Mavric got me primed-up with his speaker build and the insanity got the best of me so I decided to build some new stat panels for my old beam-spitter ESL's, even though my old stat panels still sound fine. The original stators are 18GA/.125 holes/40% open and my new stators are 22GA/.117 holes/51% open. I wanted to use 20GA rather than 22GA stators but I couldn't find any perf with the hole size and open area I wanted so I took a big risk and went with the thinner material.

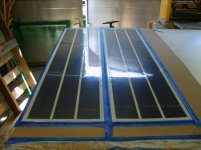

(Sanders’ Cookbook says .020 thick aluminum is ideal but I suspect it would ring like hell). I was concerned that the thinner perf would be prone to ringing so I bonded on a couple of 1/2" square vertical steel bars to the back stator on each panel; thinking that the added mass and stiffness would help dampen any ringing. I spent a ton of money on the perf since (unlike McMaster Carr) there were min-buy and min-shipping charges. I didn’t skimp on the stator coating either: I’m very happy with how well the panel coating turned out. There are absolutely no sharp edges anywhere. After clean and prep, I painted the panels black using a Martin Senour Crossfire automotive base-coat/clear-coat system from NAPA auto parts (ouch $$). After spraying the black base coat, I applied 12 mils of the 2-part polyurethane clearcoat using the fastest drying catalyst available so the the coats would set quickly without running away from the sharp edges of the holes. As you can see in the photos, the coating turned out very well indeed. Also, rather than placing the foam tape net to the stator edges I placed the tape to overhang the stator edges about 1/16”, then wrapped 1 layer of polyester tape over the edges-- this effectively adds an additional 1/16” of insulation along the critical stator edges (these babies will never arc!). I really like the TechSpray diaphragm coating too-- it goes on wet and thick looking and takes quite a while to dry but it’s 95% volatiles so it dries very thin and it’s completely clear so you can see right through the panels. These new panels are not a huge improvement in sound quality over my original panels and I would find it hard to justify the added expense but there is a noticable difference in the highs, which seem to go higher with a bit more detail. This may have more to do with the higher diaphragm tension I used this time but it could also be the perf size and increased open area. One thing is for sure-- I didn’t loose any efficiency--maybe even gained some. I guess the iron bars worked too because I don’t hear any objectionable resonances. They sound great!

(Sanders’ Cookbook says .020 thick aluminum is ideal but I suspect it would ring like hell). I was concerned that the thinner perf would be prone to ringing so I bonded on a couple of 1/2" square vertical steel bars to the back stator on each panel; thinking that the added mass and stiffness would help dampen any ringing. I spent a ton of money on the perf since (unlike McMaster Carr) there were min-buy and min-shipping charges. I didn’t skimp on the stator coating either: I’m very happy with how well the panel coating turned out. There are absolutely no sharp edges anywhere. After clean and prep, I painted the panels black using a Martin Senour Crossfire automotive base-coat/clear-coat system from NAPA auto parts (ouch $$). After spraying the black base coat, I applied 12 mils of the 2-part polyurethane clearcoat using the fastest drying catalyst available so the the coats would set quickly without running away from the sharp edges of the holes. As you can see in the photos, the coating turned out very well indeed. Also, rather than placing the foam tape net to the stator edges I placed the tape to overhang the stator edges about 1/16”, then wrapped 1 layer of polyester tape over the edges-- this effectively adds an additional 1/16” of insulation along the critical stator edges (these babies will never arc!). I really like the TechSpray diaphragm coating too-- it goes on wet and thick looking and takes quite a while to dry but it’s 95% volatiles so it dries very thin and it’s completely clear so you can see right through the panels. These new panels are not a huge improvement in sound quality over my original panels and I would find it hard to justify the added expense but there is a noticable difference in the highs, which seem to go higher with a bit more detail. This may have more to do with the higher diaphragm tension I used this time but it could also be the perf size and increased open area. One thing is for sure-- I didn’t loose any efficiency--maybe even gained some. I guess the iron bars worked too because I don’t hear any objectionable resonances. They sound great!

Attachments

Awesome!

Great job charlie!

I will consider using preforated metal for my bigger panels as well and just use the plastic grate I have left for little ones. jer

The best deal I've found for perf metal is McMaster Carr, where you can pick up two 36"x40" sheets with shipping for around $100. My stators are 48" tall though, so I had to go with McNichols Perforating and buy a whole 36"x120" sheet and pay the $80 minimum shipping fee and cutting fee-- total with shipping was around $275 -- I got the pieces cut an inch big and final cut them myself. I got some drop off left but no large pieces (I could make some bookshelf size speakers, I suppose). Also, the metal wasn't as straight & flat as the stuff Mavric got from McMaster Carr-- One piece had a crease in it, which took me a an hour or so to work down to reasonable flatness.

Bookshelf size speakers are a great idea ,kinda like what i am working on now.

How big are your left over peices?

My little panels have a surface area of 31.6875 sq. inches.

I have found that about 60 to 90 sq. inches (2 and 3 panels) they start to match up efficiency wise and start to take over my 5" woofer.

With of course a high transformation ratio and bias voltage. jer

How big are your left over peices?

My little panels have a surface area of 31.6875 sq. inches.

I have found that about 60 to 90 sq. inches (2 and 3 panels) they start to match up efficiency wise and start to take over my 5" woofer.

With of course a high transformation ratio and bias voltage. jer

What a great shop you have

It's nice to have someplace to work, even if it's just an old shed like mine that I had to pour a concrete floor in.. No heating or AC either... will soon be too hot to go in there during the day.

Bookshelf size speakers are a great idea ,kinda like what i am working on now.

How big are your left over peices?

My little panels have a surface area of 31.6875 sq. inches.

I have found that about 60 to 90 sq. inches (2 and 3 panels) they start to match up efficiency wise and start to take over my 5" woofer.

With of course a high transformation ratio and bias voltage. jer

Hi Jer,

I have one piece of perf metal 15" x 36" and two pieces 10" x 49" left over. Are you running your panels and woofer with some kind of passive crossover?I would like to create some small hybrids with a passive crossover but I can't imagine how to configure a passive crossover when part of the load (the ESL) is a capacitor with an impedance that varies with the frequency and end up with something that works and sounds OK.

yes I was using an old marantz crossover and several others I had lying around.

It's frequency was somewhere between 350hz to 800hz with my 8" woofer or higher at 4ohms.

That was back when I first fired it up and discovered all the amp loading issues and a weak bias voltage due to panel arcing.

I just used a capacitor in series with the transformer like you would on any other tweeter.

I tried different values.

10uf is about were I ended up I think,not sure I will set it up again .

I don't remember which transformer configuration I was using either.

I believe it was the double stacked core to get me a lower frequency saturation then I had switched to the quadstacked cores.

Later on I found this to be reducing my effective turns ratio and was having a hard time matching up to the efficiency of the woofer.

Although it still sounded great!

But it was eating up all the power the amp could produce while having to pad the woofer with a 10 ohm resistor ,it sound really good ,fairly loud but very inefficient.

Now with the refined bias supply, rebuilt panels and the 1:216 transformation ratio I am currently using I have been wanting to try that setup again.

So I guess that will be tomorrows test.

You could make a nice pair of 7.5" x 18" pair of panels out of the one peice.

Thats just a little smaller than my bigger panels of 9" x 24" and would look nice with 6" or 8" dayton rs series driver too boot.

Or if you feel it would be to tall go with 9" x 15" as the extra width is good as you know and no need to divide the diagphram either,I dont think.

I used a .0625" spacer on mine and was running fullrange.

The only time I had problems was when I cranked up the bass below 200hz.

So then I tried a .090" spacer and it never slapped ,as that won't be an issue in a hybrid. jer

It's frequency was somewhere between 350hz to 800hz with my 8" woofer or higher at 4ohms.

That was back when I first fired it up and discovered all the amp loading issues and a weak bias voltage due to panel arcing.

I just used a capacitor in series with the transformer like you would on any other tweeter.

I tried different values.

10uf is about were I ended up I think,not sure I will set it up again .

I don't remember which transformer configuration I was using either.

I believe it was the double stacked core to get me a lower frequency saturation then I had switched to the quadstacked cores.

Later on I found this to be reducing my effective turns ratio and was having a hard time matching up to the efficiency of the woofer.

Although it still sounded great!

But it was eating up all the power the amp could produce while having to pad the woofer with a 10 ohm resistor ,it sound really good ,fairly loud but very inefficient.

Now with the refined bias supply, rebuilt panels and the 1:216 transformation ratio I am currently using I have been wanting to try that setup again.

So I guess that will be tomorrows test.

You could make a nice pair of 7.5" x 18" pair of panels out of the one peice.

Thats just a little smaller than my bigger panels of 9" x 24" and would look nice with 6" or 8" dayton rs series driver too boot.

Or if you feel it would be to tall go with 9" x 15" as the extra width is good as you know and no need to divide the diagphram either,I dont think.

I used a .0625" spacer on mine and was running fullrange.

The only time I had problems was when I cranked up the bass below 200hz.

So then I tried a .090" spacer and it never slapped ,as that won't be an issue in a hybrid. jer

I would like to create some small hybrids with a passive crossover but I can't imagine how to configure a passive crossover when part of the load (the ESL) is a capacitor with an impedance that varies with the frequency and end up with something that works and sounds OK.

Hello Charlie,

Four or five years ago, Calvin had some posts on how to create proper passive crossovers for ESL hybrids. It is more of an example rather than a complete how to, but will give you an idea what is involved. It includes how to swamp or linearize the drastically changing ESL impedance before the crossover, and notching out the diaphragm resonance. Personally, I prefer to damp the diaphragm resonance with resistive flow damping of tightly woven cloth. But, I understand the desire of some to keep their ESL panel optically clear.

Here is the thread:

http://www.diyaudio.com/forums/planars-exotics/64620-ping-calvin.html#post727647

I will add that I found it is nearly impossible to get a properly working passive crossover for a hybrid ESL without proper measuring equipment. As you had thought, the widely varying ESL impedance has a pronounced and sometimes unpredictable effect on the response of the crossover/ESL combination.

Last edited:

Charlie, congrats! You told me you were building some more panels, but i had no idea you were replacing my inspiration panels. I will agree that the highs are so bright on mine that i have to attenuate them from time to time.

Has the sweet spot widened any in your living area? or stay the same? curious about that as the material is thinner. I guess it may be another trip to check em' out. might bring one of the ones you helped and let you have a side by side. Besides, i also have to pick up the grill cloth and magnets.

I wish you would have let me in on your project, i could have gone in on material with you as i plan on another set for the loft. I noticed some green over spray in one of your pics, did you try any of that coating "colored" that i left there? if so, what were your thoughts?

I am older tomorrow, so i wont post for a few days, cinco de mayo, and eveyone wants to take me out to every mexican place untill i cannot remember. I am getting to old for that.

But, great job Charlie, you are a unique person that has been a pleasure to meet and work with. Later

Has the sweet spot widened any in your living area? or stay the same? curious about that as the material is thinner. I guess it may be another trip to check em' out. might bring one of the ones you helped and let you have a side by side. Besides, i also have to pick up the grill cloth and magnets.

I wish you would have let me in on your project, i could have gone in on material with you as i plan on another set for the loft. I noticed some green over spray in one of your pics, did you try any of that coating "colored" that i left there? if so, what were your thoughts?

I am older tomorrow, so i wont post for a few days, cinco de mayo, and eveyone wants to take me out to every mexican place untill i cannot remember. I am getting to old for that.

But, great job Charlie, you are a unique person that has been a pleasure to meet and work with. Later

Hi Charlie!

Is is possable or even worth it to use some of the material from the cut offs from my stat metal to make a smaller set? They might not be wide enough so i was curious.

Oy yea, i am older today, not getting younger, sucks. Just pondering the idea of something for the loft, my get away place.

Take care, going to work and after getting pretty inebriated, very inebriated. Later. Mavric

Is is possable or even worth it to use some of the material from the cut offs from my stat metal to make a smaller set? They might not be wide enough so i was curious.

Oy yea, i am older today, not getting younger, sucks. Just pondering the idea of something for the loft, my get away place.

Take care, going to work and after getting pretty inebriated, very inebriated. Later. Mavric

Hi Charlie!

Is is possable or even worth it to use some of the material from the cut offs from my stat metal to make a smaller set? They might not be wide enough so i was curious.

Oy yea, i am older today, not getting younger, sucks. Just pondering the idea of something for the loft, my get away place.

Take care, going to work and after getting pretty inebriated, very inebriated. Later. Mavric

I think not, since the cutoffs are a bit less than 2" wide strips. BTW, your panels are perfect as is.

Charlie, congrats! You told me you were building some more panels, but i had no idea you were replacing my inspiration panels. I will agree that the highs are so bright on mine that i have to attenuate them from time to time.

Has the sweet spot widened any in your living area? or stay the same? curious about that as the material is thinner. I guess it may be another trip to check em' out. might bring one of the ones you helped and let you have a side by side. Besides, i also have to pick up the grill cloth and magnets.

I wish you would have let me in on your project, i could have gone in on material with you as i plan on another set for the loft. I noticed some green over spray in one of your pics, did you try any of that coating "colored" that i left there? if so, what were your thoughts?

I am older tomorrow, so i wont post for a few days, cinco de mayo, and eveyone wants to take me out to every mexican place untill i cannot remember. I am getting to old for that.

But, great job Charlie, you are a unique person that has been a pleasure to meet and work with. Later

Hi Mavric,

The sweet spot is exactly the same. I wanted 51% open stators after I heard how good the treble was on yours. I figured you were tapped out so it didn't occur to me to ask if you wanted to go in on some perf metal, especially since I couldn't find what I was looking for in 20 gauge metal and I took a risk with the thinner 22 gauge metal. Since my panels aren't as wide as yours and are only 3 1/4" between the support strips, I think I'm OK with the thinner metal.

I sprayed some test pieces with the blue coating you left-- it would probably work fine but it's very thin and would take a lot of coats with dry time between coats to get a thick buildup. In the end I decided to go with a 2-part high-build paint I was familiar with, even though it was quite expensive.

BTW: Happy Birthday, Mavric!

Charlie, i really liked the steel bracing, very inovative. as mine are sixteen inches wide, would you consider it if they were yours? or if its not broke, dont fix it, i was just thinking long term as the tape may want seperate over time, but i have to say again, thats a killer idea and you never cease to amaze me.

Charlie, i really liked the steel bracing, very inovative. as mine are sixteen inches wide, w ould you consider it if they were yours? or if its not broke, dont fix it, i was just thinking long term as the tape may want seperate over time, but i have to say again, thats a killer idea and you never cease to amaze me.

I don't think your panels need any bracing.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Jazzman's new stat panels