At a guess, it's to convert it into a 'bistable' relay. That way, a pulse of one polarity will switch it one way, and one of the opposite polarity the opposite. Saves having the coil permanently energised.

'Proper' versions are available, but are fairly expensive - this looks like a cheap bodge

'Proper' versions are available, but are fairly expensive - this looks like a cheap bodge

I suspect that the magnet increases the sensitivity of the coil, so that less current is needed to operate it. This makes sense if the relay is normally permanently energised.

Some high sensitivity relays have built-in magnets; the polarity of the coil must be observed, and will not operate if the polarity is reversed. I've been caught out by this when checking relays.

Some high sensitivity relays have built-in magnets; the polarity of the coil must be observed, and will not operate if the polarity is reversed. I've been caught out by this when checking relays.

This sounds like a plausible explanation. After all, we want it to switch off as fast as possible. The principle escapes me though.jacco vermeulen said:The magnets make the relay switch off faster.

It's an EMC Soprel 011.51-22-001 but I can't find any info with Google.

The magnets are located near the contact points and the strongest magnetic field is exactly in line with them, not with the coil. Which doesn't mean your statement is incorrect.johnnyx said:I suspect that the magnet increases the sensitivity of the coil,

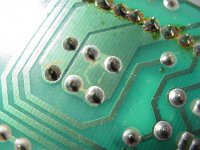

The two washers I inserted take the natural position as seen in the picture.

If I try to move them, they always return to that same point.

/Hugo

Attachments

Netlist said:sounds like a plausible explanation.

Not plausible, it's an old trick.

Ed Wijnker is SOAphobic, like a couple overhere. Stage Accompany amplifiers "were" pretty expensive. The SA1600 i had went in protection mode far to easy.

EMC= Electro Moderna Components

Soprel is the factory.

Seulement pour les potes Belges:

www.efacec.pt/presentationLayer/efacec_historia_00.aspx?idioma=3&local=13&area=1

Merci Jacco. Is that a division of ACEC or in any way related to it?

(Logo)

I reassembled the amp and it sounds like its build.

Clear and detailed mids and highs, well balanced sound and good control of the bass. I didn't measure but the 285W/ch is probably rather conservative.

/Hugo

(Logo)

I reassembled the amp and it sounds like its build.

Clear and detailed mids and highs, well balanced sound and good control of the bass. I didn't measure but the 285W/ch is probably rather conservative.

/Hugo

Hi Hugo,

The intention of the magnets is to help the relay switch off a bit faster as Jacco has suggested.

It's a technique that is used in high voltage switching. The magnets pull the arc formed as the relay opens towards the magnets because of the plasma's negative charge. As the plasma formed by the arc is now curved rather than straight across from contact to contact, is breaks slightly sooner.

This is significant where thousands of amps are being switched as it saves a lot of contact material being vapourised. Whether it's of any real use for an audio power amp where the arc length is a fraction of a millimeter is debatable.

Another technique for breaking the arc is to blow the arc out of the gap between the contacts with compressed air. I haven't seen this technique use for audio amps however!

Cheers, Ralph.

The intention of the magnets is to help the relay switch off a bit faster as Jacco has suggested.

It's a technique that is used in high voltage switching. The magnets pull the arc formed as the relay opens towards the magnets because of the plasma's negative charge. As the plasma formed by the arc is now curved rather than straight across from contact to contact, is breaks slightly sooner.

This is significant where thousands of amps are being switched as it saves a lot of contact material being vapourised. Whether it's of any real use for an audio power amp where the arc length is a fraction of a millimeter is debatable.

Another technique for breaking the arc is to blow the arc out of the gap between the contacts with compressed air. I haven't seen this technique use for audio amps however!

Cheers, Ralph.

jacco vermeulen said:The magnets make the relay switch off faster.

Well, I see something new everyday. Could you explain how it works?

ralphs99 said:It's a technique that is used in high voltage switching. The magnets pull the arc formed as the relay opens towards the magnets because of the plasma's negative charge. As the plasma formed by the arc is now curved rather than straight across from contact to contact, is breaks slightly sooner.

On page 2 of

this datasheet, the manufacturer claims 'Greater reliability and contact life' by using so called 'blow-out' magnets.

Although I can't find references to faster break times, I accept this as likely because I can imagine the arc acting as a kind of magnet for the contacts but more important a conductor for the current that needs to be eliminated as soon as possible. Could we state that in fact the arc is the current itself?

/Hugo

"When breaking under load, an arc is formed that can reach temperatures of up to 10,000 °C. This arc must be quickly extinguished (less than ten milliseconds) to prevent contact platings from melting. The zero-crossing that occurs every half cycle with an AC voltage is useful in this regard. Since there is no zero-crossing for DC voltages, other techniques must be employed.

An arc is essentially electrical current flowing through ionized air. Permanent magnets are used to stretch the arc and thereby extinguish it. Arc-chutes are required for higher voltages. These stretch, cool and disperse the arc. Most arc chutes are made using small metal plates and additional blowout magnets."

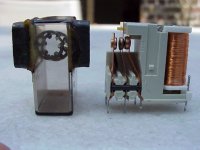

The picture below shows another example (output relays in an old Nikko Alpha amplifier).

Regards,

Milan

An arc is essentially electrical current flowing through ionized air. Permanent magnets are used to stretch the arc and thereby extinguish it. Arc-chutes are required for higher voltages. These stretch, cool and disperse the arc. Most arc chutes are made using small metal plates and additional blowout magnets."

The picture below shows another example (output relays in an old Nikko Alpha amplifier).

Regards,

Milan

Attachments

Interesting, particularly the difference made between AC and DC.

In an amplifier, both conditions can occur at the same time.

From the text, I understand that the magnets have most effect in a DC fault condition.

Nice picture of the Nikko amp. It looks rather end of life though.

/Hugo

In an amplifier, both conditions can occur at the same time.

From the text, I understand that the magnets have most effect in a DC fault condition.

Nice picture of the Nikko amp. It looks rather end of life though.

/Hugo

Magnetic blowout relays are also produced for lower voltage ratings.

Lifespan is supposed to be highly lengthened, or DC-load can be very much higher with equal life expectancy. See Tyco Agastat relays for an example.

There are also serial production magnetic latching relays, with permanent magnets within the relay case, the magnets are placed in line with the relay contacts. The magnets in these relays constantly pull the relay contacts, enabling faster switching times.(but higher switch-on response time) Supposed to be good for chatter, an RC seems a simple chatter cure.

Lifespan is supposed to be highly lengthened, or DC-load can be very much higher with equal life expectancy. See Tyco Agastat relays for an example.

There are also serial production magnetic latching relays, with permanent magnets within the relay case, the magnets are placed in line with the relay contacts. The magnets in these relays constantly pull the relay contacts, enabling faster switching times.(but higher switch-on response time) Supposed to be good for chatter, an RC seems a simple chatter cure.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- Relay with magnets