Chris, can you please elaborate on your comment about "lead spacing". I'm a bit confused. I mean I do understand that lead spacing is important for proper fitment but where I am confused is how going up in voltage rating helps maintain the lead spacing.Gnerally speaking, only the capacitors in the power supply in good equipment are under stress. Those should be looked at and it depends on how warm it was running. One thing I do is make sure the replacement capacitors have the same lead spacing, which often means going up in voltage rating (a good thing anyway). That way the parts do fit properly. Some times an 85° part will perform better than a 105 ° part. I test them looking for dissipation rating, ESR isn't that important as they are similar with good parts. Do not increase the capacitance however.

-Chris

Last edited:

Hi Mitsu,

Today's capacitors are normally much smaller than the older ones. When you look at pricing and quality, you'll find that in general, the larger case capacitors for the same voltage and capacitance are better capacitors, but more expensive. So that is my first choice, and if the lead spacing is still too small (close together), I go up in voltage until the leads are the right size. So that could be 5 mm, 7.5 mm or 10 mm for the smaller capacitors. This costs less than the time it takes to properly bend the leads.

The issue is, it takes time to properly support and bend the leads so you do not damage the rubber seal. 99% of replaced capacitors I see have simply been jammed in, and spreading the leads can easily break/damage that seal. You need to support the lead at the can base and bend out, then support the lead again between the case and where you are bending to bend them downwards. That way the replacement part fits the holes without damaging the seal. It's easier and you get a better capacitor if you simply get one with the leads spaced the correct distance.

These poorly installed parts normally do not fail soon after installation, but years later. Try and troubleshoot those ('cause there will be more than one) or simply reduced values and other changes. So all those "recap" experts are doing much more harm than good. It's the little things in the business (doesn't matter what business) that make all the difference. The true skilled people deal with the details. Those who don't gladly think they know, but haven't a clue. There is a lot to know about any profession.

-Chris

Today's capacitors are normally much smaller than the older ones. When you look at pricing and quality, you'll find that in general, the larger case capacitors for the same voltage and capacitance are better capacitors, but more expensive. So that is my first choice, and if the lead spacing is still too small (close together), I go up in voltage until the leads are the right size. So that could be 5 mm, 7.5 mm or 10 mm for the smaller capacitors. This costs less than the time it takes to properly bend the leads.

The issue is, it takes time to properly support and bend the leads so you do not damage the rubber seal. 99% of replaced capacitors I see have simply been jammed in, and spreading the leads can easily break/damage that seal. You need to support the lead at the can base and bend out, then support the lead again between the case and where you are bending to bend them downwards. That way the replacement part fits the holes without damaging the seal. It's easier and you get a better capacitor if you simply get one with the leads spaced the correct distance.

These poorly installed parts normally do not fail soon after installation, but years later. Try and troubleshoot those ('cause there will be more than one) or simply reduced values and other changes. So all those "recap" experts are doing much more harm than good. It's the little things in the business (doesn't matter what business) that make all the difference. The true skilled people deal with the details. Those who don't gladly think they know, but haven't a clue. There is a lot to know about any profession.

-Chris

Thanks, that is an old design. Nothing remarkable and certainly will not benefit from huge amounts of capacitance at all.

So for max current peaks (that is what you are talking about - right?), you need a capacitor that can take and release energy quickly. That description is not for a huge capacitor. You would probably be clipping for this to be a factor anyway. Keep in mind that music has a peak to average level of between 10 and 15 dB, although you can find examples outside of this. That means that listening to a digital source at 10 watts average, your amplifier may well be clipping. Now, reconsider what you are worried about. You will only ever draw peak currents delivering a sine wave into a dummy load (most speakers will not survive that power level even though they are rated for it). So .... you're concerned about what exactly?

You didn't list the bias current, I'll assume betwen 50 and 100 mA. Any more is excessive. I guess you have three caps per rail for the high current supply then? The driver supply doesn't need very much at all. So for the high current supply, you could use 3,300 uF (that's 9,900 uF per rail) and have a ton of excess capacity. They would perform much better and greatly reduce hot switching current and hash from rectification. the inrush current would then also be at sane levels with an E-I transformer (better), a toroid requires a soft start and doesn't do much more than allow higher frequency line noise in, and conduct heavily with effective DC on your mains if there is any.

Smaller capacitors in parallel are only effective near the point of load (or use), and even smaller ones near the rectifiers to try and reduce switching noise. The best way to to avoid generting HF hash as much as possible to begin with.

I'm cetain the designer thinks this is superior to any amplifier that ever came before. You should be more concerned about PCB layout and wire lead dress as that makes a much bigger difference in performance. Think about what I just told you, and figure out your average current at a 10 watt power level.

-Chris

Are you serious ? ANY electrolytic capacitor can work well in the audio band. Anyway at 20khz you do not have much energy in the music. The inductance of the big elcaps is insignifiance to a smaller one. Much smaller than connecting conductors. With smaller caps he will have a bigger voltage ripple.

Hi greierasul,

Please tell me what you think i said. I will address your concerns.

So tell me, how much do you think 120 Hz ripple will affect audio circuits? Hmm, now how about higher frequency ripple? How about spikes? Now, let me know what magnitude you're thinking, then compare it to the signal voltage expected - but not at a near clipping level because then there are other factors that swamp your concerns completely.

I have seen filter capacitors that had trouble with 120 Hz signals. They were admittedly massive (Bedini), but they were a perfect example of specifying the wrong capacitance. The results were predictable and yet that amp was in production for high dollars and rave reviews.

-Chris

Please tell me what you think i said. I will address your concerns.

So tell me, how much do you think 120 Hz ripple will affect audio circuits? Hmm, now how about higher frequency ripple? How about spikes? Now, let me know what magnitude you're thinking, then compare it to the signal voltage expected - but not at a near clipping level because then there are other factors that swamp your concerns completely.

I have seen filter capacitors that had trouble with 120 Hz signals. They were admittedly massive (Bedini), but they were a perfect example of specifying the wrong capacitance. The results were predictable and yet that amp was in production for high dollars and rave reviews.

-Chris

If you want to be at pease with yourself - 380LX . From an authorized distributer. Do not buy from ''ДЕД МОРОЗ''. This person doesn't existHi, guys! Now I build the Diy project of the power amp and I need to buy a large denomination of the capacitors. I am looking at two options - 380LX CDE and Nichicon LLS. They are needed in 18000uF/50V (35mm).

Which option would be better?

The series impedance of the windings transformer and rectifier are constant. With bigger cap we have a better filter in fact. If we have a smaller cap with lower ESR the situation will be worse, much more HF ripple. The biggest problem is not at rectifier opening but at closing. There is a ringing between winding parasitic capacitance and the leakage inductance of the transformer. Your smaller cap is not 100nF, is half of bigger one so is not much better at high frequency than the bigger one. If you want, you may test the capacitors for short-circuit current and see that on the oscilloscope. You will see the amplitude of the current (voltage in fact) vs time.Hi greierasul,

Please tell me what you think i said. I will address your concerns.

So tell me, how much do you think 120 Hz ripple will affect audio circuits? Hmm, now how about higher frequency ripple? How about spikes? Now, let me know what magnitude you're thinking, then compare it to the signal voltage expected - but not at a near clipping level because then there are other factors that swamp your concerns completely.

I have seen filter capacitors that had trouble with 120 Hz signals. They were admittedly massive (Bedini), but they were a perfect example of specifying the wrong capacitance. The results were predictable and yet that amp was in production for high dollars and rave reviews.

-Chris

Yes, I am well aware on how it (ringing and what causes it) works, and I have experienced this first hand over many decades and various brands. The impedance does vary with current flow however. Not much, but it does. And yes, the turn-off spike can be worse depending on the rectifier. Fast rectifiers are the worst for this.

I have studied current waveforms and voltage spikes. My current scope is a Keysight MSOX3104T with all software, and current probes. Any questions on your end about my equipment? I also have two spectrum analyzers and an audio analyzer (another specific spectrum analyzer). I also use a Keysight 6812C with internal arb. 5 19" racks full of gear with other equipment aside I can bring to the bench when needed. You are not talking to an amateur here.

Now, is circuit rejectiion higher at high frequencies or low frequencies? Where is CMRR the worst? I think that worrying about 120 Hz ripple might be the wrong focus. Large capacitors always have more HF garbage riding on the DC. ESR is not constant across the frequency spectrum. It rises quickly with frequency some times.

No one said anything about a 100nF capacitor. Not me anyway. That size range is for snubbers, or to lower HF impedance at the point of load.

-Chris

I have studied current waveforms and voltage spikes. My current scope is a Keysight MSOX3104T with all software, and current probes. Any questions on your end about my equipment? I also have two spectrum analyzers and an audio analyzer (another specific spectrum analyzer). I also use a Keysight 6812C with internal arb. 5 19" racks full of gear with other equipment aside I can bring to the bench when needed. You are not talking to an amateur here.

Now, is circuit rejectiion higher at high frequencies or low frequencies? Where is CMRR the worst? I think that worrying about 120 Hz ripple might be the wrong focus. Large capacitors always have more HF garbage riding on the DC. ESR is not constant across the frequency spectrum. It rises quickly with frequency some times.

No one said anything about a 100nF capacitor. Not me anyway. That size range is for snubbers, or to lower HF impedance at the point of load.

-Chris

With 37V rails I would go for 3 x 15.000

The thing is, we want stable supply voltage for high current draws at low frequencies.

Transistors like constant supply conditions, that is why we use cascodes, voltage drop at bass impulse is quiet the opposite.

Additional local decoupling near the output fets for the mid to high frequencies.

The thing is, we want stable supply voltage for high current draws at low frequencies.

Transistors like constant supply conditions, that is why we use cascodes, voltage drop at bass impulse is quiet the opposite.

Additional local decoupling near the output fets for the mid to high frequencies.

Yes, I am well aware on how it (ringing and what causes it) works, and I have experienced this first hand over many decades and various brands. The impedance does vary with current flow however. Not much, but it does. And yes, the turn-off spike can be worse depending on the rectifier. Fast rectifiers are the worst for this.

I have studied current waveforms and voltage spikes. My current scope is a Keysight MSOX3104T with all software, and current probes. Any questions on your end about my equipment? I also have two spectrum analyzers and an audio analyzer (another specific spectrum analyzer). I also use a Keysight 6812C with internal arb. 5 19" racks full of gear with other equipment aside I can bring to the bench when needed. You are not talking to an amateur here.

Now, is circuit rejectiion higher at high frequencies or low frequencies? Where is CMRR the worst? I think that worrying about 120 Hz ripple might be the wrong focus. Large capacitors always have more HF garbage riding on the DC. ESR is not constant across the frequency spectrum. It rises quickly with frequency some times.

No one said anything about a 100nF capacitor. Not me anyway. That size range is for snubbers, or to lower HF impedance at the point of load.

-Chris

Of course, the rejection is best at low frequencies and is worse the more you rise in frequency. In order too have a larger noise at HF, you must to have a bigger current in small time, spike rectifying current. So, that means the bigger cap is not that slow...

Bigger cap is not for filter or smaller ripple but is for a stiffer DC voltage. Anyway, there are three parallel caps, not only one. There is a lot of current for all musical program.

There is a real problem with types and values of the capacitors, but not at 50/60hz. The real problem is at smps at high frequency, tens, hundreds of thousand Hz.

I do not talking about people here, we talking only about science. I know you are a very good professional and I respect that 👍

Hi greierasul,

Actually a larger capacitance is slower in releasing and taking HF energy. Well documented. Multiple capacitors help, but what hasn't been addressed is that there is a practical upper limit on how much capacitance is effective and needed. Then of course there are all the downsides to high capacitance.

One inescapable fact is this. The more capacitance you have, the shorter the conduction angle is for the rectifier. When you reduce that, the peak current goes way up and quickly. Talk about exciting stray inductance and capacitance!

Ripple with lower HF content is actually preferred. It's easy to deal with 100 Hz or 120 Hz ripple. As you generate higher amplitude harmonics the nightmare begins. Low frequency is actually not the enemy at all. Besides, when the load currents get that high, you are probably clipping anyway. In other words, you have bigger problems than a little ripple on the supplies.

-Chris

Actually a larger capacitance is slower in releasing and taking HF energy. Well documented. Multiple capacitors help, but what hasn't been addressed is that there is a practical upper limit on how much capacitance is effective and needed. Then of course there are all the downsides to high capacitance.

One inescapable fact is this. The more capacitance you have, the shorter the conduction angle is for the rectifier. When you reduce that, the peak current goes way up and quickly. Talk about exciting stray inductance and capacitance!

Ripple with lower HF content is actually preferred. It's easy to deal with 100 Hz or 120 Hz ripple. As you generate higher amplitude harmonics the nightmare begins. Low frequency is actually not the enemy at all. Besides, when the load currents get that high, you are probably clipping anyway. In other words, you have bigger problems than a little ripple on the supplies.

-Chris

This can be tammed with a choke coil. The conduction angle will be longer and the charge current will be lower and closer to the sinusoidal waveform with lower harmonics. Anyway, that can be done naturly with the resistive and inductive impedance of the transformer if he know how. He can use E+I transformer instead of troroidal one.

There is an interesting thing about the smaller cap but is not about the speed of it, it is about RC charge constant. If you know the "R" of the transformer, you can choose the right capacitor such that the closing down is done on the top of voltage, when the speed of voltage is at minimum and the charging current is almost zero. I tried this 10 years ago and the result was amazing.

There is an interesting thing about the smaller cap but is not about the speed of it, it is about RC charge constant. If you know the "R" of the transformer, you can choose the right capacitor such that the closing down is done on the top of voltage, when the speed of voltage is at minimum and the charging current is almost zero. I tried this 10 years ago and the result was amazing.

Last edited:

Hi greierasul,

You can do all kinds of things. But being fancy can cause issues years down the road. Why open yourself to that?

Capacitors age and drop in value. Inductors add series resistance. With tube power supplies I have always used series resisatance before the first filter for those reasons you mentioned. Some call it brute force, but it works very nicely.

The fact remains, you only need so much capacitance depending on the application. That is called engineering. The current and past response from many who do not understand is to stuff as much capacitance as they can stomach. Probably decided on cost for the upper limit. It has been proved time and time again that extreme levels of capacitance causes problems while not enhancing the products performance one little bit. In fact, this is like a religion for some folks. There isn't anything wrong with a little extra capacitance, but too much always causes problems. It never, ever improves performance except in full power sine tests. This is not a realistic operational mode for music reproduction equipment. Besides, the real difference is slight even then. In industrial applications we never load an amplifier more than 75% to 80% of full power, and those are over designed to handle the heat generation.

Look at a music application. A 100 watt RMS amplifier will probably be well into clipping at 10 wrms average power with a digital source. That's pretty loud by the way. So we have a power supply designed for 100 watt peak power (very short duration), but loping along at 10 wrms. Please tell me where massive amounts of capacitance will help in that situation? With a less dynamic signal source, that same amplifier will be hitting clipping, so the same parameters still apply.

This is about DIY, and we should be free from market pressures. That means we can use our noggins and actually think instead of parroting back nonesense read on the internet and from manufacturers who are very sensitive to market fads. In other words, we can look at the actual operational situation of whatever we are building or fixing. Then figure out what reasonable circuit components should be used. If I'm wrong, please tell me. But 45 + years on the bench and testing re-enforces that view.

Old engineers were right. Who would have thought? Equipment designed and built in the 1960's still works well as designed. I'm currently working on one example of that. Believe me, they did everything reasonable to maximize performance back then. Audio engineers didn't get a case of the stupids until sometime in the 1970's, but good engineering in good products still prevailed.

-Chris

You can do all kinds of things. But being fancy can cause issues years down the road. Why open yourself to that?

Capacitors age and drop in value. Inductors add series resistance. With tube power supplies I have always used series resisatance before the first filter for those reasons you mentioned. Some call it brute force, but it works very nicely.

The fact remains, you only need so much capacitance depending on the application. That is called engineering. The current and past response from many who do not understand is to stuff as much capacitance as they can stomach. Probably decided on cost for the upper limit. It has been proved time and time again that extreme levels of capacitance causes problems while not enhancing the products performance one little bit. In fact, this is like a religion for some folks. There isn't anything wrong with a little extra capacitance, but too much always causes problems. It never, ever improves performance except in full power sine tests. This is not a realistic operational mode for music reproduction equipment. Besides, the real difference is slight even then. In industrial applications we never load an amplifier more than 75% to 80% of full power, and those are over designed to handle the heat generation.

Look at a music application. A 100 watt RMS amplifier will probably be well into clipping at 10 wrms average power with a digital source. That's pretty loud by the way. So we have a power supply designed for 100 watt peak power (very short duration), but loping along at 10 wrms. Please tell me where massive amounts of capacitance will help in that situation? With a less dynamic signal source, that same amplifier will be hitting clipping, so the same parameters still apply.

This is about DIY, and we should be free from market pressures. That means we can use our noggins and actually think instead of parroting back nonesense read on the internet and from manufacturers who are very sensitive to market fads. In other words, we can look at the actual operational situation of whatever we are building or fixing. Then figure out what reasonable circuit components should be used. If I'm wrong, please tell me. But 45 + years on the bench and testing re-enforces that view.

Old engineers were right. Who would have thought? Equipment designed and built in the 1960's still works well as designed. I'm currently working on one example of that. Believe me, they did everything reasonable to maximize performance back then. Audio engineers didn't get a case of the stupids until sometime in the 1970's, but good engineering in good products still prevailed.

-Chris

At 20hz, a 4.700uF will have a 1.7 ohm capacitive reactance. An 47.000uF will have ten times smaller, 0.17 ohm. Sometime, you can hear that. In a highend domain, the linear impedance of the power supply in all audio band is a must have. Ok, a larger capacitance for this situation is not the smartest choice but is simple to apply. In this moment, the caps will not be just a ripple filter, will be a energy reservoir for the lowest frequency too.

Generally speaking we don't need a huge capacitance but sometimes, with large and difficult speakers is good to have more then enough capacitance.

Generally speaking we don't need a huge capacitance but sometimes, with large and difficult speakers is good to have more then enough capacitance.

Last edited:

Let´s look at it from a slightly different angle.

If the existing cap has 15.000µF and another 2µF film cap parallel, which is very common in commercial amplifiers, what could be wrong soundwise adding another 100.000µF to make the supply more stable by lowering the impedance at low frequencies? Use R or R/L to limit the inrush current if you are worried.

I have for 32V rails of a monoblock: Fuse, 400W toroid, then for each rail: fuse, rectifier, 10.000µF, 0,33ohms, 115.000µF, fuse, 1000µF, 47µF film cap, 2µF film cap, output fets cascoded, and no noise.

One example: Pioneer 777/878 service manual: 2 x 22.000µF for both channels. Output stage V+ at no input signal is 56.5V, at rated power drops to 40,6V.

The supply voltage of the input stage drops accordingly. Bad enough.

That rated power voltage measured at 1kHz (?) will be fairly constant, but at 30Hz what will happen?, I guess the supply voltage drop will be modulated...

For comparison: Pioneer M25 which I have used for many years, has 4 x 22.000µF and the frontend has regulated higher voltage supply from separate winding.

In my opinion, better buy properly designed high quality stuff or built yourself the best you can without looking at parts cost.

Trying to fix other´s mistakes is not the way to go.

If the existing cap has 15.000µF and another 2µF film cap parallel, which is very common in commercial amplifiers, what could be wrong soundwise adding another 100.000µF to make the supply more stable by lowering the impedance at low frequencies? Use R or R/L to limit the inrush current if you are worried.

I have for 32V rails of a monoblock: Fuse, 400W toroid, then for each rail: fuse, rectifier, 10.000µF, 0,33ohms, 115.000µF, fuse, 1000µF, 47µF film cap, 2µF film cap, output fets cascoded, and no noise.

One example: Pioneer 777/878 service manual: 2 x 22.000µF for both channels. Output stage V+ at no input signal is 56.5V, at rated power drops to 40,6V.

The supply voltage of the input stage drops accordingly. Bad enough.

That rated power voltage measured at 1kHz (?) will be fairly constant, but at 30Hz what will happen?, I guess the supply voltage drop will be modulated...

For comparison: Pioneer M25 which I have used for many years, has 4 x 22.000µF and the frontend has regulated higher voltage supply from separate winding.

In my opinion, better buy properly designed high quality stuff or built yourself the best you can without looking at parts cost.

Trying to fix other´s mistakes is not the way to go.

Because the poor underdimensioned consumer class PSU fails. Standard transformer used instead of toroid, transformer to weak, caps to small. DC voltages in the circuit shifted, at low frequency even modulated, operating points changed, sound quality suffers, long story short: desaster.Look at a music application. A 100 watt RMS amplifier will probably be well into clipping at 10 wrms average power with a digital source. That's pretty loud by the way. So we have a power supply designed for 100 watt peak power (very short duration), but loping along at 10 wrms.

Last edited:

Hi Bernhard,

I respectfully disagree with you. When the amplifier is operating in a linear mode the output impedance is not what you see in the supply. It is lower. The only time you will see the reactance of the filters is when the output transistors are saturated. If that happens, sure impedance rises - but then you have far greater issues to deal with.

You have to understand how the entire system works instead of focusing on one aspect and forgetting the rest.

I respectfully disagree with you. When the amplifier is operating in a linear mode the output impedance is not what you see in the supply. It is lower. The only time you will see the reactance of the filters is when the output transistors are saturated. If that happens, sure impedance rises - but then you have far greater issues to deal with.

You have to understand how the entire system works instead of focusing on one aspect and forgetting the rest.

Chris

I did not say anything about the output impedance of the amplifier.

What I said was that the voltage of a weak supply collapses under load, so as you noted yourself:

A 100 watt RMS amplifier will probably be well into clipping at 10 wrms average power with a digital source.

So we have a power supply designed for 100 watt peak power (very short duration), but loping along at 10 wrms.

At rated power with normal listening material there will be a voltage drop and the amp will clip earlier, still as long as there are a few volts across CE, there will be no significant distortion.

But a single bass punch will drain a small to medium supply cap significantly, if you have more of those, the supply voltage will be fluctuating with the bass impulses...

As I mentioned before, designers try to keep CE voltages constant, this improves THD.

If the supply collapses to the rythm of the music, that can not be beneficial in any way.

When the frontend supply is not isolated from the output supply, the whole amplifier circuit will be affected.

Even worse if you have difficult speakers.

Many of that expensive high end gear has oversized transformers and caps, not just to impress people by the looks.

The smaller the power rating of a transformer, the higher the percentage of voltage drop at rated power.

Overrated transformers combined with large reservoir caps provide a rock solid supply.

Think about the effects of strong and weak engines of cars or motobikes...

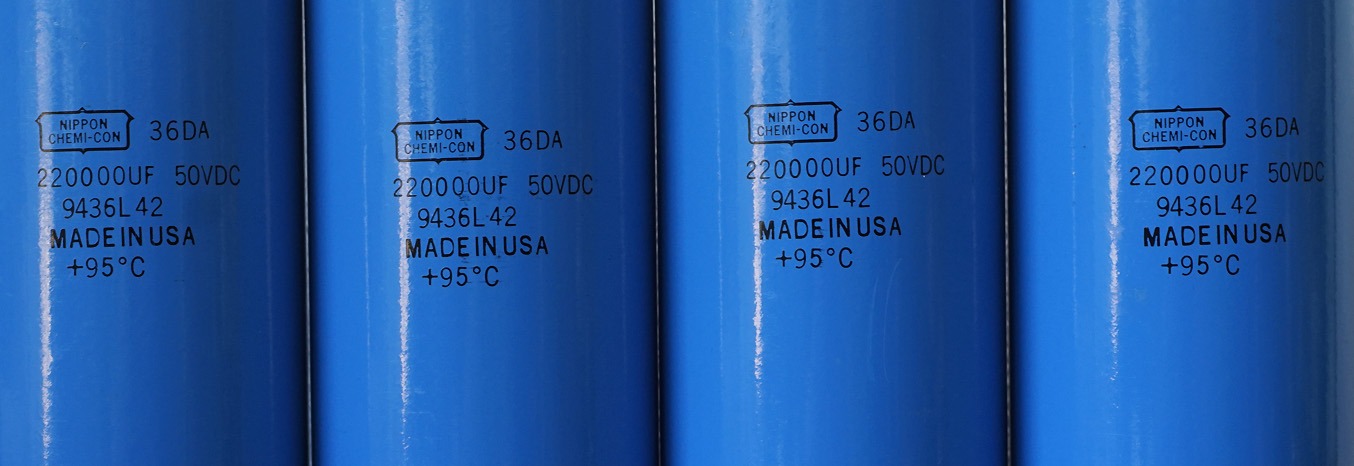

Doctor Voodoo´s recommendation for the cure: 1 each per rail.

I did not say anything about the output impedance of the amplifier.

What I said was that the voltage of a weak supply collapses under load, so as you noted yourself:

A 100 watt RMS amplifier will probably be well into clipping at 10 wrms average power with a digital source.

So we have a power supply designed for 100 watt peak power (very short duration), but loping along at 10 wrms.

At rated power with normal listening material there will be a voltage drop and the amp will clip earlier, still as long as there are a few volts across CE, there will be no significant distortion.

But a single bass punch will drain a small to medium supply cap significantly, if you have more of those, the supply voltage will be fluctuating with the bass impulses...

As I mentioned before, designers try to keep CE voltages constant, this improves THD.

If the supply collapses to the rythm of the music, that can not be beneficial in any way.

When the frontend supply is not isolated from the output supply, the whole amplifier circuit will be affected.

Even worse if you have difficult speakers.

Many of that expensive high end gear has oversized transformers and caps, not just to impress people by the looks.

The smaller the power rating of a transformer, the higher the percentage of voltage drop at rated power.

Overrated transformers combined with large reservoir caps provide a rock solid supply.

Think about the effects of strong and weak engines of cars or motobikes...

Doctor Voodoo´s recommendation for the cure: 1 each per rail.

Hi Bernhard,

I agree with you if running the system at club levels, however most people never approach this and therefore none of the effects you mention apply. Your case is a close to clipping scenario only. Now, my own system is running inefficient 4 ohm speakers (86 ~ 87 dB/watt) near clipping. I have experiemented with parallel capacitors and found no audible difference. That is a pretty severe test and if there were differences to be heard, I would have noticed them. Of course in that amplifier, each front end (voltage amp stage) has it's own regulated supply, each on its own winding. The high curernt supplies are likewise isolated.

I hyave found that expensive, boutique equipment generally has very little applied engineering. There are often layout mistakes in addition to the mindless over-sized power supply components. I will argue also that you are way further ahead with an E-I transformer. You can have a large voltage drop with sustained near clipping power poutput, but then the system is undersized. If you are doing that, electronic crossover and a higher powered bass amplifier. I know I am pushing my system much further than I should, but I am looking at 99 dB/watt speakers at 8 ohms. Now, how much equivalent power increase in amplifier power is that?

In a nutshell, most people never run their higher powered systems near clipping. Recommending they design their power supplies for a situation that probably doesn't occur is not responsible in my view. And if they do run it that high, I really doubt that sound quality to an extreme is what they are lookng for at that time. I know for me, the speakers are distorting much higher than at low power and that swamps any amplifier distortion right out. You have to have a balanced, realistic viewpoint on the entire system.

I'm just trying to be realistic here.

I agree with you if running the system at club levels, however most people never approach this and therefore none of the effects you mention apply. Your case is a close to clipping scenario only. Now, my own system is running inefficient 4 ohm speakers (86 ~ 87 dB/watt) near clipping. I have experiemented with parallel capacitors and found no audible difference. That is a pretty severe test and if there were differences to be heard, I would have noticed them. Of course in that amplifier, each front end (voltage amp stage) has it's own regulated supply, each on its own winding. The high curernt supplies are likewise isolated.

I hyave found that expensive, boutique equipment generally has very little applied engineering. There are often layout mistakes in addition to the mindless over-sized power supply components. I will argue also that you are way further ahead with an E-I transformer. You can have a large voltage drop with sustained near clipping power poutput, but then the system is undersized. If you are doing that, electronic crossover and a higher powered bass amplifier. I know I am pushing my system much further than I should, but I am looking at 99 dB/watt speakers at 8 ohms. Now, how much equivalent power increase in amplifier power is that?

In a nutshell, most people never run their higher powered systems near clipping. Recommending they design their power supplies for a situation that probably doesn't occur is not responsible in my view. And if they do run it that high, I really doubt that sound quality to an extreme is what they are lookng for at that time. I know for me, the speakers are distorting much higher than at low power and that swamps any amplifier distortion right out. You have to have a balanced, realistic viewpoint on the entire system.

I'm just trying to be realistic here.

- Home

- Design & Build

- Parts

- Best electrolytic capacitors