I am trying to get the most 90 to 300Hz out of a single easy-to-build cabinet. Size isn't an issue and I'm trying to figure out the Hornresp software but not having much luck. I figure a straight horn would be the easiest, but not opposed to folding if it doesn't mess with the upper range response too much.

The system is for a donated PA type installation so I don't have much money to spend but do have plenty of materials and a large collection of drivers. (and not opposed to buying a single more optimum driver if necessary)

I'm assuming a horn is really the only way to accomplish this as a pile of reflex boxes wouldn't have the efficiency. I've only done bass-reflex type boxes and this would be my first horn and I figure a really good way to learn the process better.

Any help would be appreciated.

The system is for a donated PA type installation so I don't have much money to spend but do have plenty of materials and a large collection of drivers. (and not opposed to buying a single more optimum driver if necessary)

I'm assuming a horn is really the only way to accomplish this as a pile of reflex boxes wouldn't have the efficiency. I've only done bass-reflex type boxes and this would be my first horn and I figure a really good way to learn the process better.

Any help would be appreciated.

Horns are one way to accomplish a goal. Your goal is not clearly defined in terms of output required, coverage area, or drivers that you would like to use, cabinet size or budget.I'm assuming a horn is really the only way to accomplish this as a pile of reflex boxes wouldn't have the efficiency. I've only done bass-reflex type boxes and this would be my first horn and I figure a really good way to learn the process better.

Adding a second front loaded cone gives a 3 dB increase in efficiency, 6 dB more output when driven equally. Going to four cones gives a 6 dB increase in efficiency, 12 dB more output when driven equally.

Horns give from around 3 dB to 10 dB increase in efficiency and or sensitivity, depending on size and dispersion.

Unless you are planning to copy a mid-bass design (few in the subwoofer forum), time to start learning how to use Hornresp.

Horns are one way to accomplish a goal. Your goal is not clearly defined in terms of output required, coverage area, or drivers that you would like to use, cabinet size or budget.

Don't laugh, but I'm trying to add a couple octaves of lower response to a cluster of cobraflex paging horns on the roof of a press box across a football field from the home-side bleachers. I can achieve the sound I'm looking for with 4 Ramsa 12" boxes that I have (with blown tweeters and the 12's wired directly to the terminals bypassing the internal crossovers.). I'm using an old BSS Minidrive 2x4 dsp as an EQ crossover and limiter.

Would just like to have a single large box that would be more weatherproof than the Ramsa boxes -a horn would keep the driver back out of the elements more. (besides, I like the Ramsa's and want to use them for my portable sound outfit after repairing them properly)

I currently have a large stack of EV 12's (DL, EVM and similar) JBL E-140's as well as a pile of stamped and cast-frame eminence 18's 15's and 12's

Adding a second front loaded cone gives a 3 dB increase in efficiency, 6 dB more output when driven equally. Going to four cones gives a 6 dB increase in efficiency, 12 dB more output when driven equally.

Horns give from around 3 dB to 10 dB increase in efficiency and or sensitivity, depending on size and dispersion.

If you think that a direct-radiating design would do it then I definitely know they are quicker and easier to build. However I thought this would be a good way to start learning horns better.

Unless you are planning to copy a mid-bass design (few in the subwoofer forum), time to start learning how to use Hornresp.

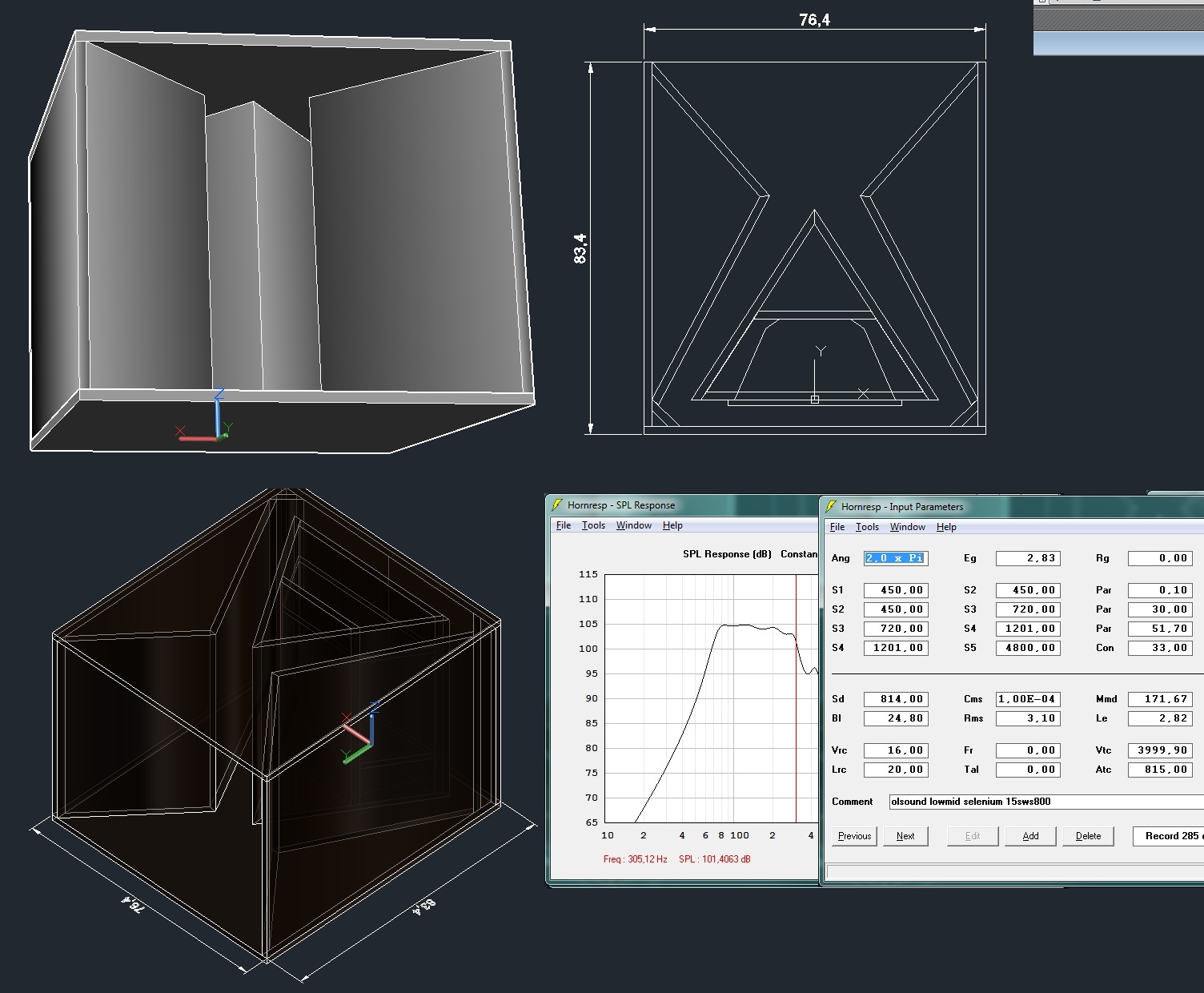

Trust me, I'm trying -its just very difficult when it feels I'm flying blind. I can grasp bass reflex concepts but horns are eluding me. (or maybe it's just me not grasping what I feel is very non-intuitive software) That and when I get thinking I have the program working, I'm still at a loss on interpreting the results into something with dimensions I can actually build.

I also didn't think I would find any designs for this in a "subwoofer" forum as it seems they are all obsessing about 3-octaves lower than I need -but I'll look. (I am trying to go beyond just "copying" too)

Thanks for all your suggestions.

Cobra Flex for top end means a crossover around 400 Hz is OK. There are dozens of folded horn designs that would work fine.Don't laugh, but I'm trying to add a couple octaves of lower response to a cluster of cobraflex paging horns on the roof of a press box across a football field from the home-side bleachers.

I currently have a large stack of EV 12's (DL, EVM and similar) JBL E-140's as well as a pile of stamped and cast-frame eminence 18's 15's and 12's

The EV 12s would work well in "W" horn designs like the EV Sentry III and IV, simple folded horns that would be quite weatherproof.

Actually, all the speakers mentioned probably would probably be fine, but the JBL E-140's bring quite decent $$ from nostalgia types.

You can simply make the FH cabinet taller (the middle of the "W" should be vertical) to enclose more 12s. Good idea to make the compression chambers individual so one failed driver does not lead to more.

A ratio of one 12" in a FLH like a Sentry to one Cobraflex is about right.

Use grill cloth to keep the bugs and birds from nesting

Art

Last edited:

Cobra Flex for top end means a crossover around 400 Hz is OK. There are dozens of folded horn designs that would work fine.

I'm using the bigger fiberglass ones and not the smaller metal ones, I seem to be getting a good strong 300 out of them. (They've actually been running fullrange most of their life on an old 100W or so University amp) Not sure of the driver, but it does have a reasonably large phenolic diaphragm.

The EV 12s would work well in "W" horn designs like the EV Sentry III and IV, simple folded horns that would be quite weatherproof.

I've dug around a bit and can't seem to find any dimensions or plans. Did find a TL-4025 as well as several Keele W-bins if I chose to go with a 15.

From what I see, those Sentry's are relatively shallow cabs, I could build a straight horn with that mouth size if I had dimensions to work with. The space I have is the entire roof of the press box (30x15') so a big wide flat horn isn't out of the question and it would make a great mounting platform for all the paging horns (4 of them)

Actually, all the speakers mentioned probably would probably be fine, but the JBL E-140's bring quite decent $$ from nostalgia types.

I'm not going to put those outside for a small town football team with only 6 home-games. They definitely do seem to be popular with the vintage guitar/bass amp crowd, I have 6 of them in old wedge cabinets with emilar HF that haven't been used in years, was trying to figure out a more worthy project for them because they are in quite pristine condition.

Hesitant about the using the EV 12's too but I do have some rather large Eminence 12's as well as the Audiopile.net ones.

You can simply make the FH cabinet taller (the middle of the "W" should be vertical) to enclose more 12s. Good idea to make the compression chambers individual so one failed driver does not lead to more.

A ratio of one 12" in a FLH like a Sentry to one Cobraflex is about right.[/quote]

I'm almost feeling like 2 to 1 would be all they need. They just want a bit better sounding rig for music playback -it's very close to useable as it is but the kids are excited about having football back in this small town for the first time in 25 years so just trying to make things a bit better. (Of course nobody has any budget for this

seriously there were so many birds nests in the old field lights that one caught on fire! I plan on using a good downangle for drainage and fine stainless steal mesh.Use grill cloth to keep the bugs and birds from nesting.

Thanks Art. I will try to post pics of the project as it proceeds.

You can scale the TL-4025 or Keele W-bins down since 12" will be adequate for your needs and you are not looking for super low extension. Shrink the compression chamber a bit more than the 12/15 ratio.I'm using the bigger fiberglass ones and not the smaller metal ones, I seem to be getting a good strong 300 out of them. (They've actually been running fullrange most of their life on an old 100W or so University amp) Not sure of the driver, but it does have a reasonably large phenolic diaphragm.

I've dug around a bit and can't seem to find any dimensions or plans. Did find a TL-4025 as well as several Keele W-bins if I chose to go with a 15.

From what I see, those Sentry's are relatively shallow cabs, I could build a straight horn with that mouth size if I had dimensions to work with. The space I have is the entire roof of the press box (30x15') so a big wide flat horn isn't out of the question and it would make a great mounting platform for all the paging horns (4 of them)

The old EV Eliminator or Klipsch La Scala or old Peavey SP1 folded horns all would work OK too.

You can "unfold" those plans for a straight horn if you would like, but the FH use less wood, and tend to be well braced to start with

The HF will "clean up" a bit if you cross them at 400 Hz.

A 12" in a FLH of the type we are discussing will just about keep up with the Cobraflex, but if you want to go two 12" to one HF, that is fine.

Double the cones and they will only need half the power.

The Cobraflex would be best arranged in a vertical line, if you need more horizontal dispersion, arrange them like a "barber pole". If the vertical dispersion becomes more narrow than you care for, then arc the vertical in a "C" or "J".

Last edited:

I wondered what a Cobraflex was, and found this... appropriate:

http://www.hifilit.com/hifilit/University/plans-1.jpg

http://www.hifilit.com/hifilit/University/plans-1.jpg

Cobreflex on top of a Klipsch LaScala bottom.

Easy build, 1 sheet.

been google-ing quite a bit and haven't found any build plans with dimensions for a "La Scala"

Found plenty of info on the huge MWM Klipsh bin. (remember using those years ago in a PA rig and had no clue who made them as they had been painted over so many times.)

You can scale the TL-4025 or Keele W-bins down since 12" will be adequate for your needs and you are not looking for super low extension. Shrink the compression chamber a bit more than the 12/15 ratio.

The old EV Eliminator or Klipsch La Scala or old Peavey SP1 folded horns all would work OK too.

You can "unfold" those plans for a straight horn if you would like, but the FH use less wood, and tend to be well braced to start with

The HF will "clean up" a bit if you cross them at 400 Hz.

A 12" in a FLH of the type we are discussing will just about keep up with the Cobraflex, but if you want to go two 12" to one HF, that is fine.

Double the cones and they will only need half the power.

The Cobraflex would be best arranged in a vertical line, if you need more horizontal dispersion, arrange them like a "barber pole". If the vertical dispersion becomes more narrow than you care for, then arc the vertical in a "C" or "J".

Been quite busy here but got my shop all set up to start making sawdust!

And the football team has been doing well.

-Been using 4 of my EV cabinet speakers in an array in front of the press box to get us by until I can get the cobraflex horns refurbished and mounted up high properly. (They "work" but coverage is not that great and too much sound is getting back into the booth.) It is the only weather-resistant place to put them or I would distribute them around the field better.

The cobraflex horn drivers all gave up after the first time using them with the new amplification. 30 years of sitting outside in the North Dakota winters while being tapped at only 15 watts then suddenly being moved and given real power along with what the kids consider music nowadays

So unless we go to playoffs, the season will end before I can get bass horns built and installed so I'm thinking this will be a good winter project for proper installation next spring.

Stepping back from the whole project has made me wonder if all the older folded horn designs I've been getting from all the great recommendations in this thread represent the best of modern designs? Has anything improved in horn design in the last 30 years or are these designs still valid and as effective as anything designed from scratch today?

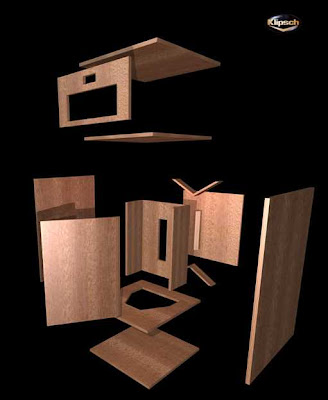

Plans abount for the full LaScala (with top).

I drew up my own plans and cut list for just the bottom, and built 24 pcs circa 1978. Mine were modified to accomodate non-standard woofer frames up to 15.75" wide, anything except the 16" Altec versions.

If you google LaScala and then click on images the full plans will show up. You should be able to adapt them.

If you need some further help I can try and resurect my old plans.

I gave some tips on cutting the 60° angles at the Klipsch forum, and some general assembly ideas. Marvel (Bruce Brown) did a 3-D drawing that came out very good.

I drew up my own plans and cut list for just the bottom, and built 24 pcs circa 1978. Mine were modified to accomodate non-standard woofer frames up to 15.75" wide, anything except the 16" Altec versions.

If you google LaScala and then click on images the full plans will show up. You should be able to adapt them.

If you need some further help I can try and resurect my old plans.

I gave some tips on cutting the 60° angles at the Klipsch forum, and some general assembly ideas. Marvel (Bruce Brown) did a 3-D drawing that came out very good.

If you need to go to 40hz, search for 'vented LaScala', an idea of mine I came up with circa 1997.

http://forums.klipsch.com/forums/storage/3/979211/1977%20LaScala%20Plans%20HDBR.pdf

http://forums.klipsch.com/forums/storage/3/979227/LaScala_correct.pdf

http://forums.klipsch.com/forums/storage/3/979211/1977%20LaScala%20Plans%20HDBR.pdf

http://forums.klipsch.com/forums/storage/3/979227/LaScala_correct.pdf

The old designs had to be good to cover a wide bandwidth with low power and little EQ available.Stepping back from the whole project has made me wonder if all the older folded horn designs I've been getting from all the great recommendations in this thread represent the best of modern designs?

Has anything improved in horn design in the last 30 years or are these designs still valid and as effective as anything designed from scratch today?

Most modern folded horn designs are for "sub" use, and as such the upper response is not as much a concern as it was in the "olden days".

Although some modern designs are more space efficient and truck pack dimensions, neither of those concern your installation.

About the only thing "new" in horn design is the Tom Danley Synergy designs, which offer good sensitivity and much better pattern control than the designs so far put forth, but require an integrated use of LF, MF, and HF drivers on a single horn.

Since the T-30s are toast, you might consider selling off the Cobraflex and starting from scratch with a large format Synergy style horn along the lines of the DSL SH-50 or JH-90 (Jericho Horn).

If you google LaScala and then click on images the full plans will show up.

Actually taking you literally nets several thousand results of an opera house in Milan.

Looks really impressive, had to take a Wikipedia detour to learn more.

(I'm figuring it's what Klipsch named the speakers after.)

So "LaScala Plans" works even if the results are in German.

I was thinking of doing the full-size box and mounting the Cobraflex horns in the place of the Mid & HF horns -it would keep them out of the weather.

Might have to rethink that though if I want to do what Welter recommended of vertical stacking the horns. I might just build a simple shed enclosure over the whole cluster instead to weatherproof it. (Building materials, tools and time are free commodities around here)

The old designs had to be good to cover a wide bandwidth with low power and little EQ available.

Most modern folded horn designs are for "sub" use, and as such the upper response is not as much a concern as it was in the "olden days".

Although some modern designs are more space efficient and truck pack dimensions, neither of those concern your installation.

About the only thing "new" in horn design is the Tom Danley Synergy designs, which offer good sensitivity and much better pattern control than the designs so far put forth, but require an integrated use of LF, MF, and HF drivers on a single horn.

Since the T-30s are toast, you might consider selling off the Cobraflex and starting from scratch with a large format Synergy style horn along the lines of the DSL SH-50 or JH-90 (Jericho Horn).

I can get 3 really good sounding loud drivers brand new for $135 and the Cobraflex are back in business.

I seriously doubt I could pull the tens of thousands out of our town of 350 people for a new Danley system.

The cobraflex's will work fine by themselves once I get them back in place, My horn project was just to add another couple lower octaves to them on my own dime.

(Funny, all the other pro audio forums I lurk on use Danley as the answer to absolutly everything. I still think they are mythical as I've never seen a single Danley product in the wild

-but then again I don't get out much anymore.

There's enough new oilwell millionaires around here that it might be a future possibility (either Danley or whatever newer/better eventually supplants it)

Meanwhile i'm unemployed and essentially on disability. I'm donating my services just to keep from getting "rusty" and like I said on other posts, I have tons of materials, a large shop, my large audio "boneyard" and plenty of free help around town.

I now have to decide which ones to build. I'm liking the LaScala size and ease of build but always been partial to the EV stuff. Some old Peavey FH-1's showed up an an estate auction the other day. Missed out on that, but they would have worked fine too!

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Live Sound

- PA Systems

- Need help with a midbass horn