Banned

Joined 2002

Well we have one channel here up in smoke.

Email :

After several weeks of sounding just fine, the amp decided over the weekend to play bad. I usually leave all my amps running when I’m out of the room for a few minutes or hours, so I can’t be sure when it happened, but it wasn’t hard to observe the results. Upon returning to the living room, a bubbling crackling noise was discernable from one speaker, along with the unmistakable smell of melted voice coil enamel, and a slight orange glow from under the dust cap of the Fostex drivers. .

One channel of the amp measures full 20V DC at the speaker terminals, with less than .002 on the other side. It’s likely gonna be a few days before I can get to putting in on my bench to pop the top and poke around. I have no idea how to measure anything other than R values – have you got any suggestions how to determine which if any of the semi’s are toast?

Once repaired, any suggestions on a hi pass output filter or other DC protection circuits? If I keep the amp, I don’t want to risk damaging drivers like the AMT Heils, Fostex or CSS full rangers.

Email :

My observations ( no stepping on toes i hope )

One of the fet's have come loose enough that the ceramic pad has moved causing the fet to not disapate the heat into the heat sink.

Or the screw metal has a diferent reaction to metal on metal at a certian tempature causing it to move or expand. That little bit of expansion made the ceramic pad fall the opposite direction of the get.

Would a fet not being properly cooled causse the amplifier to do what ? and cause rail voltage into a speaker ?

I have pictures.

J'

Email :

After several weeks of sounding just fine, the amp decided over the weekend to play bad. I usually leave all my amps running when I’m out of the room for a few minutes or hours, so I can’t be sure when it happened, but it wasn’t hard to observe the results. Upon returning to the living room, a bubbling crackling noise was discernable from one speaker, along with the unmistakable smell of melted voice coil enamel, and a slight orange glow from under the dust cap of the Fostex drivers. .

One channel of the amp measures full 20V DC at the speaker terminals, with less than .002 on the other side. It’s likely gonna be a few days before I can get to putting in on my bench to pop the top and poke around. I have no idea how to measure anything other than R values – have you got any suggestions how to determine which if any of the semi’s are toast?

Once repaired, any suggestions on a hi pass output filter or other DC protection circuits? If I keep the amp, I don’t want to risk damaging drivers like the AMT Heils, Fostex or CSS full rangers.

Email :

My observations ( no stepping on toes i hope )

One of the fet's have come loose enough that the ceramic pad has moved causing the fet to not disapate the heat into the heat sink.

Or the screw metal has a diferent reaction to metal on metal at a certian tempature causing it to move or expand. That little bit of expansion made the ceramic pad fall the opposite direction of the get.

Would a fet not being properly cooled causse the amplifier to do what ? and cause rail voltage into a speaker ?

I have pictures.

J'

Banned

Joined 2002

Here's what happens. If the fet runs too hot from no heat sink goo or too loose screw, etc., the heat cool cycles from turning it off and on cause the silicon to delaminate from the metal base, causing more overheating, then the fet shorts, and you have rail on the speaker. Don't ask me how I know.

Banned

Joined 2002

Banned

Joined 2002

azira said:Hope you don't mind me asking an unrelated question... How do you like those SIL pads inplace of thermal goop? I have quite a few of them around and I can't decide how well/poor they work.

--

Danny

Me i love them but they do have to be tightened down..

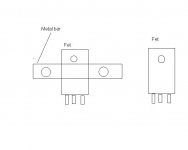

My idea.. >

Attachments

That stinks J',

I'd bet that only that 1 fet is toast (well, and the speaker of course). I have never been comfortable with mounting a fet with a single screw like that. I pretty much always use a piece of 1/2" alu bar stock across the fet with 2 stainless hex machine screws straddling the fet. Boy you can really crank down on 'em with much less risk of damaging the device and the risk if loosening is minimised. Also, the bolt feels less heat so perhaps it won't expand/change as much. Using that method I have noticed VERY little difference between device temp and sink temp probing around with an IR thermometer (maybe 3 or 4 C) and I think sink contact is way better. Just a suggestion.....

WOW!!! you posted as I was typing...COOL!

I'd bet that only that 1 fet is toast (well, and the speaker of course). I have never been comfortable with mounting a fet with a single screw like that. I pretty much always use a piece of 1/2" alu bar stock across the fet with 2 stainless hex machine screws straddling the fet. Boy you can really crank down on 'em with much less risk of damaging the device and the risk if loosening is minimised. Also, the bolt feels less heat so perhaps it won't expand/change as much. Using that method I have noticed VERY little difference between device temp and sink temp probing around with an IR thermometer (maybe 3 or 4 C) and I think sink contact is way better. Just a suggestion.....

WOW!!! you posted as I was typing...COOL!

Banned

Joined 2002

fcel said:Jason,

Schematic says plus and minus 15V rail. I remembered you saying that you are using 22V rail. Could that be the reason why you fried the MOSFET?

This was not my amp.. and mine are running at 20V rails witch will not hurt it at all. Just have to have the heat sink to cool it.. I think the main reason for this smoke show was due to heat not being transfered from the fet to heat sink..

J'

Hi jleaman,

I use a thin coat of grease with sil pads. Mica and grease seems to have a lower thermal resistance on average. The use of "Belleville" is recommended. I have an artical from Motorola I can send you. Just PM me, it's a PDF around 870 Kb. The file is named "SOLDERRM-D.PDF".

-Chris

I use a thin coat of grease with sil pads. Mica and grease seems to have a lower thermal resistance on average. The use of "Belleville" is recommended. I have an artical from Motorola I can send you. Just PM me, it's a PDF around 870 Kb. The file is named "SOLDERRM-D.PDF".

-Chris

Banned

Joined 2002

anatech said:Hi jleaman,

I use a thin coat of grease with sil pads. Mica and grease seems to have a lower thermal resistance on average. The use of "Belleville" is recommended. I have an artical from Motorola I can send you. Just PM me, it's a PDF around 870 Kb. The file is named "SOLDERRM-D.PDF".

-Chris

I dont like sil pad's i have blown up 2 amps from them dead short from a small metal shaving..

Hi Jason,

First rule: don't use exotic things (=unobtainium). Standard good quality grease and mica work great. If you want to decrease thermal resistance, then finish the heatsink to make it flatter and smoother. You can do the same to the part. The special washers move with expansion and contraction keeping a semi-constant pressure. Use threadlock on the screws to prevent them coming loose, machine screws work the best. I drill and tap the heatsink (just snapped a tap off in the heatsink - DARN

)

)

Do you want the artical?

-Chris

First rule: don't use exotic things (=unobtainium). Standard good quality grease and mica work great. If you want to decrease thermal resistance, then finish the heatsink to make it flatter and smoother. You can do the same to the part. The special washers move with expansion and contraction keeping a semi-constant pressure. Use threadlock on the screws to prevent them coming loose, machine screws work the best. I drill and tap the heatsink (just snapped a tap off in the heatsink - DARN

)

)Do you want the artical?

-Chris

Banned

Joined 2002

anatech said:Hi Jason,

First rule: don't use exotic things (=unobtainium). Standard good quality grease and mica work great. If you want to decrease thermal resistance, then finish the heatsink to make it flatter and smoother. You can do the same to the part. The special washers move with expansion and contraction keeping a semi-constant pressure. Use threadlock on the screws to prevent them coming loose, machine screws work the best. I drill and tap the heatsink (just snapped a tap off in the heatsink - DARN

)

Do you want the artical?

-Chris

Yes..

I also like nelson's way of mounting a fet with a nice large washer..

My amps have not failed at all. You guys have to remember this is not my amp that failed it is a friend's..

Actually the Ceramic/ Alumnium oxide insulators are extremely easy to get and are available from at least several places that all of you normally buy parts from... I would hardly call them exotic and they make darn good sense to use, they also cut the thermal transfer loss in half over mica. I am in the middle of offering TO-247 Ceramic/Alumnium oxide pads to the KSA-50 group and once they are content and have what they need I will also offer them to the Pass group. I can get them for 50 cents each whcih is considerably less expensive than the normal price. I will sell them for my cost(50 cents each U.S. currency) plus shipping plus PayPal and I will only work with PayPal. Now Beryllium oxide... I might consider that exotic in this day and age, and darn dangerous as well.

The pads in the photo are all spoken for but I will have at least several hundred more on Monday morning.

Mark

P.S.

Just get it anodized. The tap will completely vanish leaving the partially tapped hole.... you can then finish tapping the hole. Probably a dull tap or not using the correct tapping fluid also carbon steel taps are a no-no as they generally snap off easily no matter what... use high speed steel taps only!

The pads in the photo are all spoken for but I will have at least several hundred more on Monday morning.

Mark

P.S.

I drill and tap the heatsink (just snapped a tap off in the heatsink - DARN )

Just get it anodized. The tap will completely vanish leaving the partially tapped hole.... you can then finish tapping the hole. Probably a dull tap or not using the correct tapping fluid also carbon steel taps are a no-no as they generally snap off easily no matter what... use high speed steel taps only!

Attachments

Banned

Joined 2002

Mark A. Gulbrandsen said:Actually the Ceramic/ Alumnium oxide insulators are extremely easy to get and are available from at least several places that all of you normally buy parts from... I would hardly call them exotic and they make darn good sense to use, they also cut the thermal transfer loss in half over mica. I am in the middle of offering TO-247 Ceramic/Alumnium oxide pads to the KSA-50 group and once they are content and have what they need I will also offer them to the Pass group. I can get them for 50 cents each whcih is considerably less expensive than the normal price. I will sell them for my cost(50 cents each U.S. currency) plus shipping plus PayPal and I will only work with PayPal. Now Beryllium oxide... I might consider that exotic in this day and age, and darn dangerous as well.

The pads in the photo are all spoken for but I will have at least several hundred more on Monday morning.

Mark

P.S.

Just get it anodized. The tap will completely vanish leaving the partially tapped hole.... you can then finish tapping the hole. Probably a dull tap or not using the correct tapping fluid also carbon steel taps are a no-no as they generally snap off easily no matter what... use high speed steel taps only!

Can i buy some of these off you ?

Hi Mark,

I was actually referring to some of the specialized greases out there.

Ceramic won't help a rough surface, and are special order for most people. Surface flatness is the ultimate factor in heat transfer. The grease only helps by forcing out the air in the gaps. So the goal is to eliminate the gaps between the mounting surfaces. At that point a ceramic insulator may help heat transfer.

Sorry for not being more clear, and your point is well taken. I haven't used ceramic yet myself and so have no comment on them. Do they break if you drop them? I do drop things often as of late.

-Chris

I was actually referring to some of the specialized greases out there.

Ceramic won't help a rough surface, and are special order for most people. Surface flatness is the ultimate factor in heat transfer. The grease only helps by forcing out the air in the gaps. So the goal is to eliminate the gaps between the mounting surfaces. At that point a ceramic insulator may help heat transfer.

Sorry for not being more clear, and your point is well taken. I haven't used ceramic yet myself and so have no comment on them. Do they break if you drop them? I do drop things often as of late.

-Chris

Would both you guys e-mail me so I know how many you want.....

Thanks!

I have yet to break any of them by excess pressure or dropping or what ever. I'm sure that you oculd crush one with a pliers though. They are actually amazingly strong. They are also incredibly flat and smooth. I use them with a small amount of grease. Lapping heatsinks so theya re flat is no big deal for a DIY'er but not practical in large scale manufacturing. I think you'd be amazed at how much resistance these things cut down on even if the sinks are not perfectly flat.

Mark

Thanks!

Do they break if you drop them? I do drop things often as of late.

I have yet to break any of them by excess pressure or dropping or what ever. I'm sure that you oculd crush one with a pliers though. They are actually amazingly strong. They are also incredibly flat and smooth. I use them with a small amount of grease. Lapping heatsinks so theya re flat is no big deal for a DIY'er but not practical in large scale manufacturing. I think you'd be amazed at how much resistance these things cut down on even if the sinks are not perfectly flat.

Mark

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- Mini a's Up in SMOKE :eek: