An illustrated guide to building the Aleph J

This is a guide to building the Nelson Pass / Firstwatt 'Aleph J' amplifier.

A few links to start off -

Aleph J Manual (From firstwatt.com) http://firstwatt.com/pdf/prod_aj_man.pdf

Amplifier PCB (From DIYaudio) Aleph J (2 PCBs included, which makes 2 channels) - Circuit Boards

Discussion thread - Aleph J for Universal Mounting Spec - diyAudio

Bill of Materials (BOM) - diyAudio

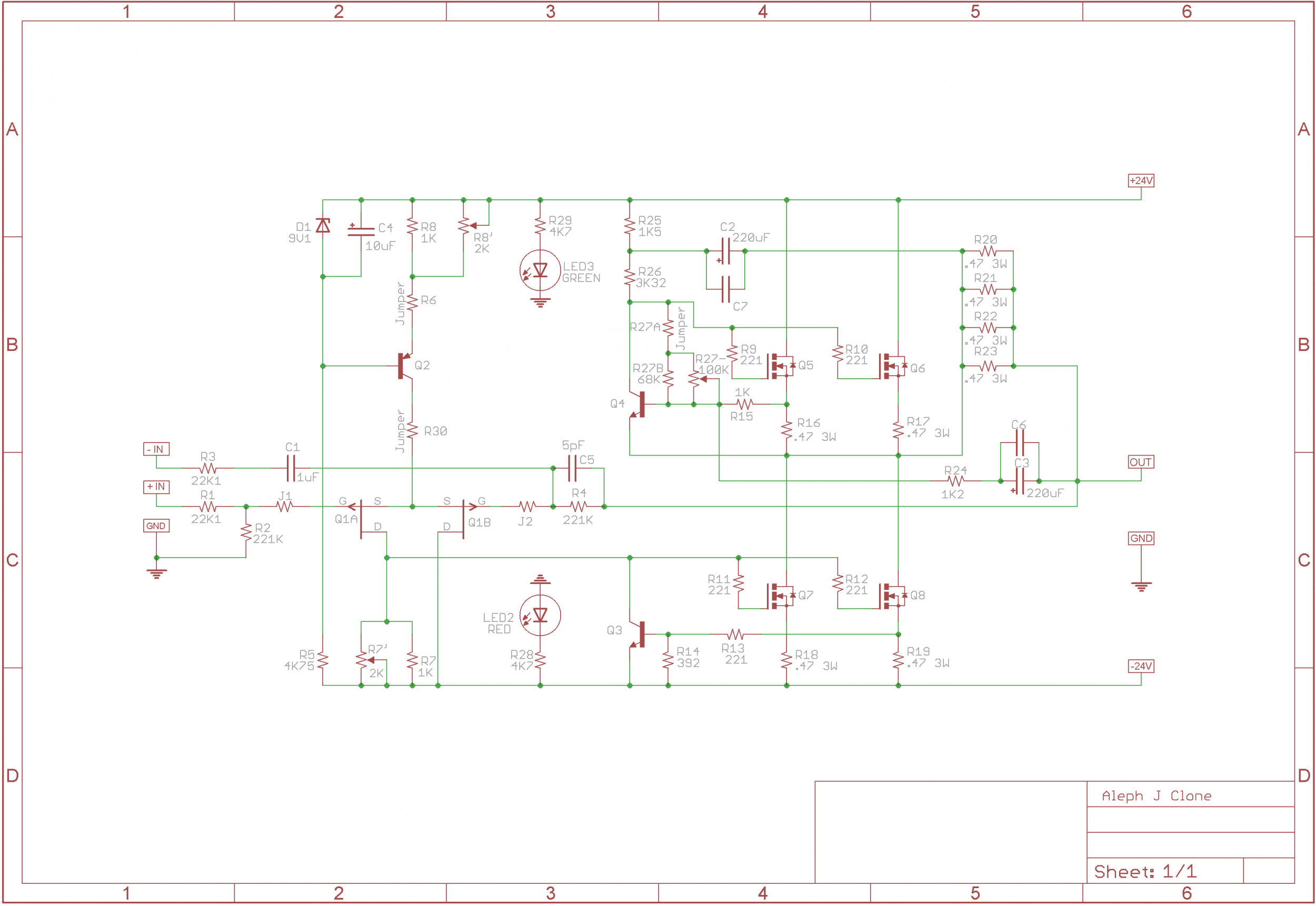

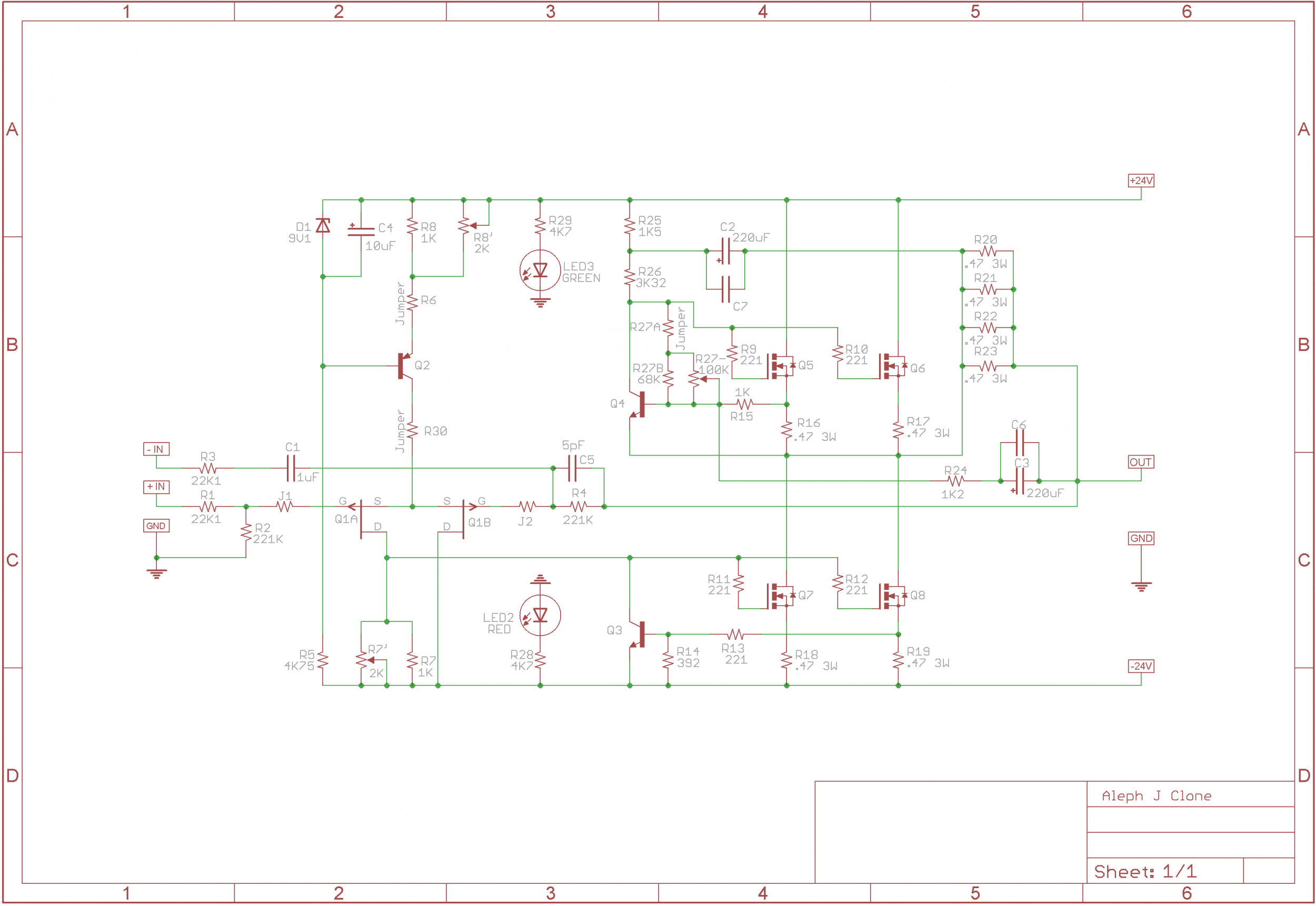

Schematic -

Ok!

The bulk of this guide is going to show the green PCB, which were proof-of-concept prototypes. The boards worked great and we needed to make very minor changes to the production boards, which are blue. There is effectively no difference between the prototype and production boards. Also worth note, the photos of the PCB will be from two different builds, mine (6L6), and Grimberg's. There are no significant differences in how the PCB was stuffed or utilized. I think Grimberg did a prettier job stuffing the PCB than I did. 🙂

Also, this build will show a 5U 'Big Amp Chassis' from the DIYaudio store. (Because that's what I have on hand.) The Aleph J can be made into the 4U 'Jack of all Chassis', everything will fit and the heatsinks are (just) big enough. All the specifics surrounding the 'premium' chassis (back panel, perforated base, pre-drilled heatsink, etc…) are functionally identical, the differences between the 4U and 5U are mainly just size. Regardless of the chassis you use, this amp does get quite hot, and good ventilation will be required around the entire chassis.

On to the guide.

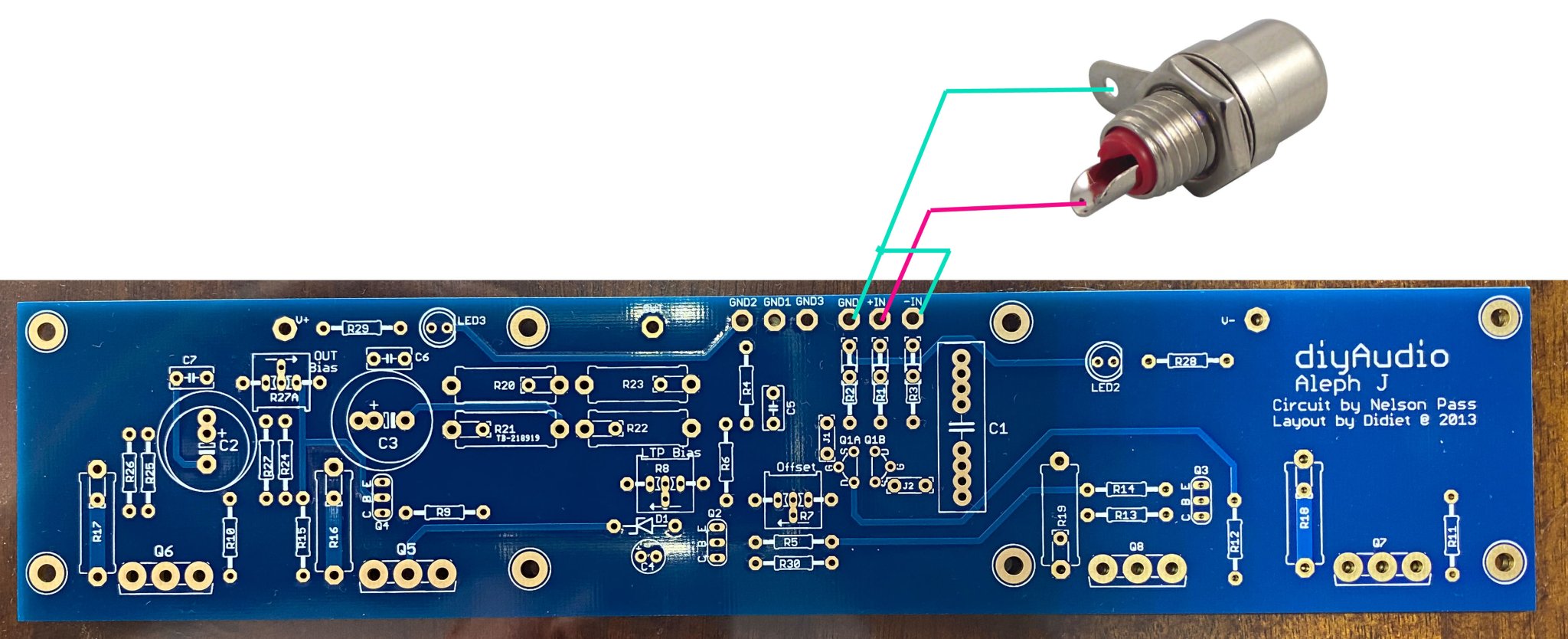

Here is the PCB. It's a great layout, please thank member Didiet78 for his work making this. 😀

Front

Back

Stuffing the PCB

The normal order of operations is to do the little things first and place the bigger things as you proceed.

This PCB has 4 connections that are normally going to be jumpers. (R6, R30, J1, J2) You can see them here. These connections can be jumpered with little bits of wire or cut-off resistor leads, your choice.

These 4 pads are there in case you need to add some resistors in case of oscillation, which may happen to some builds. It's rare, but if you need it, there is place on the PCB to add some compensating devices.

R27. SEE TEXT

Let's talk about this - as it is somewhat confusing.

There are 3 places for R27 on this PCB. The first is the pad next to the cap C2. (in the above photo it is empty) I suggest making that one a jumper.

Where the jumper is placed in the photo should be open, and under the green insulation you will find the place for a pot.

SO - place a 100K pot where the pot will fit and jumper the vertical 'R27'. Set the pot to 68K before you turn the amp on the first time.

Here you can see how the pads for the pot are arranged - (underneath where it says "LTP Bias" and similarly under "offset")

The small oval pads are where the pot connects. The larger round pads outboard of the silkscreen are for a resistor if you choose to put it there in lieu of the pot, or can be used to measure across the pot in circuit. Cool, huh?

Also, it does not matter which of the center pads you use - some pots have all three pins in a row, some have the center pin offset. Either type will be fine.

Add the resistors. Shown here are big-bodied Dale RN60. If these fit, and they do, most other resistors will as well. Use whatever parts suit your fancy.

Now add the bigger (3Watt) resistors. It's a good idea to leave some room between the PCB and the body to let air circulate. As shown here -

The best advice I can give you is this - measure every resistor before inserting into the board.

Continue on with caps and the small transistors

Eventually the board will look something like this -

For reference, know that the Power Mosfets (obviously not mounted yet…) on the Left side of the PCB, near the electrolytic capacitors are for the Constant Current Source, and the Mosfets on the Right side, closer to the red input film capacitor, are the Outputs.

Note that in this photo, the vertical R27 is jumpered, and there is a 68K resistor in the horizontal spot. I later replaced the resistor with a pot.

Here is the pot in that position. I used a single-turn because I had one on hand... I strongly suggest multi-turn pots on all of these projects.

Yes, have my LED colors reversed. The V+ should be red. I've even had it marked backwards in the schematic. Lol. 🙂 You could make them all blue, this is a Pass amp, after all… 🙂

The LED on the PCB are there to show that you have the rails connected and the amp PCB is getting voltage. If you want to extend the leads on one of these and make it a panel light, feel free.

Power Supply

The power supply for the Aleph J is going to follow the basic pattern of the Pass/Firstwatt DIY amplifiers. Please look at the following schematic --

The basic topology is this. 18+18V transformer, of at least 300VA, CRC filter with 8 15,000uF 25V capacitors and 8 (4 per rail) 0.47ohm 3W resistors.

May you use a transformer with more VA? Yes, of course.

May you use larger Capacitors? (more uF) Yes.

May you use capacitors with a different voltage rating? Yes, as long as you have 25V or more. (25V, 50V, etc…)

Remember that the factory Firstwatt amps use 300VA transformers and (8) 15,000uF 25V caps. If that's good enough for Papa… It should be good enough for you. But almost everybody makes it bigger. No problem at all. It's easy, so you might as well... 🙂

In this build I am using the old (smaller) DIYaudio PSU board. This particular one has no blue soldermask on the top of the PCB. It is otherwise identical. The section for the discrete diode bridges has been snapped off.

IMG_0822 - My Photo Gallery

Here shown with the Filter resistors (0.47Ohm, 3W, light blue), the Bleeder (2.2Kohm, 3W, dark blue) and LEDs.

For some reason I can get the LED color correct on this PCB… Red for V+, Green for V-

The PCB can accept (8) caps with 10mm lead spacing and 30mm diameter, or (4) of 35mm diameter. These are 33,000uF 35V Panasonic T-UP series caps.

I prefer to use diode bridges in these monolithic blocks.

Bridge connections.

IEC inlet.

120V AC wiring shown - this is the primaries of the transformer. AC will attach to the center terminals.

You are free to comment or question. 😀

This is a guide to building the Nelson Pass / Firstwatt 'Aleph J' amplifier.

A few links to start off -

Aleph J Manual (From firstwatt.com) http://firstwatt.com/pdf/prod_aj_man.pdf

Amplifier PCB (From DIYaudio) Aleph J (2 PCBs included, which makes 2 channels) - Circuit Boards

Discussion thread - Aleph J for Universal Mounting Spec - diyAudio

Bill of Materials (BOM) - diyAudio

Schematic -

Ok!

The bulk of this guide is going to show the green PCB, which were proof-of-concept prototypes. The boards worked great and we needed to make very minor changes to the production boards, which are blue. There is effectively no difference between the prototype and production boards. Also worth note, the photos of the PCB will be from two different builds, mine (6L6), and Grimberg's. There are no significant differences in how the PCB was stuffed or utilized. I think Grimberg did a prettier job stuffing the PCB than I did. 🙂

Also, this build will show a 5U 'Big Amp Chassis' from the DIYaudio store. (Because that's what I have on hand.) The Aleph J can be made into the 4U 'Jack of all Chassis', everything will fit and the heatsinks are (just) big enough. All the specifics surrounding the 'premium' chassis (back panel, perforated base, pre-drilled heatsink, etc…) are functionally identical, the differences between the 4U and 5U are mainly just size. Regardless of the chassis you use, this amp does get quite hot, and good ventilation will be required around the entire chassis.

On to the guide.

Here is the PCB. It's a great layout, please thank member Didiet78 for his work making this. 😀

Front

Back

Stuffing the PCB

The normal order of operations is to do the little things first and place the bigger things as you proceed.

This PCB has 4 connections that are normally going to be jumpers. (R6, R30, J1, J2) You can see them here. These connections can be jumpered with little bits of wire or cut-off resistor leads, your choice.

These 4 pads are there in case you need to add some resistors in case of oscillation, which may happen to some builds. It's rare, but if you need it, there is place on the PCB to add some compensating devices.

R27. SEE TEXT

Let's talk about this - as it is somewhat confusing.

There are 3 places for R27 on this PCB. The first is the pad next to the cap C2. (in the above photo it is empty) I suggest making that one a jumper.

Where the jumper is placed in the photo should be open, and under the green insulation you will find the place for a pot.

SO - place a 100K pot where the pot will fit and jumper the vertical 'R27'. Set the pot to 68K before you turn the amp on the first time.

Here you can see how the pads for the pot are arranged - (underneath where it says "LTP Bias" and similarly under "offset")

The small oval pads are where the pot connects. The larger round pads outboard of the silkscreen are for a resistor if you choose to put it there in lieu of the pot, or can be used to measure across the pot in circuit. Cool, huh?

Also, it does not matter which of the center pads you use - some pots have all three pins in a row, some have the center pin offset. Either type will be fine.

Add the resistors. Shown here are big-bodied Dale RN60. If these fit, and they do, most other resistors will as well. Use whatever parts suit your fancy.

Now add the bigger (3Watt) resistors. It's a good idea to leave some room between the PCB and the body to let air circulate. As shown here -

The best advice I can give you is this - measure every resistor before inserting into the board.

Continue on with caps and the small transistors

Eventually the board will look something like this -

For reference, know that the Power Mosfets (obviously not mounted yet…) on the Left side of the PCB, near the electrolytic capacitors are for the Constant Current Source, and the Mosfets on the Right side, closer to the red input film capacitor, are the Outputs.

Note that in this photo, the vertical R27 is jumpered, and there is a 68K resistor in the horizontal spot. I later replaced the resistor with a pot.

Here is the pot in that position. I used a single-turn because I had one on hand... I strongly suggest multi-turn pots on all of these projects.

Yes, have my LED colors reversed. The V+ should be red. I've even had it marked backwards in the schematic. Lol. 🙂 You could make them all blue, this is a Pass amp, after all… 🙂

The LED on the PCB are there to show that you have the rails connected and the amp PCB is getting voltage. If you want to extend the leads on one of these and make it a panel light, feel free.

Power Supply

The power supply for the Aleph J is going to follow the basic pattern of the Pass/Firstwatt DIY amplifiers. Please look at the following schematic --

The basic topology is this. 18+18V transformer, of at least 300VA, CRC filter with 8 15,000uF 25V capacitors and 8 (4 per rail) 0.47ohm 3W resistors.

May you use a transformer with more VA? Yes, of course.

May you use larger Capacitors? (more uF) Yes.

May you use capacitors with a different voltage rating? Yes, as long as you have 25V or more. (25V, 50V, etc…)

Remember that the factory Firstwatt amps use 300VA transformers and (8) 15,000uF 25V caps. If that's good enough for Papa… It should be good enough for you. But almost everybody makes it bigger. No problem at all. It's easy, so you might as well... 🙂

In this build I am using the old (smaller) DIYaudio PSU board. This particular one has no blue soldermask on the top of the PCB. It is otherwise identical. The section for the discrete diode bridges has been snapped off.

IMG_0822 - My Photo Gallery

Here shown with the Filter resistors (0.47Ohm, 3W, light blue), the Bleeder (2.2Kohm, 3W, dark blue) and LEDs.

For some reason I can get the LED color correct on this PCB… Red for V+, Green for V-

The PCB can accept (8) caps with 10mm lead spacing and 30mm diameter, or (4) of 35mm diameter. These are 33,000uF 35V Panasonic T-UP series caps.

I prefer to use diode bridges in these monolithic blocks.

Bridge connections.

IEC inlet.

120V AC wiring shown - this is the primaries of the transformer. AC will attach to the center terminals.

You are free to comment or question. 😀

Last edited:

~~~~~~~~~~~~~~~~~~~

Aleph J chassis guide

This guide shows some construction of photos using the DIYaudio store 5U "Big Amp Chassis" with the additional bag of hardware.

The 4U Chassis will also be appropriate for this amp.

The best place to begin is assembly of the heatsinks, which also form the sides of the enclosure. In this photo you can see the galvanized brackets that the black anodized heatsinks will bolt into.

The 5U heatsinks are 2-piece per side, the 4U are a single extrusion.

The UMS bolt pattern is clearly visible.

This is the hardware to assemble the amp.

This build utilizes the "DIY-friendly perforated base plate" shown here with the original packaging of the heatsink brackets and the chassis feet.

The Deluxe chassis back panel, and the chassis faceplate.

The back panel parts kit, includes PCB mounting hardware. (optional)

This shows the contents of the hardware pack from the Back Panel parts Kit.

PCB standoffs.

These may be too short for the Aleph J depending on what output transistors you use, I had no problem with the Fairchild Mosfets, but the IRF might be too thick, requiring the simple fix of using slightly taller hardware.

I haven't used the IRF first-hand and cannot verify that there is or is not an issue. Again the fix is very easy. (All the threads are M3)

Mount standoffs as shown.

The heatsink sides mount to the chassis bottom. (Not shown)

The Perforated baseplate mounts on top of the regular bottom, with the bent edge facing down. You may need taller hardware - I did. (This same screw mounts the feet to the chassis)

This is the hardware for the IEC inlet.

Mount as shown.

Speaker post inside.

Speaker post outside.

All the components of the RCA jack. Note the lip on one of the washers, this goes inside the hole to keep the metal from touching.

Also note the ground lug does not touch the metal, but is insulated by the washers.

Completed back inside.

Outside.

The Feet mount to the Chassis on the same bolt that secures the Heatsink bracket to the chassis bottom.

Bottom middle screw.

Middle screw inside, I used different hardware again, I wanted a bit more girth and some washers.

Both bottom edges should look like this when done.

This photo shows (behind all the various wires, sorry…) the mounting of the heatsink brackets to the heatsinks themselves, the back and the bottom.

Back panel in use.

This photo is of Grimberg's Aleph J, he used a chassis with the blank rear, and drilled himself. Obviously the XLR jacks are different, as well as the use of individual IEC, fuseholder, and power switch instead of the power entry module. It looks great!!

Grimberg's back panel interior. Very nice![/quote]

Post: Aleph J illustrated build guide

Forum: Pass Labs

Assigned Moderators: N/A

Posted by: 6L6

Original Content:

Aleph J chassis guide

This guide shows some construction of photos using the DIYaudio store 5U "Big Amp Chassis" with the additional bag of hardware.

The 4U Chassis will also be appropriate for this amp.

The best place to begin is assembly of the heatsinks, which also form the sides of the enclosure. In this photo you can see the galvanized brackets that the black anodized heatsinks will bolt into.

The 5U heatsinks are 2-piece per side, the 4U are a single extrusion.

The UMS bolt pattern is clearly visible.

This is the hardware to assemble the amp.

This build utilizes the "DIY-friendly perforated base plate" shown here with the original packaging of the heatsink brackets and the chassis feet.

The Deluxe chassis back panel, and the chassis faceplate.

The back panel parts kit, includes PCB mounting hardware. (optional)

This shows the contents of the hardware pack from the Back Panel parts Kit.

PCB standoffs.

These may be too short for the Aleph J depending on what output transistors you use, I had no problem with the Fairchild Mosfets, but the IRF might be too thick, requiring the simple fix of using slightly taller hardware.

I haven't used the IRF first-hand and cannot verify that there is or is not an issue. Again the fix is very easy. (All the threads are M3)

Mount standoffs as shown.

The heatsink sides mount to the chassis bottom. (Not shown)

The Perforated baseplate mounts on top of the regular bottom, with the bent edge facing down. You may need taller hardware - I did. (This same screw mounts the feet to the chassis)

This is the hardware for the IEC inlet.

Mount as shown.

Speaker post inside.

Speaker post outside.

All the components of the RCA jack. Note the lip on one of the washers, this goes inside the hole to keep the metal from touching.

Also note the ground lug does not touch the metal, but is insulated by the washers.

Completed back inside.

Outside.

The Feet mount to the Chassis on the same bolt that secures the Heatsink bracket to the chassis bottom.

Bottom middle screw.

Middle screw inside, I used different hardware again, I wanted a bit more girth and some washers.

Both bottom edges should look like this when done.

This photo shows (behind all the various wires, sorry…) the mounting of the heatsink brackets to the heatsinks themselves, the back and the bottom.

Back panel in use.

This photo is of Grimberg's Aleph J, he used a chassis with the blank rear, and drilled himself. Obviously the XLR jacks are different, as well as the use of individual IEC, fuseholder, and power switch instead of the power entry module. It looks great!!

Grimberg's back panel interior. Very nice![/quote]

Post: Aleph J illustrated build guide

Forum: Pass Labs

Assigned Moderators: N/A

Posted by: 6L6

Original Content:

Placeholder post for

Chassis / Mechanical Assembly

Build a chassis, it's fun! Or buy one, it's easier!

Either way, it's your amp. 🙂 🙂 🙂

Last edited:

Aleph J Bias and Adjustment

The bias and offset adjustment on the Aleph J amp is very straightforward. You only need one volt meter to do it.

Bias is controlled by R27. (This pot actually sets the AC gain of the Aleph Constant Current Source, but it also has a direct effect on bias.) Offset is controlled by R7.

DC offset is very easy - connect your meter, reading DC volts, across the output jacks and adjust R7 until it reads zero.

The most important suggestion is to set R27 to approx. 68K when you install the pot on the PCB, long before you get to this step.

Power up the amp, measure the voltage drop across one of the source resistors on the right side of the PCB. These are the output transistors.

Set R27 so you read approx. 0.35V across this resistor.

Let the amp sit and warm up for 1/2 hour.

Once warm, re-adjust R27 so you read 0.4V (400mV) drop across the resistor.

Now zero the DC offset with R7.

Check to see that the bias didn't change much with the change in offset, re-adjust one more time if necessary.

Place the lid on the amp and let it sit for another 1/2 hour. Check the bias one last time and see if there was any drift with everything to operating temp. The rule of thumb for maximum temperature is 65C on the devices, 55C on the heatsinks.

That's all!

……………………………………….

Now for a few measurements -

I recorded a few datapoints while giving the amp a 1000Hz sinewave of sufficient voltage to drive 1W into a 4 ohm load resistor.

5.64V pk-pk = 1.993V RMS

1.993Vrms^2 = 3.97 / 4ohm = .99W Close enough.

The top trace is the fundamental signal given to the amp. The bottom is the distortion residual waveform. The scale of the distortion analyzer and the oscilloscope is not changed in any photo.

The first measurement is at 0.24V bias. This is .5A or 11W with the 21.2V rails (under load) in my amp.

Why this number? Simple, it's about the minimum bias where the amp seems to behave properly. Lower amounts than this and weird things start to happen as the CCS isn't doing it's job…

This amount of bias sounds fine.

The important thing is to look at the general shape (well behaved, no hiccups, or strange bumps, looks mostly like a sinewave) and size of the distortion residual. (Bottom trace)

And here is the measurement. The meter is set to the 0.3 scale, look at the arc below the mirror and read 0.21%

Now to increase the bias to the recommended amount, 400mV (I had it just on the edge and the meter read .39 when I took the photo….) 400mV bias = .85A = 18W/device

You can see how the distortion residual is smaller, and of a slightly smoother shape.

The scale has not been changed and the distortion is now 0.07%

As this amp is built in a 5U chassis, I will crank the bias to the hottest I want to take it (where the Mosfets are just under 160F / 70C) This is slightly above the 65C recommended for good longevity. The heatsinks are about 130F/55C. I suspect that if I were to use the Keratherm red silpads or thin mica&grease I would have slightly cooler devices and warmer sinks. 500mV bias = 1.06A = 22.55W/device. This is hot. You could not do this if you build your amp in the 4U chassis without a fan somewhere.

Again, the residual is smaller, and flattening out a bit. (Zero distortion would be completely flat.)

http://www.diyaudio.com/forums/redirect-to/?redirect=http://files.diyaudio.com/forums/gallery/data/500/medium/600x334xAJ500mvBiasDA.jpg.pagespeed.ic.9TxW2CqEMI.jpg

So what does making things really hot gain you in THD? The new number is 0.045% This proves that you can decrease distortion a little by increasing the bias, assuming you can keep things cool.

The bias and offset adjustment on the Aleph J amp is very straightforward. You only need one volt meter to do it.

Bias is controlled by R27. (This pot actually sets the AC gain of the Aleph Constant Current Source, but it also has a direct effect on bias.) Offset is controlled by R7.

DC offset is very easy - connect your meter, reading DC volts, across the output jacks and adjust R7 until it reads zero.

The most important suggestion is to set R27 to approx. 68K when you install the pot on the PCB, long before you get to this step.

Power up the amp, measure the voltage drop across one of the source resistors on the right side of the PCB. These are the output transistors.

Set R27 so you read approx. 0.35V across this resistor.

Let the amp sit and warm up for 1/2 hour.

Once warm, re-adjust R27 so you read 0.4V (400mV) drop across the resistor.

Now zero the DC offset with R7.

Check to see that the bias didn't change much with the change in offset, re-adjust one more time if necessary.

Place the lid on the amp and let it sit for another 1/2 hour. Check the bias one last time and see if there was any drift with everything to operating temp. The rule of thumb for maximum temperature is 65C on the devices, 55C on the heatsinks.

That's all!

……………………………………….

Now for a few measurements -

I recorded a few datapoints while giving the amp a 1000Hz sinewave of sufficient voltage to drive 1W into a 4 ohm load resistor.

5.64V pk-pk = 1.993V RMS

1.993Vrms^2 = 3.97 / 4ohm = .99W Close enough.

The top trace is the fundamental signal given to the amp. The bottom is the distortion residual waveform. The scale of the distortion analyzer and the oscilloscope is not changed in any photo.

The first measurement is at 0.24V bias. This is .5A or 11W with the 21.2V rails (under load) in my amp.

Why this number? Simple, it's about the minimum bias where the amp seems to behave properly. Lower amounts than this and weird things start to happen as the CCS isn't doing it's job…

This amount of bias sounds fine.

The important thing is to look at the general shape (well behaved, no hiccups, or strange bumps, looks mostly like a sinewave) and size of the distortion residual. (Bottom trace)

And here is the measurement. The meter is set to the 0.3 scale, look at the arc below the mirror and read 0.21%

Now to increase the bias to the recommended amount, 400mV (I had it just on the edge and the meter read .39 when I took the photo….) 400mV bias = .85A = 18W/device

You can see how the distortion residual is smaller, and of a slightly smoother shape.

The scale has not been changed and the distortion is now 0.07%

As this amp is built in a 5U chassis, I will crank the bias to the hottest I want to take it (where the Mosfets are just under 160F / 70C) This is slightly above the 65C recommended for good longevity. The heatsinks are about 130F/55C. I suspect that if I were to use the Keratherm red silpads or thin mica&grease I would have slightly cooler devices and warmer sinks. 500mV bias = 1.06A = 22.55W/device. This is hot. You could not do this if you build your amp in the 4U chassis without a fan somewhere.

Again, the residual is smaller, and flattening out a bit. (Zero distortion would be completely flat.)

http://www.diyaudio.com/forums/redirect-to/?redirect=http://files.diyaudio.com/forums/gallery/data/500/medium/600x334xAJ500mvBiasDA.jpg.pagespeed.ic.9TxW2CqEMI.jpg

So what does making things really hot gain you in THD? The new number is 0.045% This proves that you can decrease distortion a little by increasing the bias, assuming you can keep things cool.

Last edited:

This post was made in January 2019 and it's got lots of fantastic information - It needs to live up here were it's easy to find:

A couple months back I skimmed through the entire thread in preparation to build the Aleph J, and made notes of the posts I thought might be useful:

Aleph J illustrated build guide

Post 384 and 390 - 6L6 on initial pot values

Aleph J illustrated build guide

Post 602 - note that when using single ended inputs, -in must be shorted to ground at the board. This is why 6L6 pictures seem to have a little wire connecting -in and GND. Better explanation on page 63.

Aleph J illustrated build guide

Post 680 - about which output mosfets to match.

Aleph J illustrated build guide

post 777 - interesting note about skipping input capacitor if you are using a capacitor coupled preamp.

Aleph J illustrated build guide

post 844 through 846 - regarding which way to mount the ZTX devices from the kit on the circuit board.

Aleph J illustrated build guide

Post 863 - How to wire up RCA jacks.

Aleph J illustrated build guide

Post 889 - about max bias temps.

Aleph J illustrated build guide

post 1013 - regarding where to attach purple wire from transformer.

post 1015 - how to test the trimpot resistance once on the PCB.

Aleph J illustrated build guide

Post 1042 - Tie little jfets together for thermal coupling.

Post 1043 - a good warning.

Aleph J illustrated build guide

Post 1165 - on wiring XLR jacks.

Post 1168 - further explanation.

Aleph J illustrated build guide

post 1191 - about how to wire if you have hum.

Aleph J illustrated build guide

Post 1295 - regarding eliminating hum.

Aleph J illustrated build guide

Post 1382 - about good caps to use in the amp.

Aleph J illustrated build guide

Post 1445 - schematic for testing fets.

Aleph J illustrated build guide

Post 1849 - on resistor values that important to match for balanced use.

Aleph J illustrated build guide

Post 1877 - on important cap position

Aleph J illustrated build guide

post 1970 - nice layout for 4U chassis.

Aleph J illustrated build guide

- picture of line thermistor wiring

Aleph J illustrated build guide

- more on cap choices.

Aleph J illustrated build guide

- rubber pad under transformer.

Last edited:

Thanks Jim;Ive been looking forward to this thread.My store boards are on their way to being fully stuffed so its good to know that I'm doing it right.I've to strip out the F5 pcb's and drill and tap the heatsinks and its time to wire the amp up.

Thanks a lot Jim🙂

Aleph J is my first amp diy

with your excellent article learn and build be much enjoyable.

Have a nice day

Aleph J is my first amp diy

with your excellent article learn and build be much enjoyable.

Have a nice day

I am planning an Aleph J build as well. Just planning part collection while building a set of ACAs. Very timely addition of this build guide, TYVM !

A request, could the Aleph J schematic be changed to something readable? Its very small, and does not magnify well. The PSU can be very easily read, not so the amp schematic.

A request, could the Aleph J schematic be changed to something readable? Its very small, and does not magnify well. The PSU can be very easily read, not so the amp schematic.

The link immediately below the schematic should take you to a huge version on the schematic. If it's not working, right-click and open it in a new tab or new window.

Hope I may add some suggestions here.

If the lead spacing of C1 allows for 27.5 mm (to me it seems to) you should consider

this film-foil type instead of the cheaper metallized poly, also available at Mouser:

Mouser 505-FKP41.0/400/10

For C6 & C7 you might consider these (same 5 mm lead spacing as Wima MKP):

Mouser 505-FKP2.022/100/5

Mouser 505-FKP20.033/63/2.5

Where a wider lead spacing is applicable FKP3 is an even better choice.

For C5 I need to say, that at least many using the PCBs of an earlier German group buy

had much better results with 10 pF - both audibly and measured. I have to admit this

might differ depending on the PCB design.

If the lead spacing of C1 allows for 27.5 mm (to me it seems to) you should consider

this film-foil type instead of the cheaper metallized poly, also available at Mouser:

Mouser 505-FKP41.0/400/10

For C6 & C7 you might consider these (same 5 mm lead spacing as Wima MKP):

Mouser 505-FKP2.022/100/5

Mouser 505-FKP20.033/63/2.5

Where a wider lead spacing is applicable FKP3 is an even better choice.

For C5 I need to say, that at least many using the PCBs of an earlier German group buy

had much better results with 10 pF - both audibly and measured. I have to admit this

might differ depending on the PCB design.

Last edited:

I am still waiting for my boards and you guys are all having fun. My boards apparently left the US at Los Angeles on the 21st of August and I still don't have them. Damn, sometimes staying in dark corners of the world bites.

Must .. be .. patient.

I am still waiting for my boards and you guys are all having fun. My boards apparently left the US at Los Angeles on the 21st of August and I still don't have them. Damn, sometimes staying in dark corners of the world bites.

Must .. be .. patient.

they are wonderful youll lovethem.

side note: i got mine already nanana booboo!

couldnt help myself sorry.

Whetted my FirstWatt appetite with the ACA. Such good sound from the simple amp.

Pawing through my left over boxes yielded a quad of Silmic II 220 mF 100v caps. They look to fit well on the board. I also found 4 nice 1 uF film caps from a pair of speaker crossovers that were upgraded. They are about 1 inch long, 1/4 inch diameter. Will they be better or worse bypass caps with the longer leads that will be needed to hook it up? It would be silly to use them, and have them be markedly worse due to longer connections. Actually, I'll put those at C1, and stick with the Wima bypass caps.

Got my boards and 500u case. AnTek Transformer was shipped this week. JFets are here, output transistors from Buzzforb en route. Finish up my Mouser BOM, and I'll be cooking.

Pawing through my left over boxes yielded a quad of Silmic II 220 mF 100v caps. They look to fit well on the board. I also found 4 nice 1 uF film caps from a pair of speaker crossovers that were upgraded. They are about 1 inch long, 1/4 inch diameter. Will they be better or worse bypass caps with the longer leads that will be needed to hook it up? It would be silly to use them, and have them be markedly worse due to longer connections. Actually, I'll put those at C1, and stick with the Wima bypass caps.

Got my boards and 500u case. AnTek Transformer was shipped this week. JFets are here, output transistors from Buzzforb en route. Finish up my Mouser BOM, and I'll be cooking.

Last edited:

- Home

- Amplifiers

- Pass Labs

- Aleph J illustrated build guide