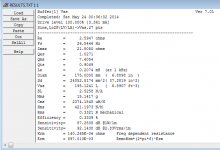

The Woofer Tester 2 from Smith and Larson arrived and I did some TS and Impedance tests.

Paper cone Dia : 7 ''

4mm winding height, 2.5 Ohm DC resistance, 55mm VC dia, 5.55m AWG 31 wire

The cone was made of 2 A4 sheets of paper glued together with PVA glue, and a layer of fiberglass added on the surface. I didn't saturate the fiberglass with epoxy properly and it's a screw up. Cone is soft and quite flexible.

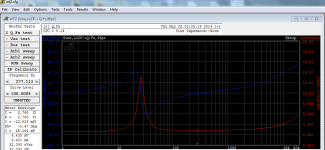

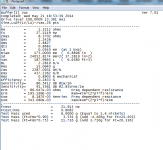

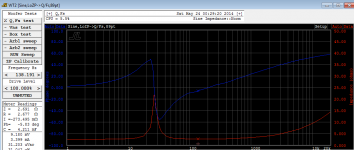

The BL is very low and Qts is too high. Inductance is very low, impedance plot is very smooth.

I noticed after adding the dustcap, the sound was less open, and midrange level increased, however it also strengthened the cone dramatically, there is hardly any buzz from the cone now. Still running surround-less and using 4 paper spiders.

Need to try a same diameter, lighter cone with more wire. Right now the cone weighs 12 grams, while the coil is 3 grams.

Is the greatest efficiency obtained from using equal weights of cone and coil? hmm..

Here is a youtube video of it playing "Instead" by Madeleine Peyroux.

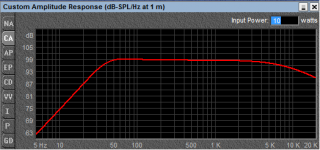

Simulated in a 100L closed box gives very nice bass extension!

Paper cone Dia : 7 ''

4mm winding height, 2.5 Ohm DC resistance, 55mm VC dia, 5.55m AWG 31 wire

The cone was made of 2 A4 sheets of paper glued together with PVA glue, and a layer of fiberglass added on the surface. I didn't saturate the fiberglass with epoxy properly and it's a screw up. Cone is soft and quite flexible.

The BL is very low and Qts is too high. Inductance is very low, impedance plot is very smooth.

I noticed after adding the dustcap, the sound was less open, and midrange level increased, however it also strengthened the cone dramatically, there is hardly any buzz from the cone now. Still running surround-less and using 4 paper spiders.

Need to try a same diameter, lighter cone with more wire. Right now the cone weighs 12 grams, while the coil is 3 grams.

Is the greatest efficiency obtained from using equal weights of cone and coil? hmm..

Here is a youtube video of it playing "Instead" by Madeleine Peyroux.

Simulated in a 100L closed box gives very nice bass extension!

Attachments

Hi Andrew, it is 2 layer, 4mm height winding currently in place. My theoretical X-max is (15-4)/2 = 5.5mm. I think I need to have at least 8mm wire height , Xmax will be reduced to 3.5mm. Still decent since the cone is fairly large.

I have done a simulation for a better optimized motor, where I can almost double the flux from 0.7T to 1.35T with a 2.5mm air gap, same copper shorting pipe, 10mm pole height and a smaller pole vent. However with a smaller pole vent hole, inductance will be increased. I'm trying to keep inductance as low as possible as I intend to use this motor for an 8'' fullrange unit. Wonderful open and detailed sound from the neo motor.

I have done a simulation for a better optimized motor, where I can almost double the flux from 0.7T to 1.35T with a 2.5mm air gap, same copper shorting pipe, 10mm pole height and a smaller pole vent. However with a smaller pole vent hole, inductance will be increased. I'm trying to keep inductance as low as possible as I intend to use this motor for an 8'' fullrange unit. Wonderful open and detailed sound from the neo motor.

Yes indeed that can be tried. I only have 9.5mm clearance to the bottom pole piece (which is the height of the neo magnet). No undercut was machined. Possible to use 20mm coil height and get 2.5mm Xmax (one way) , and 4.5mm (9.5-5) X-Limit one way or 9mm P-P before VC slams to the bottom.

Anyway I intend to stick to the underhung configuration. Going to the overhung needs a complete change of design.

Anyway I intend to stick to the underhung configuration. Going to the overhung needs a complete change of design.

Copper shorting ring effects

Here are the specs for the identical cone, without the copper pipe in the gap.

The copper pipe removed measures 52mm in diameter, 1mm thick, 25mm tall.

Le has increased to 0.2mH, a 4X increase from 0.05mH.

Qms increased by more than 2X from 2.88 to 7.6!

Qes increased slightly from 1 to 1.2

Qts remains unchanged.

BL increased from 2.28 to 2.52

I seem to have gained 1 dB sensitivity...

Having the copper in the gap does reduce inductance by a huge amount.

Listening tests prior to measurements suggests that the sound was warmer and softer without the copper, with a dull top end and a smaller soundstage. The pipe is definitely staying in the gap!

Here are the specs for the identical cone, without the copper pipe in the gap.

The copper pipe removed measures 52mm in diameter, 1mm thick, 25mm tall.

Le has increased to 0.2mH, a 4X increase from 0.05mH.

Qms increased by more than 2X from 2.88 to 7.6!

Qes increased slightly from 1 to 1.2

Qts remains unchanged.

BL increased from 2.28 to 2.52

I seem to have gained 1 dB sensitivity...

Having the copper in the gap does reduce inductance by a huge amount.

Listening tests prior to measurements suggests that the sound was warmer and softer without the copper, with a dull top end and a smaller soundstage. The pipe is definitely staying in the gap!

Attachments

"inaccurate" is hardly the correct word for the errors posted.

The mechanical workmanship looks better than good.

Hi Andrew,

I double checked the coils and have the wrong coil AWG's. I had written them

as AWG 32 and 34 but should be AWG 31 and 33.

It should be :

Old coil : AWG 33, 0.2mm, 7m, 4mm tall, dual layer, hand wound, 3 grams

~4.8 Ohms.

New coil : AWG 31, 0.25mm, 12.5m, 9mm, dual layer, hand wound, 5 grams.

~5.26 Ohms

For the AWG 33 wire, 388 ft weights exactly 1/16 lbs. 7m weighs 1.68 grams. Accounting for the Nomex former and epoxy, it could be a little over 2 grams and the scale reads 3 grams.

For the AWG 31 wire, 250 ft weights 1/16 lbs. 12.5 m weighs 4.63 grams. Epoxy + former will take it to over 5 grams. Scale shows 5 grams. Accuracy of the scale is +/- 1 gram.

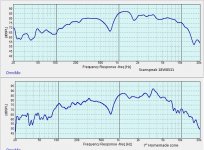

Freq response plots with Dayton Audio OmniMic measurement system measured at 1/2m from the dustcap of each speaker. I set a fixed volume at the amp and swapped each speaker into the box for testing. The strange dip at 700 Hz is due to the box.

The Scanspeak 18W8531 midwoofer is very smooth with a controlled breakup and rollfoff. My DIY cone has a sharp 7dB peak at 3.3Khz. Insufficient high freq extension and output. That peak is probably giving the impression of more highs in the DIY cone.

The Scanspeak 18W8531 midwoofer is very smooth with a controlled breakup and rollfoff. My DIY cone has a sharp 7dB peak at 3.3Khz. Insufficient high freq extension and output. That peak is probably giving the impression of more highs in the DIY cone.

Attachments

One track has the motor with the Faraday sleeve installed, and the other without. Identical mic position and volume levels.

Youtube Track A

Youtube Track B

Youtube Track A

Youtube Track B

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- Axial or Diametrical neo magnets for homemade speaker?