i think those sinks will have a hard time dissipating 300 watts...

From looking at the Aleph 1.2 service manual it looks like about

346 sq. in. of heat sink for 1 channel.

You've got 234 sq. in. with 2 heatsinks. If you could add another

heatsink like you're using, it would work for 1 ch of Aleph 1.2

From looking at the Aleph 1.2 service manual it looks like about

346 sq. in. of heat sink for 1 channel.

You've got 234 sq. in. with 2 heatsinks. If you could add another

heatsink like you're using, it would work for 1 ch of Aleph 1.2

aleph 2

To be honest i've never listened to a Class A amp, so I dont know what 100W will do. From what i've read and followed here on the forum, i believe it will be fine. The only thing i have to compare to is an old pionner sx-1280 which is 185W@8. Just wondering if its possible to move up. Once its built i'm sure replacing fets would become bothersome if i chose to go to 1.2.

I think i'll keep it the way it is, just flirtin with the idea. Moe, I saw your Alpeh 2, great work, are you happy with the sound of it

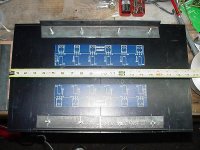

The above pics, depict just one side of a single monoblock, total heatsink area per channel is 468 sq. in.

Thanks,

JH

To be honest i've never listened to a Class A amp, so I dont know what 100W will do. From what i've read and followed here on the forum, i believe it will be fine. The only thing i have to compare to is an old pionner sx-1280 which is 185W@8. Just wondering if its possible to move up. Once its built i'm sure replacing fets would become bothersome if i chose to go to 1.2.

I think i'll keep it the way it is, just flirtin with the idea. Moe, I saw your Alpeh 2, great work, are you happy with the sound of it

The above pics, depict just one side of a single monoblock, total heatsink area per channel is 468 sq. in.

Thanks,

JH

Mega-Amp,

Just a question out of curiosity. Why didn't you use a piece of longer aluminum L bracket to connect your heatsinks together? The aluminum bracket can also be cut easily on a woodworking power chop saw with a carbide tip blade. I was also curious why you drilled all the way through the heatsink instead of most of the way and tapping the holes? Then you wouldn't see the holes in the heatsink. Was it because the heatsink base was only about .25" thick? Just curious. Keep up the good work and show us more pictures as you go along.

Just a question out of curiosity. Why didn't you use a piece of longer aluminum L bracket to connect your heatsinks together? The aluminum bracket can also be cut easily on a woodworking power chop saw with a carbide tip blade. I was also curious why you drilled all the way through the heatsink instead of most of the way and tapping the holes? Then you wouldn't see the holes in the heatsink. Was it because the heatsink base was only about .25" thick? Just curious. Keep up the good work and show us more pictures as you go along.

Re: aleph 2

Compared with your feet your sinks look huge

Keep them coming

MEGA-amp said:steel construction

Compared with your feet your sinks look huge

Keep them coming

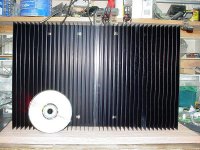

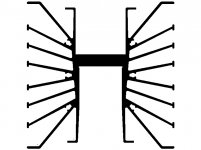

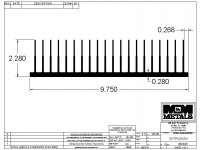

According to M&M Metals specs my heat sinks are 103 sq inches per inch of extrusion of which each is 6" long. I have 6 sinks per Aleph 2 and this gives me a total of 3709 sq inches of heatsink if I'm calculating this corectly.

6.250 X 6.250 X 0.500 Base thickness and weighs 7.550 per foot. Rated at 0.6 deg C/W

6.250 X 6.250 X 0.500 Base thickness and weighs 7.550 per foot. Rated at 0.6 deg C/W

Attachments

JH,

I wasn't counting the fin size into the sq. in. formula. Just heatsink

size. Fin size is about the same for your sinks and aleph 1.2

So i still think you're short.

I did notice that the Aleph 1.2 service manual says 500 watts of

dissipation compared to 300 watts for the Aleph 2. Either way it's

a lot of heat to dissipate. Nothing would be worse than spending

the time and money to match 12 fets X 2 for each channel, and

then have the amp run too hot!

but maybe i'm not being enough of a Fearless DIYer

I wasn't counting the fin size into the sq. in. formula. Just heatsink

size. Fin size is about the same for your sinks and aleph 1.2

So i still think you're short.

I did notice that the Aleph 1.2 service manual says 500 watts of

dissipation compared to 300 watts for the Aleph 2. Either way it's

a lot of heat to dissipate. Nothing would be worse than spending

the time and money to match 12 fets X 2 for each channel, and

then have the amp run too hot!

but maybe i'm not being enough of a Fearless DIYer

aleph 2

kilowattski, the brackets are solid steel with stainless steel machine screws, I didnt feel the need to go the length of the sink, for one mono block i used up 84" of steel brackets, this project is starting to get expensive. As it is, its very strong. As for the base thickness, its actually .28" to be exact. I didnt want to deal with threading holes, breaking taps, plus I dont really mind the screws in the sinks being visible.

When I was doing my calculation, I was just measuring flat surface area, not the fins, oh well, i'd like to go for Aleph 1.2, but I'm sure I wont be dissatisfied with the 2.

You know what they say about people with little feet, they wear little shoes

Thank you,

JH

kilowattski, the brackets are solid steel with stainless steel machine screws, I didnt feel the need to go the length of the sink, for one mono block i used up 84" of steel brackets, this project is starting to get expensive. As it is, its very strong. As for the base thickness, its actually .28" to be exact. I didnt want to deal with threading holes, breaking taps, plus I dont really mind the screws in the sinks being visible.

When I was doing my calculation, I was just measuring flat surface area, not the fins, oh well, i'd like to go for Aleph 1.2, but I'm sure I wont be dissatisfied with the 2.

You know what they say about people with little feet, they wear little shoes

Thank you,

JH

I didnt feel the need to go the length of the sink, for one mono block i used up 84" of steel brackets, this project is starting to get expensive.

I know what you mean. My wife thought that my woodworking hobby was expensive until I got into DIY audio.

Aleph 2 heatsinks

SI,

I ordered them through M&M metals. They have great service, great people, no minimums. http://www.mmmetals.com/

For my project I used 8 pieces (4 per monoblock). The total cost was $650 w/shipping. I had them do the black anodizing, which in retrospect, I should have not done that to save cost. I would have saved probably around 70 bucks. A local metal shop can anodize them cheaply.

JH

M&M Model# MM10928

SI,

I ordered them through M&M metals. They have great service, great people, no minimums. http://www.mmmetals.com/

For my project I used 8 pieces (4 per monoblock). The total cost was $650 w/shipping. I had them do the black anodizing, which in retrospect, I should have not done that to save cost. I would have saved probably around 70 bucks. A local metal shop can anodize them cheaply.

JH

M&M Model# MM10928

Attachments

For comparison

The sinks MEGA-Amp posted are !very! sweet pieces. The sinks I bought off of Ebay a while back are nice, but not as good as those for high dissipation.

Mine are 7 3/8" wide x 13 1/4" tall with a 1/4" base thickness. The total fin height (including base) is only 1 5/16", which is a significant change from the M&M product. The fins are spaced at 1/4" and there are a total of 21. They are black anodized and have 24 pre-tapped holes for some other device.

They are a significant compromise compared to his sinks. I bought 8 also, hoping for 4 per monoblock of Aleph 2 (3 mosfets per sink). It is, from what I gather, a pretty borderline application and I may have fallen victim to the too little heatsink bug.

But, I paid around $130 shipped from e-bay. In the end, MEGA-Amp will end up with a super sharp Aleph 2 and I might end up with a much smaller Aleph, due to my oversight.

I suggest looking for surplus (not exclusively e-bay), but also really compare specs and dimensions. They looked huge to me until I saw a real Pass amp. They look pretty small now. . .

Hopefully in 3 or 4 months from now, I'll be able to post whether or not they are sufficient for an Aleph 2 or not, but that project is still gathering the last few components.

Sandy.

Sandy.

The sinks MEGA-Amp posted are !very! sweet pieces. The sinks I bought off of Ebay a while back are nice, but not as good as those for high dissipation.

Mine are 7 3/8" wide x 13 1/4" tall with a 1/4" base thickness. The total fin height (including base) is only 1 5/16", which is a significant change from the M&M product. The fins are spaced at 1/4" and there are a total of 21. They are black anodized and have 24 pre-tapped holes for some other device.

They are a significant compromise compared to his sinks. I bought 8 also, hoping for 4 per monoblock of Aleph 2 (3 mosfets per sink). It is, from what I gather, a pretty borderline application and I may have fallen victim to the too little heatsink bug.

But, I paid around $130 shipped from e-bay. In the end, MEGA-Amp will end up with a super sharp Aleph 2 and I might end up with a much smaller Aleph, due to my oversight.

I suggest looking for surplus (not exclusively e-bay), but also really compare specs and dimensions. They looked huge to me until I saw a real Pass amp. They look pretty small now. . .

Hopefully in 3 or 4 months from now, I'll be able to post whether or not they are sufficient for an Aleph 2 or not, but that project is still gathering the last few components.

Sandy.

Sandy.

weight

I ordered 8 pcs of the above, they gave me 9. It was about 70 lbs of aluminum. When I was shopping around for metal, most places had 1000lb minimums, or some sort of minimums based on weight. Availability of an extrusion or lack of, raises the cost as well. I dont know what the case was with mine, but M&M gave me the lowest quote.

JH

I ordered 8 pcs of the above, they gave me 9. It was about 70 lbs of aluminum. When I was shopping around for metal, most places had 1000lb minimums, or some sort of minimums based on weight. Availability of an extrusion or lack of, raises the cost as well. I dont know what the case was with mine, but M&M gave me the lowest quote.

JH

The large flat panel sinks may not seem as complex, they are much more difficult to extrude because of the asymetry. They want to curl and warp as they come out of the die. Extrusions like Mark's are basically radial and more forgiving.

I bought 8 feet of an extrusion that is 7" wide and 2" deep with 17 fins of alternating lengths 2",1",2" etc. for about $450.

Made 2 Aleph 2's that burn 450 watts at 165 deg. I usually back the bias from 5 amps to 3 or so unless I have friends and beer over.

Letting the temp slide too high has it's cost. I need to buy another 100 ifrp244. Reliabiliy suffers greatly at 180 deg from 55 volt rails and 7 amps of bias.

I bought 8 feet of an extrusion that is 7" wide and 2" deep with 17 fins of alternating lengths 2",1",2" etc. for about $450.

Made 2 Aleph 2's that burn 450 watts at 165 deg. I usually back the bias from 5 amps to 3 or so unless I have friends and beer over.

Letting the temp slide too high has it's cost. I need to buy another 100 ifrp244. Reliabiliy suffers greatly at 180 deg from 55 volt rails and 7 amps of bias.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- aleph 2 progress