New coating causes unexpected problem???

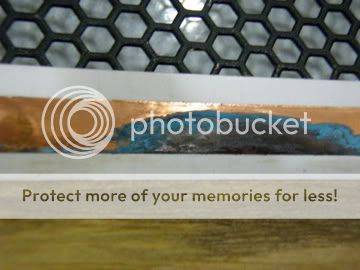

Graphite lasted pretty well but gave up eventually. Staticide always deteriorated after a few months on my DiY panels. I just tried a mixture of ISO-propanol with distilled water and a few drops of hydrogen peroxide. It appeared to work beautifully - around 25meg conductivity and full 2kV bias in the centre of the diaphragm. Big snag! More than half the bias disappears when stators connected back into the amp. My drive comes from the anodes of the o/p valves via coupling caps with a chain of resistors to ground. I've built three of these along the lines of Morgan Jones "Beast" and they normally work well. Can anyone suggest what's gone wrong. I'd be very grateful.

Graphite lasted pretty well but gave up eventually. Staticide always deteriorated after a few months on my DiY panels. I just tried a mixture of ISO-propanol with distilled water and a few drops of hydrogen peroxide. It appeared to work beautifully - around 25meg conductivity and full 2kV bias in the centre of the diaphragm. Big snag! More than half the bias disappears when stators connected back into the amp. My drive comes from the anodes of the o/p valves via coupling caps with a chain of resistors to ground. I've built three of these along the lines of Morgan Jones "Beast" and they normally work well. Can anyone suggest what's gone wrong. I'd be very grateful.

i only had one glue that worked partly, non of them where tessa. one that did worked was also watterbassed for the dutch people from the HEMA. but still i prefer deluted licron. its expensive and kind of a ****** to get but at least i got my test sample for free

Since you diluted it, I'm assuming you used the Licron that comes in a plastic spray bottle, rather than the aerosol can verison? And what was the dilution and method of application?

I've only used the aerosol version so I'm curious.

No, I've no idea about longevity here. I just looked up a list of conductive fluids which included data on conductivity and chose some I had available.

H2O2 will decompose over time and especially under light. It is not what you want for coating.

Very conductive black ink + Tesa glue did not as good as hoped, too high resistivity. I might try it again with more ink. I also ordered 120 grams of Elvamide. I think that might work well with some ink to boost the conductivity and to make it more stable in different climates. With ink the elvamide could also hopefully be be very diluted. Any experiences of this combo?

The only difference between aerosol and bottled version is a presence of propellants:Since you diluted it, I'm assuming you used the Licron that comes in a plastic spray bottle, rather than the aerosol can verison? And what was the dilution and method of application?

I've only used the aerosol version so I'm curious.

CHEMICAL NAME CAS #

2-Propanol 67-63-0

1-Butanol 71-36-3

Polymer, Proprietary

Nitromethane 75-52-5

Methanol 67-56-1

Propane (aerosol only) 74-98-6

N-Butane (aerosol only)106-97-8

Non aerosol comes in gallon bottles so price would be few hundred bucks.

Licron has urethane binder staticide has acrylic one.

I doubt dilutability of licron in water. Working with alcohol based coatings is a pain in the ... it dries too fast: spraying only

1756-G $298.99 per bottle min 4 to buy ground shipping only

quote H202 will decompose

Thanks Bazukaz for that information. I'm going to have a go at removing the new coating because it simply doesn't work in my set up. I think it must be leakage though I can't find it. I may have to make new diaphragms - ouch. I noted earlier in the thread Turtle wax F 21 recommended. May look at that now.

Thanks Bazukaz for that information. I'm going to have a go at removing the new coating because it simply doesn't work in my set up. I think it must be leakage though I can't find it. I may have to make new diaphragms - ouch. I noted earlier in the thread Turtle wax F 21 recommended. May look at that now.

Hi,

I have successfully diluted Licron crystal(spray) with distilled water to a ratio of 1:1. This slowed drying time a bit. Three very thin layers seem to be required to get sufficient conductivity when applied with a cotton wipe.

It was rather a surprise to me because I didn't expect this to work.

Have tried other substances : isopropanol, ethanol, acetone. They seemed to cause licron to gel and lose conductivity.

Edit : the surface resistance was on a boundary of my measurement equipment , somewhere between 10^10 to 10^11 ohms sq. at relative humidity of 30-40% after 24 hours. The speakers would not play to full volume instantly, and I can hear volume increasing for 10-20 seconds after powering on.

Regards,

Lukas.

Licron has urethane binder staticide has acrylic one.

I doubt dilutability of licron in water. Working with alcohol based coatings is a pain in the ... it dries too fast: spraying only

1756-G $298.99 per bottle min 4 to buy ground shipping only

I have successfully diluted Licron crystal(spray) with distilled water to a ratio of 1:1. This slowed drying time a bit. Three very thin layers seem to be required to get sufficient conductivity when applied with a cotton wipe.

It was rather a surprise to me because I didn't expect this to work.

Have tried other substances : isopropanol, ethanol, acetone. They seemed to cause licron to gel and lose conductivity.

Edit : the surface resistance was on a boundary of my measurement equipment , somewhere between 10^10 to 10^11 ohms sq. at relative humidity of 30-40% after 24 hours. The speakers would not play to full volume instantly, and I can hear volume increasing for 10-20 seconds after powering on.

Regards,

Lukas.

Last edited:

Well, licron is unobtanium for me mainly due to the shipping and/or distribution - 12 cans min to buy :-(

gohin is not clear on which way staticide did give up and what product he's tried or how he's applied it.

In my case it is OK after 3 years

EDIT: Undiluted product yields rather thick layer: there was similar post about Aussie ESL kit "problems"

gohin is not clear on which way staticide did give up and what product he's tried or how he's applied it.

In my case it is OK after 3 years

EDIT: Undiluted product yields rather thick layer: there was similar post about Aussie ESL kit "problems"

Last edited:

Is elvamide real PITA to dissolve into ethanol, am I doing something wrong?

I heated the stirring cup in a pot that's slightly filled with water and stirred the mixture of ethanol and elvamide granules for ~20 minutes. The ethanol boiled little for the last 10 minutes so it was really hot. Still I don't see any signs of dissolution.

The alcohol I used is denaturated alcohol, containing 90-95% ethanol and the rest is denaturating alcohols (1-5% propan-2-ol, 2% methyl ethyl ketone and 2% methyl isobutyl ketone).

I bought the Elvamide from here: Electrostatic Speaker Conductive Coating Elvamide 120g | eBay

I heated the stirring cup in a pot that's slightly filled with water and stirred the mixture of ethanol and elvamide granules for ~20 minutes. The ethanol boiled little for the last 10 minutes so it was really hot. Still I don't see any signs of dissolution.

The alcohol I used is denaturated alcohol, containing 90-95% ethanol and the rest is denaturating alcohols (1-5% propan-2-ol, 2% methyl ethyl ketone and 2% methyl isobutyl ketone).

I bought the Elvamide from here: Electrostatic Speaker Conductive Coating Elvamide 120g | eBay

Last edited:

Is elvamide real PITA to dissolve into ethanol, am I doing something wrong?

I heated the stirring cup in a pot that's slightly filled with water and stirred the mixture of ethanol and elvamide granules for ~20 minutes. The ethanol boiled little for the last 10 minutes so it was really hot. Still I don't see any signs of dissolution.

The alcohol I used is denaturated alcohol, containing 90-95% ethanol and the rest is denaturating alcohols (1-5% propan-2-ol, 2% methyl ethyl ketone and 2% methyl isobutyl ketone).

I bought the Elvamide from here: Electrostatic Speaker Conductive Coating Elvamide 120g | eBay

It is rather strange. I can say that this elvamide is definitely soluble in ethanol. Maybe you did not give it enough time.

I have tried 96% ethanol that comes from drug stores(the rest is mostly water).

And yeah it took quite a while to dissolve. Maybe an hour or two, I don't remember exactly. The temperature was set to somewhere 50-60 deg celsius. The solution must not come to boiling point.

Gelling time is quite fast and after some time mixture must be heated again to be useable.

Later I have stopped experimenting with it as it seems the resistance is a bit too high and layer too thick compared to some other coatings.

It is rather strange. I can say that this elvamide is definitely soluble in ethanol. Maybe you did not give it enough time.

I have tried 96% ethanol that comes from drug stores(the rest is mostly water).

And yeah it took quite a while to dissolve. Maybe an hour or two, I don't remember exactly. The temperature was set to somewhere 50-60 deg celsius. The solution must not come to boiling point.

Gelling time is quite fast and after some time mixture must be heated again to be useable.

Later I have stopped experimenting with it as it seems the resistance is a bit too high and layer too thick compared to some other coatings.

At least the vendor says it's the original Dupont Elvamide. It would help rule out the elvamide quality question if someone had experience with the same ebay vendor (apparently he has sold lots off that stuff).

Did you stirr the mixture the whole time or did you just keep it in the heat? Should the elvamide dissolve if I just place the mixture in a a bottle to 50-60deg water and leave it there for couple of hours, without stirring the solution, or is the constant stirring 100% required? Haven't figured out yet any convenient/cheap automated stirrer.

I was going to dilute the solution very thin, and add carbon black ink to boost conductivity.

Last edited:

Hi,

I used to shake the bottle every few minutes for quite a long time until it dissolved.

First of all there are several types of nylon which have different moisture content and physical properties.

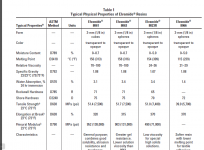

And yes they are selling DuPont elvamide I think. However there are several grades of elvamide. The one they are selling comes in small squares, see attachment below. Therefore it must be the common grade 8061 with low moisture content(see also table below).

The original coating used by Quad was Calaton. I can not find links any more but I found it is different nylon grade having higher moisture content. It would correspond to Elvamide 8066 perhaps. So my conclusion is the material sold on e-bay is not the same type of nylon as used by quads. I do not know if it works because I decided not to use this on my builds after some trials.

I think it will take a quite high carbon content to affect the resistance considerably, and then uniformity might be difficult to control. You can also try PVA glues instead of elvamide as a binder. If diluted with water to right ratio it will bond to mylar very well.

Regards,

Lukas.

I used to shake the bottle every few minutes for quite a long time until it dissolved.

First of all there are several types of nylon which have different moisture content and physical properties.

And yes they are selling DuPont elvamide I think. However there are several grades of elvamide. The one they are selling comes in small squares, see attachment below. Therefore it must be the common grade 8061 with low moisture content(see also table below).

The original coating used by Quad was Calaton. I can not find links any more but I found it is different nylon grade having higher moisture content. It would correspond to Elvamide 8066 perhaps. So my conclusion is the material sold on e-bay is not the same type of nylon as used by quads. I do not know if it works because I decided not to use this on my builds after some trials.

I think it will take a quite high carbon content to affect the resistance considerably, and then uniformity might be difficult to control. You can also try PVA glues instead of elvamide as a binder. If diluted with water to right ratio it will bond to mylar very well.

Regards,

Lukas.

Attachments

Last edited:

That's weird! The one I found dissolved in no time it was a soluble nylon sample directly from manufacturer.

Yet another trick:

http://www.diyaudio.com/forums/planars-exotics/109789-esl-diaphragm-coating-71.html#post3279696 It's also called fusible web tape for fabric...

FYI http://plastics.dupont.com/plastics/pdflit/americas/elvamide/H85929.pdf

EDIT: soluble nylon (N-methoxymethyl nylon, sold under the name of Calaton CB by ICI)

And even water soluble http://www.toray.com/business/products/plastics/chemicals/che_010.html

Yet another trick:

http://www.diyaudio.com/forums/planars-exotics/109789-esl-diaphragm-coating-71.html#post3279696 It's also called fusible web tape for fabric...

FYI http://plastics.dupont.com/plastics/pdflit/americas/elvamide/H85929.pdf

EDIT: soluble nylon (N-methoxymethyl nylon, sold under the name of Calaton CB by ICI)

And even water soluble http://www.toray.com/business/products/plastics/chemicals/che_010.html

Last edited:

- Home

- Loudspeakers

- Planars & Exotics

- ESL Diaphragm coating