I have my crossovers 90% rebuilt - going from stock components with high-quality components replacing the caps, resistors, speakerwire, and adding Blackhole 5 inside the enclosure which has elevated the sound tremendously. The only thing left as stock on my crossovers are the inductors for the midrange woofers, which are iron core. Although I have not had any issues with them, I have read that air-core inductors are actually better. I am thinking of moving to air-core to add texture to the sound. (My tweeter inductor is air-core and has been replaced with a Jantzen air-core inductor, I am quite happy with it and will not replace it any further.)

The specifications of my laminated iron core inductors are:

Set One:

4.1mH, DCR 0.60 ohms, 18AWG

1.0mH, DCR 0.25 ohms, 18AWG

Crossover Frequencies: 800 and 1500 Hertz

(I assume the third crossover frequency - 3000 Hertz - is for the tweeter inductor)

Set Two:

2.0mH, DCR 0.50 ohms, 18AWG

0.5mH, DCR 0.20 ohms, 18AWG

14mH, DCR 11.35 ohms, 26AWG (this one is air-core, I should be able to find a suitable replacement from Jantzen)

The crossover frequencies are unknown for this set, however, there are only midrange drivers. There is no tweeter involved in this set.

Is there a formula for replacing these iron cores with Air-Cores? When replacing, I will need to keep the DCR the same. I take it I need to keep the mH the same as well. Do I need to keep the AWG the same, or can I use a larger AWG (going with a smaller number)?

I am thinking of going with Solen Air Core Inductors as a replacement inductor.

I'd appreciate any input that anyone can give in this field of expertise.

Thanks much!!!

The specifications of my laminated iron core inductors are:

Set One:

4.1mH, DCR 0.60 ohms, 18AWG

1.0mH, DCR 0.25 ohms, 18AWG

Crossover Frequencies: 800 and 1500 Hertz

(I assume the third crossover frequency - 3000 Hertz - is for the tweeter inductor)

Set Two:

2.0mH, DCR 0.50 ohms, 18AWG

0.5mH, DCR 0.20 ohms, 18AWG

14mH, DCR 11.35 ohms, 26AWG (this one is air-core, I should be able to find a suitable replacement from Jantzen)

The crossover frequencies are unknown for this set, however, there are only midrange drivers. There is no tweeter involved in this set.

Is there a formula for replacing these iron cores with Air-Cores? When replacing, I will need to keep the DCR the same. I take it I need to keep the mH the same as well. Do I need to keep the AWG the same, or can I use a larger AWG (going with a smaller number)?

I am thinking of going with Solen Air Core Inductors as a replacement inductor.

I'd appreciate any input that anyone can give in this field of expertise.

Thanks much!!!

You will need additional turns with an air core inductor in order to get the same inductance as the iron core. Therefore, if you want to keep DC resistance the same you will need to increase the wire size (larger diameter). Expect the physical size to increase significantly as well.

Hi,

So you have, and actually and plan on replacing air cored

inductors with air cored inductors ? You haven't a hope

in hell of finding a standard 14mH air core with 11R DCR,

it will need to be custom wound for purpose.

If you want air cores the same DCR as the cored inductors

they are going to be very big and very expensive. At this

point you should really consider it its worth it, for each coil.

rgds, sreten.

So you have, and actually and plan on replacing air cored

inductors with air cored inductors ? You haven't a hope

in hell of finding a standard 14mH air core with 11R DCR,

it will need to be custom wound for purpose.

If you want air cores the same DCR as the cored inductors

they are going to be very big and very expensive. At this

point you should really consider it its worth it, for each coil.

rgds, sreten.

The Shavano Music site has a suitable calculator, the link is below. Just plug in your inductance and it calculates the turns and layers for minimum copper use for all the wire gauges commonly in use. You need to select the wire size based on the DC resistance you need.

Shavano Music Online - Cross-Over Network; Air Core Inductor Calculator

The hard part is finding a supply of wire long enough. I ended up buying 50kg of 2mm wire to wind my own crossover inductors, 20mH and 2mH. Way more than I really wanted.

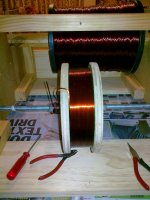

Tried a hand winder, couldn't keep the tension constant. So designed and built my own electric winder based on a scrap yard windscreen wiper motor. Had to make a pulse width modulated drive circuit to give variable speed control with good torque - 2 mm wire is quite stiff. Had to steal the foot control from you-know-who's sewing machine as well. Photo attached of the winding machine and the finished inductors. It took months to find the copper and sort out the winder and only days to actually do the coils.

The 20mH ended up weighing about 5kg. Its very big.

The end result is worth all the effort.

Shavano Music Online - Cross-Over Network; Air Core Inductor Calculator

The hard part is finding a supply of wire long enough. I ended up buying 50kg of 2mm wire to wind my own crossover inductors, 20mH and 2mH. Way more than I really wanted.

Tried a hand winder, couldn't keep the tension constant. So designed and built my own electric winder based on a scrap yard windscreen wiper motor. Had to make a pulse width modulated drive circuit to give variable speed control with good torque - 2 mm wire is quite stiff. Had to steal the foot control from you-know-who's sewing machine as well. Photo attached of the winding machine and the finished inductors. It took months to find the copper and sort out the winder and only days to actually do the coils.

The 20mH ended up weighing about 5kg. Its very big.

The end result is worth all the effort.

Attachments

Did you measure the losses of your 20mH versus frequency? The proximity effectt I reckon will be a killer with multiple layers of 2mm wire, though if its only for bass duty (say under 200Hz) this may be immaterial.

Going from iron cored to air cored, proximity effect is the thing to watch out for. Although there are no core losses with air cores, its jolly hard to get low copper losses at higher frequencies. Litz wire might be a solution though I've not tried it myself.

Going from iron cored to air cored, proximity effect is the thing to watch out for. Although there are no core losses with air cores, its jolly hard to get low copper losses at higher frequencies. Litz wire might be a solution though I've not tried it myself.

Not sure I understand you.

Yes the 20mH coil is for the woofer and there is DC resistance, but that is accounted for in the cross over to the full range. At audio frequencies there will be some interwinding capacitance but it really is not significant. And who cares if a few mV of 20kHz out of 70V gets to see the woofer, its not going anywhere.

Litz wire is used to create very large cross sectional surface area to reduce skin effects. Skin effects do not create measurable impedance until very high frequencies, MF / HF and above.

Proximity effect? If you mean external influences to the dynamic magnetic field around the coils I suggest you go back to solenoid theory. The external field is identical for iron and air cores and depends on inductance. Anyway there is nothing of a large enough scale to influence it. Both coils are separated by more than their diameters, the nearby iron is the form of stainless wood screws and nearby copper is not looped and is too short to create measurable back emf.

It is iron cores that have all the issues. Saturation. Non-linear permeability. etc

Yes the 20mH coil is for the woofer and there is DC resistance, but that is accounted for in the cross over to the full range. At audio frequencies there will be some interwinding capacitance but it really is not significant. And who cares if a few mV of 20kHz out of 70V gets to see the woofer, its not going anywhere.

Litz wire is used to create very large cross sectional surface area to reduce skin effects. Skin effects do not create measurable impedance until very high frequencies, MF / HF and above.

Proximity effect? If you mean external influences to the dynamic magnetic field around the coils I suggest you go back to solenoid theory. The external field is identical for iron and air cores and depends on inductance. Anyway there is nothing of a large enough scale to influence it. Both coils are separated by more than their diameters, the nearby iron is the form of stainless wood screws and nearby copper is not looped and is too short to create measurable back emf.

It is iron cores that have all the issues. Saturation. Non-linear permeability. etc

Not sure I understand you.

It looks from your post that you don't. I asked if you'd measured the AC losses of your coil - I take it from a lack of response to that question that you haven't. Fair enough.

Where are you crossing over the woofer?

Its standard electronagnetics, covered in Wikipedia - Proximity effect (electromagnetism) - Wikipedia, the free encyclopediaProximity effect?

Then I take it that proximity effect is currently an unknown phenomenon to you. The Wikipedia entry might help to enlighten you.It is iron cores that have all the issues. Saturation. Non-linear permeability. etc

I have seen these arguements for years about air-core versus ferrite core inductors, but with my ears long ago being shot, I can't hear a difference.

Yes, with air-core you don't have to worry about the core magnetically saturating and causing distortion, but you have either as already stated, larger series resistance, or you have to use a much heavier gauge of wire.

The only thing that I ever felt made a substantial difference was never to use electrolytic capacitors in the crossovers. And in that area my ears could never tell the difference between polyester (mylar) and polypropylene caps, which I still have piles of I would like to sell off.

Yes, with air-core you don't have to worry about the core magnetically saturating and causing distortion, but you have either as already stated, larger series resistance, or you have to use a much heavier gauge of wire.

The only thing that I ever felt made a substantial difference was never to use electrolytic capacitors in the crossovers. And in that area my ears could never tell the difference between polyester (mylar) and polypropylene caps, which I still have piles of I would like to sell off.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- Iron Core Inductors to Air Core Inductors