i use a 45 degree bevel or a chamfer bit. if you're only making one set of speakers HSS is OK.

If you get the Jasper router jig, set your center and then make the first cut the outside diameter of the speaker (to the depth required -- usually anywhere from an 1/8th to 1/4 inch), then cut the inside diameter of the speaker all the way through (in several passes). a 45 degree bevel bit can then be used for the final cut if the fit is too tight.

Helps to wear a dust mask when you do this.

If you get the Jasper router jig, set your center and then make the first cut the outside diameter of the speaker (to the depth required -- usually anywhere from an 1/8th to 1/4 inch), then cut the inside diameter of the speaker all the way through (in several passes). a 45 degree bevel bit can then be used for the final cut if the fit is too tight.

Helps to wear a dust mask when you do this.

You can also cut the speaker hole and then use a bearing-guided rabbeting bit to cut the flange recess. This is useful if you are retro-(flush)fitting in an existing cabinet.

jackinnj, I second the 45-degree bit suggestion, but disagree about HSS. If you have a router, you're going to continue using the bits, either for speakers or for something else. Buy carbide-tipped (or solid-carbide, though these are quite pricey) if you can afford it at all. If you buy the good tool, you only have to buy it once - a lesson I seem to need to relearn periodically.

Regards.

Aengus

jackinnj, I second the 45-degree bit suggestion, but disagree about HSS. If you have a router, you're going to continue using the bits, either for speakers or for something else. Buy carbide-tipped (or solid-carbide, though these are quite pricey) if you can afford it at all. If you buy the good tool, you only have to buy it once - a lesson I seem to need to relearn periodically.

Regards.

Aengus

Okay, I couldnt find any 3/4" spiral upcut bits at the local stores, they only carried

1/4" ones, but I wasn't sure if that would work well. I did get a 3/4" straight bit and a 45 deg. chamfer, both from skil and carbide tipped. Will these be okay?

If a 3/4" spiral downcut would work better, can anyone point me to a reputible online store that carries one that will work well?

I'd prefer it to be under $30 if possible. Also I need to cut a hole from a port out on the back of my veneered cabinets, so downcut bit makes the most sense.

edit: Is the 3/4" diameter actually needed? Or was that the flute length?

1/4" ones, but I wasn't sure if that would work well. I did get a 3/4" straight bit and a 45 deg. chamfer, both from skil and carbide tipped. Will these be okay?

If a 3/4" spiral downcut would work better, can anyone point me to a reputible online store that carries one that will work well?

I'd prefer it to be under $30 if possible. Also I need to cut a hole from a port out on the back of my veneered cabinets, so downcut bit makes the most sense.

edit: Is the 3/4" diameter actually needed? Or was that the flute length?

Lee Valley are reputable and reliable. Here are their spiral upcut bits.

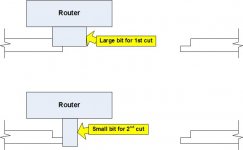

The reason for getting a 3/4" (diameter) bit, I assume, was to cut the rabbet for the recess first, then switch to a smaller bit for the through hole: this would leave a ledge without having to reset the diameter of your router jig - see drawing.

The upcut bit has spirals like a drill bit, and clears chips in the same way a drill bit does. The disadvantage, as pinkmouse points out, is that this can cause splintering in face veneers. You can overcome this by using a spiral downcut (which has the spiral in the opposite direction).

Personally, I'd just use straight bits unless I intended to work with very thick front panels; for 3/4" material a straight bit should work fine.

Regards.

Aengus

The reason for getting a 3/4" (diameter) bit, I assume, was to cut the rabbet for the recess first, then switch to a smaller bit for the through hole: this would leave a ledge without having to reset the diameter of your router jig - see drawing.

The upcut bit has spirals like a drill bit, and clears chips in the same way a drill bit does. The disadvantage, as pinkmouse points out, is that this can cause splintering in face veneers. You can overcome this by using a spiral downcut (which has the spiral in the opposite direction).

Personally, I'd just use straight bits unless I intended to work with very thick front panels; for 3/4" material a straight bit should work fine.

Regards.

Aengus

Attachments

eisenhower said:Okay, I couldnt find any 3/4" spiral upcut bits at the local stores, they only carried

1/4" ones, but I wasn't sure if that would work well. I did get a 3/4" straight bit and a 45 deg. chamfer, both from skil and carbide tipped. Will these be okay?

If a 3/4" spiral downcut would work better, can anyone point me to a reputible online store that carries one that will work well?

I'd prefer it to be under $30 if possible. Also I need to cut a hole from a port out on the back of my veneered cabinets, so downcut bit makes the most sense.

edit: Is the 3/4" diameter actually needed? Or was that the flute length?

if your location is "small dorm" you might consider walking over to the shop at the physics department or engineering school. i always found that they folks who made our models and gizmos loved to help.

in NJ we are fortunate to have a lot of sources for cutting tools -- lots of metal bending shops doing work here --

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- router bits for flush mounting