For home use of a synergy, what pattern is best, 60 x 90 or 50 x 50 for coverage?. thanks.

I did see a visaton frs 5 who do well however she are just 8 watts x 4 is 32 watts, is this enough?, I do now when in use with a high pass filter like here it is from some hunderds of hertz she can stand much more, and she are horn loaded so to loud before she get in danger right?.

thanks.

I did see a visaton frs 5 who do well however she are just 8 watts x 4 is 32 watts, is this enough?, I do now when in use with a high pass filter like here it is from some hunderds of hertz she can stand much more, and she are horn loaded so to loud before she get in danger right?.

thanks.

For home use of a synergy, what pattern is best, 60 x 90 or 50 x 50 for coverage?. thanks.Basically that depends on your room and requirements. A 50x50 horn will be much deeper than a 90x60. That last one is probably sweetspot in terms of size? Probably the closer you are to your speaker, the wider the angle should be, or you'll need to point your speakers to the listening spot. If you want to address a larger audience, use a larger angle as well. There are probably more considerations.

I did see a visaton frs 5 who do well however she are just 8 watts x 4 is 32 watts, is this enough?, I do now when in use with a high pass filter like here it is from some hunderds of hertz she can stand much more, and she are horn loaded so to loud before she get in danger right?.

This is a matter of simulating them I guess. But those things are only rated 84dB, and the midrange looks to be just above 82dB. So they might need quite a lot of power. Still, 4 of them might bring it to about 94 dB (1W), and then add the horn. Should not be to bad..

The x-o is L-R 4th order with L-pad. I'm working on adding some shaping to the response before I call it done (passive x-o).

If you're good on power, then don't worry, but paradoxically, lower order (electrical) x-o's have better power handling, as you start rolling off those first couple dB's at higher frequency (rather than closer to resonance). In reality, you do what you've got to do.

With a square sided opening over a round tweeter opening, I wouldn't consider it a chamber, although I'm sure there are reflections. In post #2149 you can see the extent of the overlap. That's a 40 mm square over a 45 mm tweeter circle

I think the key learning for me was to not force a smooth transition from the tweeter opening to the horn

Have you played around with play-doh/modeling clay to fillet the corners closest to the tweeter? I'm thinking just the first inch or so of the throat. Cannot remember who played around with this and saw some benefits. (Earl Geddes?)

For home use of a synergy, what pattern is best, 60 x 90 or 50 x 50 for coverage?. thanks.Basically that depends on your room and requirements. A 50x50 horn will be much deeper than a 90x60. That last one is probably sweetspot in terms of size? Probably the closer you are to your speaker, the wider the angle should be, or you'll need to point your speakers to the listening spot. If you want to address a larger audience, use a larger angle as well. There are probably more considerations.

This is a matter of simulating them I guess. But those things are only rated 84dB, and the midrange looks to be just above 82dB. So they might need quite a lot of power. Still, 4 of them might bring it to about 94 dB (1W), and then add the horn. Should not be to bad..

Thanks for the explaining words, I gess the 60 x 90 is then better for mine home, the visatons came in the horn close to 100 dB that is quite loud, I think most very small mids are not very high in efficienty, the horn do much work because she are loaded by them.

I go draw in sketchup, that way it is more easy, can then see also the degrees better.

regards

Have you played around with play-doh/modeling clay to fillet the corners closest to the tweeter? I'm thinking just the first inch or so of the throat. Cannot remember who played around with this and saw some benefits. (Earl Geddes?)

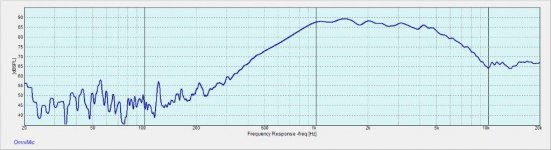

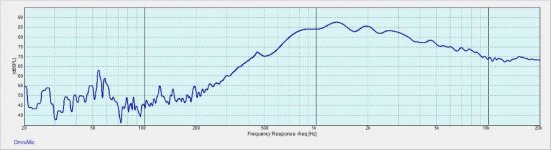

Attached are the FR graphs with fillet corners vs. square opening. The graphs are not SPL matched. This is a 60 x 90 degree horn.

I guess benefit is subjective here. I like the slope and less work.

Attachments

I'm currently comparing some woofer for a 2(ish)-way. Currently looking at Beyma 10BR60V2 and SB29NRX75-6 Two per channel should be enough. What I don't get in the simulations is that the Beyma with it's much lower Xmax has more MaxSPL than the SB at, 20Hz while both are displacement limited. They do have 8dB more efficiency, but still I always thought that down below it mostly about Xmax..

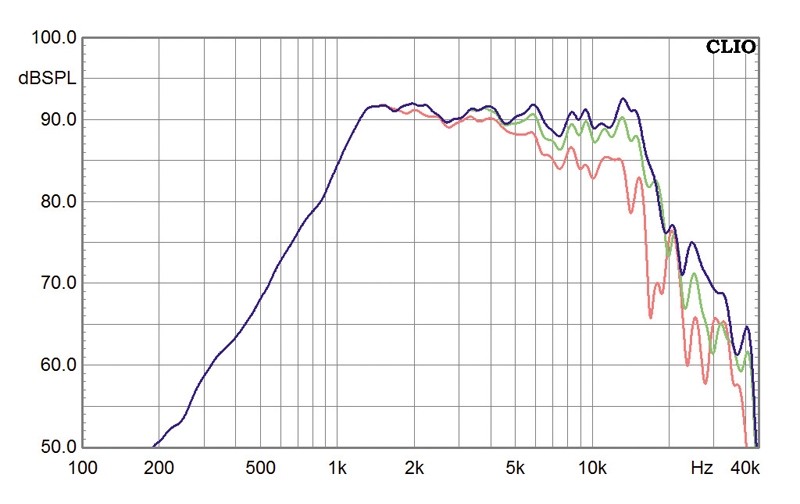

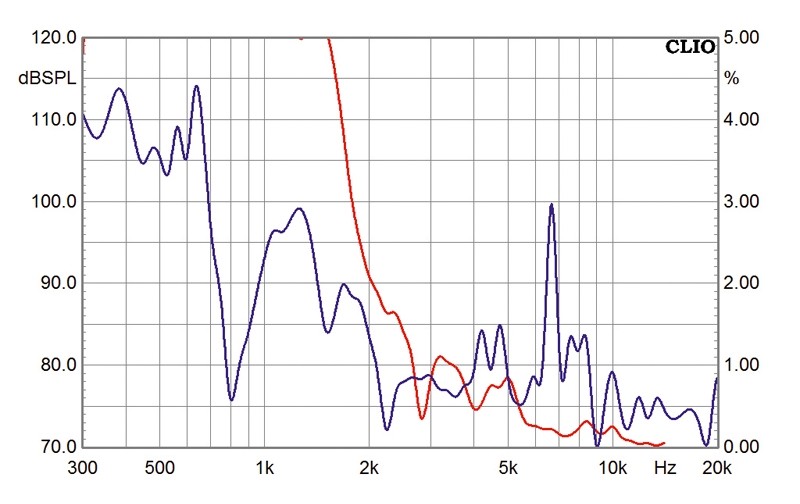

Ow, current mid/tweet candidate: BMS 4590. It probably gives most bang for buck of all the BMS coaxes and it has the annular diaphragm and seems to have the smoothest response of the coaxes.

Ow, current mid/tweet candidate: BMS 4590. It probably gives most bang for buck of all the BMS coaxes and it has the annular diaphragm and seems to have the smoothest response of the coaxes.

Last edited:

Hi all, it is a little oftopic but need a table saw, I have seen these for 125 euros it is a precision table for cabinet maker who can go - to + 50 degree, only the table do move not the saw itselfs, that is better and more precise.

Can I use such moving table one for synergy, and afcouse more things. It do not eat bread.

Can I use such moving table one for synergy, and afcouse more things. It do not eat bread.

Attachments

Hi all, it is a little oftopic but need a table saw, I have seen these for 125 euros it is a precision table for cabinet maker who can go - to + 50 degree, only the table do move not the saw itselfs, that is better and more precise.

Can I use such moving table one for synergy, and afcouse more things. It do not eat bread.

I would think twice before getting a moving table kind of table saw. I wasn't able to cut precise angles on my fixed table table saw until I constructed an out feed table for it. The piece being cut gets unstable as it starts to fall off the end of the table. I think its a lot more difficult to rig an outfeed table if the table is moving. The moving table would be fine for pieces smaller than the distance it is able to move; for larger pieces you might find it hard to hold a straight line at the end of the cut.

Anyone tried this monacor cone tweeter as mid?

HT-22/8

https://www.google.se/url?sa=t&sour...ggfMAA&usg=AFQjCNGma5yMYnus71miw6tm0vKO4t9FDg

Test here in german...

https://www.google.se/url?sa=t&sour...ggiMAE&usg=AFQjCNH0_3GVTOnC4Eif3u-rQnweQQaflg

Thanks

Petter

HT-22/8

https://www.google.se/url?sa=t&sour...ggfMAA&usg=AFQjCNGma5yMYnus71miw6tm0vKO4t9FDg

Test here in german...

https://www.google.se/url?sa=t&sour...ggiMAE&usg=AFQjCNH0_3GVTOnC4Eif3u-rQnweQQaflg

Thanks

Petter

Hi all, it is a little oftopic but need a table saw, I have seen these for 125 euros it is a precision table for cabinet maker who can go - to + 50 degree, only the table do move not the saw itselfs, that is better and more precise.

Can I use such moving table one for synergy, and afcouse more things. It do not eat bread.

Check up if the shaft diameter is standard, like Ø30,0 Ø25,4 or Ø20,0 mm. If it is 7/8", it is not easy to find new saw blades, nor inserts between Ø 30,0 => 7/8".

As the table top is so small, I would make a fairly large "sled" of 19 mm plywood or MDF, so it will be easier to cut also "larger pieces". Fit 2 long bars under the sled versus the 2 tracks in the table. Check the width of those tracks as well before bying. Finding a bar width of 3/4" may be troublesome in Europe. With a sled it will be very easy and safe to cut precise 90 or 45 degrees (or whatever you decide if you put an angle jig on top of the sled.)

I would think twice before getting a moving table kind of table saw. I wasn't able to cut precise angles on my fixed table table saw until I constructed an out feed table for it. The piece being cut gets unstable as it starts to fall off the end of the table. I think its a lot more difficult to rig an outfeed table if the table is moving. The moving table would be fine for pieces smaller than the distance it is able to move; for larger pieces you might find it hard to hold a straight line at the end of the cut.

You say that I have to find a saw who do only saw blade do move for angle? like picture.

thanks for advice.

kees

Attachments

Hi Kees:

I didn't say you had to but I did give that advice. The reason is that unless you get a very large table saw you have to add support behind the blade to support the cut piece after it passes the blade. Without that support, a long piece will get unstable when its mid point is past the edge of the table. With a tilting table saw, that support would also have to tilt. When the table stays level and just the blade tilts, then your support table can also stay level. What one does if he has the room is build a table level with the top of the saw and then route channels into the extension table behind the saw to extend the grooves that your crosscut or angle jig will slide in. You may also need support on the sides so you can make that extension table "L" or "U" shaped and you may also put the whole assembly up on casters so you can roll it out of the way when not using it.

Jack

I didn't say you had to but I did give that advice. The reason is that unless you get a very large table saw you have to add support behind the blade to support the cut piece after it passes the blade. Without that support, a long piece will get unstable when its mid point is past the edge of the table. With a tilting table saw, that support would also have to tilt. When the table stays level and just the blade tilts, then your support table can also stay level. What one does if he has the room is build a table level with the top of the saw and then route channels into the extension table behind the saw to extend the grooves that your crosscut or angle jig will slide in. You may also need support on the sides so you can make that extension table "L" or "U" shaped and you may also put the whole assembly up on casters so you can roll it out of the way when not using it.

Jack

Hi Kees:

I didn't say you had to but I did give that advice. The reason is that unless you get a very large table saw you have to add support behind the blade to support the cut piece after it passes the blade. Without that support, a long piece will get unstable when its mid point is past the edge of the table. With a tilting table saw, that support would also have to tilt. When the table stays level and just the blade tilts, then your support table can also stay level. What one does if he has the room is build a table level with the top of the saw and then route channels into the extension table behind the saw to extend the grooves that your crosscut or angle jig will slide in. You may also need support on the sides so you can make that extension table "L" or "U" shaped and you may also put the whole assembly up on casters so you can roll it out of the way when not using it.

Jack

Hi Jack

Yes now I got the drift, indeed with long peaces I need to extent it to keep save I understand. the extension needs also to tilt with the table itselfs, also this is true, I do keep that in mind, the saw in first post is a precision one, I can make sleds to get things done, there are sleves for this in the table saw bed aready.

Thanks again, closed.

If the specs can be trusted, it looks like we might FINALLY have a 3" driver that will work properly on a Unity horn.

Yowza, this has been a long time coming.

Some background:

It appears that Sound Physics Labs used a 5" driver from Misco in their Unity horns. That part number is detailed in this thread. It works, but you'll need to buy a case to get them.

Danley Sound Labs uses a 4" driver from Celestion, part number TF0410MR. That ALSO works, but it was unobtanium until Loudspeakersplus.com started stocking it a year ago.

It also works, but it's quite large for a 4". The driver is about the size of a grapefruit.

I do a lot of really small Unity horns, and I've been forced to use 2" drivers because there are quite a few that will work.

I'm not a huge fan of 2" drivers. Two of them have about as much output as one 3" driver, so you really need to use four 2" drivers to get an acceptable output level. Bill Waslo used four Gento 2" drivers in his first Synergy Horn project.

http://www.eminence.com/pdf/Alpha_3_8.pdf

So it's fairly exciting that we FINALLY have a decent 3" driver. Here's why this is cool:

1) A single Celestion TF0410MR delivers about as much output as you'll need at home, but it's relatively expensive. Worst of all, it's BIG. It really makes it difficult to design a small waveguide or horn.

2) The Misco 5" will do the job, and it's actually smaller in volume than the Celestion. But it's kinda unobtanium.

3) a pair of 3" drivers is just about ideal. But AFAIK, there's never been a 3" driver that had the right parameters. The Faital 3" drivers were an obvious option, but their BL was too low and their QES was too high.

As noted in page one of this thread, you want a driver where (2 * FS / QES) equals 500. To put this in perspective, the Faital 3FE22 works out to 275Hz (FaitalPRO 3FE25 3" Professional Full-Range Woofer 8 Ohm) and the new eminence 3" driver works out to 445Hz! Not perfect, but pretty darn close. (http://www.eminence.com/pdf/Alpha_3_8.pdf)

Yowza, this has been a long time coming.

Some background:

It appears that Sound Physics Labs used a 5" driver from Misco in their Unity horns. That part number is detailed in this thread. It works, but you'll need to buy a case to get them.

Danley Sound Labs uses a 4" driver from Celestion, part number TF0410MR. That ALSO works, but it was unobtanium until Loudspeakersplus.com started stocking it a year ago.

It also works, but it's quite large for a 4". The driver is about the size of a grapefruit.

I do a lot of really small Unity horns, and I've been forced to use 2" drivers because there are quite a few that will work.

I'm not a huge fan of 2" drivers. Two of them have about as much output as one 3" driver, so you really need to use four 2" drivers to get an acceptable output level. Bill Waslo used four Gento 2" drivers in his first Synergy Horn project.

http://www.eminence.com/pdf/Alpha_3_8.pdf

So it's fairly exciting that we FINALLY have a decent 3" driver. Here's why this is cool:

1) A single Celestion TF0410MR delivers about as much output as you'll need at home, but it's relatively expensive. Worst of all, it's BIG. It really makes it difficult to design a small waveguide or horn.

2) The Misco 5" will do the job, and it's actually smaller in volume than the Celestion. But it's kinda unobtanium.

3) a pair of 3" drivers is just about ideal. But AFAIK, there's never been a 3" driver that had the right parameters. The Faital 3" drivers were an obvious option, but their BL was too low and their QES was too high.

As noted in page one of this thread, you want a driver where (2 * FS / QES) equals 500. To put this in perspective, the Faital 3FE22 works out to 275Hz (FaitalPRO 3FE25 3" Professional Full-Range Woofer 8 Ohm) and the new eminence 3" driver works out to 445Hz! Not perfect, but pretty darn close. (http://www.eminence.com/pdf/Alpha_3_8.pdf)

- Home

- Loudspeakers

- Multi-Way

- Suitable midrange cone, for bandpass mid in Unity horn.