own source of Ribbon. I suspect that the issue now, will be how much one has to buy. AMT manufacturers are all buying it by the Tonne.

A lot of information, in a pretty short space (thread). I sensed know one had much left to say. I think you guy's covered the bases well, or more people would have jumped in.

Kinda left me wondering what you came up with though, and how I could further the "amorphous metal core" cause.

Fooeywuffle has since put forth a great, more conventional approach.

I will continue to pursue the Amorphous metal ribbon. Since there are now several Asian transformer manufacturers making AMT's; with their own source of Ribbon. I suspect that the issue now, will be how much one has to buy. AMT manufacturers are all buying it by the Tonne.

"Amorphous Core is ten times cheaper" ? You just quoted what looks like about $400/ KG for Metglas (Amorphous Metal core)

At any rate, this is insanity for this product. Might reflect the monopoly Hitachi had on this market. AT&M (china) now cranks out 40,000 metric tonnes of Amorphous Metal ribbon per year. Ya!, and Hitachi makes twice that. This is "power grid" transformer stuff'in (high efficiency) The demand is high, but I read somewhere, $3/ Kg I'm pretty sure they where talking about the foil (ribbon). And their own marketing shows Metglas built grid transformers at only 25% more. Which means manufacturers of such ( there are many) can't be paying that much.

So if we could get our hands on the ribbon, could we make our own cores. Nice money when you can get it Hitachi; 3 bucks will get ya $300. A 10,000% mark up. This just begs DIY.

FT3L is nanocrystal and not amorph and it is indeed better

Are we talking about twitter? 5k to 20+kHz? 20W of power

You may spend 20eu max for a core you need. What's the problem...

Attachments

I definitely miss read that about FT-3L. Making a lot more sense

now. Though, the power requirement with ribbon is substantially higher. I use small ribbons, more conventionally as a tweeter; 2500-3000 hz. I've noticed a few in this string crossing over at 1200-1500hz. And geroldfryjr got on to full range. Never the less, at 2500 hz I've considered 30w good, because the efficiency is high 94-96db. In my case I could throw more money at Neodymium magnets (higher efficiency/less power needed) but I am limited by the low end driver efficiency.

now. Though, the power requirement with ribbon is substantially higher. I use small ribbons, more conventionally as a tweeter; 2500-3000 hz. I've noticed a few in this string crossing over at 1200-1500hz. And geroldfryjr got on to full range. Never the less, at 2500 hz I've considered 30w good, because the efficiency is high 94-96db. In my case I could throw more money at Neodymium magnets (higher efficiency/less power needed) but I am limited by the low end driver efficiency.

Yes, I was wanting to go full range for the sake of my ESL's but much lower than 1200hz for a ribbon.

My 200 watt cores are all I have to work with for right now, and, since then I have abandoned the idea of a single full range driver.

Using some Neo's is definitely the way to go.

I do have some Apogee Duette's and they do not play very loud for the amount of power that goes into them.

My main issue is that I still have some very nice multitrack machines around and my room is not very big.

So having powerful magnets in the vicinity bothers me a bit not to mention many CRT type monitors as well.

jer

My 200 watt cores are all I have to work with for right now, and, since then I have abandoned the idea of a single full range driver.

Using some Neo's is definitely the way to go.

I do have some Apogee Duette's and they do not play very loud for the amount of power that goes into them.

My main issue is that I still have some very nice multitrack machines around and my room is not very big.

So having powerful magnets in the vicinity bothers me a bit not to mention many CRT type monitors as well.

jer

Does anybody really know the loss of these so called amorph cores over powdered iron or ferrite? Ferrite is the easiest to use and they are cheap and almost no loss and a completed one isn't that big! 2 1/4 inch square, and is easy to work with using sheet copper and wire that is large enough so minimal loss. And is good for over 100 watts and I know the ribbon would melt at this power. All other cores I have tried are very lossy unless a large number of turns are used which makes it more lossy, and not good at higher frequencies, so more loss. On having completed tweeters in a room, if the structure is a closed type, not much field is around the thing, so no problem unless laying it on your recording machines. If you really have to take apart the flybacks and pre-made ferrite transformers, just heat them in the oven until the varnish gets soft, and they will come apart easily. You will need 2 transformers of the same core to make tweeter one. They are gapped cores, so one in each is not useable. Some transformers use undercut cores for both.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- How to make a good transformer for ribbon tweeter?