I'd like to make a wooden chassis for my pre-amp, but your average pot, RCA jack, and AC power connector is just not designed to mount in a panel that's 3/4" thick.

Anyone have sources of jacks that are suited for this? Or any tricks for mounting standard jacks in a wooden chassis?

Anyone have sources of jacks that are suited for this? Or any tricks for mounting standard jacks in a wooden chassis?

countersink the holes.

http://www.diydata.com/tool/drillbits/drillbits.htm

start off with a flat wood bit and, finish it off with a drillbit the same size as the jack

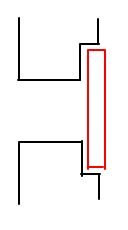

like in this pic, or you can reverse it. have the big countersink hole in the inside

and have the rca flush with the outside

http://www.diydata.com/tool/drillbits/drillbits.htm

start off with a flat wood bit and, finish it off with a drillbit the same size as the jack

like in this pic, or you can reverse it. have the big countersink hole in the inside

and have the rca flush with the outside

Attachments

Hi,

counterbore your holes from the back and/or front of the panel. You could even add a thin sub-panel to the back but this would result in a very deep recess that will not suit some fittings.

A spade bit can be used but it will give a rough edge to the hole. Instead borrow or buy a Forstner bit. Used carefully in a pedestal drill it gives a clean edged hole. Be carefull to use a speed that does not overheat it.

counterbore your holes from the back and/or front of the panel. You could even add a thin sub-panel to the back but this would result in a very deep recess that will not suit some fittings.

A spade bit can be used but it will give a rough edge to the hole. Instead borrow or buy a Forstner bit. Used carefully in a pedestal drill it gives a clean edged hole. Be carefull to use a speed that does not overheat it.

I'll have to figure out how to manage that with a hand drill. My tool budget is shot for a while, can't buy a press right now.

What about mounting pots? It seems like a shaft extender is the answer, but I have yet to find a source of those. Anyone know where I can purchase one?

What about mounting pots? It seems like a shaft extender is the answer, but I have yet to find a source of those. Anyone know where I can purchase one?

Hi,

you can use a forstner bit in a hand drill but precision is more difficult. BUT your hand drill MUST have a gearbox SLOW speed (200 to 500 RPM) not one of those adjustable trigger speed controllers.

Could you glue on a piece of plastic tubing (nearly rigid - ball point pen ?) for a shaft extender? Many of the semi con retailers do hardware and shaft extenders with grub screw attachment are usually in their range.

you can use a forstner bit in a hand drill but precision is more difficult. BUT your hand drill MUST have a gearbox SLOW speed (200 to 500 RPM) not one of those adjustable trigger speed controllers.

Could you glue on a piece of plastic tubing (nearly rigid - ball point pen ?) for a shaft extender? Many of the semi con retailers do hardware and shaft extenders with grub screw attachment are usually in their range.

preiter said:What about mounting pots? It seems like a shaft extender is the answer, but I have yet to find a source of those. Anyone know where I can purchase one?

http://www.welbornelabs.com/hardware.htm -- ready made

couplings:

http://www.smallparts.com/products/descriptions/crsx.cfm

https://sdp-si.com/eStore/

(on left menu go: couplings>rigid types>shaft coupling)

www.mcmaster.com -- same type of couplings

then you need a rod, which the above sources also have, to control the pot from the front panel. That means the pot can be right next to the RCA outs, short signal path.

alt method

Get some decent "bulkhead" through connectors. ... cut a big hole in your cabinet (chassis) ... mount the connectors on a "thinner" wood plate, locate the thinner wood plate with connectors (binding posts?) ... glue in place.

| |

|||_|

==||==

||| |

| |

... or grab some of these: http://www.wholesaleaudioaccessorie...ORIES/PROD/AVPLATES/speaker-wall-plates-AVWP2

Get some decent "bulkhead" through connectors. ... cut a big hole in your cabinet (chassis) ... mount the connectors on a "thinner" wood plate, locate the thinner wood plate with connectors (binding posts?) ... glue in place.

| |

|||_|

==||==

||| |

| |

... or grab some of these: http://www.wholesaleaudioaccessorie...ORIES/PROD/AVPLATES/speaker-wall-plates-AVWP2

ssmith said:

http://www.welbornelabs.com/hardware.htm -- ready made

couplings:

http://www.smallparts.com/products/descriptions/crsx.cfm

https://sdp-si.com/eStore/

(on left menu go: couplings>rigid types>shaft coupling)

www.mcmaster.com -- same type of couplings

then you need a rod, which the above sources also have, to control the pot from the front panel. That means the pot can be right next to the RCA outs, short signal path.

The comments above are the best ideas by far, but don't be intimidated about using a spade or forstner bit in a hand drill. I've done this numerous times without much difficulty. If you are going to use a spade bit, make sure you have a sacrificial board below your work piece. A new/sharp spade is better. Dont' forget to clamp your work piece to the bench top.

If your budget allows, get some forstner bits. They will give a cleaner hole.

Slower drill speeds will be better, but don't belabor the point. A cordless variable speed drill will likely give you the result you are looking for.

Alternatively, if you have a plunge router, use a bit to route out the back of your work piece. A router will give you a nice smooth bottomed recess. And yes, you can free hand it.

Just take your time. The tools don't make the man. The man makes the man. Good luck.

What I ended up doing was cut a rectangle out of the wood, then I screwed a thin piece of metal to the inside of the wood. The jacks were mounted in the metal. Sort of like gmphadte's suggestion, but not inset at all.

It doesn't look too bad, and who's going to be looking at the back of the box anyway?

For the pot I ordered the extender kit from wellbourne labs. Kinda pricey, but really convenient.

Thanks for the suggestions!

It doesn't look too bad, and who's going to be looking at the back of the box anyway?

For the pot I ordered the extender kit from wellbourne labs. Kinda pricey, but really convenient.

Thanks for the suggestions!

acustics may be important here

" ... Sort of like gmphadte's suggestion, but not inset at all. ..."

I believe he was trying not to change the acustics of the box too much. If your "new" terminal mount plate is of wood or similar plastic substitute, the thicker (or stiffer) the better and by insetting will probably not change the boxes' natural resonence too much. Thick without an inset might (or thin and too flexable) might make for some interesting and possible unwanted changes ... similar to adding an unwanted passive radiator in back or causing rattles or even reducing the box resonance volume ... if not inset and solidly mounted.

(Rambling missive 'cause of the fireworks last night = SF Bay Area had a great display = visible for miles = and loud enough to be felt this AM.)

" ... Sort of like gmphadte's suggestion, but not inset at all. ..."

I believe he was trying not to change the acustics of the box too much. If your "new" terminal mount plate is of wood or similar plastic substitute, the thicker (or stiffer) the better and by insetting will probably not change the boxes' natural resonence too much. Thick without an inset might (or thin and too flexable) might make for some interesting and possible unwanted changes ... similar to adding an unwanted passive radiator in back or causing rattles or even reducing the box resonance volume ... if not inset and solidly mounted.

(Rambling missive 'cause of the fireworks last night = SF Bay Area had a great display = visible for miles = and loud enough to be felt this AM.)

Re: acustics may be important here

Not too worried about the accoustics of my pre-ampFastEddy said:" ... Sort of like gmphadte's suggestion, but not inset at all. ..."

I believe he was trying not to change the acustics of the box too much.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- mounting jacks on a wooden chassis