Putting one in a vise crosswise is by far the most reasonable approach. If not on the first try, in the next few one of them will show you the die surface neatly, minus bond wires. If you're trying to save the wiring or trying to transplant the die, oh well, but for ID, especially since you have a pile, mechanical is the best way to go.

Tried several on mechanical, vise crush from the sides.

The die is not left in good condition that I can see. Nothing that can be identified one way or the other as die (A) or die (B)...

Over the weekend I can try much higher magnification and try to see what is going on in terms of seeing the surface of the die. No luck thus far.

Also the die has seemed to be partially destroyed when the plastic is de-laminated, thus far.

_-_-bear

Looks like a lost cause thus far. Paypal may save me some $$, we'll see.

PS. now that I know where the die is inside the thing, I may try some jewelers saws to hack most of the way on all sides, and then try a gentle wedge or a crush at that point, hopefully not destroying the die quite so well

The die is not left in good condition that I can see. Nothing that can be identified one way or the other as die (A) or die (B)...

Over the weekend I can try much higher magnification and try to see what is going on in terms of seeing the surface of the die. No luck thus far.

Also the die has seemed to be partially destroyed when the plastic is de-laminated, thus far.

_-_-bear

Looks like a lost cause thus far. Paypal may save me some $$, we'll see.

PS. now that I know where the die is inside the thing, I may try some jewelers saws to hack most of the way on all sides, and then try a gentle wedge or a crush at that point, hopefully not destroying the die quite so well

Some heat is a good idea.

I guess the layer of conformal coating over encapsulated power dies does't exist in the signal packages. So the epoxy is bonded directly to the die.

Enough heat would probably make some really smelly smoke. If they're copper leaded and you put a good heat sink on the collector you might be able to torch it crumbly without harming the die.

I guess the layer of conformal coating over encapsulated power dies does't exist in the signal packages. So the epoxy is bonded directly to the die.

Enough heat would probably make some really smelly smoke. If they're copper leaded and you put a good heat sink on the collector you might be able to torch it crumbly without harming the die.

Last edited:

davidsrsb, there is only *one* source for this part: Toshiba.

So there should be only one die.

As far as assembly plants, I dunno that answer.

They could all use different stuff inside the black package.

I will have at another one or two tomorrow and see if I can manage to get it to open without destroying the die...

_-_-bear

So there should be only one die.

As far as assembly plants, I dunno that answer.

They could all use different stuff inside the black package.

I will have at another one or two tomorrow and see if I can manage to get it to open without destroying the die...

_-_-bear

Are they labeled "Toshiba"? If so, contact Toshiba and tell them you suspect you have some counterfit parts. They might offer to decap them to check if you are willing to tell them exactly where these parts were purchased. Counterfit parts are a hot topic among semiconductor makers nowadays.

Good thought, but Toshiba oddly enough did not actually put a logo or label on their jfets! Also Toshiba has stopped production on this part. They are dropping their entire JFET line it would seem. Plus communicating with these companies is an exercise in futility. And, I would expect that they are acutely aware of pirating and counterfeiting in asia.

Looks like a lost cause.

_-_-bear

Looks like a lost cause.

_-_-bear

this may be of some value....a year ago I accidently asked for too much current through a Fairchild TO-92 jfet, and it let out a very small hint of smoke. It appeared mostly normal. but a loop revealed a short crack in the epoxy. A small amount of squeeze in a vise was applied and it cracked nicely into it's original pieces.

It even still had one of the wires from the legs to the die attached. I looked at it at 8 power, and it seemed to be in mostly in original condition, meaning the die had not burned up or melted. I believe it was something like 3 - 5 times the rated curent, not a total short.

If you have enough samples, maybe try to overheat it some from the inside to loosen it up a bit, before trying the crush.

It even still had one of the wires from the legs to the die attached. I looked at it at 8 power, and it seemed to be in mostly in original condition, meaning the die had not burned up or melted. I believe it was something like 3 - 5 times the rated curent, not a total short.

If you have enough samples, maybe try to overheat it some from the inside to loosen it up a bit, before trying the crush.

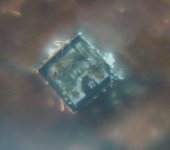

I still had the parts taped to a piece of paper, so here are a few photos. These were taken hand held with an old 4MP Sony shooting through the eye piece of a 20 power loupe, shimmed up with business cards to get the focal distance right. So it popped apart quite clean when slightly over heated.

Attachments

Jitter, I don't know exactly. But the more certain that I am that these are not Toshiba the stronger my response will be... in various regards.

One supplier has agreed to take back one batch back, it remains to be seen if I will get anything back after I send it overseas.

I had ordered from a few suppliers figuring that they all wouldn't have bogus parts... ha ha.

DaveG, looks good. I've tried to crack a few, the results were not as good as yours. I may try some external heat and then a crack... what I saw through my stereo inspection microscope was a square blob that did not reveal any discernible surface characteristics that could be identified as one type of die layout or another... reasonably confounding in fact.

_-_-bear

One supplier has agreed to take back one batch back, it remains to be seen if I will get anything back after I send it overseas.

I had ordered from a few suppliers figuring that they all wouldn't have bogus parts... ha ha.

DaveG, looks good. I've tried to crack a few, the results were not as good as yours. I may try some external heat and then a crack... what I saw through my stereo inspection microscope was a square blob that did not reveal any discernible surface characteristics that could be identified as one type of die layout or another... reasonably confounding in fact.

_-_-bear

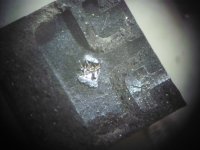

Here's the problem with the crack in the vise to open - the die surface is shattered. Apparently the epoxy is tenacious.

This one was with some significant heating first... propane torch... then a crack.

maybe next time I will apply excess heat to the pins, but I suspect that will pull the die off the flat copper area inside the package.

_-_-

This one was with some significant heating first... propane torch... then a crack.

maybe next time I will apply excess heat to the pins, but I suspect that will pull the die off the flat copper area inside the package.

_-_-

Attachments

Well, I have a TO-92 case that so far I have soaked in room temp (RT) methanol, DMSO, Toluene, Chloroform, Acetone, DMF, Octadecene and water (because why not). Nothing so far has shown any signs of working. I'm debating boiling DMSO, if that doesn't work then I'm thinking agua regia next

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- unpotting, solvent, melting agent, removal agent, for transistor or IC cases??