Thank you sir.

by the way can you send me a plan for a sub-scoop bin, if you have one.

thanks again.

i'm not a DIY expert but try to check this:

electrovoice T18 subs

you are right, it depends on the quantity of orders. from manila, perhaps not. but if really for great quantity, and especially for an OEM type of order, perhaps the best option is this.

but it needs money, more more and more money.

buying direct from thailand is i think not the best option since there is already an existing philippine distributor- Music Box II. but they only give a standard discount rate so i just order from the manila dealers to save gas, time and toll fees

@audiomachines

sir,

i am new here and I had read along this discution that you have some speaker plans. i wonder if you can send me a plan for sub zero(wbin)

(urbanista2007@yahoo.com)

thanks alot,

sir,

i am new here and I had read along this discution that you have some speaker plans. i wonder if you can send me a plan for sub zero(wbin)

(urbanista2007@yahoo.com)

thanks alot,

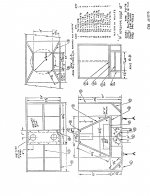

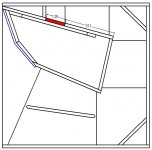

Keele April 25, 1977

K151 or 2240H "W” Horn

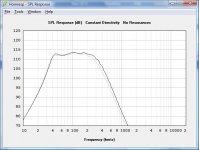

In answer to long-standing requests from dealers and end users, JBL is pleased to make available this plan for user construction of a "W"-format folded horn designed specifically for the JBL K151 18-inch loudspeaker.

The K151 "W"-box provides a 4dB sensitivity increase above 40Hz and a usable response from 32Hz to 400Hz. The horn mouth size of this enclosure is 1/8 of the size required for a full 40Hz horn. Hence, stacking 8 JBL “W”-boxes in a 4 x 2 configuration will provide true horn loading down to 40Hz.

These low frequency systems can be used as woofers in discotheques, bass guitar or organ pedal systems, or, when stacked in multiples, as the low end section of a three or four-way rock reinforcement system.

Because of the inherent midrange coloration of any "W”-horn design, the recommended crossover frequency is 300Hz or lower.

Construction Notes

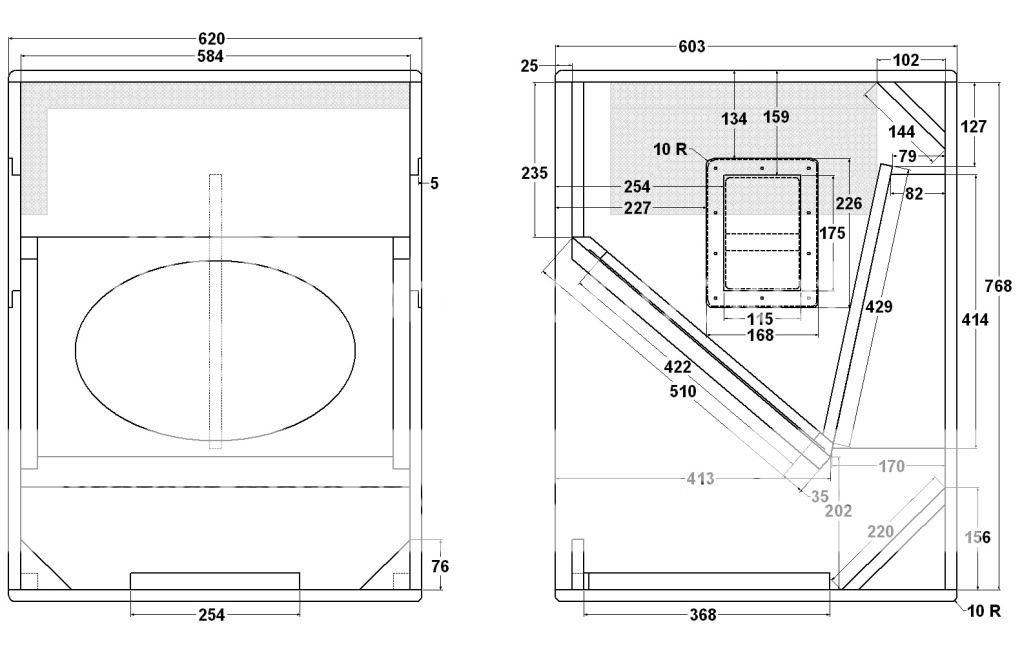

These plans are designed for 3/4" high density fir plywood. All joints must be glued and secured with 1-1/4" #8 wood screws spaced every 5 inches. Although omitted from the plans for clarity, all butt joints require I" x I" glue blocks running the length of each joint in order to maintain structural rigidity. If the enclosure will be used in portable or road service, heavier bracing may be required.

All interior surfaces of the chamber in which the K151 is mounted (except for the baffle panel) should be lined with I" fiberglass. This may be attached to the walls with staples or glue.

Piece 7 is a removable panel which allows access to the chamber for mounting the K151. The shortest dimension of the opening covered by piece 7 must be no less than 7-5/8" so that the loudspeaker will fit into the chamber. Piece 7 should be secured to pieces 13 and 14 with at least 10 #10-32 screws and T-nuts. Foam tape or caulking installed around the perimeter of the access opening will maintain the required air seal.

The K151 is secured to piece 15 by eight screws and T-nuts. The T-nuts should be installed in piece 15 before it is assembled to piece 6. The K151 bolt hole circle is 17-3/8” and the T-nut should be installed at 45 º increments.

No provision for connecting the loudspeaker to an amplifier is shown. The builder should select the connection method most suitable for his system.

:1w

"W” Horn for K151 18" Driver.

A medium-throw "W” folded horn with vented-box rear air chamber for use with our K151 18” driver providing uniform response from 55 Hz to 400 Hz when used singly in half-space environment. Its folded configuration allows a full 4 ft. long 40 Hz flair-rate exponential horn to be packaged in a relatively compact enclosure. A 5 cu. ft. 35 Hz tuned vented-box rear air chamber provides useable response and full 150 watt power handling capacity down to 32 Hz. The horn is designed to be used in multiples (2 to 8 units) to provide flat response to below 40 Hz in environments where reflective surfaces are not available. A single unit can generate some 15 to 20 acoustic watts at full power input in the 60 to 400 Hz range with less than 3% harmonic distortion.

SPECIFICATIONS:

For single unit in Half-Space (single reflective surface).

Frequency Response:*

Axial SPL: 60 Hz to 1 K Hz 3dB

Power: 55 Hz to 400 Hz 3dB

*Both on axis and total acoustic power frequency responses are given for the system. The axial response gives the output under free-field or outdoor conditions (or the direct-field in a reverberant space) while the power response indicates what one should expect if the system is used in a reverberant indoor or enclosed space.

Sound Pressure Level:

(re 20 uPa, nominal impedance assumed)

at 1 m (3.3 ft), 1 watt input:

103 dB (Ave. 80 to 400 Hz)

at 1 m, full power (150 watts) input:

124 dB (Ave. 80 to 400 Hz)

Efficiency:

15% (Ave. 80 to 400 Hz)

Maximum Input Power:

(Nominal impedance assumed)

Continuous (narrow band or sinewave): 150 watts (above 32 Hz)

50 watts (below 32 Hz)

Instantaneous Peak:

1500 watts *

*Peaks 10 dB above stated continuous maximum power inputs are permissible as long as the true RMS power averaged over any one second interval remains within continuous limits.

Beamwidth:

The beamwidth information gives the approximate coverage angles of the system between the 6-dB-down points from an axis.

Horizontal: No less than 60 º up to 400 Hz.

Vertical: No less than 45 º up to 400 Hz.

Impedance:

K151-4 K151-8

Nominal 4 ohms 8 ohms

Minimum 3 ohms 6 ohms

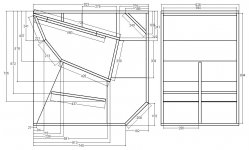

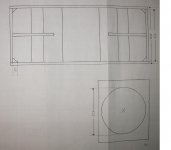

PARTS LIST K 151 "W" BOX

ITEM DESCRIPTION DIM. (INCHES) QUANITY

1 Back 3/4 x 24 x 48 1

2 End 3/4 x 22 1/2 x 29 1/4 2

3 Side 3/4 x 30 x 48 2

4 Brace 1 3/4. x 18 1/4 x 22 2

5 Chamber Side 3/4 x 22 1/2 x 23 1/2 2

6 Baffle 1 3/4 x 22 1/2 x 29 1

7 Port Plate 3/4 x 22 1/2 x 10 1

8 Horn Plate 1 3/4 x 10 9/32 x 6 1/2 2

9 Horn Plate 2 3/4 x 10 1/2 x 6 1/2 4

10 Horn Plate 3 3/4 x 9 1/4 x 22 1/2 2

11 Horn Plate 4 3/4 x 5 11/16 x 13 1

12 Horn Plate 5 3/4 x 4 15/16 x 13 1

13 Brace 2 3/4 x 3/4 x 21 2

14 Brace 3 3/4 x 3/4 x 7 5/8 2

15 Baffle 2 3/4 x 22 1/2 x 27 1/2 1

K151 or 2240H "W” Horn

In answer to long-standing requests from dealers and end users, JBL is pleased to make available this plan for user construction of a "W"-format folded horn designed specifically for the JBL K151 18-inch loudspeaker.

The K151 "W"-box provides a 4dB sensitivity increase above 40Hz and a usable response from 32Hz to 400Hz. The horn mouth size of this enclosure is 1/8 of the size required for a full 40Hz horn. Hence, stacking 8 JBL “W”-boxes in a 4 x 2 configuration will provide true horn loading down to 40Hz.

These low frequency systems can be used as woofers in discotheques, bass guitar or organ pedal systems, or, when stacked in multiples, as the low end section of a three or four-way rock reinforcement system.

Because of the inherent midrange coloration of any "W”-horn design, the recommended crossover frequency is 300Hz or lower.

Construction Notes

These plans are designed for 3/4" high density fir plywood. All joints must be glued and secured with 1-1/4" #8 wood screws spaced every 5 inches. Although omitted from the plans for clarity, all butt joints require I" x I" glue blocks running the length of each joint in order to maintain structural rigidity. If the enclosure will be used in portable or road service, heavier bracing may be required.

All interior surfaces of the chamber in which the K151 is mounted (except for the baffle panel) should be lined with I" fiberglass. This may be attached to the walls with staples or glue.

Piece 7 is a removable panel which allows access to the chamber for mounting the K151. The shortest dimension of the opening covered by piece 7 must be no less than 7-5/8" so that the loudspeaker will fit into the chamber. Piece 7 should be secured to pieces 13 and 14 with at least 10 #10-32 screws and T-nuts. Foam tape or caulking installed around the perimeter of the access opening will maintain the required air seal.

The K151 is secured to piece 15 by eight screws and T-nuts. The T-nuts should be installed in piece 15 before it is assembled to piece 6. The K151 bolt hole circle is 17-3/8” and the T-nut should be installed at 45 º increments.

No provision for connecting the loudspeaker to an amplifier is shown. The builder should select the connection method most suitable for his system.

:1w

"W” Horn for K151 18" Driver.

A medium-throw "W” folded horn with vented-box rear air chamber for use with our K151 18” driver providing uniform response from 55 Hz to 400 Hz when used singly in half-space environment. Its folded configuration allows a full 4 ft. long 40 Hz flair-rate exponential horn to be packaged in a relatively compact enclosure. A 5 cu. ft. 35 Hz tuned vented-box rear air chamber provides useable response and full 150 watt power handling capacity down to 32 Hz. The horn is designed to be used in multiples (2 to 8 units) to provide flat response to below 40 Hz in environments where reflective surfaces are not available. A single unit can generate some 15 to 20 acoustic watts at full power input in the 60 to 400 Hz range with less than 3% harmonic distortion.

SPECIFICATIONS:

For single unit in Half-Space (single reflective surface).

Frequency Response:*

Axial SPL: 60 Hz to 1 K Hz 3dB

Power: 55 Hz to 400 Hz 3dB

*Both on axis and total acoustic power frequency responses are given for the system. The axial response gives the output under free-field or outdoor conditions (or the direct-field in a reverberant space) while the power response indicates what one should expect if the system is used in a reverberant indoor or enclosed space.

Sound Pressure Level:

(re 20 uPa, nominal impedance assumed)

at 1 m (3.3 ft), 1 watt input:

103 dB (Ave. 80 to 400 Hz)

at 1 m, full power (150 watts) input:

124 dB (Ave. 80 to 400 Hz)

Efficiency:

15% (Ave. 80 to 400 Hz)

Maximum Input Power:

(Nominal impedance assumed)

Continuous (narrow band or sinewave): 150 watts (above 32 Hz)

50 watts (below 32 Hz)

Instantaneous Peak:

1500 watts *

*Peaks 10 dB above stated continuous maximum power inputs are permissible as long as the true RMS power averaged over any one second interval remains within continuous limits.

Beamwidth:

The beamwidth information gives the approximate coverage angles of the system between the 6-dB-down points from an axis.

Horizontal: No less than 60 º up to 400 Hz.

Vertical: No less than 45 º up to 400 Hz.

Impedance:

K151-4 K151-8

Nominal 4 ohms 8 ohms

Minimum 3 ohms 6 ohms

PARTS LIST K 151 "W" BOX

ITEM DESCRIPTION DIM. (INCHES) QUANITY

1 Back 3/4 x 24 x 48 1

2 End 3/4 x 22 1/2 x 29 1/4 2

3 Side 3/4 x 30 x 48 2

4 Brace 1 3/4. x 18 1/4 x 22 2

5 Chamber Side 3/4 x 22 1/2 x 23 1/2 2

6 Baffle 1 3/4 x 22 1/2 x 29 1

7 Port Plate 3/4 x 22 1/2 x 10 1

8 Horn Plate 1 3/4 x 10 9/32 x 6 1/2 2

9 Horn Plate 2 3/4 x 10 1/2 x 6 1/2 4

10 Horn Plate 3 3/4 x 9 1/4 x 22 1/2 2

11 Horn Plate 4 3/4 x 5 11/16 x 13 1

12 Horn Plate 5 3/4 x 4 15/16 x 13 1

13 Brace 2 3/4 x 3/4 x 21 2

14 Brace 3 3/4 x 3/4 x 7 5/8 2

15 Baffle 2 3/4 x 22 1/2 x 27 1/2 1

Attachments

just a thought/a dream perhaps

hindi biro ang PA sir! magastos, pero masaya. (engaging in PA is a daunting hobby coz it comes with great price, but it definitely satiates our longing for happiness) i think i got overly emotional there.

(engaging in PA is a daunting hobby coz it comes with great price, but it definitely satiates our longing for happiness) i think i got overly emotional there.

kidding aside, and thinking seriously about it, DIYers can overcome this obstacle by uniting and forming an alliance that is pro DIYers, that is not primarily profit oriented (at least in the stage of acquiring of gears). for example, a forum member can be tasked to "engineer" a driver with parameters suited to our needs and submit it for OEM orders to P Audio Thailand. and then we contribute amount according to the number of speakers we individually need. in this way, we should be able to come up with a cheaper speaker (but with good quality!) since the product once produced in numbers is good as sold.

OEM is all we can do because our pro "DIYers alliance" cannot order speakers marked P Audio due to official distributorship deals. I go with P Audio's factory and not with any other factories in china due to quality. P Audio Thailand, I believe, also makes speakers for JBL. and oh, i forgot, for OEM deals, they require at least 200 speakers. anyway, not too bad. i came to know of a friend who bought at least 32 x 650EL all in one transaction!

anyway, not too bad. i came to know of a friend who bought at least 32 x 650EL all in one transaction!

i believe that good things come with a price. but doing things together can make life easier. AMEN??? amen.

ps. we still have to talk about who will design the speaker, the shipping cost, and taxes.

buying direct from thailand is i think not the best option since there is already an existing philippine distributor- Music Box II. but they only give a standard discount rate so i just order from the manila dealers to save gas, time and toll fees

hindi biro ang PA sir! magastos, pero masaya.

kidding aside, and thinking seriously about it, DIYers can overcome this obstacle by uniting and forming an alliance that is pro DIYers, that is not primarily profit oriented (at least in the stage of acquiring of gears). for example, a forum member can be tasked to "engineer" a driver with parameters suited to our needs and submit it for OEM orders to P Audio Thailand. and then we contribute amount according to the number of speakers we individually need. in this way, we should be able to come up with a cheaper speaker (but with good quality!) since the product once produced in numbers is good as sold.

OEM is all we can do because our pro "DIYers alliance" cannot order speakers marked P Audio due to official distributorship deals. I go with P Audio's factory and not with any other factories in china due to quality. P Audio Thailand, I believe, also makes speakers for JBL. and oh, i forgot, for OEM deals, they require at least 200 speakers.

i believe that good things come with a price. but doing things together can make life easier. AMEN??? amen.

ps. we still have to talk about who will design the speaker, the shipping cost, and taxes.

Good day to all,

Can any one send me a plan for the following BINS,

L36

w-bin(sub-zero)

sub scoop

Here's my email (urbanista2007@yahoo.com)

May i ask is TnT 18's speaker are suitable for these bins.

thanks in advance,

for L36 plan - please check this link http://forum.speakerplans.com/cerwin-vega-l36-pe_topic2217_page1.html

and, as they say it, "Google is our friend", please use google, image, enter keywords.

regards

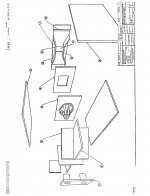

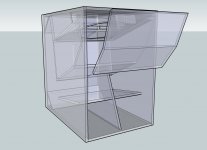

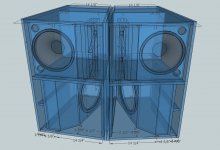

This the new version of XXX36XX...

take note that the original CV has an aluminum panel for cooling system.

Just another C-horn...DIY friendly easy to build.

For aluminum cover use a 1/4" gauge and ribbed with a 3/4" x 2" hardwood to support it from flexing.(we experience this when we built 4 for my clients install)

have a nice day

jojo

take note that the original CV has an aluminum panel for cooling system.

Just another C-horn...DIY friendly easy to build.

For aluminum cover use a 1/4" gauge and ribbed with a 3/4" x 2" hardwood to support it from flexing.(we experience this when we built 4 for my clients install)

have a nice day

jojo

Attachments

This the new version of XXX36XX...

take note that the original CV has an aluminum panel for cooling system.

Just another C-horn...DIY friendly easy to build.

For aluminum cover use a 1/4" gauge and ribbed with a 3/4" x 2" hardwood to support it from flexing.(we experience this when we built 4 for my clients install)

have a nice day

jojo

yup this looks the real thing. . . post #935

cheers!

http://www.diyaudio.com/forums/74642-konzert-amp-speakers-website-94.html#post2137261

Last edited:

http://www.paudio.ru/downloads/SD18EL.pdf

Precision Devices International Limited

the specs of the two drivers above

take note of the power handling (Watts), Fs, BL and Xmax figures of the two drivers

Precision Devices International Limited

the specs of the two drivers above

take note of the power handling (Watts), Fs, BL and Xmax figures of the two drivers

This the new version of XXX36XX...

take note that the original CV has an aluminum panel for cooling system.

Just another C-horn...DIY friendly easy to build.

For aluminum cover use a 1/4" gauge and ribbed with a 3/4" x 2" hardwood to support it from flexing.(we experience this when we built 4 for my clients install)

have a nice day

jojo

good day sir jojo..any sugestion if what driver is suitable for this new cv box.pwede b dito ung jh186 or the pd1850B of neusch ,any sugestion pls. thanks..regards

http://www.paudio.ru/downloads/SD18EL.pdf

Precision Devices International Limited

the specs of the two drivers above

take note of the power handling (Watts), Fs, BL and Xmax figures of the two drivers

Thanks for sharing.

Actually this is an old (SD 18el) spec sheet. I think the power rating has been revised to 1000 watts RMS from the time I first heard the SD 18el almost 3 years ago.

As for the Xmax, I too find it underrated and so was my previous SD18. It's the predecessor of the SD 18el which only registers (Xmax of 5.0 mm only)

As for the other parameters, I think the PD should be a better speaker over-all since it's a Precision Device

Just my two cents.

SD18 old series. For me the best 18" woofer I had.

^ yap you get what you paid for almost the same motor structure yet the other has more BL, This means the magnetic circuit where optimized, I could only imagine what the BH curve looks like, more linear, cause they where able to use a voicecoil with an 11 mm Xmax. If only someone could provide me with the the "other engineering data" cutaway view of the motor structure, the alloy or grade of the steel part (toplate, backplate) the grade of the magnet etc. or better yet the FEMM analysis of these beast. So that we will be able to see what is really going on "inside" the speaker and why the other manufacturer is charging that much. just my two cents

@amants

AB-36C...looking for 18" stroker mechanical dimension no luck...i lost my copy.

So there is no way i can tell if the JH's and the PD's will fit in.

if ever they do fit in...they will perform very differently from the original.

it may surpass the original in terms of robustness due to JH186 have approx. 6" VC and PD1850 have approx. 5" VC...if memory serves me right CV stroker have a 3" VC which requires an adequate cooling system...correct me if i am wrong.

One thing i am sure of if ever they fit in...with the JH's and PD's you got more sensitivity, SPL and power compression is so so far away.(Block of 4 boxes)

i used to have CV's a long time ago...Junior earthquake L36JE and the Senior earthquake L48SE...i know how they perform. i still have those original plan.

If ever your going to try and pursue to do the driver mods...good luck.

have fun,

jojo

AB-36C...looking for 18" stroker mechanical dimension no luck...i lost my copy.

So there is no way i can tell if the JH's and the PD's will fit in.

if ever they do fit in...they will perform very differently from the original.

it may surpass the original in terms of robustness due to JH186 have approx. 6" VC and PD1850 have approx. 5" VC...if memory serves me right CV stroker have a 3" VC which requires an adequate cooling system...correct me if i am wrong.

One thing i am sure of if ever they fit in...with the JH's and PD's you got more sensitivity, SPL and power compression is so so far away.(Block of 4 boxes)

i used to have CV's a long time ago...Junior earthquake L36JE and the Senior earthquake L48SE...i know how they perform. i still have those original plan.

If ever your going to try and pursue to do the driver mods...good luck.

have fun,

jojo

Attachments

For p-audio...Thailand site

:: Pantown :: everyone's online society

lots of plans for p-audio's Thai DIYer. i envy these people because they do support their "Local Produce", i hope someday we too will be solid to support our own...

have fun

jojo

:: Pantown :: everyone's online society

lots of plans for p-audio's Thai DIYer. i envy these people because they do support their "Local Produce", i hope someday we too will be solid to support our own...

have fun

jojo

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Live Sound

- PA Systems

- Konzert Amp & Speakers Website