Hi Geraldfryjr.,

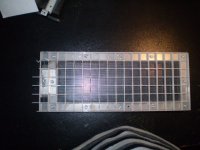

Those are nice looking stators. Do you make those?

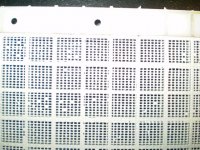

Do you have any idea where we can buy the white plastic egg crate looking thing?

Wachara C.

Seen similar on offices dual tube fluro's to difuse the light, perfect size for this app, stiff, light, and the squares are about 1/2inch

Cheers George

thanks,yes i did make them.here in the states you can get them at any home depot or menards .they're 2' x 4' standared lighting grates for florescent tube ceiling fixtures.i once had a source to get full size 4'x8' sheets but that was back in 2004.like i had stated in another thread a haven't done anything since, do to my stupidity (dui's), reasons that have set me back a few years.so i got my sh$# together and i'm back to r&d this stuff again those panels were were made in 03 or 04.man how time fly's. but they still work .the little ones (black stator) are the final design and i have (have had for years) the material to build full size 1'x4' panels.i plan to start them soon including finishing the wire grid ones also.jer

yes.i am familiar with headwise projects and have a complete (almost anyhow) photocopy of the audio amature book with esl's and amps for them.when i recently got back int r&d of this project i found a thread from 2006 on the same circuit i was developing ,needless to say i was locked up at the time,so then i decided it was still worth persuing.so i checked out what was going on now a days,so her i am.i used read these forums all the time but never posted in any discussions. i also used to play with my own diy ribbons back 1990 and so on.i still have my orginal stack of magnets and just recently bought some more smaller ones to build some nearfeild monitors to mix with.jer

thanks, but you are a long way from here, i mean distance, it is something very neat that you have constructed. Further more, i have to say or ask" how do they sound" ? I will be placing my order for stats next week, sprayed instead of powder coating, and wish me luck.

it would be a bad day if this does not work, however, i look forword, not back, so about 20 mills on the stator? that is about as thin as I can get. will post ASAP! thanks, Mavric

it would be a bad day if this does not work, however, i look forword, not back, so about 20 mills on the stator? that is about as thin as I can get. will post ASAP! thanks, Mavric

incrediable altough i never got finish them .after i got back from from my 10 month stay at michigan states finest hotel a whole lot of things got cleaned up around here (moms was pretty mad)only to find that the bias supply and only set of matched transformers amongest a few other things i had,had been discarded so they've been sitting in a closet till now.check post 16 that should give you an idea.jer

"ha,ha,ha,as a test i was listening to some rain and thunder off of a cassette tape and my dog kept running to the window to watch the rain but there wasn't any.it was the funniest thing i ever saw" if a dog can believe it heard that rain from those speakers what does that tell ya! the transformers were little 15 watt 6v6 types from an old stereo tube amp i had(gone now and still very bitter).with some where around 20 to 30 watts they would play high 80db to low 90db range 10 feet away loud enough to enjoy but not rock your socks off .it was very hard to find any decent albums to play through them even frampton comes alive was badley eq'ed and some of darkside of the moon was anoying at times because you could every little detail inclueding the edits and overdubs but i got used to it .i guess i was just over whelmed by the detail! i wouldn't change a thing and swore i would never buy or especialy listen to a another box speaker again unless i had too.jer

i mean 20 mill thickness, i use a digi to measure the thickness between metal and material.

check back in a coulple of weeks, ordering on Monday for stats, guess i might a bit. before shipping, cutting, things of that nature.

So, as said, someone here will have about 150 lbs. of material showing up soon.

you know who you are. Mavric

check back in a coulple of weeks, ordering on Monday for stats, guess i might a bit. before shipping, cutting, things of that nature.

So, as said, someone here will have about 150 lbs. of material showing up soon.

you know who you are. Mavric

yes.i ment the coating thickness.i'll be waiting here for your progress.it takes alot of patience to build these things,but is well worth it.it would be wise to do a small test sample and hook up a bias supply and se if you get any arc threw on it to determin if the coating would be thick enough.as i did .as the white ones were painted and needed several more coats to get the desired insulating factor.jer

as you said the sprayer burps at times,you dont want any air bubbles as this would make a thin spot in the coating which is one reason i asked if it is sandable.if such is the case,you could sand it and recoat if nesessary.thicker is better as long as it doesn't plug up the holes too much.jer

Last edited:

Just discovered this thread this morning. The following perforated stainless sheet is only 40% open area (as opposed to 51%), but I wonder if it would do..?

.048" x 12" x 48" Stainless 304 Perforated Sheet at OnlineMetals.com

.048" x 12" x 48" Stainless 304 Perforated Sheet at OnlineMetals.com

it should,how ever stainless is very difficult to cut if needed, i have considerd using it myself as far as the open area is concerned it is probaly okay just remeber that when you have it coated, the area of the holes will be reduced slightly,now some where in these forums there is a discussion of effect of this, i don't remeber where at the moment,but as i posted earlier on my headphone driver it seemed to be lacking some high end possibaly due to small open area,i really need to measure it to be sure because it could be the material i was listening to or i am suffering more hearing loss on the high end than i relize.jer p.s. oh yeh not to mention the cost of stainless compared to other suitable materials.

Last edited:

Just discovered this thread this morning. The following perforated stainless sheet is only 40% open area (as opposed to 51%), but I wonder if it would do..?

.048" x 12" x 48" Stainless 304 Perforated Sheet at OnlineMetals.com

I think 40% open might be a bit low, considering the holes would get even smaller once you add an insulation coating-- not to mention the $400 price tag for (4) pieces.

this is what i will do, i will video when we spray again. post it on "you tube" . there seems to be a little confusion on how this works. when said it might have a "hick up", it just burst out material out of the gun in a straight path instead of an even spread. think of it like spraying paint, if the tip gets a little clogged, it will come out uneven. and with said, it just means that i might or maybe have a panel that is not 100% perfect across the entire panel, give or take 10 mills.

its tax season and i do car audio,video, security, and so on and have had no time to check the different tips i have for the rhino gun. I was told that i do not explain things very well on posts. So i will try and be more aggressive on my descriptions.

I visited the rhino linings site, i could not find the gun or equipment that we use, much less a better detailed decription of the material being sprayed. All i can say is that, it is black super glue, non conductive and corners and edges keep popping up as leakage issues, not with this. there are no air bubbles or anything like that, i wish i could think of an analogy but nothing comes to mind.

i am however going to hold off on ordering the perf panels, as the hole diameter seems to be an issue with rhino lining, i do need larger holes, but cannot sacrafice the panel charge. my thoughts were spay a little heavy around the edges and , here is an analogy, just like a soup bowl, heavy thickness on the edges and taper thickness to the inside or center portion. with all that said, i hope i explained that a little better. kind regards.

its tax season and i do car audio,video, security, and so on and have had no time to check the different tips i have for the rhino gun. I was told that i do not explain things very well on posts. So i will try and be more aggressive on my descriptions.

I visited the rhino linings site, i could not find the gun or equipment that we use, much less a better detailed decription of the material being sprayed. All i can say is that, it is black super glue, non conductive and corners and edges keep popping up as leakage issues, not with this. there are no air bubbles or anything like that, i wish i could think of an analogy but nothing comes to mind.

i am however going to hold off on ordering the perf panels, as the hole diameter seems to be an issue with rhino lining, i do need larger holes, but cannot sacrafice the panel charge. my thoughts were spay a little heavy around the edges and , here is an analogy, just like a soup bowl, heavy thickness on the edges and taper thickness to the inside or center portion. with all that said, i hope i explained that a little better. kind regards.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Material for ESL