Hi,

I bought a used pair o Audiostatics, and after a good clean (tried to remove the disposed dust) they sound fantastic. I m a huge panel enthousiast (as you see )

)

1. I would like to ask you how i can get the side wood pieces off (left and right of the panels). (i managed to get the top and bottom screw-fixed pieces off, but i cant get the sides off).

2. Where can i buy suitable mylar from? (please i need to buy the mylars from an internet supplier - also, whats the preffered thickness i should ask for?)

3. any pictures for mylar replacement would be very-very helpful as well as any advise/directions.

Thanks for your time, i NEED your help

I bought a used pair o Audiostatics, and after a good clean (tried to remove the disposed dust) they sound fantastic. I m a huge panel enthousiast (as you see

1. I would like to ask you how i can get the side wood pieces off (left and right of the panels). (i managed to get the top and bottom screw-fixed pieces off, but i cant get the sides off).

2. Where can i buy suitable mylar from? (please i need to buy the mylars from an internet supplier - also, whats the preffered thickness i should ask for?)

3. any pictures for mylar replacement would be very-very helpful as well as any advise/directions.

Thanks for your time, i NEED your help

Hi audiostaticproject,

are you sure that you need to replace the mylar ?

To get appropriate mylar is not an issue, but to proceed the mylar the riight way.

Do you know how to tension the mylar on ist length and width, do you know about possible thermal treatment, do you know about the required coating ???

There is a certain potential that the replacemenet will end up in big frustration

Capaciti

are you sure that you need to replace the mylar ?

To get appropriate mylar is not an issue, but to proceed the mylar the riight way.

Do you know how to tension the mylar on ist length and width, do you know about possible thermal treatment, do you know about the required coating ???

There is a certain potential that the replacemenet will end up in big frustration

Capaciti

Hi audiostaticproject,

are you sure that you need to replace the mylar ?

To get appropriate mylar is not an issue, but to proceed the mylar the riight way.

Do you know how to tension the mylar on ist length and width, do you know about possible thermal treatment, do you know about the required coating ???

There is a certain potential that the replacemenet will end up in big frustration

Capaciti

so,

1. how can we tension the mylar and how can we thermically treat it ?

2. what kind of coating is required?

(have you ever done it and ended up in frustration??

please provide technical advice and photos, changing the mylar is not rocket science

has anyone done it before ?

thanks for your time, answers needed here

ok, they are playing fine, but you want to improve.

Putting 4 micron instead of the original 6 micron will give you slightly smoother sound, but only if you can do a good job in replacing the Mylar which is not obvious as capaciti already has pointed out.

It will be easier to improve electronics. Play around with the input cap for example.

With luck you might find the old mirrordrive electronics of audiostatic es200/300 models. Putting this in the es100 might solve the anemic bass issue and give them a more warm end pleasant sound which will be immediately clear in A/B comparison

Replacing the trannies with expensive amplimo's might give you something although I didn't try the latter, just what I heard from other persons.

Some persons are specialised in improving audiostatics , for example Audiofinesse, if you live in the Netherlands.

Putting 4 micron instead of the original 6 micron will give you slightly smoother sound, but only if you can do a good job in replacing the Mylar which is not obvious as capaciti already has pointed out.

It will be easier to improve electronics. Play around with the input cap for example.

With luck you might find the old mirrordrive electronics of audiostatic es200/300 models. Putting this in the es100 might solve the anemic bass issue and give them a more warm end pleasant sound which will be immediately clear in A/B comparison

Replacing the trannies with expensive amplimo's might give you something although I didn't try the latter, just what I heard from other persons.

Some persons are specialised in improving audiostatics , for example Audiofinesse, if you live in the Netherlands.

Hi audiostaticproject,

maybe you think i am crazy, but in the last 20 years of developing fullrange-ESL i learned a lot of lessons about the amount of different parameters when tensioning mylar for fullrange -ESL.

I know exactly how limited a wrong treated mylar can sound. Thats why i recommended not to do so.

But ist not up to me to compromise your enthusiasm.

Try it, but be careful, the first problem will come up, if you try to pull the sides away. The ESL frame is glued into the sides with silicone. By 80 % you will crack the aluminium crossbars of the ESL and than thats it.

Capaciti

maybe you think i am crazy, but in the last 20 years of developing fullrange-ESL i learned a lot of lessons about the amount of different parameters when tensioning mylar for fullrange -ESL.

I know exactly how limited a wrong treated mylar can sound. Thats why i recommended not to do so.

But ist not up to me to compromise your enthusiasm.

Try it, but be careful, the first problem will come up, if you try to pull the sides away. The ESL frame is glued into the sides with silicone. By 80 % you will crack the aluminium crossbars of the ESL and than thats it.

Capaciti

1. Where can i buy suitable mylar film for the audiostatics ? (I need an internet supplier)

2. Do i need to spray any conductive coating, if i have to which one should i use?

thank you for your concern on damaging the speakers - please answer my two questions above.

- please answer my two questions above.

thanks for your time

2. Do i need to spray any conductive coating, if i have to which one should i use?

thank you for your concern on damaging the speakers

- please answer my two questions above.

- please answer my two questions above.thanks for your time

I know this is not the answer you are looking for (and you're probably going to be upset) but I'm going to say this nonetheless.

You clearly do not have the expertise to do this, otherwise you would not be asking these (rather mundane) questions. Actually it's kind of arrogant to think that you can improve these speakers by just slamming on a new foil, without having the slightest clue what you are doing! Most ESLs are fine tuned devices that require craftsmanship and knowledge to perform to their best.

My advise: leave them alone or bring them to an expert. If you want to learn, start browsing this forum and build your own ESL. That way you don't have to destroy a pair of good speakers while you are learning.

I hope you'll forgive me for being blunt.

You clearly do not have the expertise to do this, otherwise you would not be asking these (rather mundane) questions. Actually it's kind of arrogant to think that you can improve these speakers by just slamming on a new foil, without having the slightest clue what you are doing! Most ESLs are fine tuned devices that require craftsmanship and knowledge to perform to their best.

My advise: leave them alone or bring them to an expert. If you want to learn, start browsing this forum and build your own ESL. That way you don't have to destroy a pair of good speakers while you are learning.

I hope you'll forgive me for being blunt.

Hi Audiostaticproject,

If I were you, I would leave those speakers alone. If you want to learn, make yourself a new pair might be easier.

About the suppliers of Mylar, you can find them easily on the internet. Ebay.com has it. Eraudio.com also has it.

About the coating materials, there are many types. You can try the DIY recipes or you can buy them from a few suppliers. For DIY versions, http://www.diyaudio.com/forums/plan...ternative-technologies-forum.html#post1847694 .

Again, if I were you, I would build a new pair and leave those beautiful ones alone.

Good luck.

Wachara C.

If I were you, I would leave those speakers alone. If you want to learn, make yourself a new pair might be easier.

About the suppliers of Mylar, you can find them easily on the internet. Ebay.com has it. Eraudio.com also has it.

About the coating materials, there are many types. You can try the DIY recipes or you can buy them from a few suppliers. For DIY versions, http://www.diyaudio.com/forums/plan...ternative-technologies-forum.html#post1847694 .

Again, if I were you, I would build a new pair and leave those beautiful ones alone.

Good luck.

Wachara C.

Hi Audiostaticproject,

If I were you, I would leave those speakers alone. If you want to learn, make yourself a new pair might be easier.

About the suppliers of Mylar, you can find them easily on the internet. Ebay.com has it. Eraudio.com also has it.

About the coating materials, there are many types. You can try the DIY recipes or you can buy them from a few suppliers. For DIY versions, http://www.diyaudio.com/forums/plan...ternative-technologies-forum.html#post1847694 .

Again, if I were you, I would build a new pair and leave those beautiful ones alone.

Good luck.

Wachara C.

If I were you, I would leave those speakers alone. If you want to learn, make yourself a new pair might be easier.

About the suppliers of Mylar, you can find them easily on the internet. Ebay.com has it. Eraudio.com also has it.

About the coating materials, there are many types. You can try the DIY recipes or you can buy them from a few suppliers. For DIY versions, http://www.diyaudio.com/forums/plan...ternative-technologies-forum.html#post1847694 .

Again, if I were you, I would build a new pair and leave those beautiful ones alone.

Good luck.

Wachara C.

Thanks for your replies!

I won't change membranes since you think its to difficult (i find it easy, i could even tension the membrane using a forcemeter - has anyone use it before - do you know the recommended force that should be applied? )

(...)

Anyway, I bought them second hand from a dirty guy who was trying to sell them for years. The membranes were so dirty that one could hardly hear them playing.

guy who was trying to sell them for years. The membranes were so dirty that one could hardly hear them playing.

The last few days i managed to clean the membranes to the factory clear state. They play really loud and balanced now, as if they were new.

If you r inerested on doing so to your Audiostatics i can tell you the way to do it. (i took a few pictures as well)

Greetings to all the diyers (who suggest not to diy, instead of giving specific advice)

I won't change membranes since you think its to difficult (i find it easy, i could even tension the membrane using a forcemeter - has anyone use it before - do you know the recommended force that should be applied? )

(...)

Anyway, I bought them second hand from a dirty

The last few days i managed to clean the membranes to the factory clear state. They play really loud and balanced now, as if they were new.

If you r inerested on doing so to your Audiostatics i can tell you the way to do it. (i took a few pictures as well)

Greetings to all the diyers (who suggest not to diy, instead of giving specific advice)

Audiostatic mirrordrive?

Could you explain what this mirrordrive is!

With luck you might find the old mirrordrive electronics of audiostatic es200/300 models. Putting this in the es100 might solve the anemic bass issue and give them a more warm end pleasant sound which will be immediately clear in A/B comparison.

Could you explain what this mirrordrive is!

Audiostatic Mirror Drive

The Audiostatic "Mirror Drive" circuit from the ES300 I measured used an AT(autotransformer) with a center tap to boost the voltage by 6dB for frequencies below about 250hz. The step-up transformers were hooked up to the ends of the AT winding.

Basically it works by sending high frequencies directly to the step up transformers thru a coupling capacitor connected to the top of the AT winding, but sends low frequencies to the center tap of the AT which then doubles the voltage at the top of the winding. This creates a shelving network with LF boost of 6dB.

For further details, see the Peters US patent.

Frequency response equalizing ... - Google Patent Search

In general, the circuit seemed to work as expected at drive voltages up to about 15Vrms. With larger voltage inputs, the amount of boost diminished. By 25Vrms(80W @ 8ohm) , the boost was only about 2.5dB. I believe this was because the cores of the step-up transformers were nearing saturation so their primary inductance was dropping and giving a more difficult load for the autotransformer to drive. I'm not sure if this behavior was intentional to limit the maximum voltage applied to the stators, or just a trade-off when sizing the transformer cores.

Could you explain what this mirrordrive is!

The Audiostatic "Mirror Drive" circuit from the ES300 I measured used an AT(autotransformer) with a center tap to boost the voltage by 6dB for frequencies below about 250hz. The step-up transformers were hooked up to the ends of the AT winding.

Basically it works by sending high frequencies directly to the step up transformers thru a coupling capacitor connected to the top of the AT winding, but sends low frequencies to the center tap of the AT which then doubles the voltage at the top of the winding. This creates a shelving network with LF boost of 6dB.

For further details, see the Peters US patent.

Frequency response equalizing ... - Google Patent Search

In general, the circuit seemed to work as expected at drive voltages up to about 15Vrms. With larger voltage inputs, the amount of boost diminished. By 25Vrms(80W @ 8ohm) , the boost was only about 2.5dB. I believe this was because the cores of the step-up transformers were nearing saturation so their primary inductance was dropping and giving a more difficult load for the autotransformer to drive. I'm not sure if this behavior was intentional to limit the maximum voltage applied to the stators, or just a trade-off when sizing the transformer cores.

Thanks, for the explanation. Interesting… it sounds a bit of the same result as I accomplished by increasing the resistors in series with the outer stators from 188k to 312k. A definite recommendation including to use metal-film types (1W have played fine in mine for about a year now).

Unfortunately, I think you are right about the saturation in the step-up transformers. They do not look impressing. Logically a high quality step-up transformer should look equivalent to a high quality valve power amplifier output transformer.

Unfortunately, I think you are right about the saturation in the step-up transformers. They do not look impressing. Logically a high quality step-up transformer should look equivalent to a high quality valve power amplifier output transformer.

Thanks, for the explanation. Interesting… it sounds a bit of the same result as I accomplished by increasing the resistors in series with the outer stators from 188k to 312k. A definite recommendation including to use metal-film types (1W have played fine in mine for about a year now).

The resulting tonal balance changes are similar, but the efficiency is not.

The mirror drive improves the bass to mid frequency tonal balance by boosting the bass to better match the level of the midrange.

When you increase the value of the resistors feeding the outer stator sections, you reduce the level of the mids while leaving the lows the same; you are in effect cutting the midrange to better match the lower level of the bass.

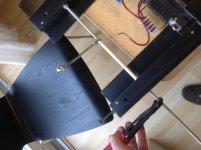

Here is a picture of how i dismanteld my audiostatic es100. I used an M8 threaded bar as a tyre wrench. Worked like magic. A picture says everything

the only thing you had to do is cut into the hotsnot around the panel and they go appart pretty easy.

there is a way to recoat the thing without destroying the membrane if at least the graphite on the sides still is connected to the copper strip. you can then tap the aluminium bars lose with a plastic hammer since the glue is not verry impact resistant. this way you can clean and recoat the side that had the coating originaly without destroying everything. (so you remove all the wires with alumnium bars as one piese and reglue later on, since the copper wires are stretched so hard they stay flat as long as you wont bend them)

the only thing you had to do is cut into the hotsnot around the panel and they go appart pretty easy.

there is a way to recoat the thing without destroying the membrane if at least the graphite on the sides still is connected to the copper strip. you can then tap the aluminium bars lose with a plastic hammer since the glue is not verry impact resistant. this way you can clean and recoat the side that had the coating originaly without destroying everything. (so you remove all the wires with alumnium bars as one piese and reglue later on, since the copper wires are stretched so hard they stay flat as long as you wont bend them)

The method described above is the same as the company audio4 uses. I have seen such panel myself as one went defective after a relatively short period and was offered to me. It can only work if there is a (good working) graphite trace on the mylar which is not always the case. Also putting new coating upon the old one can have several drawbacks. There are other issues as well. To summarize: the best and most reliable way is to replace Mylar sheets. (It is also the most time consuming but for diy this is not a big issue)

The method described above is the same as the company audio4 uses. I have seen such panel myself as one went defective after a relatively short period and was offered to me. It can only work if there is a (good working) graphite trace on the mylar which is not always the case. Also putting new coating upon the old one can have several drawbacks. There are other issues as well. To summarize: the best and most reliable way is to replace Mylar sheets. (It is also the most time consuming but for diy this is not a big issue)

I know Martin

I know its not THE way to go but when your equipment is limited its worth a try.

Getting the right resonance is not as easy as most people think, first we must know the original resonance(somewhere around 50), and some people say it does not mater much(or have no idea it mattered) , but it does mater much.

It dictated the extend of low frequency and loudness (qts) as well the limit in spl when chosen to low, hit the resonance and your done at a lower spl then a higher res panel.

I played around with quads for some time now and played with the audiostatics and its pretty hard to get it right.

It is doable as long as you know the resonance.

I had a pair of es 300RS once, and i could not get the thing where i wanted it to be, either honky or res to low and started to hit stators to early.

And another case where it even got sucked into a stator , clearly to low resonance.

I did not had the knowledge back then, that i have now but still it is no piece of cake i think.

By the way do we still have ESL meetings ? since i would love to meet some of the fellow builders again, see whats going on in ESL world and hopeflly the DIY scene is still alive in the netherlands. i might even met you already

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Audiostatic ES 100, mylar replacement