Hey,

I'm interested in building my own speaker cable, using UPOCC Neotech copper from NEOTECH - Solid Core Copper, PVC Jacket (UP-OCC Mono-Crystal design)

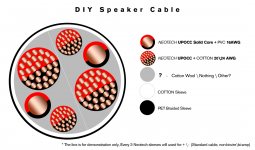

Here's some sketch that I designed, the total length of the cable supposed to be 2.5 meters (8 ft) = (x2 left \ right)

Questions:

1. What do you think about the isolation? is that 'allowed' to use a several isolation materials? (PVC+Cotton+PET sleeve)

2. Is that 'allowed' to use multi-stranded with solid-core?

3. What do you think about the whole thing?

I will use XLO 24K gold spades in both sides as termination (+shrink tube).

I'd love to hear your opinions.

Thanks, and sorry for my English.

I'm interested in building my own speaker cable, using UPOCC Neotech copper from NEOTECH - Solid Core Copper, PVC Jacket (UP-OCC Mono-Crystal design)

Here's some sketch that I designed, the total length of the cable supposed to be 2.5 meters (8 ft) = (x2 left \ right)

Questions:

1. What do you think about the isolation? is that 'allowed' to use a several isolation materials? (PVC+Cotton+PET sleeve)

2. Is that 'allowed' to use multi-stranded with solid-core?

3. What do you think about the whole thing?

I will use XLO 24K gold spades in both sides as termination (+shrink tube).

I'd love to hear your opinions.

Thanks, and sorry for my English.

Attachments

Last edited by a moderator:

I think you are wasting your time and money. That is my opinion. Except in pathological cases (including some 'high end' cables, whether DIY or expensively bought), any sound degradation introduced by a speaker cable will be entirely negligible when compared to the effects of the speaker itself. Interconnects are more important, although still relatively unimportant when compared with the electronics.

Others will disagree.

Others will disagree.

I think you are wasting your time and money. That is my opinion. Except in pathological cases (including some 'high end' cables, whether DIY or expensively bought), any sound degradation introduced by a speaker cable will be entirely negligible when compared to the effects of the speaker itself. Interconnects are more important, although still relatively unimportant when compared with the electronics.

Others will disagree.

Everything makes a difference , yes very much so ...

Simple..

Borrow some so called super cables - compare them to reasonably high current (modestly priced) equivalents [in a blind test - you need someone to help..].. If you can identify the so called better cables most of the time - spend your money if not , like most people I know who have tried this, spend your money on something that makes a noticeable difference... You may have guessed in my inexperience [tested in a recording studio situation] there is (very) little to be gained here..

Ported

Borrow some so called super cables - compare them to reasonably high current (modestly priced) equivalents [in a blind test - you need someone to help..].. If you can identify the so called better cables most of the time - spend your money if not , like most people I know who have tried this, spend your money on something that makes a noticeable difference... You may have guessed in my inexperience [tested in a recording studio situation] there is (very) little to be gained here..

Ported

I don't like the solid coreof your neotech cable. Diffilcult to make a good crimp to industrial spade lugs. 16 ga wire is pretty wimpy for power amps over 60 watts per channel. I like surplus (from the dumpster) industrial 3SO10 or 4SO10 cable. Also sold by the reel at industrial supply houses. 10 gauge, multistrand copper extra flexible wires. Easy strip rubber insulation, rated 600 VAC. Regular industrial wire is 19 strand, not very flexible. On my Dynakit ST120 amp or CS800s amp I can hear the difference on high frequencies (bells, top octave grand piano) between 25' of 16 gauge zip cord, and 8' of 10 ga 4SO10 cable. The ST70 amp has too much harmonic distortion (1%?) for this difference to be audible. This is using the 8 ohm (5.5 minimum) SP2-XT speakers.

I've seen some speaker and power cables, there were cotton or similar stuff, but sure it was not for isolation, the purpose was filling the space to look cable round after outer jacket is weared on it.1. What do you think about the isolation? is that 'allowed' to use a several isolation materials? (PVC+Cotton+PET sleeve)

I have built new cables using Cat 5 UTP cable, following these instructions: The "Full Frequency Range Cable"

I am very happy with them. They do not sound worse than my expensive cables in my main system.

Michael

I am very happy with them. They do not sound worse than my expensive cables in my main system.

Michael

copper is wonderful stuff. It conducts electricity very well.

The only substance better is Silver.

Avoid corrosion on your copper and your have the next best thing to using silver.

You can avoid the corrosion by plating. The plating can be silver, or tin, or solder (tin/lead) referred to as tinned copper.

But is solder (tinned) copper still available now that we are supposed to be rohs?

Add some insulation.

You don't need anything else !

The only substance better is Silver.

Avoid corrosion on your copper and your have the next best thing to using silver.

You can avoid the corrosion by plating. The plating can be silver, or tin, or solder (tin/lead) referred to as tinned copper.

But is solder (tinned) copper still available now that we are supposed to be rohs?

Add some insulation.

You don't need anything else !

Speaker, amp, and the cable connecting them are a system. One cannot be considered without the other.

The cable can make a difference, but what difference is system dependent.

There is certainly a lot of snake oil in cables. But that doesn't mean that cable is not important. There are also a lot of amplifier/speaker combos that do not have the DDR to be able to reveal the subtle differences. And at least as many listeners who have not had the intense critical listening training to pick out this information (the established time period for any endeavor is 10,000 hours).

So in the end you have to listen in your system and spend your money on those things that make a difference to you.

Chris & i have both worked hifi retail, and since getting out have done a lot of experimenting with speaker cables.

We are both frugal-philes (tm), and after much experimenting, with our typical speakers (small SE or PP tube amps & FR speakers) we have ended up using single strands of cryo-treated solid core cat 5, with permantly attached O'Netics groundside electron pools.

Cat 5 is quality copper wire and cheap because we get to ride on the backs of the billions of miles made for the computer industry. May not be an absolute best, but certainly wins any bang for the buck (for our systems)

dave

The cable can make a difference, but what difference is system dependent.

There is certainly a lot of snake oil in cables. But that doesn't mean that cable is not important. There are also a lot of amplifier/speaker combos that do not have the DDR to be able to reveal the subtle differences. And at least as many listeners who have not had the intense critical listening training to pick out this information (the established time period for any endeavor is 10,000 hours).

So in the end you have to listen in your system and spend your money on those things that make a difference to you.

Chris & i have both worked hifi retail, and since getting out have done a lot of experimenting with speaker cables.

We are both frugal-philes (tm), and after much experimenting, with our typical speakers (small SE or PP tube amps & FR speakers) we have ended up using single strands of cryo-treated solid core cat 5, with permantly attached O'Netics groundside electron pools.

Cat 5 is quality copper wire and cheap because we get to ride on the backs of the billions of miles made for the computer industry. May not be an absolute best, but certainly wins any bang for the buck (for our systems)

dave

copper is wonderful stuff. It conducts electricity very well.

The only substance better is Silver.

Aluminum is a better conductor per unit mass (and per unit cost).

No need to say any more. You clearly have a very advanced system which uses technology unknown to human science. With such a system it is not surprising that speaker cables make a big difference.planet10 said:with permantly attached O'Netics groundside electron pools.

The cat 5 cable the ATT telephone guy gave me to rewire my house was about 30 gauge. I would think a single pair of this would cause damping factor problems on the bass. However, considering the picture of Planet 10's speaker which had about a dozen 4"x10" horns (estimate) maybe he listens to recorder (flute) ensembles exclusively where there isn't any bass. Or Japanese No music of flutes and bells or similar source material.We are both frugal-philes (tm), and after much experimenting, with our typical speakers (small SE or PP tube amps & FR speakers) we have ended up using single strands of cryo-treated solid core cat 5, with permantly attached O'Netics groundside electron pools.

Cat 5 is quality copper wire and cheap because we get to ride on the backs of the billions of miles made for the computer industry. May not be an absolute best, but certainly wins any bang for the buck (for our systems)

dave

I paid zero for the SO4 cable I fished out of the trash. It is no longer suitable for 460 VAC motor service having been run over by a forklift. However, a shortened piece is fine for 56 VAC service into a 300W 8 ohm speaker.

As far as the training of my ear, after 10 years of private lessons and public school rehearsal, I made Tex Mus Ed Assn 1968 All State Band on bassoon. I tune the Steinway piano, myself, using the Hammond as reference. And the salesmen at Circuit City and Best Buy haven't been able to sell me anything, since the equipment they sell is such ****, the music they play is ****, and the audition room such a disaster (CC 5 sides, BB no sides at all). Home Entertainment in Houston, TX in 1976, gave the last equipment demonstration that impressed me. The speaker demonstration of the SP2/CS600s that Far Out Music (Clark Cty, IN) gave had all of 2 solo piano notes on the CD, in a tin roofed room, but was good enough to get me out to listen to a used set of SP2-XT speakers on a CS800s with my own CD in a trailer in rural KY. Its Much better in my parallelapiped living/dining room.

Last edited:

The cat 5 cable the ATT telephone guy gave me to rewire my house was about 30 gauge. I would think a single pair of this would cause damping factor problems on the bass. However, considering the picture of Planet 10's speaker which had about a dozen 4"x10" horns (estimate) maybe he listens to recorder (flute) ensembles exclusively where there isn't any bass.

Cat 5 is typically 24 g. With the amps & speakers i run it has little effect on damping factor. Further a high damping factor usually results in leaner bass.

4x10" horns? I know not what you speak of. My speakers typically have 1 3-5" driver. Some of them produce quite extrodinary bass. And there are a number of helper woofers and sub woofers that can be deployed when necessary.

dave

those facts will never convince me to dump my copper cables and change over to aluminium cables in any part of my house.Aluminum is a better conductor per unit mass (and per unit cost).

I did use aluminium with VERY thin insulation for the high current cable in my last two racing cars. But that is not about audio quality.

So they didn't sound good as speaker cables?I did use aluminium with VERY thin insulation for the high current cable in my last two racing cars. But that is not about audio quality.

IACS is the abbreviation for International Annealed Copper Standard and the number preceding "IACS" is the percentage of conductivity a material has relative to copper, which is considered to be 100% conductive. This does not, of course, mean that copper has no resistance, but rather that it is the standard by which other materials are compared. The higher the % IACS, the more conductive the material is. This standard is based on an annealed copper wire having a density of 8.89 g/cm3, 1 meter long, weighing 1 gram, with a resistance of 0.15328 ohms. This standard is assigned the value 100 at 20°C (68°F). Here are some examples of conductivity values for a few common materials. Material ICAS % Conductivity Silver 105% Copper 100% Gold 70% Aluminum 61% Brass 28% Zinc 27% Nickel 22% Iron 17% Tin 15% Phosphor Bronze 15% Lead 7% Nickel Aluminum Bronze 7% Steel 3 to 15%

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- DIY Speaker cable, need some advices \ opinions.