I'm in the process of building an alephP, and as most of you I'm having

a problem with finding good quality dual (or quad) rotary switches for a nice price.

In Sweden a dual ELMA type 4 retail at over $130...

Thats about as much as all the other components cost me combined.

Being an engineer, I was thinking of using COGWHEELS to make single rotary switches

into dual. As I was scraching my head planning on how to get the %#/"/! cogwheels

to fit nicely into one another my girlfriend asks me what I'm thinking about...

You know, a penny for your thoughts. I lay out my problem, and she says:

I know a solution! She makes a drawing and to my chargin it is a brilliant solution.

I'm sure some (many?) of you have thought and maybe implemented the

following, but for those of you for whom this is a new, here you go:

a problem with finding good quality dual (or quad) rotary switches for a nice price.

In Sweden a dual ELMA type 4 retail at over $130...

Thats about as much as all the other components cost me combined.

Being an engineer, I was thinking of using COGWHEELS to make single rotary switches

into dual. As I was scraching my head planning on how to get the %#/"/! cogwheels

to fit nicely into one another my girlfriend asks me what I'm thinking about...

You know, a penny for your thoughts. I lay out my problem, and she says:

I know a solution! She makes a drawing and to my chargin it is a brilliant solution.

I'm sure some (many?) of you have thought and maybe implemented the

following, but for those of you for whom this is a new, here you go:

Attachments

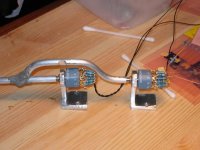

In that case ....here you go

The easy solution is to drill a hole in the backside of the switch, into the axle, then cut M2 thread or M3 if the size of the axle allows and do the same in the front of the axle of the switch you want to couple it with. Now you can couple the switches with a simple piece of threaded rod....thats the lazy solution, done it a few times with 2 mono pots some time ago.

Magura

The easy solution is to drill a hole in the backside of the switch, into the axle, then cut M2 thread or M3 if the size of the axle allows and do the same in the front of the axle of the switch you want to couple it with. Now you can couple the switches with a simple piece of threaded rod....thats the lazy solution, done it a few times with 2 mono pots some time ago.

Magura

Thanks for the ide Margua. I'm not sure I want to drill into the switch though.

Won't scrap material have a chance to pollute the internal contacts?

I admit to _not_ having been drunk at the time of construction!

Yes I'm that bad... To my defence the weld is, as Bill says, plastic padding.

And the big lump (in the plastic-p) is there because a screw was used to reinforce

the connection.

Next time I'll make sure my work is presentable.

Won't scrap material have a chance to pollute the internal contacts?

I admit to _not_ having been drunk at the time of construction!

Yes I'm that bad... To my defence the weld is, as Bill says, plastic padding.

And the big lump (in the plastic-p) is there because a screw was used to reinforce

the connection.

Next time I'll make sure my work is presentable.

Well, the clever insight here IMHO is the reminder that a typical switch or pot doesn't have to turn 360 (or 720) degrees, but probably only 270.

Another way to do it would be to make little arms out of maybe 6 mm aluminum about 40mm long say, with a 6mm hole on each end and a setscrew for each hole. Then you could put the arm on the front pot shaft, and clamp it, then clamp a shaft in the other hole extending back to the next pot, add a second arm between this shaft and the second pot shaft.

This way would be shorter, cleaner, and could connect quite a few pots. Should be a standard item!!

Do I need to draw a picture?

Another way to do it would be to make little arms out of maybe 6 mm aluminum about 40mm long say, with a 6mm hole on each end and a setscrew for each hole. Then you could put the arm on the front pot shaft, and clamp it, then clamp a shaft in the other hole extending back to the next pot, add a second arm between this shaft and the second pot shaft.

This way would be shorter, cleaner, and could connect quite a few pots. Should be a standard item!!

Do I need to draw a picture?

This is not simple, but very elegant way:

http://www.diyaudio.com/forums/showthread.php?s=&postid=62615#post62615

http://www.diyaudio.com/forums/showthread.php?s=&postid=62615#post62615

I like the idea in P #13

you can make it simpler by not using the cogwheels but a central rubber wheel (style of which you find in the K7 player systems and have it press tightly against(and situated between both shafts of which one has the knob attached to it.

Jean-Pierre

you can make it simpler by not using the cogwheels but a central rubber wheel (style of which you find in the K7 player systems and have it press tightly against(and situated between both shafts of which one has the knob attached to it.

Jean-Pierre

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- A simple way to create dual(or more!) rotary switches out of single rotary switches