Hi all,

i have been posting various questions in these forums about an F2 build i am starting. when i actually begin i will start a build thread for all my questions but for now i am buying parts and have a question regardin heatsink choices.

the extrusions available here (in Bombay, India) all have horizontal fins. i can turn these on their side and make the fins vertical but then my heatsink length is limited to the width of the extrusion.

How much of a difference does it make if the fins are horizontal?

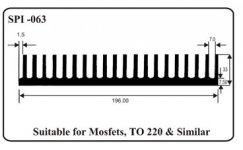

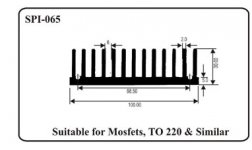

i am thinking of a length of about 14 inches. the heatsinks will make up the sides of my enclosure. can you please look at the images i have attached and advise.

thanks

mymindinside

i have been posting various questions in these forums about an F2 build i am starting. when i actually begin i will start a build thread for all my questions but for now i am buying parts and have a question regardin heatsink choices.

the extrusions available here (in Bombay, India) all have horizontal fins. i can turn these on their side and make the fins vertical but then my heatsink length is limited to the width of the extrusion.

How much of a difference does it make if the fins are horizontal?

i am thinking of a length of about 14 inches. the heatsinks will make up the sides of my enclosure. can you please look at the images i have attached and advise.

thanks

mymindinside

Attachments

this is the width of the sink, i can get it any length i want, i was just wondering about the horizontal fins

for eg: if i choose the spi-063 then the width of the heatsink is 7.7 inches and the length is 14in (or any length i want) with the fins running horizontally.

the F2's rated power consumption is 75w/ch. is it correct to assume that most of this is dumped as heat through the sinks?

Maybe i should articulate my question better: should i look for longer thinner fins that are closely packed together, or thicker fins that are farther apart? is it better to have a thicker base?

for eg: if i choose the spi-063 then the width of the heatsink is 7.7 inches and the length is 14in (or any length i want) with the fins running horizontally.

the F2's rated power consumption is 75w/ch. is it correct to assume that most of this is dumped as heat through the sinks?

Maybe i should articulate my question better: should i look for longer thinner fins that are closely packed together, or thicker fins that are farther apart? is it better to have a thicker base?

Last edited:

one device dissipating 37W on a 14inch length of 063 might just run cool enough.

If that did work, then you would need four 14inch lengths for a stereo amp.

The basic problem is that all the sinks are too thin, the 063 is only 7.5mm thick and that restricts good conduction out to a 75mm radius from the device. The sink beyond 75mm gets colder the further it is from the device.

If that did work, then you would need four 14inch lengths for a stereo amp.

The basic problem is that all the sinks are too thin, the 063 is only 7.5mm thick and that restricts good conduction out to a 75mm radius from the device. The sink beyond 75mm gets colder the further it is from the device.

Banned

Joined 2002

Banned

Joined 2002

i am still looking but i think the shipping to india will be prohibitively expensive.where is this seller located?

Here you go, Aluminum Extrusion HeatSink DIY Amp Kit IGBT Cooling - eBay (item 250509769380 end time Jan-04-10 08:41:32 PST)

And here is more searches for you

Extrusion HeatSink, great deals on Business Industrial on eBay!

SPI-063 looks close to whats suggested in F5 manual, one fore each device

But the bay thing looks nice, and cut to make fore cheapest possible shipping

4 of those would fine too

Tho, 4 of this would be my choise http://cgi.ebay.com/HEATSINK-ALUMIN...emQQptZLH_DefaultDomain_0?hash=item2a0381cc2c

Due to shipping I bought from Germany, but had to realise shipping was just as costly from there

Crazy world

But the bay thing looks nice, and cut to make fore cheapest possible shipping

4 of those would fine too

Tho, 4 of this would be my choise http://cgi.ebay.com/HEATSINK-ALUMIN...emQQptZLH_DefaultDomain_0?hash=item2a0381cc2c

Due to shipping I bought from Germany, but had to realise shipping was just as costly from there

Crazy world

Last edited:

i have checked with conrad but again the shipping is prohibitively expensive.

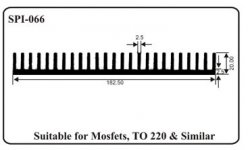

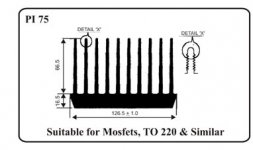

i found another extrusion with a thicker base..

please have a look and advise, it is not so wide so i can make it longer to get the needed dissipation. it has a thick base and long, serrated fins.

thanks

mymindinside

i found another extrusion with a thicker base..

please have a look and advise, it is not so wide so i can make it longer to get the needed dissipation. it has a thick base and long, serrated fins.

thanks

mymindinside

Attachments

stack two vertically forces warm air over the upper sink fins and makes the upper sink run hotter than the lower sink.Have decided to order a 7" length for each FET and stack two of these vertically on each side of the enclosure. this means that my enclosure will be 7in high and 10in deep....

hope its cool enough

This will force the two FETs to warm up at different speeds and to different temperatures.

Stack the sinks horizontally (side by side) with the fins vertical. Or wrap the four sinks around the perimeter of the amplifier chassis.

stack two of these vertically on each side of the enclosure

I suppose you mean horisontal side by side

Fins should be vertical(length)

Also remember to have good air circulation inside box

If you let the air excape along the top of heatsinks, you create some convection, making the cooling more efficient

And ofcourse fresh air should come in at the bottom of box, to make it happen

I'm sorry what i meant to say is that i would stack them side by side with the fins vertical, the same as you reccomend. the sinks will make up the sides of

the enclosure, so the fins will be exposed.

i am thinking of a al. mesh for the top and atleast part of the bottom to allow ventilation inside the enclosure.

i want to be extra safe because summer temperatures here touch 45-48 degrees C. if i was to put a fan (or two) to help cooling, where would the most effective place be? i was thinking of putting a fan under each heatsink blowing air upwards. is this more effective than having a fan blowing air onto the FET and the inner surface of the heatsink?

Do both the Mosfets in the F2 (the ccs and the output) get equally hot? right now i have an equal heatsink for both of them.

hope that isnt too many questions in one post, but i want to do the best job i can,

thanks again guys for all the help

cheers,

mymindinside

the enclosure, so the fins will be exposed.

i am thinking of a al. mesh for the top and atleast part of the bottom to allow ventilation inside the enclosure.

i want to be extra safe because summer temperatures here touch 45-48 degrees C. if i was to put a fan (or two) to help cooling, where would the most effective place be? i was thinking of putting a fan under each heatsink blowing air upwards. is this more effective than having a fan blowing air onto the FET and the inner surface of the heatsink?

Do both the Mosfets in the F2 (the ccs and the output) get equally hot? right now i have an equal heatsink for both of them.

hope that isnt too many questions in one post, but i want to do the best job i can,

thanks again guys for all the help

cheers,

mymindinside

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- Look at these heatsink diagrams for F2 please