Interesting question... could you be more specific with how you are using the finished bond?

For example, do you want a liquid adhesive, double-sided tape, UV cured or instant bond? How strong does it have to be? Does it have to be flexible or withstand temperature extremes? Will a mechanical fastener (screws) be sufficient?

You can also try any one of 3M's online selector charts. In addition to Threadlocker, Loctite also has excellent adhesives for just about every other purpose.

You are in Seattle, if you are near Boeing surplus they may be able to help you.

ensen.

ensen.

For example, do you want a liquid adhesive, double-sided tape, UV cured or instant bond? How strong does it have to be? Does it have to be flexible or withstand temperature extremes? Will a mechanical fastener (screws) be sufficient?

You can also try any one of 3M's online selector charts. In addition to Threadlocker, Loctite also has excellent adhesives for just about every other purpose.

You are in Seattle, if you are near Boeing surplus they may be able to help you.

It would be PVC tubing connected to the rear of a dipole panel made of either MDF or plywood (haven't decided yet). Its to hold a rear firing tweeter. Basically, I'm making some cosmetic changes to John K.'s NaO. http://www.geocities.com/kreskovs/John1.html

So you are putting a PVC tube between the two tweeters... wouldn't that change the dipole effect of the design?

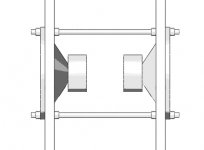

May I suggest that instead you use threaded rods instead of mounting screws for the tweeters. If the tweeter has 4 mounting holes, use 4 rods and 4 x 12mm PVC tubes. The tubes would be the length needed to space the two tweeters apart. Run the bolts/rods from the front tweeter, through the baffle, through the PVC tube through the rear baffle and through the rear tweeter. Tighten the whole thing with a nut on the back and voila... dipoles.

ensen.

ensen.

May I suggest that instead you use threaded rods instead of mounting screws for the tweeters. If the tweeter has 4 mounting holes, use 4 rods and 4 x 12mm PVC tubes. The tubes would be the length needed to space the two tweeters apart. Run the bolts/rods from the front tweeter, through the baffle, through the PVC tube through the rear baffle and through the rear tweeter. Tighten the whole thing with a nut on the back and voila... dipoles.

Chances are he's using dome tweeters, which have sealed backs, so putting them together wouldn't be any different from suspending them some other way at the same separation distance.purplepeople said:So you are putting a PVC tube between the two tweeters... wouldn't that change the dipole effect of the design?

May I suggest that instead you use threaded rods instead of mounting screws for the tweeters. If the tweeter has 4 mounting holes, use 4 rods and 4 x 12mm PVC tubes. The tubes would be the length needed to space the two tweeters apart. Run the bolts/rods from the front tweeter, through the baffle, through the PVC tube through the rear baffle and through the rear tweeter. Tighten the whole thing with a nut on the back and voila... dipoles.

ensen.

PL200 Construction Adhesive

Degloss the PVC first.

http://www.builderdepot.com/seo/SOV...BM/149392_PL200_102OZ_CONSTRCT_ADHESIVE.ihtml

Degloss the PVC first.

http://www.builderdepot.com/seo/SOV...BM/149392_PL200_102OZ_CONSTRCT_ADHESIVE.ihtml

So you are putting a PVC tube between the two tweeters... wouldn't that change the dipole effect of the design?

How?

May I suggest that instead you use threaded rods instead of mounting screws for the tweeters. If the tweeter has 4 mounting holes, use 4 rods and 4 x 12mm PVC tubes. The tubes would be the length needed to space the two tweeters apart. Run the bolts/rods from the front tweeter, through the baffle, through the PVC tube through the rear baffle and through the rear tweeter. Tighten the whole thing with a nut on the back and voila... dipoles.

I just may do that, but I'm still going to have to attatch it to the panel somehow. Seems like routing a trough and using epoxy is my best bet.

If you bond to the baffle, then you can't replace if you burn them.

Yes, router a step in the baffle to flush mount the driver. Then it is typical to drill 4 pilot holes to screw the driver to the baffle. What I suggest is to drill holes as big as the driver mount holes and use ~6" bolts to connect the front and back tweeter. I will post a quick sketch tomorrow from my office.

ensen.

ensen.

Yes, router a step in the baffle to flush mount the driver. Then it is typical to drill 4 pilot holes to screw the driver to the baffle. What I suggest is to drill holes as big as the driver mount holes and use ~6" bolts to connect the front and back tweeter. I will post a quick sketch tomorrow from my office.

I think we're having a communication problem here. The SEAS (front firing unit) is mounted normally. The back of the plywood panel would have a trough routed for the PVC for extra structural support, and then bonded to it. then the Vifa (rear firing tweeter) would be mounted "normally" on the other end of the PVC tubing via wood (or some such) plug. both units are removable. The bonding is at the one junction between the wood baffle (panel) and PVC tube.

Mats J said:What is the best adhesive for bonding PVC (plumbing) to wood?

LDPE glue sticks. Hot glue gun! Preheat the joint with a hot air gun, especially the wood side for a permanent bond as strong as nails. Be careful not to overheat the PVC.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Construction detail