Sorry about that. Fat finger on the submit reply

ALUMINUM WAVEGUIDES

I received a few emails while I was figuring out the details but please email again if you want a pair and I will keep track of things now.

The price is based on min 10 for CNC and paint.

Have 2 comitments now. Thank's Ben and Matt from Alberta.

Sincerly, Joel

ALUMINUM WAVEGUIDES

I received a few emails while I was figuring out the details but please email again if you want a pair and I will keep track of things now.

The price is based on min 10 for CNC and paint.

Have 2 comitments now. Thank's Ben and Matt from Alberta.

Sincerly, Joel

Do the waveguides exactly match the mounting plate of the tweeter and does it have matching holes so that the WG and the tweeter are mounted with the 4 screws?

If so, that would be great.

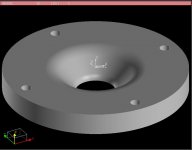

How are the WG's finished? Are they black anodised?

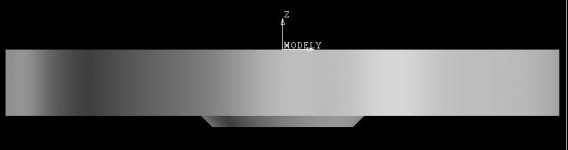

The Waveguide is wider than the tweeter mounting plate.

The holes in the WG are halfway between the outer perimeter edge of the bottom recess and the outer perimeter of the WG.

The supplied wood screws are from Solen and designed for Diy speaker projects. They look like machine screws and have an alan head and recess perfectly in the holes.

The WG will screw into the sub front panel with new pilot holes. Screws go 18mm below WG.

Black Powder Coat

Hope this helps, Joel

btw, for the big ones I can really recommend toroids

can't do without those

Arent the coils supposed to be air cores?

Arent the coils supposed to be air cores?

The largest inductor I use 2 x 9mH in series, these do not have to be air cored, but the rest should be.

Cheers, Joe R.

Joe,

Thanks for the reply. Perhaps you are willing to answer another question. It seems that half of the crossover really does not do any filtering. These parts seem to merely act as a load for the power amp. I am of course referring to strings L4-R2-C3, L5-R3-C4 and 10R-0,68u.

I have seen this before as optional for tube amps, but never before as standard part of the crossover.

Would you recommend using them for a high power, high feeback solid state amp? I am asking because these parts seem to contribute to the cost of the crossover significantly. Thst is not a problem per se, but I wouldn't want to waste my money.

Thanks, Lex

Thanks for the reply. Perhaps you are willing to answer another question. It seems that half of the crossover really does not do any filtering. These parts seem to merely act as a load for the power amp. I am of course referring to strings L4-R2-C3, L5-R3-C4 and 10R-0,68u.

I have seen this before as optional for tube amps, but never before as standard part of the crossover.

Would you recommend using them for a high power, high feeback solid state amp? I am asking because these parts seem to contribute to the cost of the crossover significantly. Thst is not a problem per se, but I wouldn't want to waste my money.

Thanks, Lex

WAVEGUIDE FILLER

What about using the existing felt and cut out the hole for the WG?

Use both pieces, one for back fill(or wood strips) to keep it flush

Tried it quickly with some left over. looks pretty good but imagine it with nice felt, veneered cabinet and accurate trimming..

Joel

What about using the existing felt and cut out the hole for the WG?

Use both pieces, one for back fill(or wood strips) to keep it flush

Tried it quickly with some left over. looks pretty good but imagine it with nice felt, veneered cabinet and accurate trimming..

Joel

Attachments

These parts seem to merely act as a load for the power amp. I am of course referring to strings L4-R2-C3, L5-R3-C4 and 10R-0,68u.

I have seen this before as optional for tube amps, but never before as standard part of the crossover.

KEF used conjugate through many years

I'm not suggesting this is just that

looks like one is dealing with driver/box ressonance

and the other, well....?

might be 'killing' anything it 'sees' above the series inductor in front of it, maybe

Good try... but no.

KEF used conjugate for a different reason. And if you look at the conjugate alone... that is simply a distraction.

I really can't say too much at this stage. If I may speak cryptically, think noise... and no, I don't think you will guess it. It is very left field - but audibly very obvious.

We know that at least one very high-end designer (very to extremely expensive speakers) who is aware of this, but he is clearly using a different approach to the same subject. So there may be other ways of dealing with it. He won't say, we won't say.

Just build it and enjoy it.

Cheers, Joe

KEF used conjugate for a different reason. And if you look at the conjugate alone... that is simply a distraction.

I really can't say too much at this stage. If I may speak cryptically, think noise... and no, I don't think you will guess it. It is very left field - but audibly very obvious.

We know that at least one very high-end designer (very to extremely expensive speakers) who is aware of this, but he is clearly using a different approach to the same subject. So there may be other ways of dealing with it. He won't say, we won't say.

Just build it and enjoy it.

Cheers, Joe

critofur Joel,

Regarding the waveguides, would it be cheaper to get one unpainted, or, say, made out of high density plastic?

Unpainted would be cheaper but needs a protective coating and slight machining lines show. Powder coat hides lines

My intitial talk with the CNC guy was to use some form of plastic. Round stock blanks for a pair was $440.

A 4x8 sheet, same material was $400ish and making them on his table CNC machine is not best idea for that profile. Still would cut the sheet into rounds for lathe.

In the end Aluminum was the way to go

Thanks, Joel

donkt88 Joel,

I would like a pair of waveguides.

I e-mailed you two days in this regard and haven't heard back, I'll resend today.

Thanks, Don

Don, Sorry I'm sure I didn't get your emails. I was checking frequently.

There was a few other emails but the machinist had to drive a bit to pick up the blanks so we had to cut it off.

12 Waveguides ready for paint. Drop off tomorrow

Attachments

Joel,

I sent you another private message yesterday.

If you didn't receive it, then please e-mail me at: don.graessle@sbcglobal.net.

Thanks, Don

I sent you another private message yesterday.

If you didn't receive it, then please e-mail me at: don.graessle@sbcglobal.net.

Thanks, Don

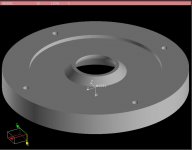

Some Waveguide fillers

Some one already mentioned it but think I'll try gluing in filler and then using filler around the edges. At this point I can level the the mdf and veneer over the front complete.

My fronts are 17.5 mm ply so have to recess Wg a little more into the sub front..

Some one already mentioned it but think I'll try gluing in filler and then using filler around the edges. At this point I can level the the mdf and veneer over the front complete.

My fronts are 17.5 mm ply so have to recess Wg a little more into the sub front..

Attachments

- Home

- Loudspeakers

- Multi-Way

- The "Elsinore Project" Thread