Heatsinks are unlikely to apply only to the one amp or another. Most of the amps we are considering use several sections, and the Aleph-X is (I think) about the same in efficiency as an Aleph 2, so 100 W amps of either design would dissipate about 300W.

Before the other group-buy got underway, I suggested in the thread to consider heatsinks by M&M. I spoke to them about a quote, before some of the other guys said (and I paraphrase here): "We don't want no stinkin' second-rate heatsinks!"

So I got the quote, but just sat on it. Thought about getting the info out once the others shipped from R-Theta, but given some hassles that they all went through (additional handling charges, some quality issues, etc.) and that I'm really ok on sinks personally right now, I've done nothing with it.

If anyone is interested in managing this, let me know, and I will be willing to turn the quote over to you to let you run with it, as long as you are more-or-less in agreement with the terms I discussed with M&M (and willing to consider stinkin' second-rate heatsinks )

)

Before the other group-buy got underway, I suggested in the thread to consider heatsinks by M&M. I spoke to them about a quote, before some of the other guys said (and I paraphrase here): "We don't want no stinkin' second-rate heatsinks!"

So I got the quote, but just sat on it. Thought about getting the info out once the others shipped from R-Theta, but given some hassles that they all went through (additional handling charges, some quality issues, etc.) and that I'm really ok on sinks personally right now, I've done nothing with it.

If anyone is interested in managing this, let me know, and I will be willing to turn the quote over to you to let you run with it, as long as you are more-or-less in agreement with the terms I discussed with M&M (and willing to consider stinkin' second-rate heatsinks

Scribble said:Quite possibly interested as im after some heatsink ideas for my aleph5 in progress. Even though i have some in mind already i wouldnt mind some more ideas

Joel

Joel,

I am building a pair of Aleph 5 monoblocks and am using Conrad Engineering's 350mm flat back heat sinks. Since you are in Australia, you might want to check them out first. Dealing with Julian Wales was a pleasant experience and the heatsinks look great. You can contact him at conrad.aus@bigpond.com.

Don't know who coined the phrase "Stinkin Second Rate Heatsinks" on this site, but who ever did doesn't knowwhat he is talking about and comes across to me as being very beligerent. The heatsinks that I purchased from them over the years, and the latest batch were flawless, no scratches, dings or anything. Each sink was individually wrapped...in acid free paper no less, so that nothing contaminated the alumnium before anodizing in case thats where they went first.

I can highly reccommend M&M for any heatsinks, especially for anything one might build on these threads.....Never a problem, always on time, lower cost, and as high of quality, or perhaps better than R- Theta, Wakefield, or any other really good heatsink manufacturer puts out. They also have reasonably priced water cooling plates as well.......

What to reccommend.....I personally reccommend that anything you build thats Class A be over heatsinked!! I some times think that many amps I see built here are barely sinked enough. So something thats past what your calculations require would in my opion be best. My sinks are probably double in sq inches to what the factory Aleph 2's have...as a result my amps only run just hot to the touch...even with the drop set at .55 volts. Ya can't fry eggs on mine!

I'd be happy to consider handling this heatsink deal and will think about it over the next day or so and get back to you all. I would only be willing to deal with US based requests though, unless M&M would take care of the international shipping end of things as I don't have alot of time to stand in line at the Post Office to ship via priority......

Mark

P.S. No I don't work for M&M, nor do I know anyone that does.

I can highly reccommend M&M for any heatsinks, especially for anything one might build on these threads.....Never a problem, always on time, lower cost, and as high of quality, or perhaps better than R- Theta, Wakefield, or any other really good heatsink manufacturer puts out. They also have reasonably priced water cooling plates as well.......

What to reccommend.....I personally reccommend that anything you build thats Class A be over heatsinked!! I some times think that many amps I see built here are barely sinked enough. So something thats past what your calculations require would in my opion be best. My sinks are probably double in sq inches to what the factory Aleph 2's have...as a result my amps only run just hot to the touch...even with the drop set at .55 volts. Ya can't fry eggs on mine!

I'd be happy to consider handling this heatsink deal and will think about it over the next day or so and get back to you all. I would only be willing to deal with US based requests though, unless M&M would take care of the international shipping end of things as I don't have alot of time to stand in line at the Post Office to ship via priority......

Mark

P.S. No I don't work for M&M, nor do I know anyone that does.

Mark A. Gulbrandsen said:Don't know who coined the phrase "Stinkin Second Rate Heatsinks"...

I did. I was joking about Grataku's reaction to my suggestion that we consider heatsinks from M&M. I've got nothing against them.

Tony,

I think you should plan a vacation up through California from LA to San Francisco. You could deliver the castings as you go!

That way you would have a place to stay every night!!

In that other thread you said they cost $85. Is that per amp or per piece? They are very attractive, and different besides.

About what is the size of one?

I think you should plan a vacation up through California from LA to San Francisco. You could deliver the castings as you go!

That way you would have a place to stay every night!!

In that other thread you said they cost $85. Is that per amp or per piece? They are very attractive, and different besides.

About what is the size of one?

Mark,

I'm about to receive 4 more pieces of this heatsinks, they were ordered for a future AX but have no intention of building them soon.

As said on the other thread, these are custom made to my design and can be built to most any (amp) size.

The ones shown on the pic are 22x10" and weigh around 16 lb each.

Up to this point they they seem an overkill for the A4, so I think will suit quite well for the A2 monos. Another member requested 6 of these for his proyects.

Yes, they cost $85 per piece including milling but no holes and the ones to be received will have shot blasted fins for a nicer look and finish.

I'm about to receive 4 more pieces of this heatsinks, they were ordered for a future AX but have no intention of building them soon.

As said on the other thread, these are custom made to my design and can be built to most any (amp) size.

The ones shown on the pic are 22x10" and weigh around 16 lb each.

Up to this point they they seem an overkill for the A4, so I think will suit quite well for the A2 monos. Another member requested 6 of these for his proyects.

Yes, they cost $85 per piece including milling but no holes and the ones to be received will have shot blasted fins for a nicer look and finish.

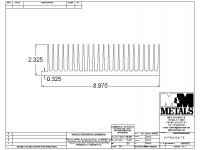

Ok, I've requested a quote from MM metals for extrusion#13633. The price for my small order (about 5') is US$6.3 per inch (about US$350 of heatsinks to build my two alephs). I can't afford this. I don't know what kind a discount a group buy could bring, but I'm a little bit discouraged  . I don't really want to pay more than US$100-150 for heatsinks but I understand that custom made has its price.

. I don't really want to pay more than US$100-150 for heatsinks but I understand that custom made has its price.

Anyway, is there anyone interested in that extrusion? This is the perfect application for my design but I'm affraid it will be hard to have enough people loving it.

Just posting what I've got, if there's any interest, please manifest. I'm open to other similar ext#.

. I don't really want to pay more than US$100-150 for heatsinks but I understand that custom made has its price.

. I don't really want to pay more than US$100-150 for heatsinks but I understand that custom made has its price.Anyway, is there anyone interested in that extrusion? This is the perfect application for my design but I'm affraid it will be hard to have enough people loving it.

Just posting what I've got, if there's any interest, please manifest. I'm open to other similar ext#.

Attachments

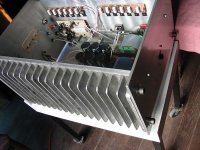

The MM5061-6 sinks ran me 22.00 each from M&M........That translates to $3.66 per inch. I used 6 of these per amp with two devices per sink. If you figure it out, this is way overkill and I probably could have gotten away with 4 of these per amp. However, this does allow me overbias if I want to. Right now with .55 volts across the resistors it is no where near as hot as many other 2's that people on these threads have built....definately now where near hot enough to fry eggs!! I prefer hand wireing and these worked out very well for my application. There is a bit more metal work to put the chassis together though........

I like the look high power industrial look these sinks have....alot different than the typical flat back heatsinks that everyone else here has been using.

Mark

I like the look high power industrial look these sinks have....alot different than the typical flat back heatsinks that everyone else here has been using.

Mark

Attachments

Copper Heatsinks

Mark,

I guess these could be cast on copper. Of course, on copper you would need quite a smaller part for the task. For casting it may well be a copper alloy I don't think a 100% Cu would be good for this proccess, but will ask the supplier.

The alloy used is alu 356, and since the finish is rather rough I don't think anodizing should be considered, there are other protection systems that could be contemplated.

One of the advantage of using something similar to what I used is that the heatsink is also a structural part of the case, this makes building the box quite easy, I used only 8 1/2" screws.

Mark,

I guess these could be cast on copper. Of course, on copper you would need quite a smaller part for the task. For casting it may well be a copper alloy I don't think a 100% Cu would be good for this proccess, but will ask the supplier.

The alloy used is alu 356, and since the finish is rather rough I don't think anodizing should be considered, there are other protection systems that could be contemplated.

One of the advantage of using something similar to what I used is that the heatsink is also a structural part of the case, this makes building the box quite easy, I used only 8 1/2" screws.

Hi Tony,

Thaks for the info!! I like the idea of cast copper for these, and copper can blackened really easily. For that matter anodizing your existing alumnium heatsinks is also not a problem as they will come out a nice black finish with that alloy. Hardcoating the rough finish mght be a tad tricky though! Ya have to be careful anodizing differetn alloys as some alloys don't come out black, but rather plum, or sometimes even brown in color. The copper idea really intregues me alot and I'd appreciate it if you would be willing to check for me as to how much it would cost. I would keep them the same size as you are making them from alumnium. Nothing wrong with too much heatsinking in my mind. Gee, with them made from copper I could even go for the maritime finish and leave them outside till they turn blue . Or perhaps build the Aleph Maritime Special Edition!!

. Or perhaps build the Aleph Maritime Special Edition!!

Mark

Thaks for the info!! I like the idea of cast copper for these, and copper can blackened really easily. For that matter anodizing your existing alumnium heatsinks is also not a problem as they will come out a nice black finish with that alloy. Hardcoating the rough finish mght be a tad tricky though! Ya have to be careful anodizing differetn alloys as some alloys don't come out black, but rather plum, or sometimes even brown in color. The copper idea really intregues me alot and I'd appreciate it if you would be willing to check for me as to how much it would cost. I would keep them the same size as you are making them from alumnium. Nothing wrong with too much heatsinking in my mind. Gee, with them made from copper I could even go for the maritime finish and leave them outside till they turn blue

Mark

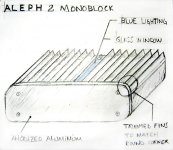

Well here it is. Sorry for the crapy scan (actually a digital photograph). The dimensions are roughly 19"Wx6"Hx14"D. I want a traditional case that's why I've placed the two heatsinks on top (nice cover!). Furthermore, placing them this way should achieve a better heat dissipation. Note there's more fins on the heatsinks than shown. The m&m extrusion have a nice flange on one side that will match the glass window...a nice addition that will reveal the guts of the beast

Attachments

Gabster said:Well here it is. Sorry for the crapy scan (actually a digital photograph). The dimensions are roughly 19"Wx6"Hx14"D. I want a traditional case that's why I've placed the two heatsinks on top (nice cover!). Furthermore, placing them this way should achieve a better heat dissipation. Note there's more fins on the heatsinks than shown. The m&m extrusion have a nice flange on one side that will match the glass window...a nice addition that will reveal the guts of the beast

Actually your heat dissapation will be worse. I looked into this myself and discovered that due to the loss of the chimney effect the heat was slower to escape into the atmosphere.

Anthony

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- Aleph 2 heatsink thread