****WARNING !!! This process uses strong chemicals that can produce health and safety hazards. The items used are neither fireproof nor flame retardant. The user must consider and assume all risks involved.

As with all DIY projects - SAFETY MUST BE THE FIRST CONSIDERATION. ****

Here is a quick pictorial on DIY PCBs. Once the materials are collected the laminating and clamping process takes less than twenty minutes.

Double waxed paper on flat surface. Some coat it with cooking spray but I haven't found it necessary.

For this project I used both woven and bulk pad fabric.

Flow an spread some of the resin/hardener mixture on the core. Don't try to make it too uniform on this step as the mat will pull apart and make uneven clogs.

Cover that with a second layer of the woven fabric. Distribute the remainder on the mixture and smooth out with a flat tool. Try to get an even amount on the entire sandwich.

You don't have to be perfect as the next step helps the distribution.

Cover the entire sandwich with another piece of waxed paper and then the top clamping plate.

If you have long reach clamps, start in the middle and work out. If you don't own clamps just place something very heavy on the top - apiece of plywood or metal, a ceramic tile or for perfectionists - a square of marble/granite flooring from your local home improvement store.

After 2 -6 hours, depending how you mixed the resin and hardner - and the thickness - this is what you get.

A little trimming (did mine on an old tile saw) and a uniform, strong product is ready for final smoothing (optional) and sizing. These are 7.5" X 7" and 1.75" X 10".

The thickness can be adjusted by using the desired amount of the matt fabric if you have it. The auto parts stores carry a variety of kits that may or may not include the matting. Several layers of the woven stuff also works well .

In the next days I'll continue with the sizing, drilling and finishing of an example PS project,

As with all DIY projects - SAFETY MUST BE THE FIRST CONSIDERATION. ****

Here is a quick pictorial on DIY PCBs. Once the materials are collected the laminating and clamping process takes less than twenty minutes.

Double waxed paper on flat surface. Some coat it with cooking spray but I haven't found it necessary.

For this project I used both woven and bulk pad fabric.

Flow an spread some of the resin/hardener mixture on the core. Don't try to make it too uniform on this step as the mat will pull apart and make uneven clogs.

Cover that with a second layer of the woven fabric. Distribute the remainder on the mixture and smooth out with a flat tool. Try to get an even amount on the entire sandwich.

You don't have to be perfect as the next step helps the distribution.

Cover the entire sandwich with another piece of waxed paper and then the top clamping plate.

If you have long reach clamps, start in the middle and work out. If you don't own clamps just place something very heavy on the top - apiece of plywood or metal, a ceramic tile or for perfectionists - a square of marble/granite flooring from your local home improvement store.

After 2 -6 hours, depending how you mixed the resin and hardner - and the thickness - this is what you get.

A little trimming (did mine on an old tile saw) and a uniform, strong product is ready for final smoothing (optional) and sizing. These are 7.5" X 7" and 1.75" X 10".

The thickness can be adjusted by using the desired amount of the matt fabric if you have it. The auto parts stores carry a variety of kits that may or may not include the matting. Several layers of the woven stuff also works well .

In the next days I'll continue with the sizing, drilling and finishing of an example PS project,

Last edited:

It's worth it to someone like me who already has the materials on hand, likes to tinker and is sometimes needing (impatient) a solution sooner than ordering and shipping can provide. Unfortunately it is not flame retardant so it's use is at the risk of the user. I suspect if temps high enough to ignite the fiberglass are present, other components will have failed before that happens. The user/builder must make the proper considerations. Mine have worked well over a long period.

As for cost, half of the $17 kit I bought many years ago was used for auto body patching. With what's left I could make 10 -12 more slabs about the size of those shown above. I'm not claiming this method to be a full on substitute for what is commonly used for PCBs. It's simply info on something that has worked for me when needed.

Thanks for pointing out the potential fire hazard. I'll put a disclaimer at the top of the thread.

As for cost, half of the $17 kit I bought many years ago was used for auto body patching. With what's left I could make 10 -12 more slabs about the size of those shown above. I'm not claiming this method to be a full on substitute for what is commonly used for PCBs. It's simply info on something that has worked for me when needed.

Thanks for pointing out the potential fire hazard. I'll put a disclaimer at the top of the thread.

Vacuum bagging is something I have always been interested in for building speaker cabinets. I haven't tried it yet but it's on my list.

The exact kit I bought is no longer available but this is the base product. Bondo has similar items. I'll take a look at West Systems, but what I have will probably fill my needs for years.

The exact kit I bought is no longer available but this is the base product. Bondo has similar items. I'll take a look at West Systems, but what I have will probably fill my needs for years.

Some more info you may find interesting.

http://www.ieca-inc.com/images/Laminate_Materials.pdf

FR4 is the same as standard GR4 just has flame retardant added, cos some electronics get hot, when they go wrong.

Still think its crazy though making your own PCB material. Its pretty much how its made anyway, so a good insight into the real basics of PCB material (car repair kit and copper).

making your own PCB material. Its pretty much how its made anyway, so a good insight into the real basics of PCB material (car repair kit and copper).

Now to be really clever you need to do a 3D PCB, shaped to perfectly fit a case, with different levels for the connectors and other bits. Many years ago, they did raise there heads (1990 ish) but never caught on due to the problems of handling and component stuffing for volume. Hand done though would not be a problem.

http://www.ieca-inc.com/images/Laminate_Materials.pdf

FR4 is the same as standard GR4 just has flame retardant added, cos some electronics get hot, when they go wrong.

Still think its crazy though

Now to be really clever you need to do a 3D PCB, shaped to perfectly fit a case, with different levels for the connectors and other bits. Many years ago, they did raise there heads (1990 ish) but never caught on due to the problems of handling and component stuffing for volume. Hand done though would not be a problem.

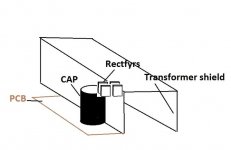

I actually was considering a multi-layer PS board for my current project yesterday. I needed to elevate the rectifiers to keep their heat snks in the air flow of a cooling fan. But I figured out a way to avoid that. Might try something fancy next time.

Attachments

Last edited:

Bob you are in the same town as the best epoxy people and company in the world.

West System Epoxy

The Gougeon Brothers

Epoxy by the Leading Epoxy Manufacturer | WEST SYSTEM Epoxy

West System Epoxy

The Gougeon Brothers

Epoxy by the Leading Epoxy Manufacturer | WEST SYSTEM Epoxy

Well now, isn't that something!! I got distracted yesterday and didn't get a chance to look them up. I was well aware of the Gougeon Brothers global reputation in power boat hulls in the sixties and seventies. An example of heir first windmill design/product is in a park about four blocks from my house. Bay City (now only about 40,000 residents) has just three internationally known figures: the worlds largest sugar broker, one of the top specialty diamond cutters in the world - and the Gougeons.

This is one of those strange "six degrees of separation" stories: The man who owns the auto parts store where I bought my fiberglass stuff is an avid bicycler (also plays trumpet). One of his riding buddies is a Gougeon, and a few months ago we were discussing the bike that dude owns - $23,000. Today a guy in Ohio tells me that the same guy is a great source for fiberglass materials and expertise for my PCB projects - right in my own backyard. That's funny.

I'll check out West next time I cross the river. Maybe I can convince them to develop a new fangle-dangle fiberglass/metal combo amp chassis design.

OOPS! Cant forget Madonna - Born here and lived with her grandmother who's grave she visits often. Ran into her at Jack's Fruit Market about fifteen years ago.

This is one of those strange "six degrees of separation" stories: The man who owns the auto parts store where I bought my fiberglass stuff is an avid bicycler (also plays trumpet). One of his riding buddies is a Gougeon, and a few months ago we were discussing the bike that dude owns - $23,000. Today a guy in Ohio tells me that the same guy is a great source for fiberglass materials and expertise for my PCB projects - right in my own backyard. That's funny.

I'll check out West next time I cross the river. Maybe I can convince them to develop a new fangle-dangle fiberglass/metal combo amp chassis design.

OOPS! Cant forget Madonna - Born here and lived with her grandmother who's grave she visits often. Ran into her at Jack's Fruit Market about fifteen years ago.

Last edited:

OOPS! Cant forget Madonna - Born here and lived with her grandmother who's grave she visits often. Ran into her at Jack's Fruit Market about fifteen years ago.

Nope, can't forget Madonna. She graduated from Rochester Adams High School in Rochester, Michigan in 1976. I graduated from there in 1975. As far as cheerleaders go, let's just say there were several others that were, ahem, better looking...

This smoothing step is optional. A blob of Bondo, some paste hardener and a full mixture with a plastic tool.

A thin layer that mostly just fills in the fabric weave.

Some sanding and flat black paint (might use red someday) and the board is ready.

This is where the PS layout changed so I used the big piece shown earlier.

Layout/spacing for parts.

Drew out the plates and connections and transferred that to the 0.025 copper.

This time I used both scissors and a scrolling band saw blade for the cuts.

Attached double sided tape and stacked everything for uniform hole positions when drilled on a drill press. Still messed up a little.

Everything seems to fit !!

]

]

Caps were soldered in first. Hand drill and file still needed for a few adjustments

Alu scrap to keep resistors up off the board.

Was going to insulate and wrap 0V leg over the rectifier leads but placed it on the top of the board instead.

That's it!!! Both units make +/- 25.4 VDC on today’s tests.

Now don't be telling me that it's too much fuss and mess and takes too long. I have a bunch of friends my age who don't realize that if you don't hit a silly white ball with a stick – you wouldn't have to go chase it. They spend hours doing that repeatedly and never get the point.

Some spend endless hours polishing their vintage silver 1968 Shelby Mustang - and never drive it.

I think this is a more productive use of my time.

A thin layer that mostly just fills in the fabric weave.

Some sanding and flat black paint (might use red someday) and the board is ready.

This is where the PS layout changed so I used the big piece shown earlier.

Layout/spacing for parts.

Drew out the plates and connections and transferred that to the 0.025 copper.

This time I used both scissors and a scrolling band saw blade for the cuts.

Attached double sided tape and stacked everything for uniform hole positions when drilled on a drill press. Still messed up a little.

Everything seems to fit !!

Caps were soldered in first. Hand drill and file still needed for a few adjustments

Alu scrap to keep resistors up off the board.

Was going to insulate and wrap 0V leg over the rectifier leads but placed it on the top of the board instead.

That's it!!! Both units make +/- 25.4 VDC on today’s tests.

Now don't be telling me that it's too much fuss and mess and takes too long. I have a bunch of friends my age who don't realize that if you don't hit a silly white ball with a stick – you wouldn't have to go chase it. They spend hours doing that repeatedly and never get the point.

Some spend endless hours polishing their vintage silver 1968 Shelby Mustang - and never drive it.

I think this is a more productive use of my time.

Pass DIY Addict

Joined 2000

Paid Member

Thanks.

Yea, when I was in high school "The Market" was always set up for hockey or speed skating. Now days they only use it for flea markets and Christmas tree sales. My HS choral director had a son who did speed skating in the Olympics - and Terry McDermott got the gold in 1964. We'll put him on the BC favs list right after Madonna

Yea, when I was in high school "The Market" was always set up for hockey or speed skating. Now days they only use it for flea markets and Christmas tree sales. My HS choral director had a son who did speed skating in the Olympics - and Terry McDermott got the gold in 1964. We'll put him on the BC favs list right after Madonna

Terry McDermott, I remember him. As a kid I did a little local speedskating. Then we had a big meet (maybe 1959) and Terry was in it. Then told me that the next season I would race in Terry's class. I didn't race that next season. 15 years later we got a new rink and I slowly got back into racing.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- DIY Fiberglass PCB Strata Construction