Here in Brazil most people use a board perfurator to open the holes in the PCB. Some time ago I discovered, for my great surprise, that this is not very common abroad.

Who know this? What countries use this manual punchq, and who has never heard of?

I'm posting this because Nordic asked me for some pics in another thread... here it goes!

First pic is my pet robot showing how to operate.

Who know this? What countries use this manual punchq, and who has never heard of?

I'm posting this because Nordic asked me for some pics in another thread... here it goes!

First pic is my pet robot showing how to operate.

Attachments

Close-up of the punch (sorry for the bad focus...) The upper piece is an "extractor" to hold the board when the punch comes up.

It's just a lever pushing the steel-wire-made punch. There is a strong coil that pushes the lever up when you release it, and a metal hook that holds the lever so it doesn't go flying and hit your eyes.

The punch breaks sometimes... It's usually sold with a replacement one, and you can buy the punch separately.

It's just a lever pushing the steel-wire-made punch. There is a strong coil that pushes the lever up when you release it, and a metal hook that holds the lever so it doesn't go flying and hit your eyes.

The punch breaks sometimes... It's usually sold with a replacement one, and you can buy the punch separately.

Attachments

The residue are small and manageable fenolite cylinders... (I'm not sure if PCBs abroad are made of fenolite too!  ) I imagine drilling PCBs must generate an awful ammount of plastic poweder!!

) I imagine drilling PCBs must generate an awful ammount of plastic poweder!!  That's gross!

That's gross!

The paper on the right is how I usually work: draw the setup on Eagle, print the tracks, put it over the board, tape it, and do the holes. Then I just draw the tracks by hand. In this case, it was a PSU, and I needed thick tracks, that I didn't want to draw in Eagle. So I "transfered" the holes to another paper to plan the thicker tracks before drawing.

That's gross!

That's gross!

The paper on the right is how I usually work: draw the setup on Eagle, print the tracks, put it over the board, tape it, and do the holes. Then I just draw the tracks by hand. In this case, it was a PSU, and I needed thick tracks, that I didn't want to draw in Eagle. So I "transfered" the holes to another paper to plan the thicker tracks before drawing.

Attachments

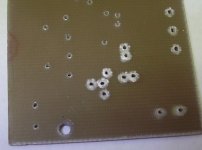

Last pic, of the holes... Sometimes they are just right, sometimes they get a little bump around the hole, what actually helps the drawing.

It's better to punch starting from the copper, because on the other way sometimes the copper can come out, ruining the connection... That's another reason why it's better to make the holes first!

It's better to punch starting from the copper, because on the other way sometimes the copper can come out, ruining the connection... That's another reason why it's better to make the holes first!

Attachments

Hi, NIC1138

Most pcb nowadays use FR-4 , combination of fibreglass and epoxy

(example : computer motherboard/ pci card)

Phenolic is cheaper and have problem with higher leakage (and moisture ? ) which can be problem and add noise.

However phenolic still have their use in RF and power amp , their dimensional stability is superior to FR-4 in this regard, where FR-4 easily bends because of heat expansion.

Most pcb nowadays use FR-4 , combination of fibreglass and epoxy

(example : computer motherboard/ pci card)

Phenolic is cheaper and have problem with higher leakage (and moisture ? ) which can be problem and add noise.

However phenolic still have their use in RF and power amp , their dimensional stability is superior to FR-4 in this regard, where FR-4 easily bends because of heat expansion.

cuibono said:wow, thats really interesting. I've never seen something like that. Drilling is a big PITA...

Punching small tracks sometimes lifts the metal?

Wha tdo you mean by punchin a small track??... Sorry, didn't quite get it.

The punch has a 1mm diameter. I think I saw a different size once...

What can "lift" the metal is that sometimes the hole get a little bump around it, and sometimes a harsh edge. This happens a lot if you punch from the other side.

The board on the other side sometimes get a little ugly. You have to find the right ammount of force to apply...

jpg said:Looks like this works even with FR4 (epoxy laminate)?

Hmmm I heard of fiberglass. Gota check on the electronics store here if they sell it. Then I post some tests!Hartono said:Most pcb nowadays use FR-4 , combination of fibreglass and epoxy

(example : computer motherboard/ pci card)

I guess perfboard and stripboard have machine-punched holes (also 1mm), but I've never seen a device for DIY use that goes that small. I've used one at work slightly like this one but the smallest punch available was 1/8" (approx 3mm) IIRC. It was excellent for exactly-positioned holes as the punch part had a central pip which could be located in a centre-punched pit.

Hartliege have a similar-looking device and stock punches down to 1/16" (1.6mm).

Hartliege have a similar-looking device and stock punches down to 1/16" (1.6mm).

Fiberglass test

I finally bought a fiberglas copper board, and tested the punch on it. Results are not very good, unfortunately...

First of all, I had a hard time to cut the thing in the shape I wanted!...

Then I started punching... It looked like everything was fine, but sudenly the punch bended!!

The topside doesn't look very nice too.

Now, I don't know if this is a general rule... I bought this punch a short time ago, and I already broke the first punch that came with it... Perhaps it's just a low-quality product... It does have a suspicious light brown colour...

Perhaps it's just a low-quality product... It does have a suspicious light brown colour...

Here is a picture of the topside. Guess what holes were drilled, and what were punched.

I finally bought a fiberglas copper board, and tested the punch on it. Results are not very good, unfortunately...

First of all, I had a hard time to cut the thing in the shape I wanted!...

Then I started punching... It looked like everything was fine, but sudenly the punch bended!!

The topside doesn't look very nice too.

Now, I don't know if this is a general rule... I bought this punch a short time ago, and I already broke the first punch that came with it...

Perhaps it's just a low-quality product... It does have a suspicious light brown colour...

Perhaps it's just a low-quality product... It does have a suspicious light brown colour...Here is a picture of the topside. Guess what holes were drilled, and what were punched.

Attachments

The fault isn't that of your punch. It would have really, really surprised me if you could punch (nice) holes in FR4.

Even worse: drilling FR4 generates glass powder. Bad for your lungs (not that phenolic powder was healthy!). Breathing mask strongly recommended, as your face is usually very close to the PCB that you drill.

I imagine drilling PCBs must generate an awful amount of plastic powder

Even worse: drilling FR4 generates glass powder. Bad for your lungs (not that phenolic powder was healthy!). Breathing mask strongly recommended, as your face is usually very close to the PCB that you drill.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- PCB perfurator