How's everyone doing the speaker holes? Last time I did some I used a hole saw and a rebate bit to flush mount the driver. I've only got a 9.5mm rebate bit which isn't going to cut it.

I also used holesaw for 15", stupid but it worked.

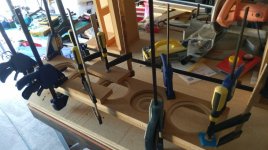

Now i build my jasper jig with 6mm plywood

One thing I learned when cutting the holes was when you cut the complete circumference in one go the piece you are cutting out sort of cog wheels with the router bit and takes a chunk out of the edge of the hole. I found it best to almost complete the hole, stop the router and knock out the centre piece, and then clean up the edge with the router. Looks like you're making good progress. What finish are you planning for them? One piece of advise, do the finishing before you take them inside for listening otherwise you may never get them back into the workshop!!

If the pin for your hole jig is long enough, its best to put a piece of scrap wood under and clamped to the piece you are cutting, drill your center hole for the pin through both pieces and set the router depth to just get through the piece you are cutting. When the hole is completed, even though the cutout is loose, the pin is still set in the lower piece and the router is still secured and not set loose.

Wife and I still can't decide. Probably just a high gloss paint, either black or a bright colour.

What screws are people using for the drivers?

I found some 8g x 38mm pan head in black on ebay, does that sound about right? It looks like the SB drivers use a non-countersunk screw.

What screws are people using for the drivers?

I found some 8g x 38mm pan head in black on ebay, does that sound about right? It looks like the SB drivers use a non-countersunk screw.

rampage101,

From the diagram on the product page, looks like M4 or size 8 guage screws should work:

6" SB17NRXC35-8 :: SB Acoustics

I would also prefer a non-countersunk screw.

Screw length - possibly 25mm (screw body length only, without the pan-head cap) would be enough? How thick is the part where the screws will get inserted? If it's not too thick, and you use much longer screws, the sharp points will just stick out from the other side... in case you need to adjust the fill or internal wiring etc. there is a chance of getting pricked.

Max diameter on the pan-head cap needs to be within ~8mm.

High quality gloss black can look very nice, but can be a lot of work. Have you painted gloss black on MDF before?

From the diagram on the product page, looks like M4 or size 8 guage screws should work:

6" SB17NRXC35-8 :: SB Acoustics

I would also prefer a non-countersunk screw.

Screw length - possibly 25mm (screw body length only, without the pan-head cap) would be enough? How thick is the part where the screws will get inserted? If it's not too thick, and you use much longer screws, the sharp points will just stick out from the other side... in case you need to adjust the fill or internal wiring etc. there is a chance of getting pricked.

Max diameter on the pan-head cap needs to be within ~8mm.

High quality gloss black can look very nice, but can be a lot of work. Have you painted gloss black on MDF before?

Last edited:

I had intended on cutting the screws off if need be, but thinking about it now 25mm should be plenty.

I have done black before on another set, did it in 2k gloss black. For the most part was good, except one section I didn't use enough filler or it shrunk back. Veneer was sounding like a better option but was going to end up costing me too much.

I have done black before on another set, did it in 2k gloss black. For the most part was good, except one section I didn't use enough filler or it shrunk back. Veneer was sounding like a better option but was going to end up costing me too much.

Hi Guys

I am pre-empting the fact that somebody is sure to point out that SB Acoustics are bringing out a new version of the SB driver we are using in the Elsinores. In fact, last November I was in Denmark and went to Herning in Jutland where AB Acoustics designs their drivers which are of course made in Indonesia. I met with Frank Nielsen who in turn took me to the conference room to meet their designer Ulrik Schmidt and had a solid three hours and a bit discussing a very wide range of topics, some fairly exotic like thermal distribution of heat in the voice coils.

I was shown a number of samples of new drivers coming out and they are now available to see on the website, one in particular that caught my eye was the new white cone 7" Sartori driver - and I am definitely in mind to use it in a design in the future. I gather that Ulrik is very much thinking this is the pinnacle of design. One topic was about where to choose crossover frequencies and my remark was that many designs cross over to low and that I find that around 3KHz is where it seems to work best. Ulrik then chimed in that he had come to believe that 3KHz was a 'natural' frequency to have the crossover. That alone made my day.

I was also shown the new NRX2 driver and again was able to handle it, very nice indeed. I was also told that they would eventually bring out a tweeter with an integral waveguide - and as you guys may well gather, I am definitely a waveguide fan boy. Alas, no sign of that tweeter yet. I note that Scan-Speak has brought out a waveguide tweeter and I had seen the PDF file and details and is not suitable for my requirements for such a tweeter. So I hope SB might be able to do it the way I like it.

This is what the current 6" NRX driver used in the Elsinores look like:

And this is the new NRX2 version:

They look similar, but note the difference in the dustcap and also the general cone profile has been tweaked.

So when I saw the new NRX2 driver and had it in my hands, I thought "oh, oh, does this mean a new Mark 7 version of Elsinores"?

Alas, no.

The new NRX2 has other not obvious changes that show up in the PDF datasheet. There are several of them, but chiefly is that the sensitivity of the earlier NRX driver is not matched. One of the main philosophical design decisions is to keep the voice coils in the drivers as cool as possible. It is apparent that the new driver, the heat dissipation is up 60% - part of it is a heavier cone, but other Thiele-Small Parameters are also significantly difference, so much that the alignment needed is very different. The drivers look so similar, but they are not!

So there will not be a Mark 6 and we can only hope that the current NRX driver will continue to be available for some time yet. It is NOT a direct replacement.

BTW, this is the 7" Sartori driver I was talking about:

This could be a nice match for the Scan-Speak D2608 / Peerless HDS tweeter using the same Elsinore waveguides.

Cheers, Joe

I am pre-empting the fact that somebody is sure to point out that SB Acoustics are bringing out a new version of the SB driver we are using in the Elsinores. In fact, last November I was in Denmark and went to Herning in Jutland where AB Acoustics designs their drivers which are of course made in Indonesia. I met with Frank Nielsen who in turn took me to the conference room to meet their designer Ulrik Schmidt and had a solid three hours and a bit discussing a very wide range of topics, some fairly exotic like thermal distribution of heat in the voice coils.

I was shown a number of samples of new drivers coming out and they are now available to see on the website, one in particular that caught my eye was the new white cone 7" Sartori driver - and I am definitely in mind to use it in a design in the future. I gather that Ulrik is very much thinking this is the pinnacle of design. One topic was about where to choose crossover frequencies and my remark was that many designs cross over to low and that I find that around 3KHz is where it seems to work best. Ulrik then chimed in that he had come to believe that 3KHz was a 'natural' frequency to have the crossover. That alone made my day.

I was also shown the new NRX2 driver and again was able to handle it, very nice indeed. I was also told that they would eventually bring out a tweeter with an integral waveguide - and as you guys may well gather, I am definitely a waveguide fan boy. Alas, no sign of that tweeter yet. I note that Scan-Speak has brought out a waveguide tweeter and I had seen the PDF file and details and is not suitable for my requirements for such a tweeter. So I hope SB might be able to do it the way I like it.

This is what the current 6" NRX driver used in the Elsinores look like:

And this is the new NRX2 version:

They look similar, but note the difference in the dustcap and also the general cone profile has been tweaked.

So when I saw the new NRX2 driver and had it in my hands, I thought "oh, oh, does this mean a new Mark 7 version of Elsinores"?

Alas, no.

The new NRX2 has other not obvious changes that show up in the PDF datasheet. There are several of them, but chiefly is that the sensitivity of the earlier NRX driver is not matched. One of the main philosophical design decisions is to keep the voice coils in the drivers as cool as possible. It is apparent that the new driver, the heat dissipation is up 60% - part of it is a heavier cone, but other Thiele-Small Parameters are also significantly difference, so much that the alignment needed is very different. The drivers look so similar, but they are not!

So there will not be a Mark 6 and we can only hope that the current NRX driver will continue to be available for some time yet. It is NOT a direct replacement.

BTW, this is the 7" Sartori driver I was talking about:

This could be a nice match for the Scan-Speak D2608 / Peerless HDS tweeter using the same Elsinore waveguides.

Cheers, Joe

Last edited:

WES Components have these screws which have a nice appearance. They suited the Pereless Nomex drivers very well.

Wife and I still can't decide. Probably just a high gloss paint, either black or a bright colour.

What screws are people using for the drivers?

I found some 8g x 38mm pan head in black on ebay, does that sound about right? It looks like the SB drivers use a non-countersunk screw.

Attachments

It would be nice if SB do a tweeter with an integral waveguide. It would make life a lot easier for construction. I'm surprised there aren't more around.

I think that gradually that will change, a gradual but definite increase in the popularity of waveguides is happening. The problem I have with their use is that they can be used to lower the crossover frequency (and there are admittedly some advantages there) or lower distortion. I definitely believe waveguides should be used to lower distortion and at the same time also increase power handling, as the two go hand-in-hand.

.

Joe (and anyone else with a viable opinion):

My very-slow-to-start efforts to build Elsinores are now in high gear -- the cabinets have been completed and I am poised to order all of the components (photos to come). I'd be grateful for your opinion regarding damping materials. I had tentatively decided to use two different products: a 1" thick bonded Dacron material (Bonded Dacron - Meniscus Audio) and a 3.5" thick cotton-based material (Eco-Core - Meniscus Audio). The cotton-based material would need to be shaved down slightly to approximate the 75mm thickness you recommend; fortunately, the supplier has told me that layers can be gently peeled off.

My question: you have indicated the need for low density damping. I spoke with the vendor and they could not tell me whether their Eco-Cor material qualified as "low density" damping. Do you believe that it would be suitable or should I seek a foam sheeting material or other alternative? I have no experience in this area and would appreciate any guidance you could offer.

Regards,

Scott

My very-slow-to-start efforts to build Elsinores are now in high gear -- the cabinets have been completed and I am poised to order all of the components (photos to come). I'd be grateful for your opinion regarding damping materials. I had tentatively decided to use two different products: a 1" thick bonded Dacron material (Bonded Dacron - Meniscus Audio) and a 3.5" thick cotton-based material (Eco-Core - Meniscus Audio). The cotton-based material would need to be shaved down slightly to approximate the 75mm thickness you recommend; fortunately, the supplier has told me that layers can be gently peeled off.

My question: you have indicated the need for low density damping. I spoke with the vendor and they could not tell me whether their Eco-Cor material qualified as "low density" damping. Do you believe that it would be suitable or should I seek a foam sheeting material or other alternative? I have no experience in this area and would appreciate any guidance you could offer.

Regards,

Scott

- Home

- Loudspeakers

- Multi-Way

- The "Elsinore Project" Thread