Hi,

my first attemt of building an ESL is "completed" and tested..and failed.

The reciepie is as follows:

1000 X 350 X 2mm perforated, powder coated steel plates, 48% open

6my mylar, Elvamide coated

2mm plastic spacers, epoxied to stators and mylar. (Epoxy sucs, will use cyanoacrylate next time)

Power supply: EMCO G60r power module capable of 6kV

Transformer:

Test 1: 50 Va EI-transformer 2 X 115v primary 2 X 6v sec hooked up in reverse with 2x6 in parallell and 2x115 in series.

Test 2: 2 of 50 Va toroid-transformers 1 X 115v primary 2 X 6v sec hooked up in reverse with 2x6 in parallell and 2x115 in series.

Both test gave a faint sound. Measured about 25v between the stators.

Tried with polarizing voltage negative to diaphragm first, then reversed.

Same result, almost no sound.

I have no idea what could be wrong, but the dissapointment is huge!

Regard (regrets?)

bent

my first attemt of building an ESL is "completed" and tested..and failed.

The reciepie is as follows:

1000 X 350 X 2mm perforated, powder coated steel plates, 48% open

6my mylar, Elvamide coated

2mm plastic spacers, epoxied to stators and mylar. (Epoxy sucs, will use cyanoacrylate next time)

Power supply: EMCO G60r power module capable of 6kV

Transformer:

Test 1: 50 Va EI-transformer 2 X 115v primary 2 X 6v sec hooked up in reverse with 2x6 in parallell and 2x115 in series.

Test 2: 2 of 50 Va toroid-transformers 1 X 115v primary 2 X 6v sec hooked up in reverse with 2x6 in parallell and 2x115 in series.

Both test gave a faint sound. Measured about 25v between the stators.

Tried with polarizing voltage negative to diaphragm first, then reversed.

Same result, almost no sound.

I have no idea what could be wrong, but the dissapointment is huge!

Regard (regrets?)

bent

Attachments

Hi,

my first attemt of building an ESL is "completed" and tested..and failed.

The reciepie is as follows:

1000 X 350 X 2mm perforated, powder coated steel plates, 48% open

6my mylar, Elvamide coated

2mm plastic spacers, epoxied to stators and mylar. (Epoxy sucs, will use cyanoacrylate next time)

Power supply: EMCO G60r power module capable of 6kV

Transformer:

Test 1: 50 Va EI-transformer 2 X 115v primary 2 X 6v sec hooked up in reverse with 2x6 in parallell and 2x115 in series.

Test 2: 2 of 50 Va toroid-transformers 1 X 115v primary 2 X 6v sec hooked up in reverse with 2x6 in parallell and 2x115 in series.

Both test gave a faint sound. Measured about 25v between the stators.

Tried with polarizing voltage negative to diaphragm first, then reversed.

Same result, almost no sound.

I have no idea what could be wrong, but the dissapointment is huge!

Regard (regrets?)

bent

With such a low measured output voltage, my guess is that your secondaries are wired out of phase, so the voltages are canceling each other. Try running a test with just one of the transformers applying 6 volt input to the paralleled primaries. Then measure each of the secondaries separately and make sure you are getting ~ 100 Vac. Then hook the two secondaries in series measure the output. If you get 200 Vac or more, you have them hooked up properly, if not swap the ends of one of the secondaries.

Once you have each of the transformer secondaries putting out 200 Vac, then hook up both transformers together, secondaries in series, all the primaries in parallel. You should still be getting ~ 200 Vac from each of the transformer, and ~400Vac across both. If you get 200Vac across each, but almost nothing across both, swap the polarity on one of the set of transformer primaries.

You didn't mention it specifically, so I'll add the comment to hook one end of your HV supply to the diaphragm, and the other end to the center point of your series connected 4 secondaries.

Good Luck!

Hi Bentl,

Don't be too pessimistic. Your amp power might not be enough. What kind of amp do you use to drive the ESL? What is the bias voltage you use?

About glue, I find contact cement to be extremely good for gluing spacers to the stators. I use thin double sided tape for gluing my diaphragm to the spacer. It works very well for me.

If you want to, I can introduce a local transformer maker in Thailand to make a couple of transformers for you. I find their price and quality to be very good.

Wachara C.

Don't be too pessimistic. Your amp power might not be enough. What kind of amp do you use to drive the ESL? What is the bias voltage you use?

About glue, I find contact cement to be extremely good for gluing spacers to the stators. I use thin double sided tape for gluing my diaphragm to the spacer. It works very well for me.

If you want to, I can introduce a local transformer maker in Thailand to make a couple of transformers for you. I find their price and quality to be very good.

Wachara C.

Hi,

I´d think the same direction as bolserst and check if prim and sec. windings are wired correctly. If You drive just 1 primary and volume rises it´s one wrong primary, if not interchange one of the secondaries.

If its nott the tranny, the source of fail should be found around the bias-supply. A failure of the HV-Bias-supply is unlikely, but the diaphragm connection might not work, so it won´t charge up.

Hope You haven´t glued everything together? Because You can test each stator alone before putting everything together.

jauu

Calvin

I´d think the same direction as bolserst and check if prim and sec. windings are wired correctly. If You drive just 1 primary and volume rises it´s one wrong primary, if not interchange one of the secondaries.

If its nott the tranny, the source of fail should be found around the bias-supply. A failure of the HV-Bias-supply is unlikely, but the diaphragm connection might not work, so it won´t charge up.

Hope You haven´t glued everything together? Because You can test each stator alone before putting everything together.

jauu

Calvin

Hi, I have rewired the transformers and get approx 60X voltage rise on the output.

Applying the polarizing voltage does not affect the sound level, so I guess there is a problem with charging.

Either the coating (Elvamide) or the copper foil tape used to electrically connect the diaphragm.

I wil buy a better multimeter tomorrow and see if I can measure electric contact on the diaphragm.

Regards,

Bent

Applying the polarizing voltage does not affect the sound level, so I guess there is a problem with charging.

Either the coating (Elvamide) or the copper foil tape used to electrically connect the diaphragm.

I wil buy a better multimeter tomorrow and see if I can measure electric contact on the diaphragm.

Regards,

Bent

I am glad for you!

congratulations.

increase the volume takes the same number and volume decline.

your coating 10 * e10

excellent result!

ps: next step - direct drive amplifier

I'll be d@mned!!

After half an hour of faint sound the speaker plays louder and louder....and louder!

Seems like it takes some time to charge the diaphragm!

Great!!

congratulations.

increase the volume takes the same number and volume decline.

your coating 10 * e10

excellent result!

ps: next step - direct drive amplifier

Last edited:

I'll be d@mned!!

After half an hour of faint sound the speaker plays louder and louder....and louder!

Seems like it takes some time to charge the diaphragm!

Great!!

Do you have your copper foil contacting the diaphragm in just a small area?

If so, you might improve the diaphragm charging by running the copper foil the full length(top to bottom) on both left and right sides of the panel.

Dear Bent,Hi, I have rewired the transformers and get approx 60X voltage rise on the output.

Applying the polarizing voltage does not affect the sound level, so I guess there is a problem with charging.

Either the coating (Elvamide) or the copper foil tape used to electrically connect the diaphragm.

I wil buy a better multimeter tomorrow and see if I can measure electric contact on the diaphragm.

Regards,

Bent

the contact appeared to be of great importance and not only when you measure coating resistance.

Coins or thick (0.05mm) copper strip do not provide reliable contact, IMO.

Sprayed grapfite from aerosol can seems to be much better, just make an appropriate stencil.

Another thing to consider: it appeared that corona discharge easily develops at the edges of the contact strip, rendering your measurements quite inaccurate.

By the way - have you tried to do scotch test i.e. to see if the coating peels away by Scotch tape?

Congratulations,

Alex

Hi, I have 10mm wide copper foil tape running all the way around the perimeter of the spacer.

I saw some sparks in the connection between the tape and cable connector at one point, maybe the tape burnt and there is a loss of contact there.

I will built the next element and see if I can improve the construction somewhat.

The elvamide coating seems to stick to the mylar wery well after heat-treating.

(I coated and heatet the diaphragm in a temporary frame before cluing it to the stator/spacer assembly

Regards

Bent

Regards,

Bent

I saw some sparks in the connection between the tape and cable connector at one point, maybe the tape burnt and there is a loss of contact there.

I will built the next element and see if I can improve the construction somewhat.

The elvamide coating seems to stick to the mylar wery well after heat-treating.

(I coated and heatet the diaphragm in a temporary frame before cluing it to the stator/spacer assembly

Regards

Bent

Regards,

Bent

Lessons learned

Hi,

just an update on my first ESL.

I have not done much more to it, but after playing a few hours the sound has loosend up at the speaker plays louder.

But, I hear some sort of saturation, like "fuzz guitar". I believe the problem is the transformers, that they can't cope with a full range signal.

I will try to make a low-cut x-over using a 120microFarad capacitor in series with the audio signal before the trafo.

Oh yes- I have added a small, active subwoofer to the system to add some juice in the lower frequencies! That made a world of difference!

I will start assembly of the other panel tonigth, using cyanoacrylate instead of epoxy to fasten the diaphragm to the spacers, and using nylon pop-rivets to mount the stators. No more running, smelling and sticky epoxy!

And....my girlfriend is busy on the CNC machine manufacturing 8 stator plates in PMMA plastic...just to test the difference.

BTW, i accidently touched both front and back stator when playing music today. I will avoid doing that again!!!

regards

Bent

Hi,

just an update on my first ESL.

I have not done much more to it, but after playing a few hours the sound has loosend up at the speaker plays louder.

But, I hear some sort of saturation, like "fuzz guitar". I believe the problem is the transformers, that they can't cope with a full range signal.

I will try to make a low-cut x-over using a 120microFarad capacitor in series with the audio signal before the trafo.

Oh yes- I have added a small, active subwoofer to the system to add some juice in the lower frequencies! That made a world of difference!

I will start assembly of the other panel tonigth, using cyanoacrylate instead of epoxy to fasten the diaphragm to the spacers, and using nylon pop-rivets to mount the stators. No more running, smelling and sticky epoxy!

And....my girlfriend is busy on the CNC machine manufacturing 8 stator plates in PMMA plastic...just to test the difference.

BTW, i accidently touched both front and back stator when playing music today. I will avoid doing that again!!!

regards

Bent

Hi Bentl

Glad to hear that you are making some progress. The "fuzzy guitar" sound might have come from your amp clipping. How loud do you play it? If you can, please try to adjust your ESL bias voltage to around 5,000V. You will find that the sound go louder.

If you have to wait that long for the diaphragm to charge up, I think the coating you use isn't so good. Maybe the surface resistance is too high. It's just my thought - I'm not sure though.

When you touched both stators, did you get a shock? I, too, unintentionally touched both stators. Luckily, nothing happened.

Wachara C.

Glad to hear that you are making some progress. The "fuzzy guitar" sound might have come from your amp clipping. How loud do you play it? If you can, please try to adjust your ESL bias voltage to around 5,000V. You will find that the sound go louder.

If you have to wait that long for the diaphragm to charge up, I think the coating you use isn't so good. Maybe the surface resistance is too high. It's just my thought - I'm not sure though.

When you touched both stators, did you get a shock? I, too, unintentionally touched both stators. Luckily, nothing happened.

Wachara C.

Hi,

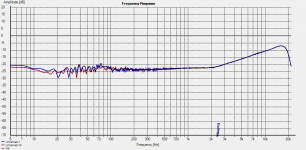

did a quick freqyency response test on the speaker that is finished.

Made with HOLMImpulse, and a Bheringer ECM 8000 microphone.

I find it srtange that re response is so flat, even if the speaker plays little bass.

And, doing a frecuency sweep from 5Hz to 20.000Hz makes the room rumble, but when playing music a bass drum sounds like a snare drum..

Strange..

Regards, Bent

did a quick freqyency response test on the speaker that is finished.

Made with HOLMImpulse, and a Bheringer ECM 8000 microphone.

I find it srtange that re response is so flat, even if the speaker plays little bass.

And, doing a frecuency sweep from 5Hz to 20.000Hz makes the room rumble, but when playing music a bass drum sounds like a snare drum..

Strange..

Regards, Bent

Attachments

Hi,

did a quick freqyency response test on the speaker that is finished.

Made with HOLMImpulse, and a Bheringer ECM 8000 microphone.

I find it srtange that re response is so flat, even if the speaker plays little bass.

And, doing a frecuency sweep from 5Hz to 20.000Hz makes the room rumble, but when playing music a bass drum sounds like a snare drum..

Strange..

Regards, Bent

How close to the speaker did you have the microphone placed when you made the measurements?

Bentl: I totally agree with Capaciti, because if that was a true measurement of your speaker we all want to know how you built it!

Me too..

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- One ESL completed - disappointed..