Best solder and wire for Pass diy amplifiers

http://www.vishaypg.com/docs/11051/tn501.pdf

I try them in my amp prototype

L'Audiophile with schematics inside:

index

index

Thanks 2PicoDumbs

Have nice day!

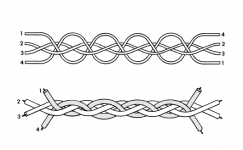

Have today make samples of this stranded wires from copper UTP cableI'd rather build myself a Zen amp and contemplate different circuit ideas, and then hang out with ZM in the pub.

http://www.vishaypg.com/docs/11051/tn501.pdf

I try them in my amp prototype

L'Audiophile with schematics inside:

index

index

Thanks 2PicoDumbs

Have nice day!

Attachments

I don't agree with everything JC says but I am not going to waste my time arguing with him.

With respect to soldering, nobody is arguing with him. He described a methodology for cleaning leads which he introduced to techs building some product to produce product which looks prettier. He also mentioned their surprise on the procedure he showed them.

I pointed out the problems that can result, why it could be a problem, and how to solve the look issue while maintaining metallurgical integrity.

No arguing. A simple discussion of chemistry, metallurgy, process control, and visual criteria for soldering.

BTW, most large companies, especially ones where critical equipment is made, will not allow an electronics designer to simply walk into the production line and modify how the techs perform their work. There is a very good reason for that. More cases than not, problems will result down the line, either short term, or long term.

jn

Hi,

as for the initial Q of this thread:

Make, type and alloy don´t play any rule whatsoever ..... just let it pass.

jauu

Calvin

ps. no pun intended, just joking

as for the initial Q of this thread:

I´d say the solder and wire has to be marked ´PASSed´.Best solder and wire for Pass diy amplifiers ?

Make, type and alloy don´t play any rule whatsoever ..... just let it pass.

jauu

Calvin

ps. no pun intended, just joking

Well, I can't really explain it

Enough said.

or wont

You just said you can't.

Two consecutive thoughts which are mutually exclusive.

Your diatribe does not belong on an intelligent forum.more than the ego scientific f$%^&s

toodles, lemming.

jn

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- Best solder and wire for Pass diy amplifiers ?