Peter Daniel said:Dennis,

I thought you were planning for frugile pile Aleph X. Two heatsinks per side will make a very big amp. I wouldn't recommend it, because you have to run a lot of long wires and connectionns inside. It's better to do two smaller amps and if you need more power, go bi-amp and stack them on top ea. other.

Peter, thanks for your comments. The frugal Aleph-X is what

I plan on building. The 'parallel heatsink' question was

more for my friend with the Apogees, who will need to build

high current Aleph-Xs.

Peter Daniel said:

The way things go now, I think the will be an interest in such a thread (but better check, someone started similar one before).

I will check. I ended up getting my transformer for 12.5 VAC with 4 pairs of secondaries, 1kVA total. This should account for the high current draw of a stereo Aleph-X.

--

Brian

Peter,

This is certainly a deal that is can't be refused.

I think there are a couple of quesions that need resolution to better understand how this process would work.

1. Does the shipping cost per 4 or 8 units represent rho-Theta subdividing the order and shipping to the various non-local destinations?

2. Are there any Canadian or US taxes, international shipment fees, duties, or tariffs that need to be factored in?

3. What method of money transfer would work best, such as PayPal?

I am sure other people have questions as well.

Thanks much for all your efforts,

Chris Cassell

This is certainly a deal that is can't be refused.

I think there are a couple of quesions that need resolution to better understand how this process would work.

1. Does the shipping cost per 4 or 8 units represent rho-Theta subdividing the order and shipping to the various non-local destinations?

2. Are there any Canadian or US taxes, international shipment fees, duties, or tariffs that need to be factored in?

3. What method of money transfer would work best, such as PayPal?

I am sure other people have questions as well.

Thanks much for all your efforts,

Chris Cassell

Sure, I agree with your principle. I however think it does not applicable to all diyers. I supposePeter Daniel said:Ask the guys from 47Laboratory. They claim the shortest signal path in their amp: only 35mm. Maybe it's just me, but recently I try to make everything as compact as possible. I also like the purity and simplicity in design. Big chassis just doesn't allow it. I have my amps standing on a floor right now. If I put them one behind the other, they would look ugly and big. If I put them one on top of the other, they look really cool.

you have read this: http://sound.westhost.com/madashell8.htm#gaincard.

JH

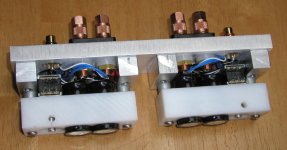

Oh yes, mosfet will be directly mounted on to the heatsinks. Bars are just for the structural integrity of the chassis.

Personally I would prefer not to drill the heatsinks except for the mounting points for the L-bars or L-corners. The reasoning for this is that heatsink can be used for whatever type of transistor case in the future. Just change the L-bars for different transistors, then I can compare or play with different banks of transistors. Have a bank of TO-3 for JLH or other class A and a bank of TO-247 mount for AlephX on different L-bars, may Aleph-2. Then no need to damage the heatsinks with different holes to on it.

Any other ideas are welcome,

Chris

chris ma said:

...I can compare or play with different banks of transistors. Have a bank of TO-3 for JLH or other class A and a bank of TO-247 mount for AlephX on different L-bars, may Aleph-2. Then no need to damage the heatsinks with different holes to on it.

Any other ideas are welcome,

Chris

Now that would be fun experiment. You can build the basic

Aleph you've chosen and then plug in different banks of

output devices and compare their sonic characteristics.

>>1. Does the shipping cost per 4 or 8 units represent rho-Theta subdividing the order and shipping to the various non-local destinations? <<

Yes

>>2. Are there any Canadian or US taxes, international shipment fees, duties, or tariffs that need to be factored in?<<

USA orders might be subject to duties, but I'm not sure. How is it with Plitron?

>>3. What method of money transfer would work best, such as PayPal?<<

For me the best way will be Money Order in Canadian Funds, maybe even written directly for R-Theta.

I will discuss shipping and other details with them on Monday.

Yes

>>2. Are there any Canadian or US taxes, international shipment fees, duties, or tariffs that need to be factored in?<<

USA orders might be subject to duties, but I'm not sure. How is it with Plitron?

>>3. What method of money transfer would work best, such as PayPal?<<

For me the best way will be Money Order in Canadian Funds, maybe even written directly for R-Theta.

I will discuss shipping and other details with them on Monday.

Peter Daniel said:jh6you,

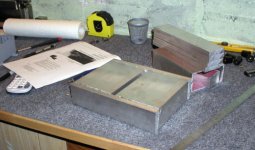

This make the whole, stereo amp (2x25W). The only additional thing is transformer and a bridge, which are separate.

That's very neat, Peter!

Curious: What design, and do you have heatsinking to add?

I guess I got confused about the shipping costs. 60 USD is still not too bad for an 80 lb package.

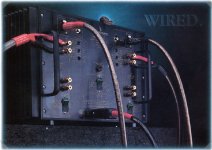

Peter, I don't understand what am I looking at, whatever that is I want the same binding posts! What are they?

What are they?

Four heatsinks per chassis would make a 22 in deep monster, just too huge.

Here is what I am going to do (see below). That is pretty much what tyou did for yours, right? 1/2 x 1.5 x 10 5/8 inches bar are about 2 bucks each. 3/16 plates will complete the four sides. I am guessing a max total of $40 (USD) of Al for two chassis. Milling the bars is no big deal, not so 8 plates. That's a four hours Gjob. The ideal would be to be able cut plates with whatever they use to cut the stock, it looks not as nice as a milled part but is pretty darn close. Do you understand what type of cut I mean? Can you do it?

Peter, I don't understand what am I looking at, whatever that is I want the same binding posts!

Four heatsinks per chassis would make a 22 in deep monster, just too huge.

Here is what I am going to do (see below). That is pretty much what tyou did for yours, right? 1/2 x 1.5 x 10 5/8 inches bar are about 2 bucks each. 3/16 plates will complete the four sides. I am guessing a max total of $40 (USD) of Al for two chassis. Milling the bars is no big deal, not so 8 plates. That's a four hours Gjob. The ideal would be to be able cut plates with whatever they use to cut the stock, it looks not as nice as a milled part but is pretty darn close. Do you understand what type of cut I mean? Can you do it?

Attachments

For my 4 chassis' of A75 I was ordering 1/4" plates from a local metal supplier which operates somewhat different than Metal Supermarkets (more commercial way). I was dealing with cash sales dept. and they were able to precut sheets to my dimensions. All I had to do is sand the edges on a belt sander.

My bars were 3/4" thick and I think the extra thickness is useful for spacing screws farther away from the edge.

The binding posts are probably the best posts you can get for your money (at least that's what Michel Percy claims ). They are Cardas.

). They are Cardas.

My bars were 3/4" thick and I think the extra thickness is useful for spacing screws farther away from the edge.

The binding posts are probably the best posts you can get for your money (at least that's what Michel Percy claims

Peter,

In the past six months, I have been amazed again and again by your projects. I thank you for sharing your projects with us and giving me so many ideas. I have an idea of making my own heatsinks and want to post some drawings on the forum. I am currently struggling with a couple of different low cost CAD programs trying to decide which I like the best. By my calculations I can build a set of sinks for a moderately powered (50 watts/ch) Aleph X for @ $100. The tools required to do this is pretty minimal. Once I get the dwgs sorted out I'll post them. I would appreciate any of the readers' honest opinions.

In the past six months, I have been amazed again and again by your projects. I thank you for sharing your projects with us and giving me so many ideas. I have an idea of making my own heatsinks and want to post some drawings on the forum. I am currently struggling with a couple of different low cost CAD programs trying to decide which I like the best. By my calculations I can build a set of sinks for a moderately powered (50 watts/ch) Aleph X for @ $100. The tools required to do this is pretty minimal. Once I get the dwgs sorted out I'll post them. I would appreciate any of the readers' honest opinions.

grataku said:I want the same binding posts!What are they?

Speaking of Cardas and their binding posts, I always liked this add, run by Stereophile.

Attachments

Speedy metals cuts plates using the band saw, however, I am pretty retarded with the belt sander.

I already have some great material to do a mid shelf, something similar to g10 but much finer fiber, nice phsychedelic green. I like to keep the capacitors ACAP. and inverse-mount the trafo.

I like to keep the capacitors ACAP. and inverse-mount the trafo.

Cardas eh? Mike Percy is indeed one of my favourite places. I wish they had retail stores, uhmm, maybe not. I would already be divorced.

Do you countersink your screws? Is 1/4 in deep enough to do that?

Great pic, you keep it for inspiration? I like the power switches, amazing.

I already have some great material to do a mid shelf, something similar to g10 but much finer fiber, nice phsychedelic green.

Cardas eh? Mike Percy is indeed one of my favourite places. I wish they had retail stores, uhmm, maybe not. I would already be divorced.

Do you countersink your screws? Is 1/4 in deep enough to do that?

Great pic, you keep it for inspiration? I like the power switches, amazing.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- Aleph X heat sink thread

Your latest 2x25W amp is killing me. Great!

Your latest 2x25W amp is killing me. Great!