Hi,

I have decided to built a magnetic driven planar speaker.

Got most of the parts, and the design is illustrated below. A perforated steel plate as I have used in my ESL projects, with 10x10x40mm neo magnets. A alu frame in 1/2" x 1/2" square alu tube provides stiffness and spacing between diaphragm and magnets (distance will be 2,7mm + 1mm vhb tape.

Diaphragm will be 6micron mylar, with 9mm wide CPC alarm tape as conductor (0,6 ohms/meter resulting in a 5,4 ohm dc resistance I should imagine.

Horisontal spacing between magnets will be 15mm, and 10mm vertical spacing.

Outer dimensions of the frame will be 190mm wide and 1000mm high.

There will be 8X18 = 144 magnets pr speaker.

As the back plate is bigger than the diaphragm, it will be easy to mount baffles, and easy to add a ribbon tweeter if I should decide to do so later.

I am very exited by this project, it should be easy to build and hopefully give more satisfying results than my ESL attempts has given so far.

Any comment to my idea? Should i make it wider, bigger/smaller distance between magnets, distance between magnets and diaphragm?

Theese magnets cost a fortune, so I am reluctant to increase the number of magnets in the first test (I have 205 in stock)

All that remains now, is to unite theory with practice and see how it turns out!

Regards,

Bent

I have decided to built a magnetic driven planar speaker.

Got most of the parts, and the design is illustrated below. A perforated steel plate as I have used in my ESL projects, with 10x10x40mm neo magnets. A alu frame in 1/2" x 1/2" square alu tube provides stiffness and spacing between diaphragm and magnets (distance will be 2,7mm + 1mm vhb tape.

Diaphragm will be 6micron mylar, with 9mm wide CPC alarm tape as conductor (0,6 ohms/meter resulting in a 5,4 ohm dc resistance I should imagine.

Horisontal spacing between magnets will be 15mm, and 10mm vertical spacing.

Outer dimensions of the frame will be 190mm wide and 1000mm high.

There will be 8X18 = 144 magnets pr speaker.

As the back plate is bigger than the diaphragm, it will be easy to mount baffles, and easy to add a ribbon tweeter if I should decide to do so later.

I am very exited by this project, it should be easy to build and hopefully give more satisfying results than my ESL attempts has given so far.

Any comment to my idea? Should i make it wider, bigger/smaller distance between magnets, distance between magnets and diaphragm?

Theese magnets cost a fortune, so I am reluctant to increase the number of magnets in the first test (I have 205 in stock)

All that remains now, is to unite theory with practice and see how it turns out!

Regards,

Bent

THat looks promising, with alll those powerfull magnets. by the way how did you get the tape and what is the width of the tape and most of all where did you get it. i looked like everywhere to get aluminium tape in small width also in the security branche but it looks like they dont use it anymore or something. i still got 4 perf plates with all the magnets of a Magnepan wich i would like to use for something after all the searching

sorry you metnion the width of the tape but with 0,6 ohm a meter this is nice thing foil

but with 0,6 ohm a meter this is nice thing foil

sorry you metnion the width of the tape

Hi,

I got the tape from cpc.co.uk by recommendation from mr JAMESBOS

They ship internationally but have a rigid ordering system with prepayment.

5 rolls costed me 5 GBP and 18GBP including freight

The tape is 0,006 thick, 9mm wide. I haven´t opened the tape yet, so I am unsure if it comes with a liner or not. If it has a liner it can be rolled out and splitted in half.

I have decided to order some more magnets and make the speaker a bit bigger, and have a few magnets in spare for some ribbon tweeters.

Regards,

Bent

I got the tape from cpc.co.uk by recommendation from mr JAMESBOS

They ship internationally but have a rigid ordering system with prepayment.

5 rolls costed me 5 GBP and 18GBP including freight

The tape is 0,006 thick, 9mm wide. I haven´t opened the tape yet, so I am unsure if it comes with a liner or not. If it has a liner it can be rolled out and splitted in half.

I have decided to order some more magnets and make the speaker a bit bigger, and have a few magnets in spare for some ribbon tweeters.

Regards,

Bent

splitted in half ? what do you mean, so the tap is 4.5 mm ? or. dont know what a liner isi amfraid explain

Hi,

tape is 9mm wide, but if it has a peelable backing/protection one can lay it out on the table and split it in half with a knife to get 4,5mm...and then run 2 lengths.

Bent

Thx for the explanation. wel the knife thing is a horror i used it on normal aluminium tape to cut it in small tapes. did not really liked the work and the result. but 0.6 ohm a meter for a 9 mm width tape is also really nice so im gone get a look at the site Many THx. and keep us updated im really curious

Hi,

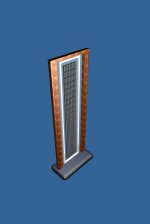

uploading a new illustration on how it is going to be built. I guess I will make the trim out of pine, and wax and polish it in a dark wood colour.

Planning on making a inner frame that holds the speaker grill cloth, and fit it with magnets so it snaps to the perforated plate.

I am planning on casting the base in concrete, the type used on bathrooms. It's on sale this week ;-)

I might have to reduce the widt of the speaker element in order to fit a ribbon tweeter.

Regards

Bent

uploading a new illustration on how it is going to be built. I guess I will make the trim out of pine, and wax and polish it in a dark wood colour.

Planning on making a inner frame that holds the speaker grill cloth, and fit it with magnets so it snaps to the perforated plate.

I am planning on casting the base in concrete, the type used on bathrooms. It's on sale this week ;-)

I might have to reduce the widt of the speaker element in order to fit a ribbon tweeter.

Regards

Bent

Thx for the explanation. wel the knife thing is a horror i used it on normal aluminium tape to cut it in small tapes. did not really liked the work and the result. but 0.6 ohm a meter for a 9 mm width tape is also really nice so im gone get a look at the site Many THx. and keep us updated im really curious

For cutting aluminum tape and thin diaphragm material I have found rotary razor blade cutters to work well, cutting smoothly in straight lines without snagging, wrinkling or tearing.

Attachments

I have tried different sizes of membranes, and to me it seems to be a problem to make a fullrage magnetostat with one membrane. My next model could use the design from Magneplanar MG.1B.They use one membrane ,and uses a crossover too feed an extra set off alufoil "coil´s",on the same membrane.

Have fun.

Båndsei.

Have fun.

Båndsei.

ah yeah got such blade as well now for mylar , the thing still crappy to cut 20 meter of foil tape exact 4,5 without looking crappy.

nice image,you could raise the element itself from the floor a bit so the high frequency sounds better when standing. nobody listen with there head on the floor so

nice image,you could raise the element itself from the floor a bit so the high frequency sounds better when standing. nobody listen with there head on the floor so

I have tried different sizes of membranes, and to me it seems to be a problem to make a fullrage magnetostat with one membrane. My next model could use the design from Magneplanar MG.1B.They use one membrane ,and uses a crossover too feed an extra set off alufoil "coil´s",on the same membrane.

Have fun.

Båndsei.

yeah they do it on every speaker. really easy just make some more foil only thinner so hence lighter for the high frequency. they wont get the power the bass portion does. magnepan used magnets that where smaller but thicker for the threble piece (3mm instead of 2mm) so they are closer to the membrane (coil)so output would be higher, and more wire vs mebrane for better controll because of the smaller rows of magnets.

Last edited:

Long time ago I cut several different serpentine woofer diaphragms

big ones, and in one piece

cut them on a glas plate

and I threw out more than I completed

it was great fun, and back then it was worth it

but those big ones can be pretty uncontrolled bastards

especially when playing those vinyl records

alone foot tapping could be a problem

I would think twice with them very big ones

btw, I used butter to fix the serpentine pattern to a glass plate, when I glued it to the film diaphragm

sounds funny, but it worked

btw, you could also consider a 50-100mm wide true ribbon, but with a magnet design like a big planar

big ones, and in one piece

cut them on a glas plate

and I threw out more than I completed

it was great fun, and back then it was worth it

but those big ones can be pretty uncontrolled bastards

especially when playing those vinyl records

alone foot tapping could be a problem

I would think twice with them very big ones

btw, I used butter to fix the serpentine pattern to a glass plate, when I glued it to the film diaphragm

sounds funny, but it worked

btw, you could also consider a 50-100mm wide true ribbon, but with a magnet design like a big planar

Ok

For once I did a small scale trial!

I made a A4 size planar speaker and the diaphragm, 6my Mylar with 6my cpc alarm tape

Unfortuneatly, the alu conductor ripped apart and the speaker did not work.

I will try again tomorrow; the two seconds of sound I got out of the panel was impressive, but the tape is more fragile than I imagined

If it should prove impossible to corner the tape I will try straight lengths and cubdyct them With ordinary cable

For once I did a small scale trial!

I made a A4 size planar speaker and the diaphragm, 6my Mylar with 6my cpc alarm tape

Unfortuneatly, the alu conductor ripped apart and the speaker did not work.

I will try again tomorrow; the two seconds of sound I got out of the panel was impressive, but the tape is more fragile than I imagined

If it should prove impossible to corner the tape I will try straight lengths and cubdyct them With ordinary cable

Just a point of interest (I hope). The Acoustat ESL loudspeaker uses a 0.65 mil thick (just over half a thousandths of an inch) HS (heat shrink) Mylar diaphragm with a resistive coating at least as thick as the film itself. The unsupported width of the diaphragm is 9 inches. That film even without the mass of the resistive coating cannot pull enough tension when heat shrunk to keep the diaphragm fully stable under low frequency hard drive situations.

I would say that you are going to have to use a thicker diaphragm than the 6 micron you have chosen. Or you might consider resistive damping in close proximity to the diaphragm (which was what Acoustat did). In the case of Acoustat the resistive damping in the form of felt pads just barely gets the job done. So in your situation (with far higher moving mass) it will help but will not get the job done.

This is the old weight on a spring situation. By using a thinner diaphragm material you have substituted a weaker spring plus you have increased the diaphragm mass load by adding the conductor and adhesive so that amounts to making the weight hanging on the spring heavier. You need to be able to make sure there is enough diaphragm tension to centre the diaphragm as soon as the driving force is removed.

I would say that you are going to have to use a thicker diaphragm than the 6 micron you have chosen. Or you might consider resistive damping in close proximity to the diaphragm (which was what Acoustat did). In the case of Acoustat the resistive damping in the form of felt pads just barely gets the job done. So in your situation (with far higher moving mass) it will help but will not get the job done.

This is the old weight on a spring situation. By using a thinner diaphragm material you have substituted a weaker spring plus you have increased the diaphragm mass load by adding the conductor and adhesive so that amounts to making the weight hanging on the spring heavier. You need to be able to make sure there is enough diaphragm tension to centre the diaphragm as soon as the driving force is removed.

where did it ripped appart ? i had these problems when i let the conductor run on to the spacer made a turn and got back to the mebrane, should make the turns on the mebrane. also with this wide foil it dificult to make the bend, you need to fold it to get the sticky side down after the bend.

Hi,

the conductor ripped in the corners when making the 2X 45 degrees angles.

I did another diaphragm just now with the same tecnique and it worked better but not perfect.

I will try an other diaphragm where I let the conductors run all across the diaphragm and outside the spacer, and connect them together with wire or copper foil tape.

This time I will also heath tension the mylar on the frame before adding the conductors, as mylar shrinks but alu foil doesn't and that causes wrinkles.

When I built my ESLs I got the diaphragm perfect on the second try....this I think will take some more tries.

regards,

Bent

the conductor ripped in the corners when making the 2X 45 degrees angles.

I did another diaphragm just now with the same tecnique and it worked better but not perfect.

I will try an other diaphragm where I let the conductors run all across the diaphragm and outside the spacer, and connect them together with wire or copper foil tape.

This time I will also heath tension the mylar on the frame before adding the conductors, as mylar shrinks but alu foil doesn't and that causes wrinkles.

When I built my ESLs I got the diaphragm perfect on the second try....this I think will take some more tries.

regards,

Bent

yeah i did fidl around myself allot with this problem i had also problems with resonaces of the foil. better stretch first indeed and then aplly the foil. best is when aplied tot the stator. because you can easy stick the foil between the magnet rows. next month ill get the same alufoil as you and gone blow some life in my magnepanar speakers as well. 2 know more then one!

push pull full range planars using cpc alu tape.

Hi, I have nearly finished 2 pairs of push pull full range planar speakers. Using neo magnets 50 x 12.7 x 3 mm. Size of the planars- 60 x 40 cm. They sound great, with bass down to 15 Hz. Very tight and not at all plummy unlike the QUAD ESL 63 which is very plummy and lacking in real bass,( I know I have 3 and 1 ESL 57), which is very similar, plummy and resonant in the bass.

These p/p full range planars sound great. I used the cpc tape which does have a backing, and I cut the tape down the middle using a small pair of scissors all 90 meters of it!! You get more sensitivity ,because the membrane is lighter. The p/p design give you tighter control of the membrane. I have used 6 mm thick magnets on 1 of the pair, which gives even greater control of the diaphragm. I am not bothering to design any more planars as I have reached the ultimate design after 20 years of endeavour.

Hi, I have nearly finished 2 pairs of push pull full range planar speakers. Using neo magnets 50 x 12.7 x 3 mm. Size of the planars- 60 x 40 cm. They sound great, with bass down to 15 Hz. Very tight and not at all plummy unlike the QUAD ESL 63 which is very plummy and lacking in real bass,( I know I have 3 and 1 ESL 57), which is very similar, plummy and resonant in the bass.

These p/p full range planars sound great. I used the cpc tape which does have a backing, and I cut the tape down the middle using a small pair of scissors all 90 meters of it!! You get more sensitivity ,because the membrane is lighter. The p/p design give you tighter control of the membrane. I have used 6 mm thick magnets on 1 of the pair, which gives even greater control of the diaphragm. I am not bothering to design any more planars as I have reached the ultimate design after 20 years of endeavour.

- Home

- Loudspeakers

- Planars & Exotics

- Planar speaker - first try