I've been itchin to go ahead with water-cooling for quite some time now. I've spoken to NP regarding raising the front end bias on the Aleph, and he definitely helped me figure out what needed to be changed. Do any other values around the front end need to be changed if i'm doubling the front end bias? FQP3P20 for the diff pair and 12 FQA19N20C for the outputs.

The cold plate is part# 6P-12, 10"x12", 0.0033 Rth, 6 pass. The part is 200USD; a bit pricey, but better than shelling out 500-600 or more for huge sinks.

http://www.d6industries.com/HeatSinks.htm

and of course my favorite cheat sheet is attached:

The cold plate is part# 6P-12, 10"x12", 0.0033 Rth, 6 pass. The part is 200USD; a bit pricey, but better than shelling out 500-600 or more for huge sinks.

http://www.d6industries.com/HeatSinks.htm

and of course my favorite cheat sheet is attached:

Attachments

Hi Mega-Amp,

Actually, I have been toying with the idea of a water cooled transistor amplifier. So far, I have been building vacuum tube amps, and now to drive my Magnepan MG12QR to reasonable levels, I have been thinking of a T amp. With water cooling. The only draw back that I can think of is the fan noise.

Have you visited websites offering CPU water cooling systems? They may offer a cheaper solution than d6 industries. Have a look at Tom's hardware. That's where I noticed a German manufacturer http://www.webshop-innovatek.de/assets/s2dmain.html?http://www.webshop-innovatek.de/

You can communicate with them in English, no problems. They may have a reseller in the US.

I should be able to start work on this amp next year. Hopefully. I'll post text and pix.

Serge

Actually, I have been toying with the idea of a water cooled transistor amplifier. So far, I have been building vacuum tube amps, and now to drive my Magnepan MG12QR to reasonable levels, I have been thinking of a T amp. With water cooling. The only draw back that I can think of is the fan noise.

Have you visited websites offering CPU water cooling systems? They may offer a cheaper solution than d6 industries. Have a look at Tom's hardware. That's where I noticed a German manufacturer http://www.webshop-innovatek.de/assets/s2dmain.html?http://www.webshop-innovatek.de/

You can communicate with them in English, no problems. They may have a reseller in the US.

I should be able to start work on this amp next year. Hopefully. I'll post text and pix.

Serge

I have used Innovatek water cooling in my PC in the past. If you get a good radiator, you can cool the water by convection alone (without a fan). I was water cooling my chipset, video card and cpu without a fan. The radiator was outside the case. HighSpeedPC sells Innovatek in the U.S., but they no longer seem to sell the radiator I had.

If I may offer my 2cents here - if you're just in the proof of concept phase, you can go the same route pioneer computer watercoolers went - diy waterblocks and raid the autoparts counter, pond/aquarium pumps

You may want to work on soldering skills and just solder copper tubing to a copper plate (it works pretty well), or you can just take a small heatsink and epoxy a water box around it (works pretty well too) and drill/tap pipe fittings into it.

A cheap aquarium pump should be in the $30-50 range (I had a small RIO way back then, don't remember the model number - then I bought a 400GPH unit later on).

For cooling the water, try the junkyard - scrounge up a heatercore - most of the extreme computer watercooling radiators were originally heatercores or oil coolers. I picked up one brand new from the auto parts store for a 80's chevrolet chevette.

In the end, it's your project, so just make sure you have fun with it and be sure to post plenty of updates and pictures

You may want to work on soldering skills and just solder copper tubing to a copper plate (it works pretty well), or you can just take a small heatsink and epoxy a water box around it (works pretty well too) and drill/tap pipe fittings into it.

A cheap aquarium pump should be in the $30-50 range (I had a small RIO way back then, don't remember the model number - then I bought a 400GPH unit later on).

For cooling the water, try the junkyard - scrounge up a heatercore - most of the extreme computer watercooling radiators were originally heatercores or oil coolers. I picked up one brand new from the auto parts store for a 80's chevrolet chevette.

In the end, it's your project, so just make sure you have fun with it and be sure to post plenty of updates and pictures

At around 1280watts dissipation for my setup, I think those may be a bit small for this application. I will be using a car radiator, 2 dc car fans, and a used dishwasher pump @ 1-5 gal/m(variac adjustable). The cooling unit will have to be run remotely of course due to noise and space constraints. I'm just not sure how much I can increase bias and voltage. According to that sheet, 50watts fet dissipation, 73c junction temp, i should be safe, but how far can you push these numbers when your water cooling?

edit> yes its definitely an experiment to see how far you can push it. I'll post some pics as I progress....might be a while though.

edit> yes its definitely an experiment to see how far you can push it. I'll post some pics as I progress....might be a while though.

Have you read GROLLINS post on water cooling?

http://www.diyaudio.com/forums/showthread.php?s=&threadid=190&highlight=

http://www.diyaudio.com/forums/showthread.php?s=&threadid=190&highlight=

Hi Twitchie,

Yes, that the Spirit of DIY.

Hi Mega-amp,

Do you need that much power?

I intend to build a 50W RMS (into 4 ohms) transistor amp.

At the moment, I feel that is right. My Williamson (tube) has an output of 22W. Depending on the CD quality, that can be a bit low.

But I can double the power to 100W RMS very easily using the X concept. Bridged amp.

Serge

Yes, that the Spirit of DIY.

Hi Mega-amp,

Do you need that much power?

I intend to build a 50W RMS (into 4 ohms) transistor amp.

At the moment, I feel that is right. My Williamson (tube) has an output of 22W. Depending on the CD quality, that can be a bit low.

But I can double the power to 100W RMS very easily using the X concept. Bridged amp.

Serge

Do you need that much power?

Of course not. Its definitely a proof of concept project. I don't have a set pair of speakers, the ones I have now aren't even mine, and they're many in my project folder that i'd like to experiment with. This would provide a solid foundation for just about any speaker combination I want to try.

I'm still using water cooling. Still love it. For all the fact that the engineering involved was of the "that looks about right" nature, things have worked flawlessly for years and I still haven't found the limits of what the system can dissipate passively; the only active part of the system is the pump (which is in another room--can't hear it). If I were to go to forced air cooling on the heat exchanger I could probably run enough power to play a concert in a coliseum.

One of the young 'uns donated a digital camera to my wife when she left for college (something I didn't have access to when I started the thread, yea these many moons ago). If I remember, I'll get her to crank the thing up and take some pictures of the rig. My verbal description was always a sticking point for people trying to understand what I did.

Grey

One of the young 'uns donated a digital camera to my wife when she left for college (something I didn't have access to when I started the thread, yea these many moons ago). If I remember, I'll get her to crank the thing up and take some pictures of the rig. My verbal description was always a sticking point for people trying to understand what I did.

Grey

Watercooling

I have read the tread and in the moment I am building a F5 with watercooling.

I got one of those:

Asetek cooler

It can remove 200 - 250 Watt with low noise. Now I am looking after a smart low box. The power trafo is in a aeparate box.

They also have a bigger version.

Asetek big cooler

They promise 50000 hours MTBF = 5.5 year.

Benny

I have read the tread and in the moment I am building a F5 with watercooling.

I got one of those:

Asetek cooler

It can remove 200 - 250 Watt with low noise. Now I am looking after a smart low box. The power trafo is in a aeparate box.

They also have a bigger version.

Asetek big cooler

They promise 50000 hours MTBF = 5.5 year.

Benny

water cooling

You can fabricate your own custom water blocks - all you need is some aluminum, drill and tap. THe big question is if you want to make the amp completely portable...if not this gives you some advantages in cooling (send the heat outside) and noise (can remotely mount fans/pumps).

You can fabricate your own custom water blocks - all you need is some aluminum, drill and tap. THe big question is if you want to make the amp completely portable...if not this gives you some advantages in cooling (send the heat outside) and noise (can remotely mount fans/pumps).

As promised above, I have--with the assistance of my long-suffering wife--posted some pictures of the water cooling rig in my old thread:

http://www.diyaudio.com/forums/showthread.php?s=&threadid=190&highlight=

Grey

http://www.diyaudio.com/forums/showthread.php?s=&threadid=190&highlight=

Grey

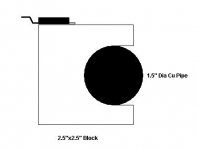

I posted the initial new idea in the thread that Grey linked, here's a better pic of what I'm trying to do. Its definitely cheaper, but the block now has to be machined; adding slight cost, but cheaper than a pre-made cold plate. Then there's the question of I should use bolts through the block and use rubber sealing grommets, thermal epoxy to mate the pipe and block, or a strap of some sorts to secure the pipe in the channel with regular thermal compound The block will be Aluminum, as a 2.5"sq Cu piece @ 1ft, is insanely expensive.

Attachments

While the added contact area between the pipe and the mounting block will be useful, you'll be giving up what you've gained in heat transfer by using a mechanical connection. I used (I think) 1/4" copper bar soldered against 1/2" copper pipe. The solder provides a metal-to-metal-to-metal connection that the heat finds simply irresistible. When you can dump several thousand watts of heat into the thing and leave your finger on the output devices all day, you've got a workable system.

The gory details are somewhere in the other thread. If you can't find what you want to know, ask. I'll go measure things or scratch my head and see if I can remember the finer points.

Incidentally, my system didn't require anything more exotic than a tubing cutter, a hack saw, and a file to build. No zillionth of an inch tolerance problems and no leakage. Cheap. Efficient. High weird factor. Works great. What's not to like?

Grey

The gory details are somewhere in the other thread. If you can't find what you want to know, ask. I'll go measure things or scratch my head and see if I can remember the finer points.

Incidentally, my system didn't require anything more exotic than a tubing cutter, a hack saw, and a file to build. No zillionth of an inch tolerance problems and no leakage. Cheap. Efficient. High weird factor. Works great. What's not to like?

Grey

Yeah, the soldered metal to metal connection looks like the easiest way to do it and much more efficient than a mechanical connection. Simple, cheap, and elegant, I'm sold. Looks like I may be a copycat. Thanks again for the pics of the setup.

OR:

I'd use Aluminum, as Cu block like that would be big $$

OR:

I'd use Aluminum, as Cu block like that would be big $$

Attachments

How do I figure out the thermal efficiency at different GPH? The block is being drilled and tapped next week. It definitely helps when you have friends that own a machine shop, especially ones that machine aerospace components......nothing beats free machining. Would it be better to loop it and have one water input/output, or two seperate inputs/outputs running to the radiator?

Here's the final plan:

Here's the final plan:

Attachments

The following is a quote from an engineering forum:

Am I wasting my time with this design? Would a bigger block with two symmetrically aligned channels running the length be better?

john

I think you're wasting water and aluminum. The simple math is specific heat times flow rate times delta temperature. But with a 1-in diameter, most of the water will probably flow with little or no heat transferred. Your arrangement is asymmetric, which makes the thermal resistance worse. Even placing both channel symmetrically on either side under of the FET would easily reduce the thermal resistance to the second channel. 4 1/2-in channels would have double the water contact area.

Am I wasting my time with this design? Would a bigger block with two symmetrically aligned channels running the length be better?

john

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- Water-cooled Aleph idea