Alain Dupont said:Do I qualify for DIYer ?

Of course. Kurt Vonnegut would say, "You are what you

pretend to be."

trigon,

The 2 battery of caps by channel will go under the rails CRC with 5 * 5600micro F - 0.5ohm and 5 * 5600micro F, i will send an other photo for that soon... so for the preamp part fixed on the back pannel, using Peter Daniel's idea ; pot's on the back of the PCb for easy adjust.

Nelson,

Thanks, always funny...

Regards for all precious comments.

Alain.

PS: Still drilling the right channel heatsinks, a lot of holes...

The 2 battery of caps by channel will go under the rails CRC with 5 * 5600micro F - 0.5ohm and 5 * 5600micro F, i will send an other photo for that soon... so for the preamp part fixed on the back pannel, using Peter Daniel's idea ; pot's on the back of the PCb for easy adjust.

Nelson,

Thanks, always funny...

Regards for all precious comments.

Alain.

PS: Still drilling the right channel heatsinks, a lot of holes...

Drafance007,

Only to drive my 2 Martin Logan Aerius i

At that time there is only 1 transfo Plitron 750 VA; but if it works well

I could add an other 750VA ... The goal is 2*100 Watts "pure class A"

The A75 will replace my C350 NAD

There is also the subwoofer with a 12" Shiva MK III from Adire with a 270 Watts amplifier inside...

I plan to build after that a Aleph-X at 2*60 Watts to try biamping...

Regards.

Alain.

Only to drive my 2 Martin Logan Aerius i

At that time there is only 1 transfo Plitron 750 VA; but if it works well

I could add an other 750VA ... The goal is 2*100 Watts "pure class A"

The A75 will replace my C350 NAD

There is also the subwoofer with a 12" Shiva MK III from Adire with a 270 Watts amplifier inside...

I plan to build after that a Aleph-X at 2*60 Watts to try biamping...

Regards.

Alain.

Attachments

Djk,

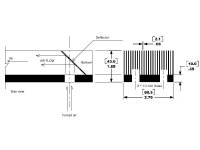

The Heatsinks are dissipating 25watts for a 8" length in natural convection

and there are 12 pieces (6* by channel)

So in Natural convection that is roughtly 300 watts...

for a 50 centigrade rize over ambiant....

But the two 10 mm holes in the lower part of the sinks

will receive an air flux of 200 to 400 LFM to cool them down...

The idea is to deviate the flux passing through the sink horizontaly

and deviate it verticaly ; and the trick is a serie of little sheets (plates)

placed at a 45 degree angle right inside the sinks ; see the shema.

To be able to acheive a temperature rise of only 30 to 35 degrees over ambiant...

The Heatsinks are dissipating 25watts for a 8" length in natural convection

and there are 12 pieces (6* by channel)

So in Natural convection that is roughtly 300 watts...

for a 50 centigrade rize over ambiant....

But the two 10 mm holes in the lower part of the sinks

will receive an air flux of 200 to 400 LFM to cool them down...

The idea is to deviate the flux passing through the sink horizontaly

and deviate it verticaly ; and the trick is a serie of little sheets (plates)

placed at a 45 degree angle right inside the sinks ; see the shema.

To be able to acheive a temperature rise of only 30 to 35 degrees over ambiant...

Attachments

Bricolo,

Yesterday I broke a tap inside the last heatsink (Murphy's law applies also to DIYer's), I will have to by a new 10-32 tap this morning

and try to remove the broken one, a nightmare

Overall dimensions ot the amplifier are 17" length by 17" deep and 8" height

Well, I have to go buy my new tap...

Nice day to all, and thanks so much for you wonderful comments.

Alain.

Yesterday I broke a tap inside the last heatsink (Murphy's law applies also to DIYer's), I will have to by a new 10-32 tap this morning

and try to remove the broken one, a nightmare

Overall dimensions ot the amplifier are 17" length by 17" deep and 8" height

Well, I have to go buy my new tap...

Nice day to all, and thanks so much for you wonderful comments.

Alain.

Alain Dupont said:Bricolo,

Yesterday I broke a tap inside the last heatsink (Murphy's law applies also to DIYer's), I will have to by a new 10-32 tap this morning

and try to remove the broken one, a nightmare

Overall dimensions ot the amplifier are 17" length by 17" deep and 8" height

Well, I have to go buy my new tap...

Nice day to all, and thanks so much for you wonderful comments.

Alain.

Almost impossible unless you have some left hanging out. Easier to redrill the hole elsewhere and hide the old one. A professional is one who can hide his mistakes. We all do it. Next time use parrafin to lubricate your taps. Good luck with your cooling plan, I hope it works.

Alain Dupont said:Bricolo,

Yesterday I broke a tap inside the last heatsink (Murphy's law applies also to DIYer's), I will have to by a new 10-32 tap this morning

and try to remove the broken one, a nightmare

Overall dimensions ot the amplifier are 17" length by 17" deep and 8" height

Well, I have to go buy my new tap...

Nice day to all, and thanks so much for you wonderful comments.

Alain.

Guess what... exatly the same thing happend to me with my gainclone

In the last hole

I was tapping a 20mm deep plate, absolutely impossible to remove the broken tap in this situation.

In your case, if you're tapping the heatsinks or a thin metal sheet (not 20mm!) maybe you can remove the broken tap. But it won't be easy.

There are 2 solutions (in fact 3, but the last one isn't for DIYers...)

-find or make a tool with 3 "tooths", and try to turn the tap out of the hole. Something with 2 'tooths" sometimes work, like a big pair of compasses.

-punch it out of the hole. But this will destroy the tapping, you'll have to do another hole or a bigger tapping in this one

-the last solution is to burn the tap. they are made of a special alloy that burns and turns into powder. This is done by connecting the tap and the piece of metal to high voltage. But not a diyer friendly solution. Don't try this without the stuff specially made for this!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- Pure Delight