A piece of bad news today, unfortunately.

Both team members for PCB layout are temporary out of action, due to computer problems and unexpected events.

Though they both emailed to say they would try to catch up, I have asked them to take their time to get things properly settled first.

There are more important things in life than this hobby.

For the delay, I beg for your understanding.

Patrick

.

Both team members for PCB layout are temporary out of action, due to computer problems and unexpected events.

Though they both emailed to say they would try to catch up, I have asked them to take their time to get things properly settled first.

There are more important things in life than this hobby.

For the delay, I beg for your understanding.

Patrick

.

Last edited:

A piece of bad news today, unfortunately.

Both team members for PCB layout are temporary out of action, due to computer problems and unexpected events.

Though they both emailed to say they would try to catch up, I have asked them to take their time to get things properly settled first.

There are more important things in life than this hobby.

For the delay, I beg for your understanding.

Patrick

.

there are indeed, we've waited this long, whats another short while. no sense rushing and risking further problems, or risking your health working too hard. all the same of course i hope things sort themselves out soon, but not at the expense of the developers

transformer

Hi qusp,

I too have not heard from fitzfish. I sent an inquiry to SumR with EUVL's recommended specs and received the following reply:

I was wondering what transformer you (and others) were ordering.

well i have received no reply from fitzfish on the transformer query. perhaps he will see here. perhaps i am not worthy?anyone else in the build team i can contact who might know?

perhaps the switch to fets also was congruent with his advertising byline creating 'all fet' designs hehe

Hi qusp,

I too have not heard from fitzfish. I sent an inquiry to SumR with EUVL's recommended specs and received the following reply:

A/ Re 500VA toroid

- your max dimensions 150 x 75 allow for a larger core, which allows for

winding heavier wire.

- However, to wind heavy wire bifilar becomes a difficulty, both in size of

machine and amount of stress one has to put on the core when winding.

- we can wind, on this larger core, the heavy awg wire, but only single

file.

- You have asked for everything to be Class B 130C. All transformer parts

used in assembly meet 130C, except the stranded leads 105C which are in

stock.

Please let us know if you require teflon or other higher temperature

leads as this adds to cost.

- The secondaries can be solid wire, with sleeving, again all sleeving in

stock is UL listed Class A 105C.

I was wondering what transformer you (and others) were ordering.

yeah i got the same reply this morning, except one of us ordered a 600va version, seems 500va is the limit. but havent thought about the email yet, only just woke up. we need some input here from patrick, or someone who knows, because we were given rather specific instructions for the order by Patrick, so i'm not sure whether the limitations and lack of biflar is a deal killer.

also i gave him the model number generated by the enquiries, i wasnt expecting to get questions back since he made the number

also i gave him the model number generated by the enquiries, i wasnt expecting to get questions back since he made the number

Last edited:

Here is what the invoice said:

RC0600 915 5 banded transformer

My invoice number is 5149.

Hope this will help.

The transformer Mark Lai ordered has not yet arrived, so I cannot give you many more details.

Fitzfish will be out of action for a while for reasons I promised not to disclose. Please try to understand.

As I said, there are thing in life much more important than this hobby.

I can give you my opinion to those questions.

But since we already ordered once, I don't want to add to the confusion.

Please be patient for a few weeks.

Thx,

Patrick

Fitzfish will be out of action for a while for reasons I promised not to disclose. Please try to understand.

As I said, there are thing in life much more important than this hobby.

I can give you my opinion to those questions.

But since we already ordered once, I don't want to add to the confusion.

Please be patient for a few weeks.

Thx,

Patrick

The transformer Mark Lai ordered has not yet arrived, so I cannot give you many more details.

Fitzfish will be out of action for a while for reasons I promised not to disclose. Please try to understand.

As I said, there are thing in life much more important than this hobby.

I can give you my opinion to those questions.

But since we already ordered once, I don't want to add to the confusion.

Please be patient for a few weeks.

Thx,

Patrick

No doubt that real life takes priority. I wasn't complaining about Fitzfish. I wish him well.

While trying to give fitzfish more time, I shall post a few comments to SumR’s reply :

a) There is no need to use up the maximum volume completely. A 500VA core already has quite some reserve. If one were to go for a 600VA core (as we did in the GB), it is only for the reason that the core will have even more margin from magnetic saturation, and hence should be quieter. The winding is still 500VA. It is not necessary to go to a heavier winding.

b) Bifilar winding means that the 2 secondaries are wound side-by-side. This means that they see the same magnetic fields, and hence gives the same output voltage. The inter-winding capacitance also increases, and this has been used advantageously e.g. by Plitron in their NBT transformers :

6moons audio reviews: BPT BP-3.5 Signature

But it is not must have. If SumR feels happier without bifilar for whatever reasons, then so be it.

c) The specification I wrote was based on a transformer with enamel wires (where Class B insulation is standard and also required inside the transformer) as output leads, and not stranded wires. Various other people wanted stranded leads for the GB, so that’s why it came with stranded leads. There is no need to specify 130°C insulation for the output leads, so Class A is good enough. There is no need to go teflon.

As always, the above only represent my personal opinion. I am no expert in transformer design, and we have not tested the SumR toroidals as yet. If you do not want ot wait for your results and want to go ahead now, for whatever reason, I suggest that you should at least inform yourselves by looking into issues like bifilar winding, insulation classes, etc. before making any decision.

On top of that, you can always open a new thread just for power transformers, and ask Nelson of his opinion. It is his daily bread & butter, as opposed to just a hobby for me.

Patrick

a) There is no need to use up the maximum volume completely. A 500VA core already has quite some reserve. If one were to go for a 600VA core (as we did in the GB), it is only for the reason that the core will have even more margin from magnetic saturation, and hence should be quieter. The winding is still 500VA. It is not necessary to go to a heavier winding.

b) Bifilar winding means that the 2 secondaries are wound side-by-side. This means that they see the same magnetic fields, and hence gives the same output voltage. The inter-winding capacitance also increases, and this has been used advantageously e.g. by Plitron in their NBT transformers :

6moons audio reviews: BPT BP-3.5 Signature

But it is not must have. If SumR feels happier without bifilar for whatever reasons, then so be it.

c) The specification I wrote was based on a transformer with enamel wires (where Class B insulation is standard and also required inside the transformer) as output leads, and not stranded wires. Various other people wanted stranded leads for the GB, so that’s why it came with stranded leads. There is no need to specify 130°C insulation for the output leads, so Class A is good enough. There is no need to go teflon.

As always, the above only represent my personal opinion. I am no expert in transformer design, and we have not tested the SumR toroidals as yet. If you do not want ot wait for your results and want to go ahead now, for whatever reason, I suggest that you should at least inform yourselves by looking into issues like bifilar winding, insulation classes, etc. before making any decision.

On top of that, you can always open a new thread just for power transformers, and ask Nelson of his opinion. It is his daily bread & butter, as opposed to just a hobby for me.

Patrick

I just open a new thread to promote discussions and exchange of experiences on the power transformers :

http://www.diyaudio.com/forums/pass...r-class-amplifiers-what-your-experiences.html

Patrick

http://www.diyaudio.com/forums/pass...r-class-amplifiers-what-your-experiences.html

Patrick

Some news :

We got some but not all of the parts for the prototype case.

Will post some photos of loose parts middle of next week.

Patrick

I've been looking forward to this one...

I can only apologise for the delays. A lot of those are not up to me.

We have had bad luck of a computer crash and other unexpected domestic matters that hinders the progress of the PCBs, although we are weeks away only (only the main amp daughter board to do).

There is a economic boom in Asia right now, which means the workshops are short of people, and the order books are full. You can understand that prototyping for a hobby project will not have any priority, and quite rightly so.

But we are discussing with the forum on details now, which is progress. So I still hope to be able to finish the prototype case before Easter, and the PCB testing depends again on how long the vendor will take. The circuit optimisation will take longer.

For those who cannot wait, I can only encourage you to make a working prototyping first using a pair of the standard F5 board you can purchase from the forum (using e.g. cheaper parts like IRFP MOSFETs), and then upgrade later.

Thank you again for your continuous support,

Patrick

We have had bad luck of a computer crash and other unexpected domestic matters that hinders the progress of the PCBs, although we are weeks away only (only the main amp daughter board to do).

There is a economic boom in Asia right now, which means the workshops are short of people, and the order books are full. You can understand that prototyping for a hobby project will not have any priority, and quite rightly so.

But we are discussing with the forum on details now, which is progress. So I still hope to be able to finish the prototype case before Easter, and the PCB testing depends again on how long the vendor will take. The circuit optimisation will take longer.

For those who cannot wait, I can only encourage you to make a working prototyping first using a pair of the standard F5 board you can purchase from the forum (using e.g. cheaper parts like IRFP MOSFETs), and then upgrade later.

Thank you again for your continuous support,

Patrick

no need to apologize, though i understand the compulsion, even when something is beyond your control it is still easy to feel something when people are waiting. there really is no reason to be sorry for doing a nice thing for the forum members, even if slowly, but surely; many of whom are strangers to you. we will be here ready and waiting and when you are ready you will not get the smiles off our faces.

keep up the good work, we really do appreciate it!!!

keep up the good work, we really do appreciate it!!!

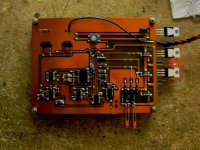

I had some time today and got the control & protection board working.

This is the start up state.

The mains relay to the 500VA transformer will turn on 2 seconds after power on switch. (as represented by the red LED top right).

.

This is the start up state.

The mains relay to the 500VA transformer will turn on 2 seconds after power on switch. (as represented by the red LED top right).

.

Attachments

Last edited:

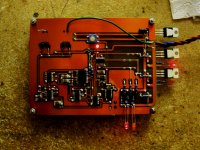

One press of the push button (blue) will put it to the standby state, where the regulators would be turned on (as indicated by the red LED bottom left), but the inputs are still shunted, and the outputs are disconnected (if you choose to use a series speaker protection relay).

The red LED on the front panel will also turn on (middle, below the push button).

The red LED on the front panel will also turn on (middle, below the push button).

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- F5X -- the EUVL Approach

, all true but

, all true but