NS, maybe post a photo of your VU meter. I'd like to add some visuals if they are cool and not too complex.

Hi Nrg2009,

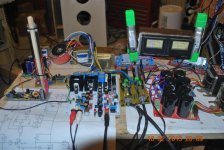

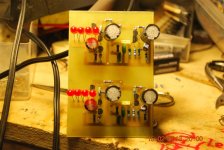

I didn't forget about the plasma vu meters see the pics ,just been busy built 2 Salas Riaa and the shunt supplies for Riaa for my old turntable ( had nothing to plug it into) and also built 2 Salas DCB1's board for a preamp, I will run them Balanced,My F5'ss are water cooled,I am doing a layout for the cabinets to put them all in,Lol,got to have fun,lol

Happy Listening!

NS

Attachments

Last edited:

NoSmoking,

If that is the folded, you are going to like it very much. Be forewarned, it is good enough that it dissapears and is largely defined by the cap at the output. Rush coupled the secondstage to a DCB1, dropping the buffer, and was able to use high quality .1uf cap vs 2+uF recommended for the standard layout. Luckily i was feeding high Zin tube and was able to use a SIO. I wi ll be trying K75 bypassed by teflon next.

If that is the folded, you are going to like it very much. Be forewarned, it is good enough that it dissapears and is largely defined by the cap at the output. Rush coupled the secondstage to a DCB1, dropping the buffer, and was able to use high quality .1uf cap vs 2+uF recommended for the standard layout. Luckily i was feeding high Zin tube and was able to use a SIO. I wi ll be trying K75 bypassed by teflon next.

Anyone have some "cool" power switch suggestions for the front panel of a V2?

Push button round would be nice. I have been looking at Digikey but not really found anything.

Folks:

I was wondering about finding large (25mm) illuminated anti-vandal switches myself; I have a preference for blue ring variants and found the following: http://www.langir.com/46FC2DAD-28AF...-FCBA05499329/pdf/vandal-resistant-switch.pdf

These are rated at 250VAC/5A, which I assume would be suitable for an F5T V2 (120VAC and presumably less than 10A). My attempts at locating a commercial retailer of these switches was unsuccessful, but Langir apparently offers them directly at volumes of at least 20 units. Is there enough interest to justify a group buy?

Regards,

Scott

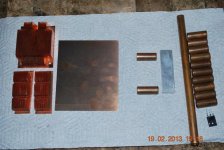

The extra heatsinks arrived today...( see pictures) pfff.. that's a whole new ballgame...

Construction of the case and lay-out inside the case must be reconsidered with this much of height...

And that for "only" 50 Watts of class A into 4 Ohms

Construction of the case and lay-out inside the case must be reconsidered with this much of height...

And that for "only" 50 Watts of class A into 4 Ohms

Attachments

The extra heatsinks arrived today...( see pictures) pfff.. that's a whole new ballgame...

Construction of the case and lay-out inside the case must be reconsidered with this much of height...

And that for "only" 50 Watts of class A into 4 Ohms

Where did you order the heatsinks from?

No, they are Austerlitz KS300.6

Did you buy them direct from austerlitz?

No, I bought them from www.distrelec.nl . It's now a Swedish company, Elsa or so..

Heatsinks are around 50 Euro's a piece...

Walter

Heatsinks are around 50 Euro's a piece...

Walter

Hi oiphy,@ noSmoking. care too tell/show more of your water cooling rig??

If this gets going I'll start a new thread for it so, here's the PLAN,

I will use a radiator with a small fan hopefully whisper type,and I have a thermal switch that is settable to control the temp of the sinks,I am still determining the optimum temp for the fets to operate at I know the limits ,but where's the "sweet spot" for temp vs bias,

The heatsinks themselves came from ebay auctions they are all copper and were called server heatsinks,I cut them in half and covered them with light weight copper sheet,I tried a spray bay and a tube projecting water in the middle of the backside onto the heat sink ,it didn't care so now I run in one end and out the other ,temp over the fet mounting surface is the same temp,so good enough,I used .5 ' copper tube in and out,I soldered it all together with hard solder no leaks so far!

I bought several pumps most of them would have to be out of the listening area due to noise whine,I found these (pic) at harbor freight ,I left them plugged in and really couldn't hear them running at all,so use something like them ,not the motor frame to pump types ,I also cut a piece of aluminum to act as a clamp for the front of the fets,I haven't done this but I am going to shave the fronts of the fet till it's at lease smooth and maybe machine a small piece of aluminum to go in the space between the clamp and the heatsink to transfer as much heat off the front too,

I use neoprene tube no problemswith it so far, use a heat gun to warm it up on the ends and it will slip right on the in/out tubing,

I have the bias at 1.2 and all is well sinks are at 110 degrees,

Transformers are warm so I hope it's all about right,

Comments,Ideas are welcome

NS

Attachments

Finished wiring up a V2 monoblock last night. I am in the process of powering up the first time right now. I'm kinda guessing that P3 gets set near the middle of its range.

Anyhow, here are some photos. New UKToecutter boards, diyA chassis.

The plan is to get it up and running (biased) by tonight.

I'll post more details a bit later when I've got a spare moment and the amp's done.

-Nelson

Hi,

Does anybody know the dimensions of the small PCB?

Thanks

- Home

- Amplifiers

- Pass Labs

- F5 Turbo Builders Thread