Hi all,

I am about to resurrect a number of poweramps from storage. I have read numerous times that storing electrolytics reduces their performance/voltage capacity.

Is there a simple and foolproof method to reform the electrolytic without taking the caps out of circuit?

I have a variac to hand if this helps.

regards Andrew T.

I am about to resurrect a number of poweramps from storage. I have read numerous times that storing electrolytics reduces their performance/voltage capacity.

Is there a simple and foolproof method to reform the electrolytic without taking the caps out of circuit?

I have a variac to hand if this helps.

regards Andrew T.

Electrotraining greatly improves the sound of electrolytic capacitors

the member NAZAR Iv could be know arround this subject.

Author of :

Electrotraining of electrolytic capacitors

DIYaudio.org.ua • ????????????????? ??????????????? ?????????????

the member NAZAR Iv could be know arround this subject.

Author of :

Electrotraining of electrolytic capacitors

DIYaudio.org.ua • ????????????????? ??????????????? ?????????????

I mess around repairing and restoring vintage valve radios and high power amps here in the UK and never use a variac, preferring to follow the practices used by those who have been doing it longer than me. That is, you hit them with full voltage straight off and see what happens. About 80% of the sets I power up seem either to be ok with the original power supply electrolytics left in, or else they fail within an hour of use. This is of course with high-voltage types (250 volts and more and I've never actually measured the capacitance. (I dont have a meter for that either). Just my experience with dozens of the dusty old relics. Steve.

You're pretty much sorted by having the variac, like everyone else said, just run the amps at a lower voltage for a while. A couple of caveats though:

- Many switch mode power supplies don't like being run at lower than normal voltages. Again, some may self destruct, but in SMPSs this isn't that rare. I would only use this method on amps with linear power supplies.

- Some amps that use linear supplies still react very badly (and possibly self destruct) when run at a lower than normal voltage. I'm pretty sure a couple of Carvers were like this, but it's pretty rare.

- Many switch mode power supplies don't like being run at lower than normal voltages. Again, some may self destruct, but in SMPSs this isn't that rare. I would only use this method on amps with linear power supplies.

- Some amps that use linear supplies still react very badly (and possibly self destruct) when run at a lower than normal voltage. I'm pretty sure a couple of Carvers were like this, but it's pretty rare.

I can see something in stevekendal's recommendation to just power up and see what happens. Capacitors that have stood long enough to need re-formation are probably also dried out and/or unreliable. So if they can't handle being powered up normally, they probably need replacement anyway. Only problem is, when they pop, they make a bit of a mess. Ramping up with a variac can indeed prevent them from going off, bit IMHO it is not more than a crude trick to temporarily revive a capacitor that is already well underway towards failure.

So, I'd recommend taking the larger electrolytics out of the equipment, and ramp up the voltage towards their rated working voltage using a resistor such that the RC time constant is about 10 seconds. If, after a few minutes, a significant leakage current still runs (more than 1V drop across the resistor), treat the cap with suspicion and replace it. If the cap survives this test, it is probably safe, but it may still have dried out. This is very likely with capacitors that are 20+ years old and exposed to high ripple currents and/or elevated temperatures. When in doubt, replace.

So, I'd recommend taking the larger electrolytics out of the equipment, and ramp up the voltage towards their rated working voltage using a resistor such that the RC time constant is about 10 seconds. If, after a few minutes, a significant leakage current still runs (more than 1V drop across the resistor), treat the cap with suspicion and replace it. If the cap survives this test, it is probably safe, but it may still have dried out. This is very likely with capacitors that are 20+ years old and exposed to high ripple currents and/or elevated temperatures. When in doubt, replace.

Reforming electrolytics

back when I worked in the power supply industry we occasionally had to reform NOS electrolytics. We usually had to do batches of several dozen at a time. the method below protects against catastrophic failure and limits current to safe levels. If your dealing with high voltages, BE CAREFUL, getting yourself across a high voltage cap will ruin the rest of your life!

The method i always used was to supply the full dc voltage through a resistor to limit the current to about a milliamp - 150 volt would need a 150k resistor. i would leave this on for a day and then measure the voltage across the resistor to see how things were going. Assuming nothing looked bad I would solder a resistor to limit the current to 10 ma (for 150 v use 15 k). I would leave this for another day. If the cap shorts out the resistor may well smoke but it will prevent exploding caps and highlight the bad caps pdq.

If your setup allows you to easily disconnect the plus side of the caps you can look at the voltage to see how fast they decay as the caps dischrges through it's own leakage to get an idea for the caps "health". Any cap that had excessive leakage was discarded, the rest were discharged and put to use.

back when I worked in the power supply industry we occasionally had to reform NOS electrolytics. We usually had to do batches of several dozen at a time. the method below protects against catastrophic failure and limits current to safe levels. If your dealing with high voltages, BE CAREFUL, getting yourself across a high voltage cap will ruin the rest of your life!

The method i always used was to supply the full dc voltage through a resistor to limit the current to about a milliamp - 150 volt would need a 150k resistor. i would leave this on for a day and then measure the voltage across the resistor to see how things were going. Assuming nothing looked bad I would solder a resistor to limit the current to 10 ma (for 150 v use 15 k). I would leave this for another day. If the cap shorts out the resistor may well smoke but it will prevent exploding caps and highlight the bad caps pdq.

If your setup allows you to easily disconnect the plus side of the caps you can look at the voltage to see how fast they decay as the caps dischrges through it's own leakage to get an idea for the caps "health". Any cap that had excessive leakage was discarded, the rest were discharged and put to use.

Electrolytic caps have rubber seals to keep the water in. Historic rubber is dirt on a stick. You can reform historic caps, and they might work a while if they haven't leaked already, but the rubber is still ancient and the ozone has been working all that time to ruin it. That said, when I run tube stuff that hasn't been used a couple of years but the caps are under 20 years old, I run it at half line voltage for a while first. I built a box with fuses in and out for my variac, but it was a trash can reject, and no matter what the pointer says, it puts out half the line voltage- which is good enough for my purposes to gently warm in the electrolytics. No cap explosions yet! See the leslie cap explosion thread of organforum.com for what can happen with the "plug it in and see if it is okay" method. That cap was fifty years old, and was removed molecule by molecule with a towel and scrub brush.

Last edited:

hi,

Another way to test a cap is to use the variac and a volt meter across the terminals,set on dc and run it up slowly,if it stops taking the juice stop and see if it's getting hot or use a temp meter on it,if ok keep turning it up till at working vdc and check it often if it starts to get warm it's going bad.if not turn it off after a while and watch the meter,if it's not loaded it will sit for a while then start to discharge, all of caps have internal leakage,just a better one goes down real slow,a bad cap real fast,

cap meters are on ebay for under 50.00

Hope that helps,

Cheers

Another way to test a cap is to use the variac and a volt meter across the terminals,set on dc and run it up slowly,if it stops taking the juice stop and see if it's getting hot or use a temp meter on it,if ok keep turning it up till at working vdc and check it often if it starts to get warm it's going bad.if not turn it off after a while and watch the meter,if it's not loaded it will sit for a while then start to discharge, all of caps have internal leakage,just a better one goes down real slow,a bad cap real fast,

cap meters are on ebay for under 50.00

Hope that helps,

Cheers

The professional method (which I use  ) is to charge the capacitor with a Megohmmeter in 10V increments and see the isolation resistance go over 10Mohm under voltage. Same can be achived with a variac.

) is to charge the capacitor with a Megohmmeter in 10V increments and see the isolation resistance go over 10Mohm under voltage. Same can be achived with a variac.

Megohmmeter IM6 Radio Radiometer;

Megohmmeter IM6 Radio Radiometer;

I don't understand this term:The professional method (which I use) is to charge the capacitor with a Megohmmeter in 10V increments and see the isolation resistance go over 10Mohm under voltage. Same can be achived with a variac.

Megohmmeter IM6 Radio Radiometer;

"the isolation resistance go over 10Mohm under voltage"

mean you, that the isolation resistance is much lower than 10 M-Ohm without DC voltage bias between the positive and the negative connectors from your electrolytic capacitor?

BTW - I am looking for a electrolytic capacitor analyser. The most important thing for me is to get a graph about the frequency dependent electrical serial resistance (ESR) while various ripple current surge loads and various ambient temperatures.

What model is here the best choise?

Last edited:

I have a question on NOS caps not mounted in a circuit

In order to assess their conditions could it be useful to charge it to the working voltage and then disconnecting the PS and see how the voltage across caps terminal varies with time ?

how long should it take for a cap to discharge with open terminals ?

I think that caps are the most strange of the components ... they act in a mysterious way

Thanks and regards,

gino

In order to assess their conditions could it be useful to charge it to the working voltage and then disconnecting the PS and see how the voltage across caps terminal varies with time ?

how long should it take for a cap to discharge with open terminals ?

I think that caps are the most strange of the components ... they act in a mysterious way

Thanks and regards,

gino

Last edited:

Use the formula

deltaV per second = I / C

A 1uA of leakage will reduce the voltage of a 10mF capacitor by about 0.01mV per second.

i.e. about 1mV per 100seconds, or about 1V/day

If you measure (intermittantly) a loss of 8mV over 100seconds then the 10mFcap has 8uA of leakage.

Compare that to the cap datasheet.

Expect a reformed cap to perform about 100times to 1000times better than the specification leakage value, when you need to throw the capacitor away, or reform back to a very good value.

It's this reforming reducing the leakage current that I attribute many Members opinion that caps need burn in time. Balderdash!

deltaV per second = I / C

A 1uA of leakage will reduce the voltage of a 10mF capacitor by about 0.01mV per second.

i.e. about 1mV per 100seconds, or about 1V/day

If you measure (intermittantly) a loss of 8mV over 100seconds then the 10mFcap has 8uA of leakage.

Compare that to the cap datasheet.

Expect a reformed cap to perform about 100times to 1000times better than the specification leakage value, when you need to throw the capacitor away, or reform back to a very good value.

It's this reforming reducing the leakage current that I attribute many Members opinion that caps need burn in time. Balderdash!

Last edited:

Thank you very much indeed for your advice.

Caps are a unavoidable nightmare

They are the only component changing with time

They are absolutely unstable. I am referring to electrolytics of course

Their characteristics vary with time, they have a life time, a shelf life time, they short, they leak, they can even explode .... what a mess of component !

But they are unavoidable

Thanks again and kind regards

gino

Caps are a unavoidable nightmare

They are the only component changing with time

They are absolutely unstable. I am referring to electrolytics of course

Their characteristics vary with time, they have a life time, a shelf life time, they short, they leak, they can even explode .... what a mess of component !

But they are unavoidable

Thanks again and kind regards

gino

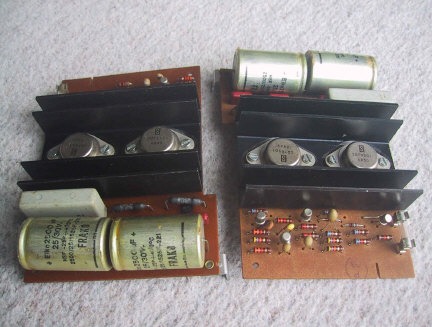

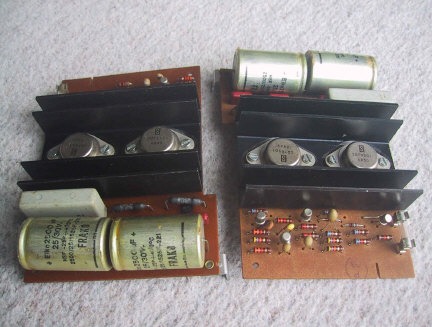

I've measured the tan-delta and capacitive values of many old electrolytics.The number of them which could be said to be bad is very low. The last ones tested were four examples coming from the 10 W power amplifier fitted in the Revox A77 recorder which is 40 years old. They were FRAKO Elko 2500 µF 35-30 V. They had no voltage across them since years. For the four examples, the capacity was higher than 2700 µF, two around 3000 µF. Tan-delta was 0.1, one of them 0.12.

A refreshing breath of common sense in the recapping madness.I've measured the tan-delta and capacitive values of many old electrolytics.The number of them which could be said to be bad is very low.

Yes, it is true that a number faults on older equipments can be traced down to failing Elytics.

But!!!

-this doesn't mean all older Elytics are faulty

-this doesn't mean all faults on older equipments are caused by Elytics

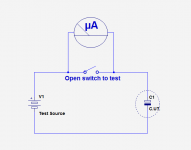

Measuring the leakage of E-cap is not difficult:

After some hours of reforming, use the following arrangement.

Note that a DVM in the 200mV range also behaves as a nanoamperemeter, 20nA full scale

Attachments

Measuring leakage is one thing, but measuring capacitance another. Not every DIYer has the resources to do the latter, while degraded (dried-up) capacitors that fall short on capacitance may still pass the leakage test and be safe in terms of not blowing up when you turn on the equipment.

I have had a couple of devices (most notably, a lab power supply that was given to me) that had no visible capacitor failures and would work on first glance, but all caps were out of spec, some so much that it didn't matter anymore that they were even there. Think of a 3300 uF reservoir cap measuring only about 100 uF. The capacitors that were mounted close to the heatsink had degraded most. These caps were significantly younger than 40 years, but they all required replacement. After replacing the caps (which was only a € 10,- job at most) the power supply worked according to spec. So old capacitors are a mixed bag at best. Some very old ones may be very good still, while others may be completely dead. Unless they are very large, they are not that expensive, so it would probably be best to replace them when in doubt about the amount of life left in them.

I have had a couple of devices (most notably, a lab power supply that was given to me) that had no visible capacitor failures and would work on first glance, but all caps were out of spec, some so much that it didn't matter anymore that they were even there. Think of a 3300 uF reservoir cap measuring only about 100 uF. The capacitors that were mounted close to the heatsink had degraded most. These caps were significantly younger than 40 years, but they all required replacement. After replacing the caps (which was only a € 10,- job at most) the power supply worked according to spec. So old capacitors are a mixed bag at best. Some very old ones may be very good still, while others may be completely dead. Unless they are very large, they are not that expensive, so it would probably be best to replace them when in doubt about the amount of life left in them.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- reforming electrolytic capacitors