Hello everyone, I am fairly new at DIY and I have a very simple question about the internal wiring .

I ve chosen as my first proj the GC 3886 from BrianGt. Everything was simple to do .... till i had to use wiring between the PS and the amp board, and the Line in line out ....

I thought well .... why dont i buy an expensive audio interconnect for the line in and sacrifice it in oder not to risk loosing "quality" of the sound... Well the holes on the PCB are not familiar with "quality cabling" and the resutly looks a bit terrible...

As for the Line out and the interconnection between PS and Amp board i went for the solution of the thicker the better ( used some 3X25 cable) whitch doesnt look mouch better anyway...

My question is: What do you use for the internal wiring? Are there some giudelines or best practices I should follow?

Thank you in advance for all your help

I ve chosen as my first proj the GC 3886 from BrianGt. Everything was simple to do .... till i had to use wiring between the PS and the amp board, and the Line in line out ....

I thought well .... why dont i buy an expensive audio interconnect for the line in and sacrifice it in oder not to risk loosing "quality" of the sound... Well the holes on the PCB are not familiar with "quality cabling" and the resutly looks a bit terrible...

As for the Line out and the interconnection between PS and Amp board i went for the solution of the thicker the better ( used some 3X25 cable) whitch doesnt look mouch better anyway...

My question is: What do you use for the internal wiring? Are there some giudelines or best practices I should follow?

Thank you in advance for all your help

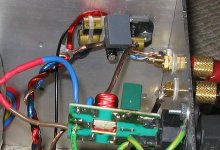

I recently made a gainclone, for the input wiring I used unshielded twisted pair wire. It is very short at about 3cm max.. might as well not have bothered as it only has one twist

for the output I used 1mm enammeled copper wire again short probably less than 5cm.

for the PS connections I used 16 gauge OFC wire super flexible stuff 65 X 0.16mm strands.

The signal ground was light duty hookup wire, and the speaker returns (I think) 25A auto cable....

Picture attached of the amp when half done. Note I have no idea whether the braiding of the PS wire actually does anything (+ve or -ve) but I think it looks cool

Tony.

for the output I used 1mm enammeled copper wire again short probably less than 5cm.

for the PS connections I used 16 gauge OFC wire super flexible stuff 65 X 0.16mm strands.

The signal ground was light duty hookup wire, and the speaker returns (I think) 25A auto cable....

Picture attached of the amp when half done. Note I have no idea whether the braiding of the PS wire actually does anything (+ve or -ve) but I think it looks cool

Tony.

Attachments

I like to use stranded, silver plated, teflon insulated wire. Not because it sounds any better than any other wire (I'm sure it doesn't sound any better, or any worse, for that matter), but because the insulation doesn't melt and look ugly when I solder the stuff. Stranded wire is more flexible than solid wire, so in some situations is easier to handle and less prone to breakage after flexing. You need a good stripper to use teflon insulated wire.

Teflon insulated wire is a little expensive, but sometimes you can buy it in bulk cheaply on ebay, like I did. I spent about $60 a few years ago and got enough for the next ten years worth of DIY projects.

I would not "sacrifice" an expensive interconnect cable because I wouldn't pay a lot for one in the first place, and the use of multiple pieces of relatively thick, coaxial cable in a small space to connect to a PCB that is not designed for such a cable is frought with mechanical difficulties, as you have discovered.

I_F

Teflon insulated wire is a little expensive, but sometimes you can buy it in bulk cheaply on ebay, like I did. I spent about $60 a few years ago and got enough for the next ten years worth of DIY projects.

I would not "sacrifice" an expensive interconnect cable because I wouldn't pay a lot for one in the first place, and the use of multiple pieces of relatively thick, coaxial cable in a small space to connect to a PCB that is not designed for such a cable is frought with mechanical difficulties, as you have discovered.

I_F

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.