Any ideas whether the Hifi2000 5U cases (400 mm depth) are sufficient to house a V3 ?

Can't find dissipation figures anywhere...

From the site - the MODU 5U 400 mm deep unit is good for 295W of disipation with 4 transistors/FETs per side, but they dont quote the temperature rise.

So you wouldneed to build them as mono blocks

Thanks for the explanation Jacco.

I think 200W continuous Class A with considerably higher class AB power to (particularly) low impedance range would be a very desirable option for many mainstream power hogger speakers.

per channel. Quick calculation tells me that at rather not-too-extreme 45V rail voltage, and 1A per FET bias, one could get ~ 250W class and ~500W Class AB continuous to 8 ohm with heat dissipation of 730W per channel. While this number probably sound too good, much higher Class AB power expected under impedance lower than 4 ohm ohm is good for power hogger speakers. No need for exotic electrolytes.

Assuming we find some cheap source via group buy or something in future, do you think this kind of configuration would be good enough for heat sinking requirement of 200W continuous Class A V3, Jacco?

But X leaves class A at merely 40W cotinuous. Of course, these kinds of amp\ make sense only with power hogger like full range electrostatics. Are you saying such speakers don't deserver class A power?Frankly, i have trouble to understand why anyone would be willing to spend so many dollars on such an amp design.

An X600 in X1000 dress, ...... is more elegant, ........

I think 200W continuous Class A with considerably higher class AB power to (particularly) low impedance range would be a very desirable option for many mainstream power hogger speakers.

I was thinking more of balanced V3 with 4 pararell pairs per channel. That means 16 total FETsA source for affordable big can electrolytics with >100V rating (125V surge) would be a big help.

per channel. Quick calculation tells me that at rather not-too-extreme 45V rail voltage, and 1A per FET bias, one could get ~ 250W class and ~500W Class AB continuous to 8 ohm with heat dissipation of 730W per channel. While this number probably sound too good, much higher Class AB power expected under impedance lower than 4 ohm ohm is good for power hogger speakers. No need for exotic electrolytes.

Let's focus on natural convectio, and forget about cost optimization on heat sink for the moment and do some imaginary amp building. How about using 1 of HEATSINK-KL-285(P)/180 for each FETs above? At given literature C/W value of 0.39 and numbers above, the temperature raise is only 18C. And of course, putting them side by side will drastically reduce the sinking efficiency, so how about putting some space between each of them? And since we don't want a out-of-hand-deep amplifer, lets make this as 2 row per each monoblock, each row having 4 heat sinks per side, with 2 inch space present between each heasinks, and with 6 inch space between each row. This will result in roughly 30 deep 20 inch high rectagular monoblock. It certainly is big but not out of hand and in line with what XS series looks like, although I don't have any mean to simulate temperature profile. And yes ,this would cost a lot of money for heat sinks.Without access to a heatsink that's optimised for some 100W dissipation each, at a ballpark figure height of some 10 inches, a natural convection monaural will become pretty voluptuous (aka Fat Betty).

Assuming we find some cheap source via group buy or something in future, do you think this kind of configuration would be good enough for heat sinking requirement of 200W continuous Class A V3, Jacco?

I would be grateful for someone's confirmation of the following calculations as I haven't made a balanced amp before. I understand the calcs for a single ended design but I'm not quite sure exactly about the balanced amp figures.

Here's the plan to get a balanced F5 monoblock giving 100W class A.

Use 2 Mosfets in parallel, so 8 total. Each biased to 1.3A. This should give me 5.2 x 5.2 X 8 = 216W (into 8ohms), which is 108W average.

Use 25V rails. So 25 x 1.3 x 8 = 260W dissipation.

A heat sink with 0.1c/W leads to 26C rise in temp.

The following heat sink PS275 I will cut in half and make a tunnel and use a fan will give me some safety margin.

http://www.gdrectifiers.co.uk/uploads/Heatsinks_for_capsule_devices.pdf

Here's the plan to get a balanced F5 monoblock giving 100W class A.

Use 2 Mosfets in parallel, so 8 total. Each biased to 1.3A. This should give me 5.2 x 5.2 X 8 = 216W (into 8ohms), which is 108W average.

Use 25V rails. So 25 x 1.3 x 8 = 260W dissipation.

A heat sink with 0.1c/W leads to 26C rise in temp.

The following heat sink PS275 I will cut in half and make a tunnel and use a fan will give me some safety margin.

http://www.gdrectifiers.co.uk/uploads/Heatsinks_for_capsule_devices.pdf

Max dissipation, is not the same as constant dissipation.

The Modu shop number is interesting only for Class AB.

wrong

first hand experians. at 220W the 500mm just get up to about 15-17C above ambient.

Frankly, i have trouble to understand why anyone would be willing to spend so many dollars on such an amp design.

An X600 in X1000 dress, with lower rails and higher bias level, is more elegant, more to the point for such an expenditure (and you'll have more backup during the build).

Dear Jacco,

At least in my case, I''m willing to build a heavy duty mosfet amp for pa use. I do have here the boards of the AV1000 amp that I bought from Mr. Holton some time ago but he doesn't seem to want to support this design anymore and I couldn't find anyone that had built it and said it really works. Since I don't want risk losing my o/p Toshiba pairs, I started looking for other designs and came across F5T. I was amazed by "simple" the circuit is (with respect to the number of components) and nothing else has to be said since it a Nelson Pass design. So I thought that v3 with lower bias would fit my needs, but if you know a better design for this purpose please tell me.

Thanks

Daniel

at 220W the 500mm just get up to about 15-17C above ambient.

The 5U-500 case is not a 5U-400.

17C divided by 220W is 0.077 C/W

4 times 0.40C/W for the heatsinks, 0.40C/W added for the rest of the chassis, makes 0.08C/W for the entire case.

The front panel of the case (450 wide x 210 high x 10mm thick) will handle quite a portion of the dissipation, so i'll buy the 17C number.

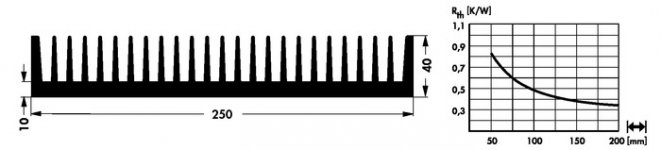

Fischer SK524 =>

Attachments

But X leaves class A at merely 40W continuous.

AR2 built them with lower bias, use enough output devices and plenty heatsink, and bias as high as desired.

The X600/X1000 only differ in size and number, can be scaled to personal flavor in any direction.

Folks:

I sent the following email to SiliconRay:

The SiliconRay chassis that looks to be their best starting point for a big box alternative to HiFi2000's Pisante Dissipante enclosures can be found at RE4015 400 x 150 x 373 Aluminum Enclosure - Boards | Kits | Components | Modules | Tools

Is this a viable solution and, if so, is anyone interested in helping me spec out a custom SilconRay chassis?

Regards,

Scott

I sent the following email to SiliconRay:

Hello:

As you may be aware, Nelson Pass recently posted a new schematic for the F5 Turbo. This new design has garnered a lot of interest on diyaudio.com, but the F5 Turbo design is a big Class A amplifier with very demanding heatsinking requirements. I was wondering whether you could develop a custom enclosure, similar to but much larger than your RE4015 400 x 150 x 373 Aluminum Enclosure. If so, and if it was adequately sized, it would likely be very popular amongst those of us who would like to build large stereo or monoblock F5 Turbo amplifiers.

If you can offer it at a reasonable cost, I would be happy to assess interest at diyaudio.com for such a custom amp enclosure. I might also be willing to organize a group buy. But you would need to provide information about the enclosure first (size, c/w rating for heatsinks, price, etc). Are you interested?

SiliconRay responded with the following:As you may be aware, Nelson Pass recently posted a new schematic for the F5 Turbo. This new design has garnered a lot of interest on diyaudio.com, but the F5 Turbo design is a big Class A amplifier with very demanding heatsinking requirements. I was wondering whether you could develop a custom enclosure, similar to but much larger than your RE4015 400 x 150 x 373 Aluminum Enclosure. If so, and if it was adequately sized, it would likely be very popular amongst those of us who would like to build large stereo or monoblock F5 Turbo amplifiers.

If you can offer it at a reasonable cost, I would be happy to assess interest at diyaudio.com for such a custom amp enclosure. I might also be willing to organize a group buy. But you would need to provide information about the enclosure first (size, c/w rating for heatsinks, price, etc). Are you interested?

Thanks for the good suggestion. Of course we can develop a custom enclosure. The height and depth of RE4315 can be modified in any other size.

We can start the custom project if there's enough demand (15 or 20 pcs) on such enclosure.

Probably you should discuss with the DIYers about the size, cutout and accessories. We are capable of arrange almost everything necessary (from enclosure to components, PCB, transformers) for this project.

Actually there're several other custom made DIY projects is under discussion in the forum, all started by other members. The nCore enclosure project has already begun.

We can start the custom project if there's enough demand (15 or 20 pcs) on such enclosure.

Probably you should discuss with the DIYers about the size, cutout and accessories. We are capable of arrange almost everything necessary (from enclosure to components, PCB, transformers) for this project.

Actually there're several other custom made DIY projects is under discussion in the forum, all started by other members. The nCore enclosure project has already begun.

The SiliconRay chassis that looks to be their best starting point for a big box alternative to HiFi2000's Pisante Dissipante enclosures can be found at RE4015 400 x 150 x 373 Aluminum Enclosure - Boards | Kits | Components | Modules | Tools

Is this a viable solution and, if so, is anyone interested in helping me spec out a custom SilconRay chassis?

Regards,

Scott

the5 500mm can handle 300WThe 5U-500 case is not a 5U-400.

17C divided by 220W is 0.077 C/W

4 times 0.40C/W for the heatsinks, 0.40C/W added for the rest of the chassis, makes 0.08C/W for the entire case.

The front panel of the case (450 wide x 210 high x 10mm thick) will handle quite a portion of the dissipation, so i'll buy the 17C number.

Fischer SK524 =>

ond the 400mm can sure handle 250W

and what the hell are your numbers worth when real life expeiance say otherwise?the5 500mm can handle 300W

ond the 400mm can sure handle 250W

It seems that I missed the bus for F5 turbo. Looks like an interesting project. Is it too late to design a F5 turbo board to offering free (just like JLH) now? Or sombody can give me the gerber for fabrication?

I received several demand on the enclosure for F5 and F5 turbo these days. Everybody is intended to a larger version of RE4015

I received several demand on the enclosure for F5 and F5 turbo these days. Everybody is intended to a larger version of RE4015

Last edited:

I like how it looks. But I for one would certainly would like larger heat sinking capability. I think 100W + alpha class A capability per enclosure would be desirable to most. ( with alpha bieng enough margin). This will allow V2 builder to use single box for stereo amp with continuous class A 50W / chan and V3 builder to use single box for 100W continuous class mono block. And some crazys can build up big cube monoblock using 2 boxes per channel for their seemingly obscene and illegalFolks: I sent the following email to SiliconRay: ------------

the RE4015 is originally designed for a 30W stereo class A. that means it's enough for 60W mono block. the width can't be modified but height and depth are variable. I think a 400x400x200 would be enough for a 100W mono block.

That would only be adding 50mm(2 inches) to the height. Not sure it would be enough.

If want to make your amp looks like a monster cost $5000 you may need this enclosure. size 480x230x440

Personally I don't like it's apperence although it's extremely well built. But we just manufacture per the customer's design. This modle is also allowed to be supplied to DIYers now.

Personally I don't like it's apperence although it's extremely well built. But we just manufacture per the customer's design. This modle is also allowed to be supplied to DIYers now.

Attachments

then 250mm height? be care the depth is also extended to 400mm. original depth is 317mm.

That would only be adding 50mm(2 inches) to the height. Not sure it would be enough.

Interesting.. although for now I fail to see the advantage over the hifi2000 enclosures (of course except Siliconray's active involvement and support here  )

)

As the rest of my diy stuff is based on their enclosures, and they are based in Europe, I would prefer hifi2000, of course except Siliconray can provide additional benefits, e.g.

-customizing for this project

-cost benefits

-better heatsinking properties

-etc.

As the rest of my diy stuff is based on their enclosures, and they are based in Europe, I would prefer hifi2000, of course except Siliconray can provide additional benefits, e.g.

-customizing for this project

-cost benefits

-better heatsinking properties

-etc.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- F5 Turbo Circuit Boards