you can reverse connection so that both driver move together (front or back) if you wish and still get teh magnet to attach to.

BTW I have only 1 of each driver (per side) I would ask for dirver donations but Indian customs wouldtreat that as an import and assign some ridiculous value to them.AARGH! :-( So I have to make do with what I get here.

Thanks and Regards

BTW I have only 1 of each driver (per side) I would ask for dirver donations but Indian customs wouldtreat that as an import and assign some ridiculous value to them.AARGH! :-( So I have to make do with what I get here.

Thanks and Regards

Yes that`s exactly how I do it.I am not sure how you do the coating one panel at a time. If you have a rectangular box, do you simply cover the side that is at the bottom, wait for this side to cool, turn the box and continue with the next side?

I`m, not sure what You mean with shrinking. The bitumen can be poured up to a thickness of 10mm or more depending of the kind. Usually they are different kinds of bitumen with different viscosity when hardened . If the layer is too thick there might be a problem that the mass "runs" down the walls when the enclosure is in it´s upright position and when it gets warm (particularer with black enclosures and when the sun shines on it). This can be avoided when the bitumen is stabilized with an internal structure (Armierung) for example with a kind of mesh or something like that. Another solution is another layer of a somewhat stiffer material on top.How thick can the coat be before you get problems with shrinkage etc.?

I do not know how hot is bitumen while melting

I guess it`s around 200°C - 300°C .

Once I even tried to pour concrete in an already very stiff wooden box. The relatively small enclosure was incredible heavy but I felt it was a not so good idea then the bitumen approuch what concerns good damping of the enclosure.

What I will try next is a kind of sand filled two component epoxy to be poured. I saw this kind of stuff first at a friend of mine who used this as a form for his bike construction. He made ultralightweight bike frames from laminated carbon fiber sheets.

He has built a positive wood frame and used the epoxy sand mixture for casting a two halfs negative in which he laminated the carbon fiber finally. This epoxy sand mixture form was incredible rigid, heavy and seemed to be an acoustical most excellent suited material for building enclosures.

Thanks to ebay I´m a proud owner of a couple of professional accelerometers and charge amplifiers and I will make some investigations in the future about different material mixes like epoxy/sand, bitumen and wood and composites about their damping properties. I´m very curious what are the measure results of the epoxy/sand mix alone - I feel it will be excellent.

Again about the bitumen fumes: the fumes are mainly an issue for vented boxes. It may take indeed several weeks until they dissapear completly and it is definetly a good idea to keep it away from babys during that time. Sealed enclosures are far less critical in this regard.

I´m not sure if plastic spray is a solution to to prevent bitumen from leaking gases. I think it just won`t hold on bitumen.Plastic spray ceases to outgas after about 48 h and should work well enough as a sealant.

Eric:

Yes the thing in my avatar is a Manger driver. I do not yet have them. Take a look at this thread when You are interested about what I`m planning:http://www.diyaudio.com/forums/showthread.php?s=&threadid=4557

And fine that the coil article went through okay!

And by the way folks: here is a nice and simple instrument (I don`t know what to call this in English) to quickly get an idea how "dead" (or not) Your enclosures really are. Get it working in free air, on a wall, a table and at different locations on Your enclosures - You will be surprised how nice Your enclosures will ring ..............

Attachments

Someone suggested damping the torsion brace with heat shrink tubing.

My torsion brace is 2 or 3" dia does heat shrink tubing come in that dia.

alternately can I use the stuff the use to cover HVAC ducts.

thanks guys.

P.S

I am still looking at how to bend 4mm MDF and whether ply would bend easier if anyone has answers to that help me! please!

My torsion brace is 2 or 3" dia does heat shrink tubing come in that dia.

alternately can I use the stuff the use to cover HVAC ducts.

thanks guys.

P.S

I am still looking at how to bend 4mm MDF and whether ply would bend easier if anyone has answers to that help me! please!

the pipes are then mounted to the rear of the driver (on the magnet) using blu tak

ahhh blu tak!

if there's one material that i can't do without in speaker building blu tak has to be it!

it is to the speaker builder as duct (gaffa) tape is to the live music crew worker (roadie) imho.

Pritex

Take a look on a material named pritex. It is used in the car industry and sold by some companies that sell drivers such as www.speakerland.com.

They also sell bitumen plates ready for installation without any need to be melted.

Can solid oak (5cm) outperform an MDF construction? Oak is much more expensive but is it better than MDF. Why is everybody using MDF and not original wood?

George Christofilopoulos

Greece

Take a look on a material named pritex. It is used in the car industry and sold by some companies that sell drivers such as www.speakerland.com.

They also sell bitumen plates ready for installation without any need to be melted.

Can solid oak (5cm) outperform an MDF construction? Oak is much more expensive but is it better than MDF. Why is everybody using MDF and not original wood?

George Christofilopoulos

Greece

Do you want to die?!

The phobia of wood stems (!) from the fact that it can warp out of shape, damaging the enclosure. The other "Advantage" to MDF is that it is easy to work with - and the dust contributes to cancer!!!

If you use well dried wood - such as that which has been salvaged from demolished buildings - you will see no problems. Bracing it well should help.

As long as you deaden the interior until it is as dead a dodo, I can't see there being that many differences in sound either (someone correct me if I'm wrong).

Working with Oak is more difficult, but easier to finish and won't kill you!

Hope this helps,

Gaz

The phobia of wood stems (!) from the fact that it can warp out of shape, damaging the enclosure. The other "Advantage" to MDF is that it is easy to work with - and the dust contributes to cancer!!!

If you use well dried wood - such as that which has been salvaged from demolished buildings - you will see no problems. Bracing it well should help.

As long as you deaden the interior until it is as dead a dodo, I can't see there being that many differences in sound either (someone correct me if I'm wrong).

Working with Oak is more difficult, but easier to finish and won't kill you!

Hope this helps,

Gaz

cocolino said

<b>I will make some investigations in the future about different material mixes like epoxy/sand, bitumen and wood and composites about their damping properties. I´m very curious what are the measure results of the epoxy/sand mix alone - I feel it will be excellent. </b>

Could you please give some more detail about the sand epoxy mixes, even if they're just untested ideas. This is something I'm very interested in and am going to experiment with again in the near future. I tried a couple of simple experiments last year filling some small surplus die cast RF eclosures (faulty potted circuitry removed) with expanded foam, resin/leadshot, silicon and glop (sand,oil,leadshot). I tested it by hanging each from a nylon monfiment in my garage, and striking them and listening to the resultant sound. The glop was best: you had to hit it really hard to get any sound from it at all, and then most of that was a very short sound generated by two surfaces colliding, ie the sound was more dependent on what you struck it with. But the stuff can be messy, and you can't attach it to the underside of things.

Not a definite test for sure, but I'd like to try more ideas to stop the ringing in some pressure diecast Al items I have, and want a better idea on "best" before I make permanent changes. Leadshot is hard to get here too.

Cheers

Brett

<b>I will make some investigations in the future about different material mixes like epoxy/sand, bitumen and wood and composites about their damping properties. I´m very curious what are the measure results of the epoxy/sand mix alone - I feel it will be excellent. </b>

Could you please give some more detail about the sand epoxy mixes, even if they're just untested ideas. This is something I'm very interested in and am going to experiment with again in the near future. I tried a couple of simple experiments last year filling some small surplus die cast RF eclosures (faulty potted circuitry removed) with expanded foam, resin/leadshot, silicon and glop (sand,oil,leadshot). I tested it by hanging each from a nylon monfiment in my garage, and striking them and listening to the resultant sound. The glop was best: you had to hit it really hard to get any sound from it at all, and then most of that was a very short sound generated by two surfaces colliding, ie the sound was more dependent on what you struck it with. But the stuff can be messy, and you can't attach it to the underside of things.

Not a definite test for sure, but I'd like to try more ideas to stop the ringing in some pressure diecast Al items I have, and want a better idea on "best" before I make permanent changes. Leadshot is hard to get here too.

Cheers

Brett

Epoxy / Sand Mix

Hi Brett:

Indeed it is just a very untested idea and I fear I can`t give You much more useful info about it as mentenioned in my previous post already.

The only thing I can remember is that this 2-component epoxy was used in model construction and needs about a day or so to harden. Another, if I remember right unless epoxy and sand something else was involved - kind of filler balls - but I can`t remember the material and why it was used.

The form I saw made from this material was incredible rigid and appeared to me to have outstanding good acoustical damping effect. I just tried it the way You did with knocking on it with different materials, so of course also this could not be called a real test but I just felt that this should be excellent material to build speaker enclosures from.

I got the idea at a buddy of mine while helping with his bike frame project. Unfortunately I cannot ask him anymore about the exact receipt of materials.

He was a fanatic biker (cyclist) as we are fanatic about DIY audio. I said "was" because he died at a bike race by crashing with a car several years ago (I still have the crashed carbon bike frame on which he died and that was the particular one I helped to laminate it). What a tragedy - not only because he was one of the very few of my best friends but he was so young, with incredible bright and helpful mind, and has been an outstanding talented universal craftsman too.

We used to spent hole nights discussing ideas of his bike construction stuff as well as my audio projects in which he was highly interested too.

It seems to be true that only the good die young - I still miss him.

I still know some of his fellow bikers from that time and I believe the form still exists and must be somewhere. One of them was involved somewhat more in the technical concerns about the frame building and he still might tell me something about the receipt.

Also his parents live only a couple of kilometers away and I might ask them too.

Anyway, if I get hand on more info about it I`ll post it here(maybe with some photos too) but it may take a while.

BTW: Brett could You please explain me what is "glop" (thanks in advance for it)?

and: Your leadshot idea triggered me that a Epoxy/Leadshot might be even better than Epoxy/Sand mix.

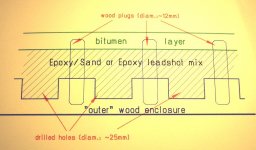

Eventually, my conception of a "dead enclosure approuch" :

- A heavily braced (perhaps matrix style) rigid "outer" enclosure from multiple layered birch plywood ~30mm.

- A poured Epoxy/Sand or Epoxy/Leadshot mix about 25mm thick (kinda second inside enclosure)

-Upon that a ~15mm poured bitumen layer

In order to "teeth" the materials to each other, I thought to drill holes in the outer enclosure (see picture) repectively to drill and glue wood plugs in it. This also might prevent the bitumen coating from flowing down to the bottom of the enclosure during the time in case when lower viscosity bitumen type is used .

Hi Brett:

Indeed it is just a very untested idea and I fear I can`t give You much more useful info about it as mentenioned in my previous post already.

The only thing I can remember is that this 2-component epoxy was used in model construction and needs about a day or so to harden. Another, if I remember right unless epoxy and sand something else was involved - kind of filler balls - but I can`t remember the material and why it was used.

The form I saw made from this material was incredible rigid and appeared to me to have outstanding good acoustical damping effect. I just tried it the way You did with knocking on it with different materials, so of course also this could not be called a real test but I just felt that this should be excellent material to build speaker enclosures from.

I got the idea at a buddy of mine while helping with his bike frame project. Unfortunately I cannot ask him anymore about the exact receipt of materials.

He was a fanatic biker (cyclist) as we are fanatic about DIY audio. I said "was" because he died at a bike race by crashing with a car several years ago (I still have the crashed carbon bike frame on which he died and that was the particular one I helped to laminate it). What a tragedy - not only because he was one of the very few of my best friends but he was so young, with incredible bright and helpful mind, and has been an outstanding talented universal craftsman too.

We used to spent hole nights discussing ideas of his bike construction stuff as well as my audio projects in which he was highly interested too.

It seems to be true that only the good die young - I still miss him.

I still know some of his fellow bikers from that time and I believe the form still exists and must be somewhere. One of them was involved somewhat more in the technical concerns about the frame building and he still might tell me something about the receipt.

Also his parents live only a couple of kilometers away and I might ask them too.

Anyway, if I get hand on more info about it I`ll post it here(maybe with some photos too) but it may take a while.

BTW: Brett could You please explain me what is "glop" (thanks in advance for it)?

and: Your leadshot idea triggered me that a Epoxy/Leadshot might be even better than Epoxy/Sand mix.

Eventually, my conception of a "dead enclosure approuch" :

- A heavily braced (perhaps matrix style) rigid "outer" enclosure from multiple layered birch plywood ~30mm.

- A poured Epoxy/Sand or Epoxy/Leadshot mix about 25mm thick (kinda second inside enclosure)

-Upon that a ~15mm poured bitumen layer

In order to "teeth" the materials to each other, I thought to drill holes in the outer enclosure (see picture) repectively to drill and glue wood plugs in it. This also might prevent the bitumen coating from flowing down to the bottom of the enclosure during the time in case when lower viscosity bitumen type is used .

Attachments

1. solid wood can warp. i have not built speakers with solid wood but window frames as well as doors in my apt that was built in 1961 and where they used old burma teak still get stuck every monsoon.

dry solid wood will absorb moisture from the atmosphere and then will warp so unless you live in dry climes avoid solid wood. atleast i do.

my project as gotten a bit delayed as i came down with typhoid. at one time no one could figure out why i was running a 104 deg. fever and not responding to any ammount ot tylenol. they ran blood tests for cerebral malaria etc... and finally it is now known that i am infected with 2 strains of typhoid. i will be out of action for atleast 5 more days. it has been 5 days before i can sit and type this.

dry solid wood will absorb moisture from the atmosphere and then will warp so unless you live in dry climes avoid solid wood. atleast i do.

my project as gotten a bit delayed as i came down with typhoid. at one time no one could figure out why i was running a 104 deg. fever and not responding to any ammount ot tylenol. they ran blood tests for cerebral malaria etc... and finally it is now known that i am infected with 2 strains of typhoid. i will be out of action for atleast 5 more days. it has been 5 days before i can sit and type this.

yeah ran thru my whole collection of CDs the past 8 days. i was listeing for 3, 4 hour sessions per day. 500 CDs+ from AC/DC to Zappa, from Brahms to Tchkovsky from Armstrong (louis) to Peterson (Oscar) and some world music too.

would have spent more time listening but a had a few visitors.

would have spent more time listening but a had a few visitors.

Hello,

I have been experimenting with making molds and pouring my "cabinets" from concrete. I am making dipole panels, but was going to try a box braced with bent rebar placed in the still wet concrete for support. This allows for many strange shapes, as well as the curves you want make. I was thinking of having it sprayed with the same stuff they use to make truck bed liners.

What are the downsides of concrete?

I have been experimenting with making molds and pouring my "cabinets" from concrete. I am making dipole panels, but was going to try a box braced with bent rebar placed in the still wet concrete for support. This allows for many strange shapes, as well as the curves you want make. I was thinking of having it sprayed with the same stuff they use to make truck bed liners.

What are the downsides of concrete?

Hi,

My Dad suggested the same thing the other day. My response was the same as this:

I seem to remember a project undertaken by someone who used a concrete sewerage pipe to build some speakers. They were incredibly heavy. The end result - if I remember rightly - was that the sound quality was excellent.

-: Click here to see them :-

Hope this helps!

Gaz

My Dad suggested the same thing the other day. My response was the same as this:

I seem to remember a project undertaken by someone who used a concrete sewerage pipe to build some speakers. They were incredibly heavy. The end result - if I remember rightly - was that the sound quality was excellent.

-: Click here to see them :-

Hope this helps!

Gaz

navin said:Zappa

about 5% of the vinyl in my main music shelves... bartender, make that a pina colada...

dave

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Help! How does make "dead" cabinet?