My toroid was foolishly mounted on a shrapnel of metal, which scraped off the insulation from the windings and caused a mean hum. I replaced the toroid years ago but now have thought that it might be fixed.

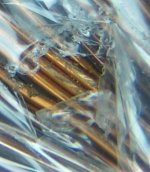

As you can see from the pic, it appears that the insulation is missing from the bottom of the windings only, and when used the exposed areas shorted to the metal case. In other words there appears to be no need to unwind, insulate, and rewind since the scraping of insulation is only (apparently) on the bottom.

hmm... How would I fix this?

I am thinking of removing some of the platic wrapping, cleaining out the chips, coating the area/windings in epoxy and then re-wrapping with electrical tape around the repaired area.

Good idea or are there better ones?

As you can see from the pic, it appears that the insulation is missing from the bottom of the windings only, and when used the exposed areas shorted to the metal case. In other words there appears to be no need to unwind, insulate, and rewind since the scraping of insulation is only (apparently) on the bottom.

hmm... How would I fix this?

I am thinking of removing some of the platic wrapping, cleaining out the chips, coating the area/windings in epoxy and then re-wrapping with electrical tape around the repaired area.

Good idea or are there better ones?

Attachments

Sounds like a good plan as long as you can vacuum out all the metal filings and junk.

Epoxy is quite permanent- my inclination would be to use varnish/lacquer/clear nail polish as a trial. In fact, from the looks of things, just a cleanup would probably do for testing purposes- I can't see any winding-to-winding contact areas.

Cheers

John

Epoxy is quite permanent- my inclination would be to use varnish/lacquer/clear nail polish as a trial. In fact, from the looks of things, just a cleanup would probably do for testing purposes- I can't see any winding-to-winding contact areas.

Cheers

John

Hi,

when re-wrapping the insulation, overlap the tape by 55% at the outside edge of the toroid. This guarantees two layers of insulation for that first wrap.

Add a second wrap again with 55% overlap, giving a minimum of 4layers of insulation.

You will find that the overlap at the inside of the toroid will be >67% and this guarantees that the two wraps give more than 6layers of insulation.

You will also find that the toroid is slightly thicker (taller) near the middle and this is the most vulnerable part of the winding and the 55% overlap rule has given most insulation in this area.

Try to find non adhesive tape for the wrapping. Kapton is perfect. Mylar does almost as well.

A couple of coats of nail varnish will insulate the wires from each other.

when re-wrapping the insulation, overlap the tape by 55% at the outside edge of the toroid. This guarantees two layers of insulation for that first wrap.

Add a second wrap again with 55% overlap, giving a minimum of 4layers of insulation.

You will find that the overlap at the inside of the toroid will be >67% and this guarantees that the two wraps give more than 6layers of insulation.

You will also find that the toroid is slightly thicker (taller) near the middle and this is the most vulnerable part of the winding and the 55% overlap rule has given most insulation in this area.

Try to find non adhesive tape for the wrapping. Kapton is perfect. Mylar does almost as well.

A couple of coats of nail varnish will insulate the wires from each other.

thanks

I did use them but I did not observe the sharp protrusions on one area of the case. The problem is on the outer edge of the toroid, the soft rubber gaskets are never big enough to cover the entire toroid! This time I am going to use some extra speaker gasket tape and cover the whole business.

Will do. I intend to wrap only the affected part and perhaps enough other areas so it mounts flat.

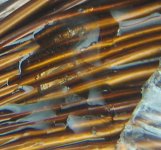

I tested this and it worked without load and without needing any insulation, good news. I put about 3 coats on 2-ton epoxy on the exposed parts anyway (pic attached). There should be no problem with insulation, though I will do as AndrewT suggets.

Now I have to figure out how to lengthen the short primary and secondary leads (that were cut)... What is the best way to do that?

richie00boy said:And next time use a rubber gasket on the bottom as well as the top like you are supposed to! I agree though it looks easily fixable.

I did use them but I did not observe the sharp protrusions on one area of the case. The problem is on the outer edge of the toroid, the soft rubber gaskets are never big enough to cover the entire toroid! This time I am going to use some extra speaker gasket tape and cover the whole business.

AndrewT said:Hi,

when re-wrapping the insulation, overlap the tape by 55% at the outside edge of the toroid.

**

Add a second wrap again with 55% overlap, giving a minimum of 4layers of insulation.

You will find that the overlap at the inside of the toroid will be >67% and this guarantees that the two wraps give more than 6layers of insulation.

**

Try to find non adhesive tape for the wrapping. Kapton is perfect. Mylar does almost as well.

A couple of coats of nail varnish will insulate the wires from each other.

Will do. I intend to wrap only the affected part and perhaps enough other areas so it mounts flat.

I tested this and it worked without load and without needing any insulation, good news. I put about 3 coats on 2-ton epoxy on the exposed parts anyway (pic attached). There should be no problem with insulation, though I will do as AndrewT suggets.

Now I have to figure out how to lengthen the short primary and secondary leads (that were cut)... What is the best way to do that?

Attachments

Re: thanks

open up the insulation and shorten the solid core leads to stay inside. Solder on flexible insulated leads as long as you require + some extra. Securely tape the solid core ends to the toroid. Ensure that there is sufficient robust insulation between the main toroid core and the hard bulge where the soldered joint is located. A couple of layers of thick sticky tape that you used to secure the solid core can be used here if the solid core is curved back on itself so that the solder lies on top of the previous securing tape. Insulate the soldered joins.

Securely tape the the insulated lead outs to the toroid. Now re-wrap the insulation.

Hi,lgreen said:Now I have to figure out how to lengthen the short primary and secondary leads (that were cut)... What is the best way to do that?

open up the insulation and shorten the solid core leads to stay inside. Solder on flexible insulated leads as long as you require + some extra. Securely tape the solid core ends to the toroid. Ensure that there is sufficient robust insulation between the main toroid core and the hard bulge where the soldered joint is located. A couple of layers of thick sticky tape that you used to secure the solid core can be used here if the solid core is curved back on itself so that the solder lies on top of the previous securing tape. Insulate the soldered joins.

Securely tape the the insulated lead outs to the toroid. Now re-wrap the insulation.

AndrewT said:A couple of coats of nail varnish will insulate the wires from each other.

Oh... I didn't know nail varnish could be used for that. Thanks for the tip.

I've got a transformer with a similar problem. A drill went further than expected and made contact for a split second with the toroid. Enough to scrap the insulation of a few wires.

AndrewT said:Hi,

**

Try to find non adhesive tape for the wrapping. Kapton is perfect. Mylar does almost as well.

***

AndrewT is completely correct. I was thinking about this again...If you use sticky tape the tape roll will not pass through the small toroid hole. Non adhesive tape is great because you just unwrap a good length in advance, if you try this with sticky tape it will be awful as it sticks to itself.

Thanks AndrewT.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- Fixing These Scratched Toroid Windings?