I finished these original monoblocks a couple years ago. Happy with the sound and performance, but between the size of the amps, and the rest of my accumulated gear, our living room looks like a dorm room.

So after many hours searching images of shelving, cabinetry, and console’s I decided to build a console. It will be similar to the pic but a little longer and made from teak.

These amps will be rebuilt in new 24” x 16” x 8” (HxWxD) electrical enclosure’s. With new Pass Labs style heatsinks mounted to the 24” x 16” back. The console will be built to receive one on each side from the rear behind the speaker box sections. With the heatsinks exposed on the rear. I think with a couple inches of spacing away from the wall should be good dissipation.

The heat sinks are 10” tall x 6” wide x 3” thick. 2 1/2 heatsinks will be applied in 2 rows stacked with a 3” gap between to minimize heat transfer from lower to upper rows.

Enclosures, heat sinks, and other parts are ordered and on the way.

So after many hours searching images of shelving, cabinetry, and console’s I decided to build a console. It will be similar to the pic but a little longer and made from teak.

These amps will be rebuilt in new 24” x 16” x 8” (HxWxD) electrical enclosure’s. With new Pass Labs style heatsinks mounted to the 24” x 16” back. The console will be built to receive one on each side from the rear behind the speaker box sections. With the heatsinks exposed on the rear. I think with a couple inches of spacing away from the wall should be good dissipation.

The heat sinks are 10” tall x 6” wide x 3” thick. 2 1/2 heatsinks will be applied in 2 rows stacked with a 3” gap between to minimize heat transfer from lower to upper rows.

Enclosures, heat sinks, and other parts are ordered and on the way.

....The heat sinks are 10” tall x 6” wide x 3” thick. ...

OR--- move to Maine. I can't imagine those big hot monsters in your mild climate. Here they would be very stylish electric heaters, 100% efficient. Even at our high-ish electric rates, they would be good spot-heat when the family is all in one room and we let the wood stove slacken. (Actually I burn propane at 94%, but still good to have spot-heat.)

I would buy a bigger house or build a dedicated listening room on to my house before I took those monoblocks apart. Those are awesome!

PRR and No 4, thanks for the comments!

I enjoy building things, from audio gear, to cars, to commercial buildings. These amps were fun to design and build but I get bored easy. We have been in Hawaii (both Maui and Oahu) just under 7 years and have moved 7 times, as an example. I have been accumulating audio gear along the way and time to organize it.

I’m excited about building this console and incorporating the F5’s into it. The final design is a little different than the previous pic, but generally close. With all the stuff I want to include I’m up to 94” in length. But probably a benefit by spreading the speakers farther apart.

Been working out the engineering of the cabinet to keep from sagging with the length/weight. The problem is my little turntable weights over 65 lbs (plinth 100% panzerholz) and will be right in the center. The heatsinks weight 85 lbs. but at least they are on each end.

The legs, heatsinks, pocket hardware for the lid, new Keratherm pads, aluminum spanner bars, amp enclosures, and speaker grill cloth have been ordered and arrive next week.

Tomorrow I’ll be at the cabinet shop to start the woodwork. (I have full acces to a production/custom cabinet shop, including high end cutting machines, CNC, and paint booth).

I have been running the F5’s trying to get some break in time on the rebuilt JBL LE8T’s before they all get married in the console. Interesting sound, Class A/full range driver. Of course I’m kinda cheating with a pair of 13” Scanspeak subs with REL accustic amp boards filling in the lower end.

PRR, you can have the cold! Hate it! Nothing better than weather you can count on 98% of the time. Without thinking or planning my wife and I can eat outside and enjoy the day, year round. I think Hawaii has the highest electric rates in the country, so double/triple bad to run the F5’s plus the air conditioning!

I enjoy building things, from audio gear, to cars, to commercial buildings. These amps were fun to design and build but I get bored easy. We have been in Hawaii (both Maui and Oahu) just under 7 years and have moved 7 times, as an example. I have been accumulating audio gear along the way and time to organize it.

I’m excited about building this console and incorporating the F5’s into it. The final design is a little different than the previous pic, but generally close. With all the stuff I want to include I’m up to 94” in length. But probably a benefit by spreading the speakers farther apart.

Been working out the engineering of the cabinet to keep from sagging with the length/weight. The problem is my little turntable weights over 65 lbs (plinth 100% panzerholz) and will be right in the center. The heatsinks weight 85 lbs. but at least they are on each end.

The legs, heatsinks, pocket hardware for the lid, new Keratherm pads, aluminum spanner bars, amp enclosures, and speaker grill cloth have been ordered and arrive next week.

Tomorrow I’ll be at the cabinet shop to start the woodwork. (I have full acces to a production/custom cabinet shop, including high end cutting machines, CNC, and paint booth).

I have been running the F5’s trying to get some break in time on the rebuilt JBL LE8T’s before they all get married in the console. Interesting sound, Class A/full range driver. Of course I’m kinda cheating with a pair of 13” Scanspeak subs with REL accustic amp boards filling in the lower end.

PRR, you can have the cold! Hate it! Nothing better than weather you can count on 98% of the time. Without thinking or planning my wife and I can eat outside and enjoy the day, year round. I think Hawaii has the highest electric rates in the country, so double/triple bad to run the F5’s plus the air conditioning!

Been working out the engineering of the cabinet to keep from sagging with the length/weight. The problem is my little turntable weights over 65 lbs (plinth 100% panzerholz) and will be right in the center. The heatsinks weight 85 lbs. but at least they are on each end.

What about 6 legs to the console ?

Best regards,

Claas

P.S.: By the way, I can absolutely understand your feelings toward Hawaii. We have only once spent 2,5 weeks on Maui while we had been living in the U.S. Absolutely loved it !

What about 6 legs to the console ?

Best regards,

Claas

P.S.: By the way, I can absolutely understand your feelings toward Hawaii. We have only once spent 2,5 weeks on Maui while we had been living in the U.S. Absolutely loved it !

Chede, thanks for commenting. I have received the legs I’m going to use;

The floor of the console will be made of 24 pieces of 3/4” plywood cut 2” wide laminated to 12 pieces of 2” wide 1/4” steel plate (3/4” ply, 1/4” steel, 3/4” ply, repeat). This 2” thickness will be buried and won’t show from the front or back. The various sections of the console will be built together to help support itself.

If this doesn’t work then I’ll be stuck adding a center leg.

Capacity of the legs is 150 lbs each. Might be close to capacity when finished and loaded with audio gear.

Since the new mono block chassis will be built-in to the rear of the console, function over beauty here.

I purchased these used electrical enclosures made by Rittle (WM241608NC). Like the part number they are 24” tall x 16” wide x 8” deep, and made from 16 guage steel. $100 ea including delivery to the house. Will be plugging the old holes, repainting, and changing the hinges to the long side.

The plan is to bolt the heatsinks to the door. Route the wires to the hinge side so from the rear of the console I can swing the door/heatsink bank open for access to the amp.

I have 3/8” x 2” aluminum bars that the devices will be attached to and then bolted to the heatsinks to hold them together/spread heat. 4 ea bars per amp. So the case doors will be cut open at these locations and insulated spacers between the door and the heatsinks to reduce heat transfer to the enclosure.

Looks like a big space, but preliminary layout shows to be tight.

Enclosures even have a built in copper ground lug, bonus!

I purchased these used electrical enclosures made by Rittle (WM241608NC). Like the part number they are 24” tall x 16” wide x 8” deep, and made from 16 guage steel. $100 ea including delivery to the house. Will be plugging the old holes, repainting, and changing the hinges to the long side.

The plan is to bolt the heatsinks to the door. Route the wires to the hinge side so from the rear of the console I can swing the door/heatsink bank open for access to the amp.

I have 3/8” x 2” aluminum bars that the devices will be attached to and then bolted to the heatsinks to hold them together/spread heat. 4 ea bars per amp. So the case doors will be cut open at these locations and insulated spacers between the door and the heatsinks to reduce heat transfer to the enclosure.

Looks like a big space, but preliminary layout shows to be tight.

Enclosures even have a built in copper ground lug, bonus!

If you actually did all the work yourself for building the F5 and the chassis they are currently in and the console your skills as a craftsman are phenomenol. And your engineering skills must be pretty good too. I wish I had the opportunity to follow the path you did to achieve those skills. Not to brag...I'm pretty good at engineering and fabrication using machine and woodworking tools also but not nearly as good as your examples present.

I knew another engineer I worked with in Maine that worked his way through college by making violins he said sold for $10000. We've both moved on from the co,pansy we both worked for in Scarbourough.

I knew another engineer I worked with in Maine that worked his way through college by making violins he said sold for $10000. We've both moved on from the co,pansy we both worked for in Scarbourough.

The current F5 builds, as in the pic, are 100% my design and fabrication, thanks for the compliment.If you actually did all the work yourself for building the F5 and the chassis they are currently in and the console your skills as a craftsman are phenomenol. And your engineering skills must be pretty good too. I wish I had the opportunity to follow the path you did to achieve those skills. Not to brag...I'm pretty good at engineering and fabrication using machine and woodworking tools also but not nearly as good as your examples present.

I knew another engineer I worked with in Maine that worked his way through college by making violins he said sold for $10000. We've both moved on from the co,pansy we both worked for in Scarbourough.

I have just started on the console. The pic above is just a reference to what I’m building.

Due to a couple factors, I’ve changed my plans for the size. It will now be 94” wide, 32 3/4” tall (including the 6” legs), and the cabinet will be 24” deep but the 3” heatsinks will protrude the rear of the cabinet by 2”, for a total depth of 26”.

The extra width will spread the speakers apart for sound and allow me 3 middle sections for audio gear. The turntable will be in the middle with just a 23” wide opening lid.

Thanks for commenting!

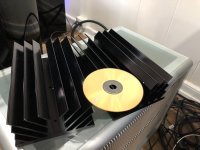

Heat sinks arrived from Singapore.

They are basically 10” long, 6” wide and 3” deep. There will be 5 on each monoblock. I will split one for each channel and have 2 1/2 on the bottom, then a 4” space, then 2 1/2 on top. This will fill up the 24” tall x 16” enclosure door.

5 heat sinks weigh 27 lbs.

View attachment 642431

The quality and finish of those appear to be nice. Did you find those on eBay or somewhere else on the web?

I have also had a couple private requests for info on these heatsinks.The quality and finish of those appear to be nice. Did you find those on eBay or somewhere else on the web?

I purchased them on eBay, item #263262235520. The same seller has them in natural aluminum also, for a little less money.

Ebay shows the sale from China, but they were shipped to me via DHL leaving out of Singapore.

The weight, finish, and overall feel is perfect. The seller answers questions almost immediately, shipped like the next day and arrived a week earlier than quoted.

Sound like an advertisement? I guess I’m jaded from other bad experiences on eBay and overjoyed I actually received something better and quicker than I had hoped for.

Of course the job of the heatsink is not to look good but to transfer heat. So that review can’t happen until after I’m done. But I think WalterW here on diyaudio also used them on his Sony chip amp. That’s where I got the idea from. And WalterW didn’t report any heat transfer issues.

Of course the job of the heatsink is not to look good but to transfer heat. So that review can’t happen until after I’m done. But I think WalterW here on diyaudio also used them on his Sony chip amp ( chip amp??? ..... aaaarghhhh😱😱😱 ) That’s where I got the idea from. And WalterW didn’t report any heat transfer issues.

yes there are serious issues, see this post: VFET-X (or my 1/3 40th Anniversary Sony VFET Clone)

You have to sand them a lot, then they are good to go.😀

Thanks WalterW for speaking up. I kind of assumed that smoothing heatsinks before bolting devices was a standard practice.

The backs of mine are pretty flat, but I will be blocking them and removing the coating on the backside.

Stripped my first monoblock tonight. Came apart pretty fast. Man do I have a lot of drilling and tapping to do. Totally forgot how much work went into this first pair.

I’ll get one up and running first, and use the first one as reference. Been a good couple years so I can’t remember everything.

The backs of mine are pretty flat, but I will be blocking them and removing the coating on the backside.

Stripped my first monoblock tonight. Came apart pretty fast. Man do I have a lot of drilling and tapping to do. Totally forgot how much work went into this first pair.

I’ll get one up and running first, and use the first one as reference. Been a good couple years so I can’t remember everything.

Why is HiFi so heavy?😥

The weight of the amp cases, heatsinks, transformers, turntable, and all the other equipment the console has to carry is a pretty good load. Since it is going to be 94” long, and I’m planning for only 4 legs, a really strong base is needed.

Today I put together the base of the cabinet. It is 2” thick, 92” long and 21 5/8” wide. To aid in building, assembly, and finishing I built a 10” high platform and sitting on a moving dolly on each end.

The base is built out of 24 rips of 3/4” shop grade maple plywood, 2 rips of 1” baltic birch plywood, 8 strips of 1/4” steel plate, 2 tubes of Sika adhesive, and about a 1/2 gallon of wood glue. Layered up and clamped.

The steel plate weight 12 lbs each, so 96 lbs.

After a few days I’ll do a load test. Hope is that it will hold 200 lbs in the middle without deflecting any.

The weight of the amp cases, heatsinks, transformers, turntable, and all the other equipment the console has to carry is a pretty good load. Since it is going to be 94” long, and I’m planning for only 4 legs, a really strong base is needed.

Today I put together the base of the cabinet. It is 2” thick, 92” long and 21 5/8” wide. To aid in building, assembly, and finishing I built a 10” high platform and sitting on a moving dolly on each end.

The base is built out of 24 rips of 3/4” shop grade maple plywood, 2 rips of 1” baltic birch plywood, 8 strips of 1/4” steel plate, 2 tubes of Sika adhesive, and about a 1/2 gallon of wood glue. Layered up and clamped.

The steel plate weight 12 lbs each, so 96 lbs.

After a few days I’ll do a load test. Hope is that it will hold 200 lbs in the middle without deflecting any.

Tomorrow I’ll start bolting in the amp parts into the chassis.

This is roughly the plan. The chassis will be in the back of the console behind the speaker. The enclosure will stand upright, 24” tall and 15” wide. The hinges will get moved to the side.

Connections and a cooling fan will be in the side facing the center of the console. Power at the bottom, input/output in the center, fan at the top.

Heatsinks and the boards on the door, including the FE board.

Layout will be optimized to good flow and short runs of wire.

This is roughly the plan. The chassis will be in the back of the console behind the speaker. The enclosure will stand upright, 24” tall and 15” wide. The hinges will get moved to the side.

Connections and a cooling fan will be in the side facing the center of the console. Power at the bottom, input/output in the center, fan at the top.

Heatsinks and the boards on the door, including the FE board.

Layout will be optimized to good flow and short runs of wire.

As I’m organizing the layout I’m wondering if I should make any upgrades? It’s been a couple years since building. After a few hours of reading it looks like one upgrade could be the power supply by going CLC.

As I’m barely a novice, I understand that cleaning up the power is a big part of the power supplies duties. In the old days coils were very popular as caps were more expensive. If I understand correctly.

In my amps now I have (per mono block);

Toroidy 1500VA transformer 38v,

4ea Rifa 82,000uF 63vdc caps

8ea Mundorf M-Lytic 15,000uF 63vdc caps

Rail voltage 51vdc

Has 2 sets of 7ea 0.47 resistors before the last pairs of 15000uF caps. (Store boards)

I have room for a pair of coils, but unsure how to calculate for my application.

My first guess, to show I’m not being lazy, is this Jantzen Air Core 000-0153. 3.5mH +/-3%, AWG14, 0.552Ohm

Any comments and suggestions welcome.

As I’m barely a novice, I understand that cleaning up the power is a big part of the power supplies duties. In the old days coils were very popular as caps were more expensive. If I understand correctly.

In my amps now I have (per mono block);

Toroidy 1500VA transformer 38v,

4ea Rifa 82,000uF 63vdc caps

8ea Mundorf M-Lytic 15,000uF 63vdc caps

Rail voltage 51vdc

Has 2 sets of 7ea 0.47 resistors before the last pairs of 15000uF caps. (Store boards)

I have room for a pair of coils, but unsure how to calculate for my application.

My first guess, to show I’m not being lazy, is this Jantzen Air Core 000-0153. 3.5mH +/-3%, AWG14, 0.552Ohm

Any comments and suggestions welcome.

Last edited:

If you're pulling a bit over 5A per rail, all that capacitance is giving you something on the order of 90mV of ripple. However, the capacitance is a bit unbalanced, which isn't ideal.

Moving all the Mundorfs to after the resistors would knock it down to ~ 65mV. I would think that's pretty damn good.

Adding the Jantzen gets it down to about 4mV (at the expense of some voltage on the rails). That's probably overkill.

However, if you're pulling a lot more current, then it might be worth going to CLC.

Note: there's an issue with how much current you pull through the coil, but I can't remember the details.

Moving all the Mundorfs to after the resistors would knock it down to ~ 65mV. I would think that's pretty damn good.

Adding the Jantzen gets it down to about 4mV (at the expense of some voltage on the rails). That's probably overkill.

However, if you're pulling a lot more current, then it might be worth going to CLC.

Note: there's an issue with how much current you pull through the coil, but I can't remember the details.

Thanks for replying.If you're pulling a bit over 5A per rail, all that capacitance is giving you something on the order of 90mV of ripple. However, the capacitance is a bit unbalanced, which isn't ideal.

Moving all the Mundorfs to after the resistors would knock it down to ~ 65mV. I would think that's pretty damn good.

Adding the Jantzen gets it down to about 4mV (at the expense of some voltage on the rails). That's probably overkill.

However, if you're pulling a lot more current, then it might be worth going to CLC.

Note: there's an issue with how much current you pull through the coil, but I can't remember the details.

Yes I’m looking at removing the 0.47 Ohm resistors and replacing with a coil for CLC.

So asking if the coil I listed is a good fit and where in the path to insert it? Or other?

Thanks.

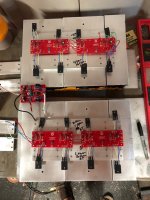

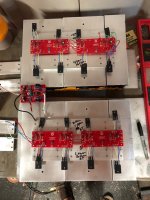

Spent today working on the heatsinks.

The coating is pretty hard. Here is a pic after a few passes with a standard palm sander with 80 grit paper. The circular marks and the line down the middle are not very deep and were there before the coating was applied.

Similar condition on all 10 I purchased. So I hit each one with my angle grinder with a 120 grit flapper type sanding disk to knock off the coating. You need to have some experience with sanding like this or you could end up with a mess. I took it down to where there were almost no defects, then used the palm sander with 80 grit. (FYI, I used a respirator as I don’t know what the coating is). It took me about 3 hours to clean up the 10 heatsinks, including cutting 2 in half.

Then cut up the 3/8” x 2” aluminum bar stock I’m using to hold the heatsinks together, to transfer the heat load between the pieces and hold the boards and devices. I’ll be removing the extension wires I added in the last build and solder the devices to the board directly, like your supposed to. I drilled all the bar to heatsink mounting holes (80) and called it a day.

Here is a pic that kind of shows the physical layout. And yes, I’m going to be mounting the FE board to the chassis door in the 2 1/2” gap between the top and bottom heatsinks. The board will face outside the enclosure and be exposed. Since this will be the back of the console and not exposed to the public it won’t be a safety issue and I will be able to tweak without having to open the door.

The coating is pretty hard. Here is a pic after a few passes with a standard palm sander with 80 grit paper. The circular marks and the line down the middle are not very deep and were there before the coating was applied.

Similar condition on all 10 I purchased. So I hit each one with my angle grinder with a 120 grit flapper type sanding disk to knock off the coating. You need to have some experience with sanding like this or you could end up with a mess. I took it down to where there were almost no defects, then used the palm sander with 80 grit. (FYI, I used a respirator as I don’t know what the coating is). It took me about 3 hours to clean up the 10 heatsinks, including cutting 2 in half.

Then cut up the 3/8” x 2” aluminum bar stock I’m using to hold the heatsinks together, to transfer the heat load between the pieces and hold the boards and devices. I’ll be removing the extension wires I added in the last build and solder the devices to the board directly, like your supposed to. I drilled all the bar to heatsink mounting holes (80) and called it a day.

Here is a pic that kind of shows the physical layout. And yes, I’m going to be mounting the FE board to the chassis door in the 2 1/2” gap between the top and bottom heatsinks. The board will face outside the enclosure and be exposed. Since this will be the back of the console and not exposed to the public it won’t be a safety issue and I will be able to tweak without having to open the door.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Pass Labs

- Aloha F5 v3 part 2, console build