Ah, I misread and thought you were talking about R11/12 since you said you had them biased to 4V. Is there a reason to measure voltage across R3 and R4? I only checked resistance to verify the pot position.

Also, re: thermal compound, I would use it for the mica pads. You want the sinks to be as smooth as possible AND use thermal compound to reduce the thermal resistance from the body of the MOSFET. Is it absolutely necessary? Probably depends on how big your sinks are, ambient temp, etc. But it can only improve the reliability and long term life span of those MOSFETs.

My 2 cents.

Well id noticed the votage across R3 and R4 go above the 4.2V at times, rising when adjusting the bias , so got cautious. i dont know if that is "safe" saying that i have 26v Rails and i dont know if that is a good thing but i cant change that, i want to play it safe lol

Anyone know if there is anything to change or take note of when the rail voltage is 26v rather than the 24v required ? i have 26.5v

Cheers i will buy some Thermal compound, what i have found with this project is it would be nice to have about 4 DMM to watch the voltages all at once!

Cheers

Last edited:

hi,

will there be any problem if i build my F5 without the thermistors?

my F5 wont work if i put the thermistors and i can not trim the bias at R 0,47ohm/3w (no voltages), but when i unplug the thermistors - F5 start running and i can bias them.

so far the only problem occur is - while the F5 running and connected to the music,

the bias voltage always going up slowly and never down, so the heatsink getting hot and hotter, then i have to trim the bias down again and again.

any suggest to my F5?

thanks.

so i have to

will there be any problem if i build my F5 without the thermistors?

my F5 wont work if i put the thermistors and i can not trim the bias at R 0,47ohm/3w (no voltages), but when i unplug the thermistors - F5 start running and i can bias them.

so far the only problem occur is - while the F5 running and connected to the music,

the bias voltage always going up slowly and never down, so the heatsink getting hot and hotter, then i have to trim the bias down again and again.

any suggest to my F5?

thanks.

so i have to

hi,

will there be any problem if i build my F5 without the thermistors?

my F5 wont work if i put the thermistors and i can not trim the bias at R 0,47ohm/3w (no voltages), but when i unplug the thermistors - F5 start running and i can bias them.

so far the only problem occur is - while the F5 running and connected to the music,

the bias voltage always going up slowly and never down, so the heatsink getting hot and hotter, then i have to trim the bias down again and again.

any suggest to my F5?

thanks.

so i have to

Are you sure you're using the correct thermistors?

Are you sure you're using the correct thermistors?

i use the 5K blue thermistors, i think the value still tolerance.

There are many posts describing builds that work successfully without the Thermistors.

I think that Pass confirmed the same.

i do think so, and i don't see any effect with the quality of sound.

but what about the increasing value of bias?

is that cause by the absent of thermistors?

but what about the increasing value of bias?

is that cause by the absent of thermistors?

Very likely.

Very likely.

You should increase the value of R3 and R4. and put the thermistors again.

(Supposing all resistors value are correct)

thanks i think i am going to increase into 0.68ohm as described at the manual.

i hope this will stabilize the bias.

I have put the Thermistors very close to the mosfets, when i hold my finger on the mosfets the temp goes from luke warm to scortching within 20 - 40 seconds then slowly go back to warm, then over again.

when the thermistors are half inch away from the mosfet, the heating and cooling effect speeds up, bias goes up (presume that part is natural)

Is this normal ?

I have Mica Pads and thermal Grease on, and currently biased at .30v instead of .58v as im slowly working my way towards that value.

when the thermistors are half inch away from the mosfet, the heating and cooling effect speeds up, bias goes up (presume that part is natural)

Is this normal ?

I have Mica Pads and thermal Grease on, and currently biased at .30v instead of .58v as im slowly working my way towards that value.

Last edited:

I have put the Thermistors very close to the mosfets, when i hold my finger on the mosfets the temp goes from luke warm to scortching within 20 - 40 seconds then slowly go back to warm, then over again.

when the thermistors are half inch away from the mosfet, the heating and cooling effect speeds up, bias goes up (presume that part is natural)

Is this normal ?

.

Yes all normal >thermistor change themperature >resistance change > bias >change >mosfet change temperature >thermistor change themperature >resistance change > bias >change >mosfet change temperature >thermistor change themperature >resistance change > bias >change >mosfet change temperature...

I glue them to drain leg of the mosfet right close to body, that is the hottest place apart from mosfet back metal tagg.

Being hot place and glued on no mather how hard I wave my fingher or shout at the thermistor the temperature wont change much (bead of epoxi resin around it isolating some from ambient)

Surround the thermistor with air and you can sing at it causing bias change.

Obwiously if you know better you are free to do as you like (not going in to this argument again)

does anyone know to get some nice psu boards? it would be awesome if diy audio store could sell some psu boards that match all those nice boards that the store sells.

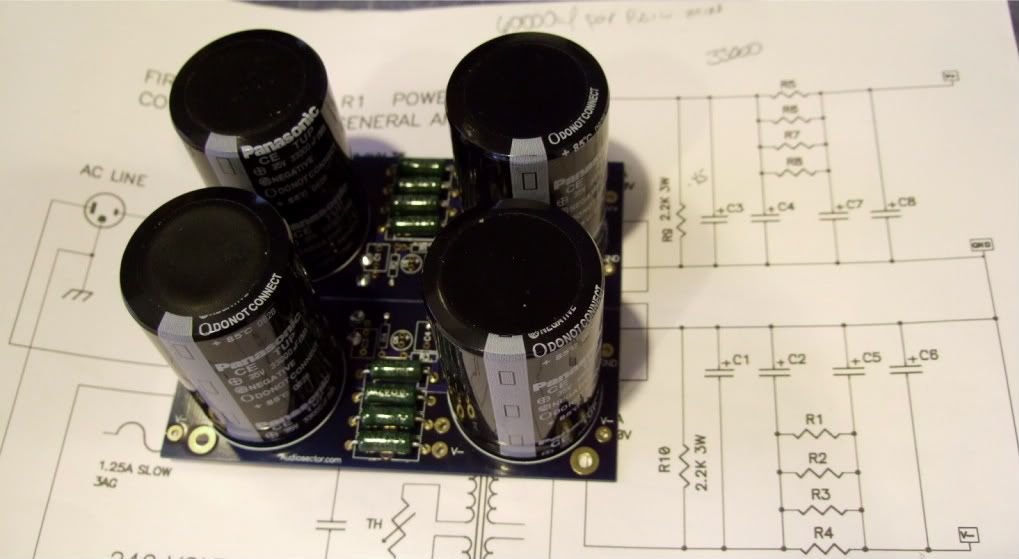

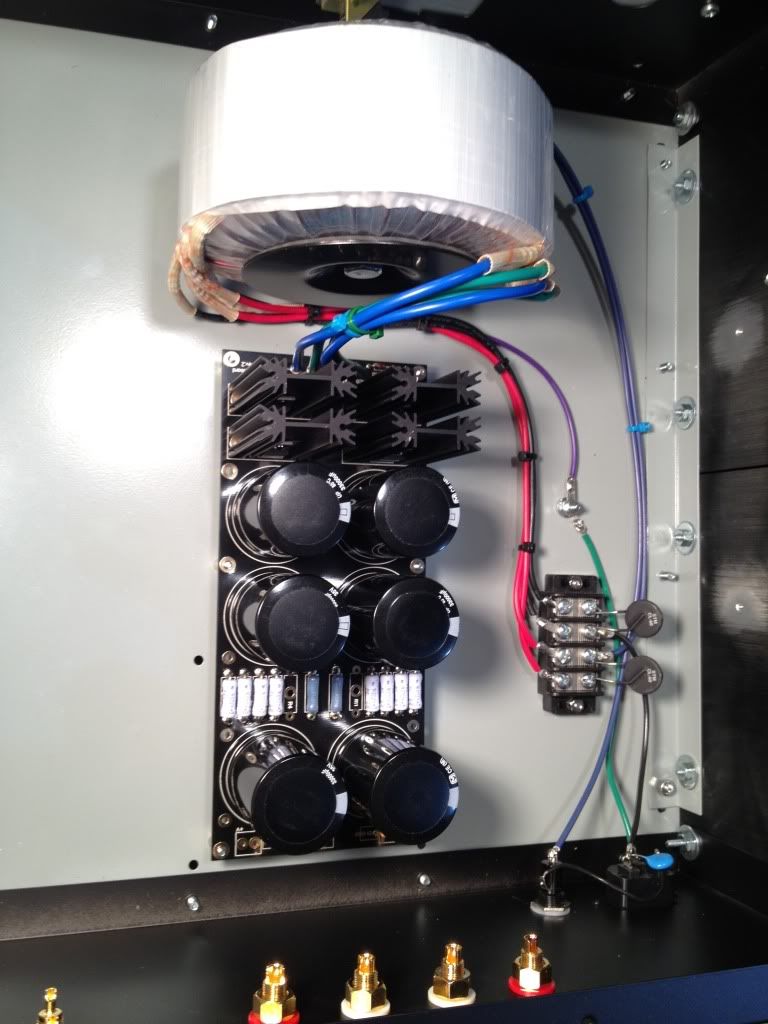

There are 2 convenient options -

Peter Daniel's 'Universal' Power supply board from Audiosector.com (Contact Peter through his website, this board is not listed)

This uses diode bridges that are not attached to the board. More information in this thread - http://www.diyaudio.com/forums/audio-sector/149672-universal-power-supply-pcb.html

And the 'Aleph PSU' board from chipamp.com --

This has a single bridge that uses TO-220 diodes. It also has room for more filter capacitors.

Yes all normal >

I glue them to drain leg of the mosfet right close to body, that is the hottest place apart from mosfet back metal tagg.

Being hot place and glued on no mather how hard I wave my fingher or shout at the thermistor the temperature wont change much (bead of epoxi resin around it isolating some from ambient)

Surround the thermistor with air and you can sing at it causing bias change.

Obwiously if you know better you are free to do as you like (not going in to this argument again)

Haha Cheers, good to know im a singer but ill be singing outside the chassis

Those PSU baords look great!

I made the mistake of adding too much thinking its better, you only need to fill the air gaps i see- as little of thermal paste as possible; basically, so thin that it's almost completely transparent

"So much for the descriptions, but why would mica get a section all of its own? Simply because the quality control is virtually non-existent (from what I have seen lately). The overall shape is fine, but the thickness is generally too great - commonly by a huge margin. I have used mica washers that were so thick that I was able to separate them with a (very) sharp knife, and obtained four washers for the price of one (plus some scrap from the splitting operation). "

Worked Wonders! so im going to try that and find out if the thermals are better or worse, actualy i seperated one with my finger nail haha

Last edited:

- Home

- Amplifiers

- Pass Labs

- F5 power amplifier