XJ Balanced connected.

+ Page

R11/R18 R12/R19 = 3.31Volt

R9/R16 R10/R17 = 3,89Volt

R16 - R19 = 0Volt

R7=3.4Volt

- Page

R11/R18 = 4,36 Volt

R12/R19 = 4,68Volt

R9/R16 R10/R17 = 4,19Volt

R16 - R19 = 0,52Volt

R7= 4,3Volt

Out +/- 16,2 Volt

Only - Page

- Page

R11/R18 = 3,26 Volt

R12/R19 = 3,48Volt

R9/R16 R10/R17 = 3,19Volt

R16 - R19 = 0,05Volt

R7= 2,21Volt

Out +/- 16,2 Volt

+ Page

R11/R18 R12/R19 = 3.31Volt

R9/R16 R10/R17 = 3,89Volt

R16 - R19 = 0Volt

R7=3.4Volt

- Page

R11/R18 = 4,36 Volt

R12/R19 = 4,68Volt

R9/R16 R10/R17 = 4,19Volt

R16 - R19 = 0,52Volt

R7= 4,3Volt

Out +/- 16,2 Volt

Only - Page

- Page

R11/R18 = 3,26 Volt

R12/R19 = 3,48Volt

R9/R16 R10/R17 = 3,19Volt

R16 - R19 = 0,05Volt

R7= 2,21Volt

Out +/- 16,2 Volt

Last edited:

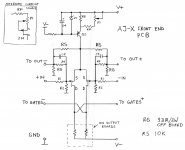

My aleph XJ is not working proberly.

RP = Euvl Version J74, capacitor + after Rp before P1, - ground.

Measuring points

R7 = 4,3V setpoint.

only + circuit board

R7= 4,6 V

only - circuit board

R7= 2,21V

sym. boards (+ and - board )

R7 + Boards = 3,4V

R7 - boards = 4,3V

Measuring points

P1 over R16 .

only + circuit board

R16 = 0,55V

only - circuit board

R16 = 0,05V

sym. boards (+ and - board )

R16 + board = 0,00V

R16 - board = 0,52V

Measuring points

R9 - R16 = 4,3V setpoint.

only + circuit board

R9 - R16 = 4,0V

only - circuit board

R9 - R16 = 3,89

sym. boards (+ and - board )

R9 - R16 + board 3,89V

R9 - R16 - board 4,19V

Out over RG (100R, 100W) max 50,0 mV DC

out only + board = 10,32V

out only - board = 0,00V

Out over + Board and – Board = 16,2 V

I hope the measurements are understandable.

My question, is 2SJ109 (Q1B) defective?

Pictures only with connected + board.

Lg Dirk

RP = Euvl Version J74, capacitor + after Rp before P1, - ground.

Measuring points

R7 = 4,3V setpoint.

only + circuit board

R7= 4,6 V

only - circuit board

R7= 2,21V

sym. boards (+ and - board )

R7 + Boards = 3,4V

R7 - boards = 4,3V

Measuring points

P1 over R16 .

only + circuit board

R16 = 0,55V

only - circuit board

R16 = 0,05V

sym. boards (+ and - board )

R16 + board = 0,00V

R16 - board = 0,52V

Measuring points

R9 - R16 = 4,3V setpoint.

only + circuit board

R9 - R16 = 4,0V

only - circuit board

R9 - R16 = 3,89

sym. boards (+ and - board )

R9 - R16 + board 3,89V

R9 - R16 - board 4,19V

Out over RG (100R, 100W) max 50,0 mV DC

out only + board = 10,32V

out only - board = 0,00V

Out over + Board and – Board = 16,2 V

I hope the measurements are understandable.

My question, is 2SJ109 (Q1B) defective?

Pictures only with connected + board.

Lg Dirk

Attachments

Last edited:

Hello Thanks for the help.

The amplifier sings.

But I still have a small problem.

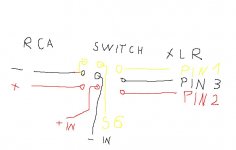

If I have connected both channels via rca with a CD player, a slight hum comes out of the speakers in the break position.

If only the right or left channel is connected, the humming is not there.

The amplifier sings.

But I still have a small problem.

If I have connected both channels via rca with a CD player, a slight hum comes out of the speakers in the break position.

If only the right or left channel is connected, the humming is not there.

Did you short the XLR neg pin to ground pin on both channels?Hello Thanks for the help.

The amplifier sings.

But I still have a small problem.

If I have connected both channels via rca with a CD player, a slight hum comes out of the speakers in the break position.

If only the right or left channel is connected, the humming is not there.

I have a switch for switching between XLR and RCA.

IN the RCA position is negative and mass is bridged.

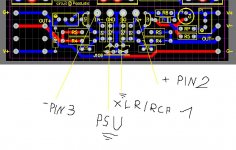

Could now only take pictures of the assembled amplifier.

I don't think this is very strong.

IN the RCA position is negative and mass is bridged.

Could now only take pictures of the assembled amplifier.

I don't think this is very strong.

Attachments

Sorry the bad drawing hopefully can recognize something.

Both inputs RCA short-circuited, no humming.

I found an error.

NTC on 1board, 2 pcb connected to metal abtan holders, NTC bridged.

( Only CD player (Euro plug) slight humming. CD and preamplifier (Schukostecker) very strong humming.)

Both inputs RCA short-circuited, no humming.

I found an error.

NTC on 1board, 2 pcb connected to metal abtan holders, NTC bridged.

( Only CD player (Euro plug) slight humming. CD and preamplifier (Schukostecker) very strong humming.)

Attachments

......

I found an error.

......

that means - no more hum, or it is still huming, with preamplifier connected?

now, you know that - when one apparatus in chain is connected to safety GND, you can lift other ones from safety GND, either in organized way ( option in apparatus itself) or with "cheater" plug - sometimes even simple isolating Schuko contacts on Schuko connector with sturdy isolation tape is good enough

Hello Pos.

1-4 after warming up and adjusting without load, preamplifier RCA and speakers connected.

1. Upper board with capacitors insulated by plastic spacer, Strong hum.

2. Scam plug built, strong humming.

3. 100 ohm resistors installed in the ground line PSU, but no longer rest stable bais. Values are constantly changing.

4. CL 60 mass input removed from the board and placed directly on the star mass.

The amplifier starts to swim, no longer holds values and knocks loud 50 HZ.

With and without a scammer plug.

LG Dirk

1-4 after warming up and adjusting without load, preamplifier RCA and speakers connected.

1. Upper board with capacitors insulated by plastic spacer, Strong hum.

2. Scam plug built, strong humming.

3. 100 ohm resistors installed in the ground line PSU, but no longer rest stable bais. Values are constantly changing.

4. CL 60 mass input removed from the board and placed directly on the star mass.

The amplifier starts to swim, no longer holds values and knocks loud 50 HZ.

With and without a scammer plug.

LG Dirk

Attachments

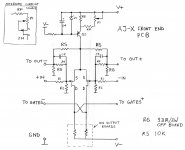

Hello,

the JX sings wonderfully without humming, but the Bais values always change.

One day the values hold, the next day they change continuously.

I now want to build Peter's circuit using BJT, but I can't find a value for RP and P1.

After looking at the JX circuit, P1 / RP are parallel to R8 (1KOhm original J).

If I can take R8 2.2 KOhm, RP 1KOhm and P1 5KOhm, then I can regulate below and above 1KOhm R8.

the JX sings wonderfully without humming, but the Bais values always change.

One day the values hold, the next day they change continuously.

I now want to build Peter's circuit using BJT, but I can't find a value for RP and P1.

After looking at the JX circuit, P1 / RP are parallel to R8 (1KOhm original J).

If I can take R8 2.2 KOhm, RP 1KOhm and P1 5KOhm, then I can regulate below and above 1KOhm R8.

Attachments

- Home

- Amplifiers

- Pass Labs

- Aleph J-X Amp Project