A few more pics, the Tl cuts are finished, just did a mock up to get the idea.

The challenge has been met, detacbale stat panels, done. Thanks to my friends here. will post more as i can, woking 65+ hrs a week and trying to provide the best information is tough.

The challenge has been met, detacbale stat panels, done. Thanks to my friends here. will post more as i can, woking 65+ hrs a week and trying to provide the best information is tough.

Attachments

here are a few pics of the stators mock up, just to give an idea, 45"tall, 20' wide and a pedestal or mount to the Tl, there is also an electronics box that will be out of sight but very easy to get to. As this was held together with tape, the final will have to be done when the stats are coated and mounted.

the pedastal is about 11' long, will be mounted atop the TL, but with a large floor space can stand on its own., with all the electronics still in the stat, nice and neat.

You will also see a 45 degree notch "in" for the top of the stat, this will have to be notched as soon as the panels are done. due to the highth and just general measurements, some more cutting useing an over arm radial saw,

The other pics should speak for them selves, just mocked up right now. I need some rest and I hope this inspires anyone else, its really not that hard, just alot of patience, listening to different people and different ideas and settling on your own. Wish me luck!

You will also notice the poly fill for the TL, this is a must have due to paralell surfaces and more phase canceling as the stats are Di-pole.

There are many other comments on the pics, but it is another work week, so,,, take a look, tell me what you think.

the pedastal is about 11' long, will be mounted atop the TL, but with a large floor space can stand on its own., with all the electronics still in the stat, nice and neat.

You will also see a 45 degree notch "in" for the top of the stat, this will have to be notched as soon as the panels are done. due to the highth and just general measurements, some more cutting useing an over arm radial saw,

The other pics should speak for them selves, just mocked up right now. I need some rest and I hope this inspires anyone else, its really not that hard, just alot of patience, listening to different people and different ideas and settling on your own. Wish me luck!

You will also notice the poly fill for the TL, this is a must have due to paralell surfaces and more phase canceling as the stats are Di-pole.

There are many other comments on the pics, but it is another work week, so,,, take a look, tell me what you think.

Attachments

-

P3080200.jpg343.6 KB · Views: 121

P3080200.jpg343.6 KB · Views: 121 -

P3080201.jpg346.3 KB · Views: 94

P3080201.jpg346.3 KB · Views: 94 -

P3080202.jpg327.5 KB · Views: 140

P3080202.jpg327.5 KB · Views: 140 -

P3080205.jpg306.4 KB · Views: 46

P3080205.jpg306.4 KB · Views: 46 -

P3080204.jpg429.8 KB · Views: 59

P3080204.jpg429.8 KB · Views: 59 -

P3080203.jpg288.4 KB · Views: 60

P3080203.jpg288.4 KB · Views: 60 -

P3080206.jpg276.8 KB · Views: 44

P3080206.jpg276.8 KB · Views: 44 -

P3080207.jpg360.6 KB · Views: 70

P3080207.jpg360.6 KB · Views: 70 -

P3080208.jpg411.1 KB · Views: 70

P3080208.jpg411.1 KB · Views: 70 -

P3080209.jpg304.2 KB · Views: 72

P3080209.jpg304.2 KB · Views: 72

all of the finger points will be routed with 3/4" to smooth all edges.

The others are bracing and support. Each tower will weigh about 200lbs, so bracing is very important. With that said, good night everyone, i have had a very long week.

Thank you Charlie for your time and engineering on this, you deserve the credit. ^_^

very happy.Later

last pic of the day

The others are bracing and support. Each tower will weigh about 200lbs, so bracing is very important. With that said, good night everyone, i have had a very long week.

Thank you Charlie for your time and engineering on this, you deserve the credit. ^_^

very happy.Later

last pic of the day

Attachments

Last edited:

need some advice on "de greesing" these stats. I have a 2200psi pressure washer, with a solvent pick up line. This might sound a little weird, but what about using engine cleaner, and then cleaning it with the pressure washer? since it is steel and prone to rust, i posted a pics that had a big red scuffer that i used to prep surfaces for rhino. As soon as i remove any oil from the panels, i will have to coat it with something.

Just to the point. what kind of primer spray can i use to put a light coating to prevent rust? maufaure name and brand, or "what did you use"?

Things are coming together, and this the most important, so advice is what i am seeking, sincerely, Mav

Just to the point. what kind of primer spray can i use to put a light coating to prevent rust? maufaure name and brand, or "what did you use"?

Things are coming together, and this the most important, so advice is what i am seeking, sincerely, Mav

need some advice on "de greesing" these stats. I have a 2200psi pressure washer, with a solvent pick up line. This might sound a little weird, but what about using engine cleaner, and then cleaning it with the pressure washer? since it is steel and prone to rust, i posted a pics that had a big red scuffer that i used to prep surfaces for rhino. As soon as i remove any oil from the panels, i will have to coat it with something.

Just to the point. what kind of primer spray can i use to put a light coating to prevent rust? maufaure name and brand, or "what did you use"?

Things are coming together, and this the most important, so advice is what i am seeking, sincerely, Mav

I hung mine and sprayed them with naptha first and then acetone, using a paint gun.

I hung mine and sprayed them with naptha first and then acetone, using a paint gun.

Charlie, where can get naptha and what is it? I have tons of acetone, but will it deterioate the plasic container on a spray gun?

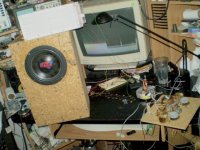

It's alive! Resurected after 7 years and still sounds fricken awesome! jer

Ger, what in the heck is that? looks like someone tossed a grenade into an electronics store, computer power supply on the left, a scope behind the sub, siriesed resistors, and looks like a tube amp. Im gonna start calling you "electronic frankenstein" you can something from nothing and something, umm come alive. I rember the conversation, on this, but what do you plan on doing with it?

It is definatly ALIVE. check your mail on Monay or Tuesday of next week.

If you think thats alive, check out this, it is off post a little, but i can explain the relavance for this project.

The owner wanted to as bis as possable, those are 24" wheels on a Crown Victoria,Ford. No different the panels i want, as big as possable.

Mine a little shorter but wider for a better sweet spot, i am putting alot of love into this and sacrificing things along the way, as my friend did with his car, it may be big and oversized, but thats what made him happy, he does drive it on a daily basis, redone the rear end to accomadate the wheels.

In other words, no corners were cut to get something right, so there is the relevance, I work on those for a living, all of them for a living. Here is the picture, its worth a thousand words.

If you think thats alive, check out this, it is off post a little, but i can explain the relavance for this project.

The owner wanted to as bis as possable, those are 24" wheels on a Crown Victoria,Ford. No different the panels i want, as big as possable.

Mine a little shorter but wider for a better sweet spot, i am putting alot of love into this and sacrificing things along the way, as my friend did with his car, it may be big and oversized, but thats what made him happy, he does drive it on a daily basis, redone the rear end to accomadate the wheels.

In other words, no corners were cut to get something right, so there is the relevance, I work on those for a living, all of them for a living. Here is the picture, its worth a thousand words.

Attachments

Charlie, I have a small hick up on the mock up for the stats, easy fix, what do you think? it was when we, you, well we decided to recut the sides. here is a pic of the hick up, now i just fiqured it out.

here are two hands trying to four. the cut-outs fit ferfect. but some more pics.

here are two hands trying to four. the cut-outs fit ferfect. but some more pics.

Attachments

Naptha????

now i have a description;

Naphtha (pronounced /ˈnæfθə/ or /ˈnæpθə/) normally refers to a number of different flammable liquid mixtures of hydrocarbons, i.e. a distillation product from petroleum or coal tar boiling in a certain range and containing certain hydrocarbons, a broad term encompassing any volatile, flammable liquid hydrocarbon mixture.

In petroleum engineering, full range naptha is defined as the lightest or most volatile fraction of the hydrocarbons in petroleum, those boiling between 30°C and 200°C[1] It consists of a complex mixture of hydrocarbon molecules generally having between 5 and 12 carbon atoms. It typically constitutes 15-30% of crude oil, by weight. Light naptha is the fraction boiling between 30°C and 90°C and consists of molecules with 5-6 carbon atoms. Heavy naptha boils between 90°C and 200°C and consists of molecules with 6-12 carbons.

Naphtha is used primarily as feedstock for producing high octane gasoline (via the catalytic reforming process). It is also used in the petrochemical industry for producing olefins in steam crackers and in the chemical industry for solvent (cleaning) applications. Common products made with it include lighter fluid, fuel for camp stoves, and some cleaning solvents.

This almost sounds like fuel injector cleaner. But as said, I will use this and clean any residue off with acetone. Other products i have, denatured alohol, zylolal,

So where can i find naptha? Charlie, i have never in my life ever heard or read about anything similar or close to this stuff. You jnow i smoke( ciggarettes), i do not have plans on blowing myself up.

So thats where the weights come in, to steady the panels from spraying,

i have one air-line cooling conditioner for the compressor, two moister catchers, and what is called "an air cooler" for the final line running to my equipment at the shop. Auot drainage for the tank, pneumatic , every 30 secs whike running or every time it hits 120-125 psi, guess i need to post some pics instead of trying to explain.

But, where can i buy "naptha?"

very very curios, you should know me by now. I would like to have it yesterday or the week before.

I simply cannot solder my leads on the stats untill they are clean, very clean.

someone please throw me some information, i have given everything i can think of while i have the time to post( wife watching something stupid on tv) so this is it, I will check again, naptha??? and how to use it. Mavric

now i have a description;

Naphtha (pronounced /ˈnæfθə/ or /ˈnæpθə/) normally refers to a number of different flammable liquid mixtures of hydrocarbons, i.e. a distillation product from petroleum or coal tar boiling in a certain range and containing certain hydrocarbons, a broad term encompassing any volatile, flammable liquid hydrocarbon mixture.

In petroleum engineering, full range naptha is defined as the lightest or most volatile fraction of the hydrocarbons in petroleum, those boiling between 30°C and 200°C[1] It consists of a complex mixture of hydrocarbon molecules generally having between 5 and 12 carbon atoms. It typically constitutes 15-30% of crude oil, by weight. Light naptha is the fraction boiling between 30°C and 90°C and consists of molecules with 5-6 carbon atoms. Heavy naptha boils between 90°C and 200°C and consists of molecules with 6-12 carbons.

Naphtha is used primarily as feedstock for producing high octane gasoline (via the catalytic reforming process). It is also used in the petrochemical industry for producing olefins in steam crackers and in the chemical industry for solvent (cleaning) applications. Common products made with it include lighter fluid, fuel for camp stoves, and some cleaning solvents.

This almost sounds like fuel injector cleaner. But as said, I will use this and clean any residue off with acetone. Other products i have, denatured alohol, zylolal,

So where can i find naptha? Charlie, i have never in my life ever heard or read about anything similar or close to this stuff. You jnow i smoke( ciggarettes), i do not have plans on blowing myself up.

So thats where the weights come in, to steady the panels from spraying,

i have one air-line cooling conditioner for the compressor, two moister catchers, and what is called "an air cooler" for the final line running to my equipment at the shop. Auot drainage for the tank, pneumatic , every 30 secs whike running or every time it hits 120-125 psi, guess i need to post some pics instead of trying to explain.

But, where can i buy "naptha?"

very very curios, you should know me by now. I would like to have it yesterday or the week before.

I simply cannot solder my leads on the stats untill they are clean, very clean.

someone please throw me some information, i have given everything i can think of while i have the time to post( wife watching something stupid on tv) so this is it, I will check again, naptha??? and how to use it. Mavric

Thanks Ger, guess i will be in the paint depatment.

BTW, what are your plans with your construction? It looks to me as a mean sub(vented or Tl) i know that the sub is old as mine as well, I think they were made a little better back in the day.

Much thanks on my reciever!!! I covered up everything with 3m hot glue before reassembling the cover plate, no need on pics of that, you could not see it now anyway.

Just make sure you check mail at home.

I have so much to learn and blessed with people with people with knowledge ,Mav

BTW, what are your plans with your construction? It looks to me as a mean sub(vented or Tl) i know that the sub is old as mine as well, I think they were made a little better back in the day.

Much thanks on my reciever!!! I covered up everything with 3m hot glue before reassembling the cover plate, no need on pics of that, you could not see it now anyway.

Just make sure you check mail at home.

I have so much to learn and blessed with people with people with knowledge ,Mav

originaly I was planning a dipole sub sytem since i have like 8 or 10 of these drivers. but i'd like to try a transmission line also.this particular design i have right now is the best of both worlds,sealed and vented.it is vented with a small volume.giving a very tight clean sound while slighty augmenting the extreme lowend about 1.5db to 2db with a vent. jer

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- different ideas for ESL panels